Preparation method of net structure titanium-silicon alloy phase reinforced TiAl-based composite

A network structure, composite material technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of strength reduction and strength reduction, and achieve the effect of high compressive strength and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

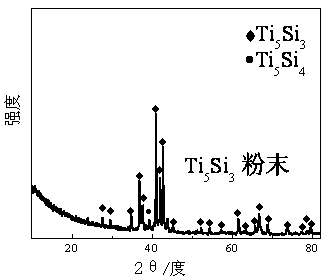

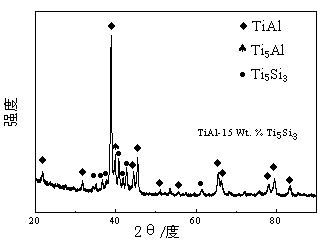

[0022] Example 1 A method for preparing a network-structured titanium-silicon alloy phase-reinforced TiAl-based composite material. In terms of mass fraction, 85% of pre-alloyed Ti-46Al-2Cr-2Nb powder and 15% of Ti 5 Si 3 The powder is mixed uniformly in a low-energy ball mill at a speed of 300r / min for 8 hours. Mix the TiAl-Ti evenly 5 Si 3 The powder material was put into a graphite mold, and placed in a vacuum hot-press sintering furnace, the sintering temperature was 1300°C, the pressure was 28MPa, and the heat preservation and pressure holding time was 30min. After vacuum hot pressing sintering and cooling at room temperature, the network structure Ti 5 Si 3 Reinforced TiAl-based composites.

[0023] Among them: pre-alloyed Ti-46Al-2Cr-2Nb powder refers to weighing Ti, Al, Cr, Nb element powders according to the atomic percentage of 50:46:2:2 and mixing them in a low-energy ball mill at a speed of 350 r / min 8h; after mixing evenly, put the mixed powder in a hot-pres...

Embodiment 2

[0024] Example 2 A method for preparing a network structure titanium-silicon alloy phase-reinforced TiAl-based composite material, by mass fraction, 70% of pre-alloyed Ti-46Al-2Cr-2Nb powder and 30% of Ti 5 Si 3 The powder is mixed evenly in a low-energy ball mill at a speed of 350r / min for 12h. Mix the TiAl-Ti evenly 5 Si 3 The powder material was put into a graphite mold and placed in a vacuum hot-press sintering furnace with a sintering temperature of 1350 °C, a pressure of 30 MPa, and a holding time of 60 min. After vacuum hot pressing sintering and cooling at room temperature, the network structure Ti 5 Si 3 Reinforced TiAl-based composites.

[0025] Among them: pre-alloyed Ti-46Al-2Cr-2Nb powder refers to weighing Ti, Al, Cr, Nb element powders according to the atomic percentage of 50:46:2:2 and mixing them in a low-energy ball mill at a speed of 350 r / min 8h; After mixing evenly, put the mixed powder in a hot-press furnace, and conduct pressureless heat treatment ...

Embodiment 3

[0026] Example 3 A method for preparing a network structure titanium-silicon alloy phase-reinforced TiAl-based composite material, by mass fraction, 65% of pre-alloyed Ti-46Al-2Cr-2Nb powder and 35% of Ti 5 Si 3 The powder is mixed evenly in a low-energy ball mill at a speed of 400r / min for 10h. Mix the TiAl-Ti evenly 5 Si 3 The powder material is put into a graphite mold, and placed in a vacuum hot-press sintering furnace, the sintering temperature is 1400°C, the pressure is 20MPa, and the heat preservation and pressure holding time is 2h. After vacuum hot pressing sintering and cooling at room temperature, the network structure Ti 5 Si 3 Reinforced TiAl-based composites.

[0027] Among them: pre-alloyed Ti-46Al-2Cr-2Nb powder refers to weighing Ti, Al, Cr, Nb element powders according to the atomic percentage of 50:46:2:2 and mixing them in a low-energy ball mill at a speed of 350 r / min 8h; After mixing evenly, put the mixed powder in a hot-press furnace, and carry out...

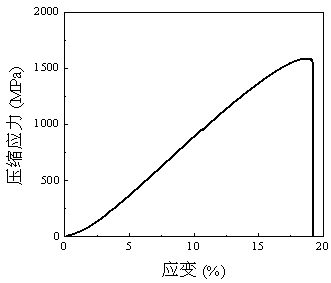

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com