A kind of preparation method of titanium-silicon alloy phase reinforced tial-based composite material with network structure

A technology of titanium-silicon alloy and mesh structure, which can be used in metal processing equipment, transportation and packaging, etc., and can solve the problems of strength reduction and strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

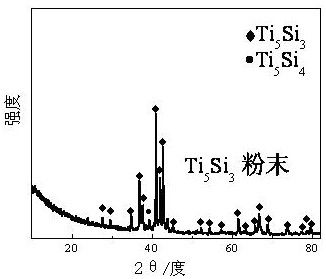

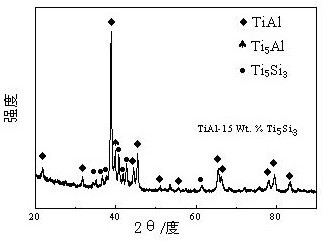

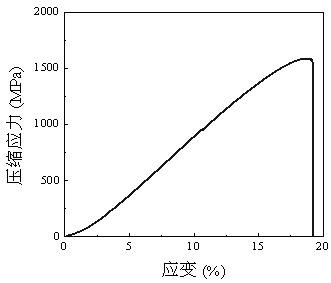

[0022] Example 1 A method for preparing a network-structured titanium-silicon alloy phase-reinforced TiAl-based composite material. In terms of mass fraction, 85% of pre-alloyed Ti-46Al-2Cr-2Nb powder and 15% of Ti 5 Si 3 The powder is mixed uniformly in a low-energy ball mill at a speed of 300r / min for 8 hours. Mix the TiAl-Ti evenly 5 Si 3 The powder material was put into a graphite mold, and placed in a vacuum hot-press sintering furnace, the sintering temperature was 1300°C, the pressure was 28MPa, and the heat preservation and pressure holding time was 30min. After vacuum hot pressing sintering and cooling at room temperature, the network structure Ti 5 Si 3 Reinforced TiAl-based composites.

[0023] Among them: pre-alloyed Ti-46Al-2Cr-2Nb powder refers to weighing Ti, Al, Cr, Nb element powders according to the atomic percentage of 50:46:2:2 and mixing them in a low-energy ball mill at a speed of 350 r / min 8h; after mixing evenly, put the mixed powder in a hot-pres...

Embodiment 2

[0024] Example 2 A method for preparing a network structure titanium-silicon alloy phase-reinforced TiAl-based composite material, by mass fraction, 70% of pre-alloyed Ti-46Al-2Cr-2Nb powder and 30% of Ti 5 Si 3 The powder is mixed evenly in a low-energy ball mill at a speed of 350r / min for 12h. Mix the TiAl-Ti evenly 5 Si 3 The powder material was put into a graphite mold and placed in a vacuum hot-press sintering furnace with a sintering temperature of 1350 °C, a pressure of 30 MPa, and a holding time of 60 min. After vacuum hot pressing sintering and cooling at room temperature, the network structure Ti 5 Si 3 Reinforced TiAl-based composites.

[0025] Among them: pre-alloyed Ti-46Al-2Cr-2Nb powder refers to weighing Ti, Al, Cr, Nb element powders according to the atomic percentage of 50:46:2:2 and mixing them in a low-energy ball mill at a speed of 350 r / min 8h; After mixing evenly, put the mixed powder in a hot-press furnace, and conduct pressureless heat treatment ...

Embodiment 3

[0026] Example 3 A method for preparing a network structure titanium-silicon alloy phase-reinforced TiAl-based composite material, by mass fraction, 65% of pre-alloyed Ti-46Al-2Cr-2Nb powder and 35% of Ti 5 Si 3 The powder is mixed evenly in a low-energy ball mill at a speed of 400r / min for 10h. Mix the TiAl-Ti evenly 5 Si 3 The powder material is put into a graphite mold, and placed in a vacuum hot-press sintering furnace, the sintering temperature is 1400°C, the pressure is 20MPa, and the heat preservation and pressure holding time is 2h. After vacuum hot pressing sintering and cooling at room temperature, the network structure Ti 5 Si 3 Reinforced TiAl-based composites.

[0027] Among them: pre-alloyed Ti-46Al-2Cr-2Nb powder refers to weighing Ti, Al, Cr, Nb element powders according to the atomic percentage of 50:46:2:2 and mixing them in a low-energy ball mill at a speed of 350 r / min 8h; After mixing evenly, put the mixed powder in a hot-press furnace, and carry out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com