Telescopic high-branch saw transmission rod combination

A transmission rod, high-branch saw technology, applied in the direction of electric pruning saws, cutting tools, cutting equipment, etc., can solve the problems of weak aluminum alloy shaft, inconvenient operation and use, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

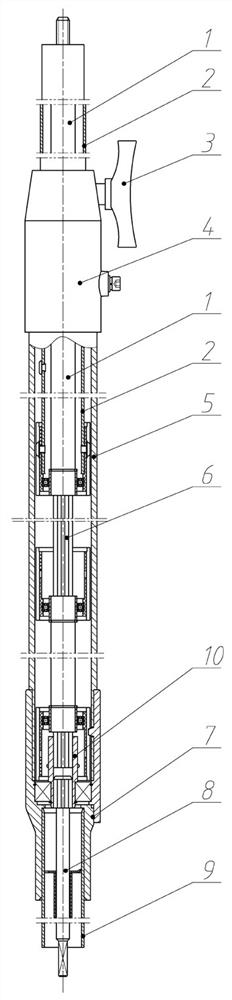

[0009] Such as figure 1 As shown, a telescopic high-branch saw transmission rod combination includes a front transmission shaft 1, a front sleeve 2, a manual locking device 3, a front connection sleeve 4, an intermediate sleeve 5, an intermediate transmission shaft 6, and a rear connection sleeve 7 , rear transmission shaft 8, rear casing 9, connecting shaft 10.

[0010] The specific embodiment of the present invention is: the front transmission shaft 1 and the front casing 2 are axially fixed, the front casing 2 is connected with the middle casing 5 through the front connecting sleeve 4, and the front connecting sleeve 4 is provided with a manual locking device 3. When the locking device 3 is loosened, the front sleeve 2 can slide into the middle sleeve 5. When the manual locking device 3 is tightened, the positions of the front sleeve 2 and the middle sleeve 5 are fixed and cannot move relative to each other; the middle sleeve 5 The position is fixed with the intermediate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com