Elbow pipe and method for producing an elbow pipe

A pipe bending and pipe body technology, applied in the field of pipe bending and manufacturing of pipe bends, can solve the problems of time-consuming and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

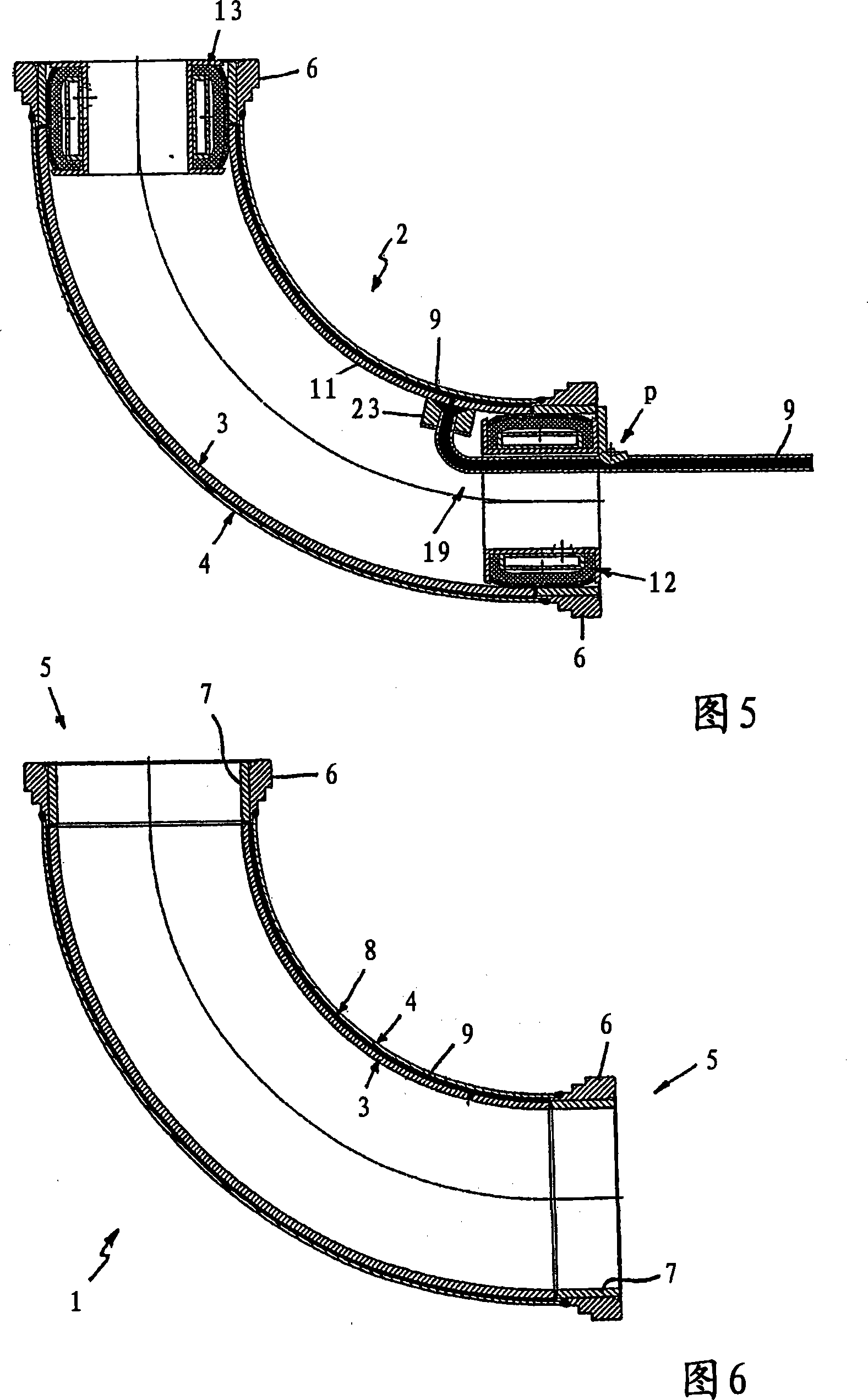

[0014] The resulting bend is shown in Figure 6. The bend 1 is used inside pipes for the fluid transport of solids, for example in the distribution boom of an automatic concrete pump.

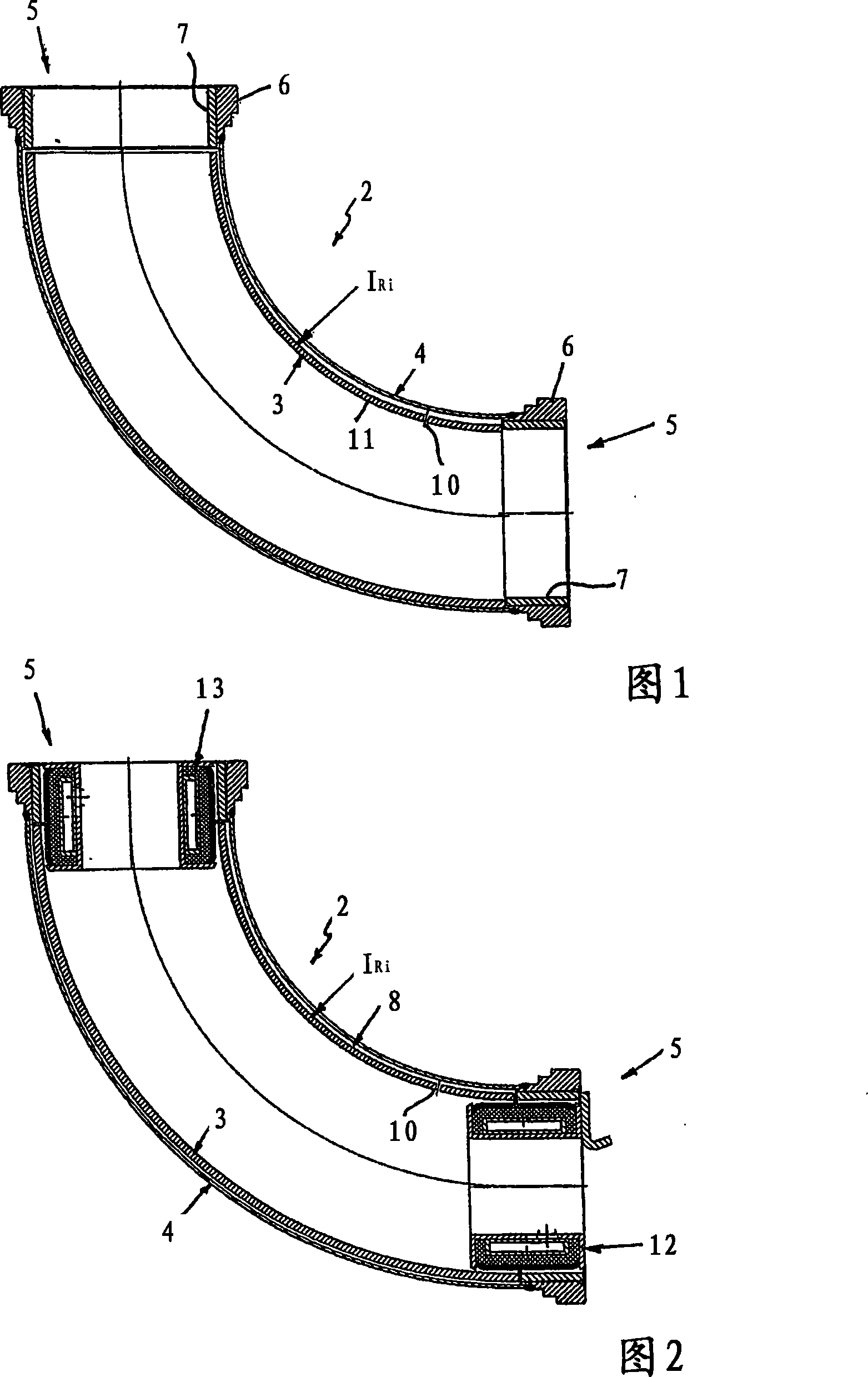

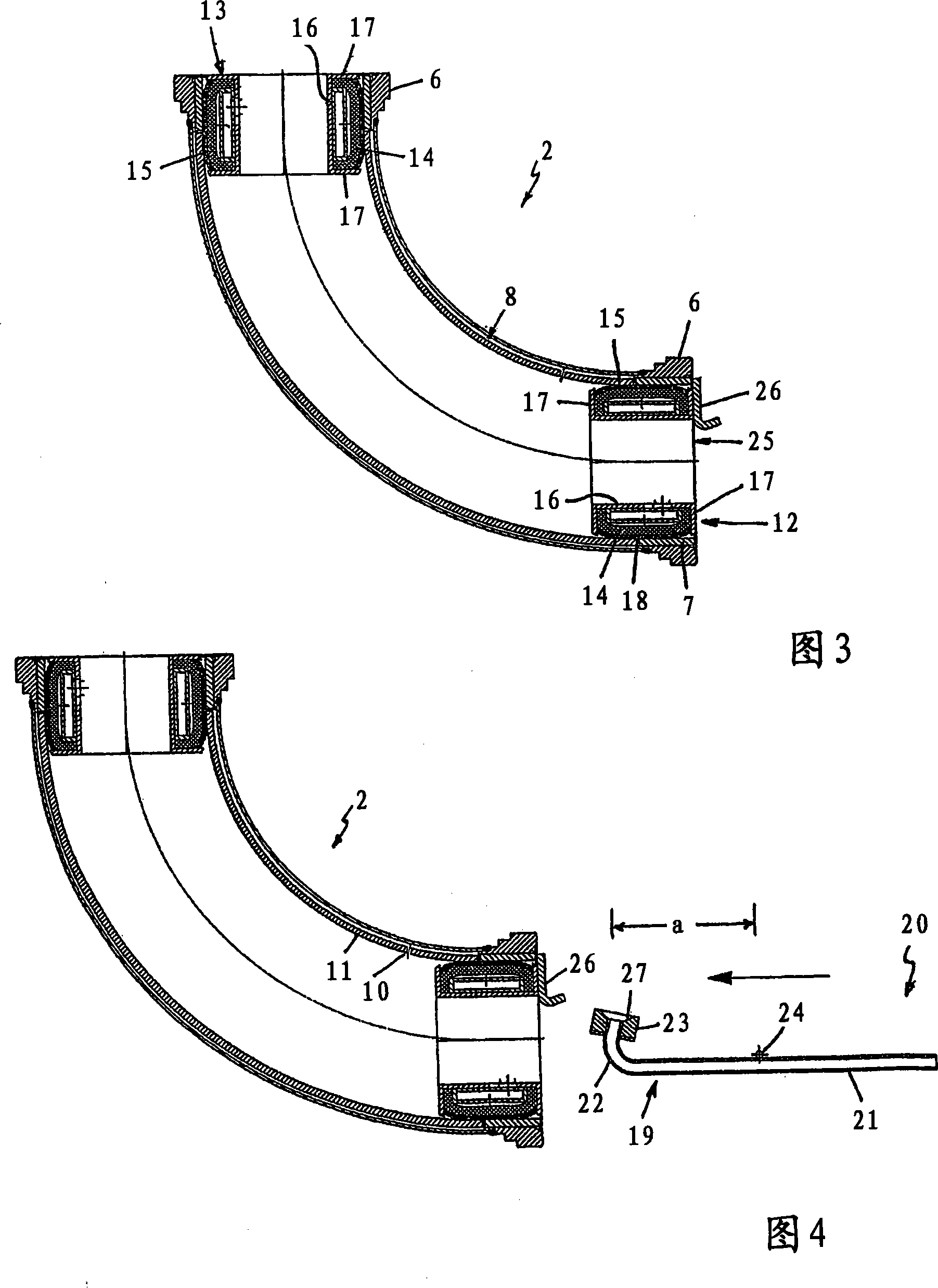

[0015] As can be seen in particular in FIG. 2 , the pipe bend 1 has a double-layer pipe body 2 comprising a highly wear-resistant hardened inner bend 3 and a pressure-resistant weldable outer bend 4 . A coupling flange 6 is attached to each pipe end 5 of the pipe body 2 . The coupling flanges 6 each surround an inner wear ring 7 and are welded to the outer bend 4 .

[0016] The annular space 8 between the inner bend 3 and the outer bend 4 is filled with concrete as filler 9 . In order to introduce the filler 9, the inner radius I of the inner elbow 3 Ri A filling opening 10 is arranged on it, which passes transversely through the wall 11 of the inner bend 3 (see FIGS. 1 to 5 here).

[0017] To produce the pipe bend 1 , the inner pipe bend 3 , the outer pipe bend 4 and the coupling flange 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com