A kind of water-based wood paint and preparation method thereof

A technology of water-based wood paint and water-based dispersion, which is applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of water-based paints such as difficult defoaming, to solve the problem of difficult defoaming, increase the hardness and wear resistance of paint films, Full and beautiful effect of paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

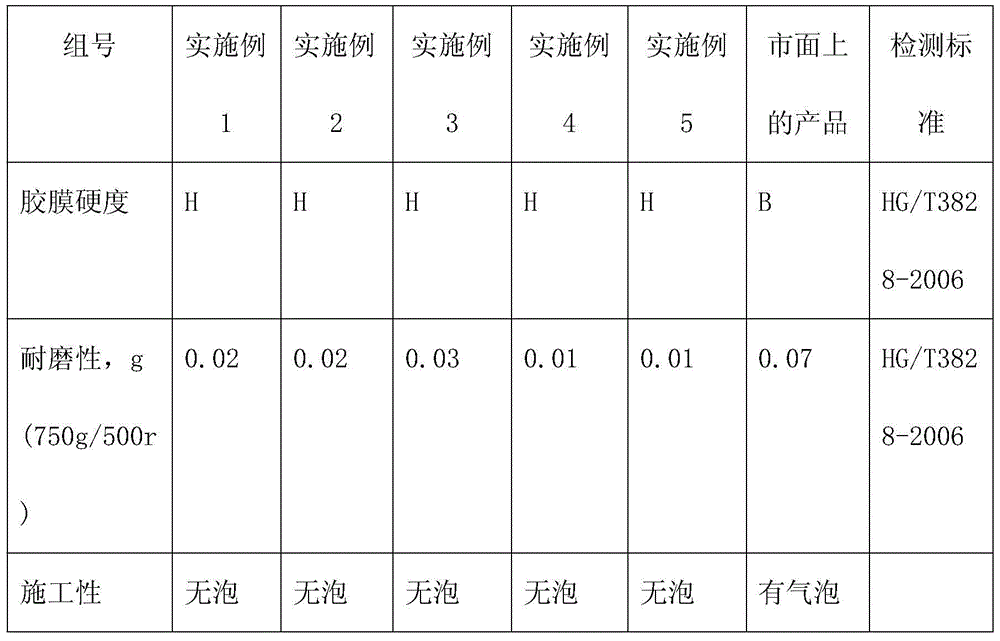

Examples

Embodiment 1

[0027] A water-based wood paint, comprising the following raw materials in parts by weight: acrylic emulsion: 60-80; polyurethane water-based dispersion: 30-50; filler: 1-40; additives: 0.1-10, the additives include leveling agent, defoamer, accelerator and initiator, the leveling agent is at least one of polyether modified silicone leveling agent, fluorine-modified polyacrylate leveling agent, and the defoamer is a solvent The type does not contain silicon defoamer; the filler is at least one of magnesium carbonate and calcium carbonate.

Embodiment 2

[0029] A water-based wood lacquer, comprising the following raw materials by weight: acrylic acid emulsion: 80; polyurethane water-based dispersion: 50; and initiator, the leveling agent is at least one of polyether modified silicone leveling agent, fluorine-modified polyacrylate leveling agent, and the defoamer is a solvent-type non-silicon defoamer; The filler is at least one of magnesium carbonate and calcium carbonate.

Embodiment 3

[0031] A water-based wood lacquer, comprising the following raw materials by weight: acrylic acid emulsion: 70; polyurethane water-based dispersion: 40; and initiator, the leveling agent is at least one of polyether modified silicone leveling agent, fluorine-modified polyacrylate leveling agent, and the defoamer is a solvent-type non-silicon defoamer; The filler is at least one of magnesium carbonate and calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com