High-strength cast aluminum and preparing method thereof

A casting aluminum alloy, high-strength technology, applied in the field of metal materials, can solve problems such as low strength, poor fluidity, thermal cracking, etc., and achieve the effect of strength advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

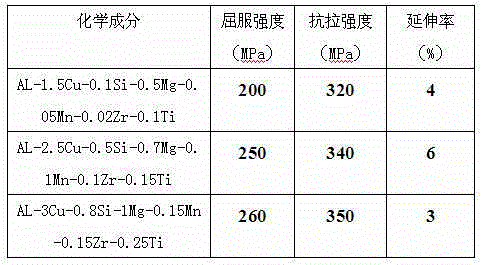

[0029] Taking 25kg as an example, according to the ratio of AL-1.5Cu-0.1Si-0.5Mg-0.05Mn-0.02Zr-0.1Ti as an example, calculate the quality of the master alloy and prepare the material.

[0030] Prepare raw materials and clean the furnace. The furnace needs to be cleaned to avoid residual alloys affecting the performance of the alloy. Now prepare materials according to the alloy composition ratio, alloy elements can be added in pure alloy and intermediate form, Cu element can be added in Al-Cu alloy, Si element can be added in simple substance or Al-Si intermediate alloy form, Mg element can be added in pure Mg or Al-Mg The alloy is added, the Mn element is added in the form of Al-Mn alloy; the Zr element is added in the form of Al-Zr alloy; the Ti element is added in the form of Al-Ti alloy.

[0031] After the surface of the aluminum ingot is cleaned, put the pure aluminum ingot into the crucible of the pit furnace, heat the crucible for smelting, and control the temperature of...

specific Embodiment example 2

[0037] Taking 25kg as an example, according to the ratio of AL-2.5Cu-0.5Si-07Mg-0.1Mn-0.1Zr-0.15Ti as an example, calculate the quality of the master alloy and prepare the material.

[0038] Prepare raw materials and clean the furnace. The furnace needs to be cleaned to avoid residual alloys affecting the performance of the alloy. Now prepare materials according to the alloy composition ratio, alloy elements can be added in pure alloy and intermediate form, Cu element can be added in Al-Cu alloy, Si element can be added in simple substance or Al-Si intermediate alloy form, Mg element can be added in pure Mg or Al-Mg The alloy is added, the Mn element is added in the form of Al-Mn alloy; the Zr element is added in the form of Al-Zr alloy; the Ti element is added in the form of Al-Ti alloy.

[0039] After the surface of the aluminum ingot is cleaned, put the pure aluminum ingot into the crucible of the pit furnace, heat the crucible for smelting, and control the temperature of the...

specific Embodiment example 3

[0045] Taking 25kg as an example, according to the ratio of AL-3Cu-0.8Si-1Mg-0.15Mn-0.15Zr-0.25Ti as an example, calculate the quality of the master alloy and prepare the material.

[0046] Prepare raw materials and clean the furnace. The furnace needs to be cleaned to avoid residual alloys affecting the performance of the alloy. Now prepare materials according to the alloy composition ratio, alloy elements can be added in pure alloy and intermediate form, Cu element can be added in Al-Cu alloy, Si element can be added in simple substance or Al-Si intermediate alloy form, Mg element can be added in pure Mg or Al-Mg The alloy is added, the Mn element is added in the form of Al-Mn alloy; the Zr element is added in the form of Al-Zr alloy; the Ti element is added in the form of Al-Ti alloy.

[0047] After the surface of the aluminum ingot is cleaned, put the pure aluminum ingot into the crucible of the pit furnace, heat the crucible for smelting, and control the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com