Composite material for automotive interior parts and production method thereof

A technology for automobile interior parts and composite materials, which is applied in the field of composite materials for automobile interior parts and its production, can solve the problems of easily causing harm to the human body, difficult to degrade waste, pollution of the natural environment, etc., and achieves outstanding environmental protection performance, water content Low rate, good sound absorption and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

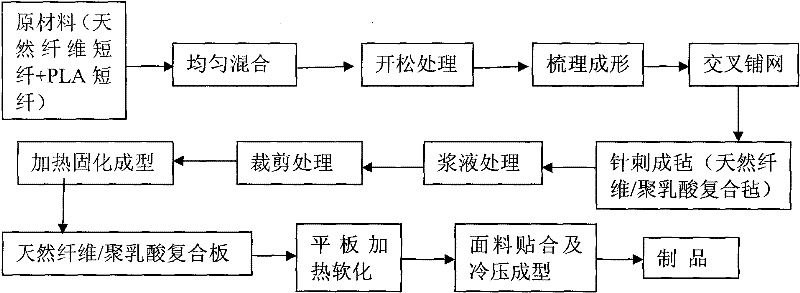

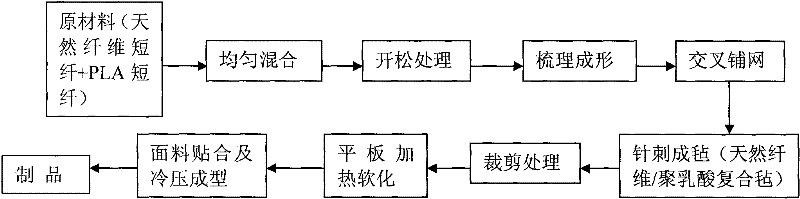

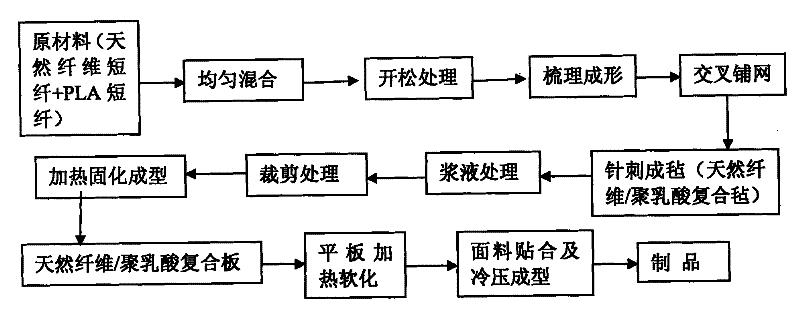

Method used

Image

Examples

Embodiment 1

[0035] Weigh the raw material (kg) according to the following weight:

[0036] Polylactic acid fiber 40, jute fiber 60;

[0037] Methods of producing automotive interior composites:

[0038] (1) the jute fiber of 7-15cm and 40 kilograms of 8-12cm polylactic acid fiber are evenly mixed by 60 kilograms of length;

[0039] (2) Put the mixed fiber into the opener to open and mix, mix for 30s, and then send it into the cotton box;

[0040] (3) The loosened and mixed fibers stored in the cotton box are transported to the carding machine by airflow for carding;

[0041] (4) The fiber after carding is sent to cross-lapping in the web-laying machine;

[0042] (5) After the laid net is folded according to the required requirements, it is sent into the pre-needling machine for pre-needling into felt;

[0043] (6) Send the pre-needled mat to the main needling machine for main needling. After reaching the predetermined gram weight, heat and pre-press it into a coil. The heating tempera...

Embodiment 2

[0048] Weigh the raw material (kg) according to the following weight:

[0049] Polylactic acid fiber 50, hemp fiber 30, flax 20;

[0050] Methods of producing automotive interior composites:

[0051] (1) 30 kilograms of length are the hemp fiber of 7-15cm, the flax fiber of 20 kilograms of length 7-15cm and 50 kilograms of 8-12cm polylactic acid fiber are evenly mixed;

[0052] (2) Put the mixed fiber into the opener to open and mix, mix for 40s, and then send it into the cotton box;

[0053] (3) Transport the loosened and mixed fibers stored in the cotton box to the carding machine for carding;

[0054] (4) The fiber after carding is sent to cross-lapping in the web-laying machine;

[0055] (5) Fold the laid net and send it into the pre-needling machine for pre-needling into felt;

[0056] (6) Send the pre-needled mat to the main needling machine for main needling. After reaching the predetermined gram weight, heat and pre-press it into a coil. The heating temperature is ...

Embodiment 3

[0059] Weigh the raw material (kg) according to the following weight:

[0060] Polylactic acid fiber 60, ramie fiber 20, sisal fiber 10, kenaf fiber 10;

[0061] Methods of producing automotive interior composites:

[0062] (1) the ramie fiber of 7-15cm, the sisal fiber of 7-15cm, the kenaf fiber of 7-15cm and the polylactic acid fiber of 60 kilograms of 8-12cm are evenly mixed in 10 kilograms of lengths by 20 kilograms of lengths;

[0063] (2) Put the mixed fiber into the opener to open and mix, mix for 20s, and then send it into the cotton box;

[0064] (3) The loosened and mixed fibers stored in the cotton box are transported to the carding machine by airflow for carding;

[0065] (4) The fiber after carding is sent to cross-lapping in the web-laying machine;

[0066] (5) After the laid net is folded according to the required requirements, it is sent into the pre-needling machine for pre-needling into felt;

[0067] (6) Send the pre-needled mat to the main needling mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com