ti-5mo-5v-6cr-3al titanium alloy extruded pipe and its processing method

A processing method and titanium alloy technology, applied in the field of new metastable β-titanium alloy, can solve the problems of poor corrosion resistance, high-strength steel quality, weakening the carrying capacity of aircraft or ships, etc., and achieve high tensile strength and toughness good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to the following proportions, the main alloying element content (wt%) is: Mo4.8, V4.9, Cr6.0, Al3.1, Fe0.11, C0.008, N0.010, H0.0015, O0 .10, the balance being titanium. The ingredients are pressed into electrodes on a 2,000-ton oil press, and cast ingots are obtained by melting three times in a vacuum consumable electric furnace. The temperature of the vacuum consumable electric furnace is about 2000°C, and the diameter of the ingot is Φ510mm. The ingot is heated at 1150°C for 2 hours and forged into a Φ350mm bar. After the billet is blanked, it is punched on a 2,000-ton hydraulic press to obtain a tube blank of Φ350×Φ85×500mm, and then the inner and outer surfaces of the tube blank are covered with copper. After heating at ℃, a Φ99×Φ85×Lmm pipe was obtained on a 5000-ton extruder, aged at 600℃ for 2 hours, and sample 1 was obtained.

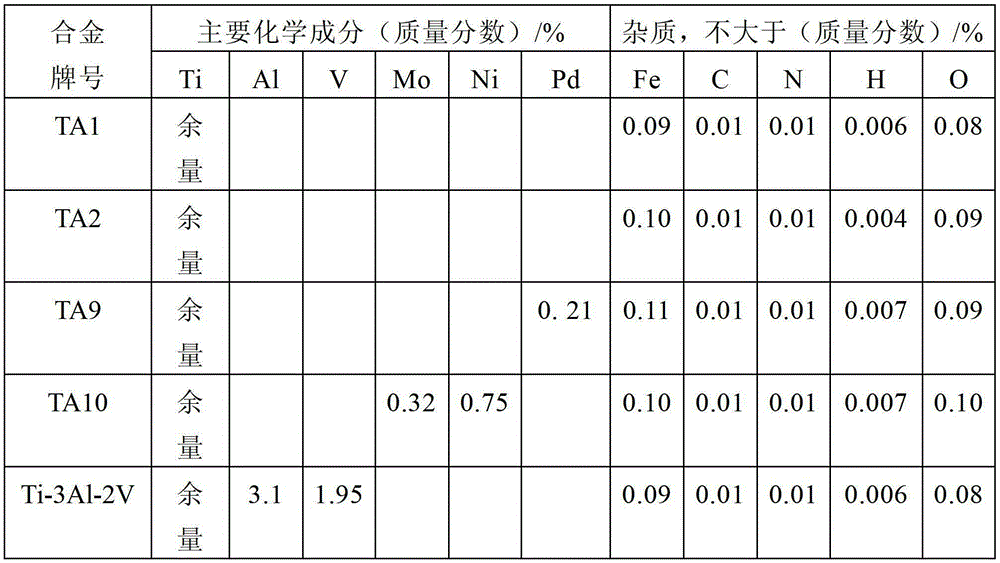

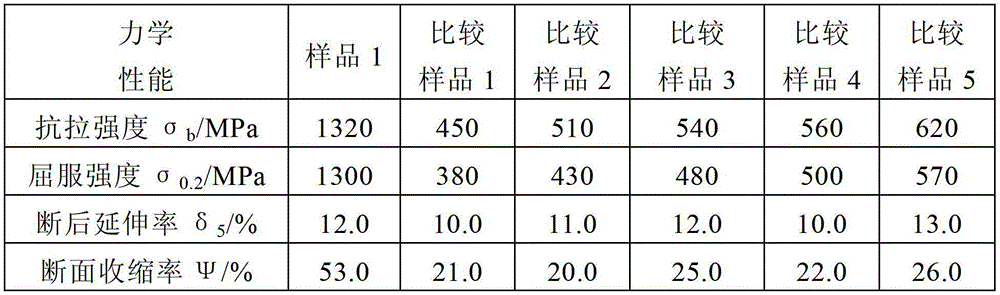

[0024] Repeat the same steps above to obtain 5 grades of extruded pipes of the same size including TA1, TA2, TA9, TA10 and T...

Embodiment 2

[0035] According to the following proportions, the main alloying element content (wt%) is: Mo4.5, V5.7, Cr5.5, Al3.5, Fe0.08, C0.005, N0.007, H0.0008, O0 .06, balance titanium. The ingredients are pressed into electrodes on a 2,000-ton hydraulic press, and the ingots are obtained through three times of melting in a vacuum consumable electric furnace. The diameter of the ingots is Φ400mm. The ingot was heated at 1050°C for 2 hours, and forged into a Φ300mm bar. After the billet was blanked, it was punched on a 2,000-ton hydraulic press to obtain a tube blank of Φ300×Φ72×500mm. After heating at ℃, a Φ80×Φ72×Lmm pipe was obtained on a 5000-ton extruder, aged at 480℃ for 8 hours, and sample 4 was obtained. The Φ80×Φ72×Lmm pipe was cut, and then welded by electron beam to obtain sample 5. Samples 4 and 5 were processed into Φ3mm unconventional tensile specimens. The test was completed on an AG50KNE testing machine. The mechanical properties are shown in Table 4.

[0036] Table...

Embodiment 3

[0039] According to the following proportions, the main alloying element content (wt%) is: Mo5.7, V4.5, Cr6.5, Al2.5, Fe0.11, C0.015, N0.016, H0.003, O0 .12, the balance being titanium. The ingredients are pressed into electrodes on a 2,000-ton hydraulic press, and the ingots are obtained by melting three times in a vacuum consumable electric furnace. The diameter of the ingots is Φ550mm. The ingot was heated at 1200°C for 2 hours, and forged into a Φ380mm bar. After the billet was blanked, it was punched on a 2,000-ton hydraulic press to obtain a tube blank of Φ380×Φ90×500mm. After heating at ℃, a Φ120×Φ90×Lmm pipe was obtained on a 5000-ton extruder, aged at 650℃ for 1 hour, and sample 6 was obtained. The Φ120×Φ90×Lmm pipe was cut, and then welded with an electron beam to obtain sample 7. Samples 6 and 7 were processed into Φ5mm conventional tensile specimens, and the test was completed on an AG50KNE testing machine. The mechanical properties are shown in Table 5.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com