Composite negative-stiffness energy absorption honeycomb structure and preparation method thereof

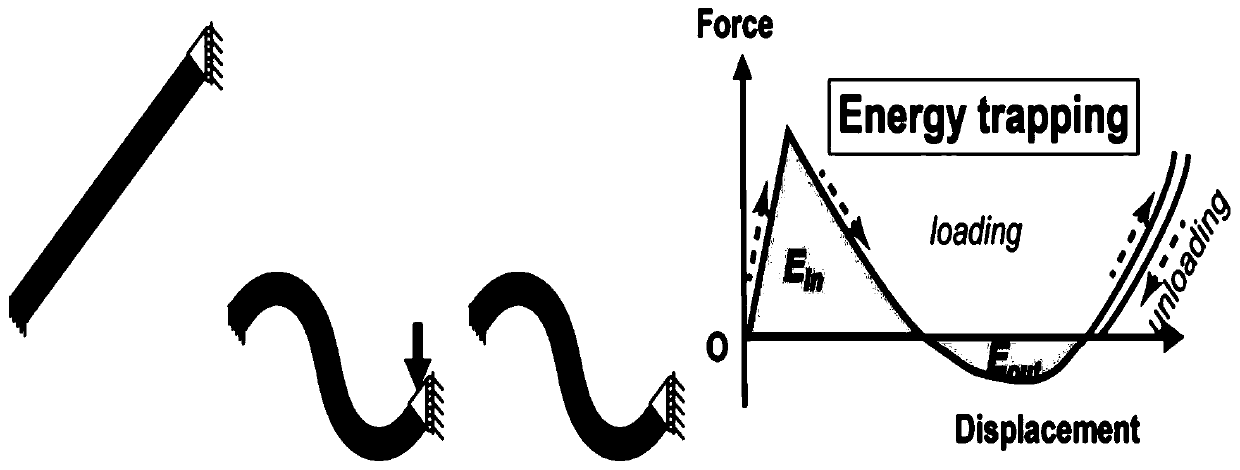

A honeycomb structure, negative stiffness technology, applied in mechanical equipment, instruments, electrical and digital data processing, etc., can solve the problems of low strength, poor energy absorption effect, low reusability, etc., to achieve improved energy absorption, improved positive stiffness, The effect of high-order reusability energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

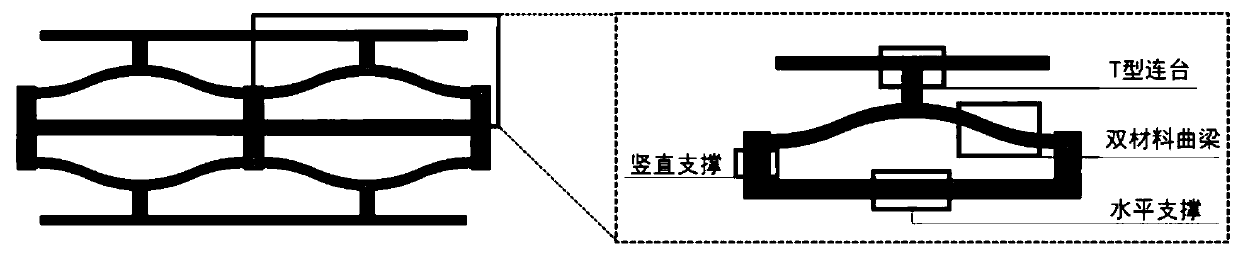

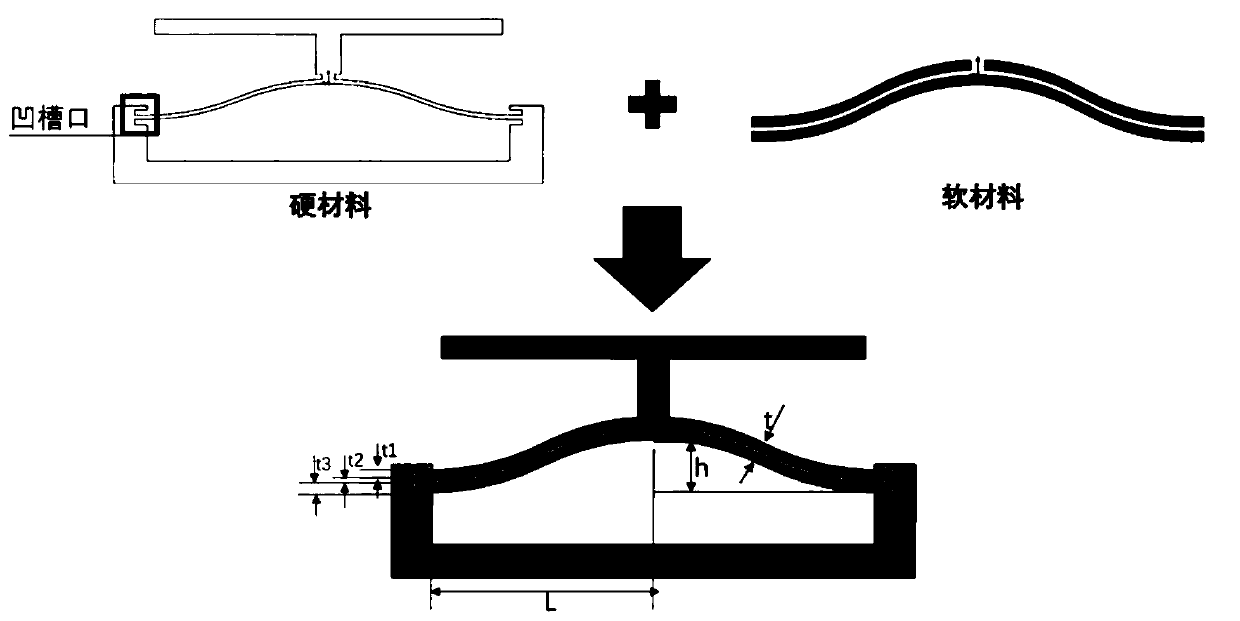

[0028] Specific Embodiment 1: A composite negative stiffness energy-absorbing honeycomb structure of this embodiment, which is interlocked by four inserts 1 to form a "well"-shaped structure; each insert 1 is made of It is surrounded by hard-shaped material body 2, "T"-shaped connecting platform 3 and curved beam 4;

[0029] The "King" shaped hard material body 7 is placed laterally, and is divided into four parts along the central axis and the vertical line of the "King" shaped hard material body 7. Shape hard material body 2; each The hard-shaped material body 2 is made up of two vertical support bodies 2-1 and a horizontal support body 2-2; two vertical support body 2-1 upper end inner sidewalls respectively offer a groove-5; 4 Both ends are respectively connected to the bottom of the groove 1 5, and the groove 1 5 is divided into two grooves; the upper surface of the middle part of the curved beam 4 is connected to the bottom of the "T"-shaped connecting platform 3, an...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the curved beam 4 is "wave-shaped", and its upper part is a convex arc edge, and its lower part is a concave arc edge. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 in that: the length of the curved beam 4 is 90-95 mm, the thickness is 0.5-1.5 mm, and the height is 9-10 mm. Others are the same as in the first embodiment.

[0033] The optimal length of the curved beam 4 in this embodiment is 93.88 mm, the thickness is 1 mm, and the height is 9.6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com