Patents

Literature

60results about How to "Wrinkle resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

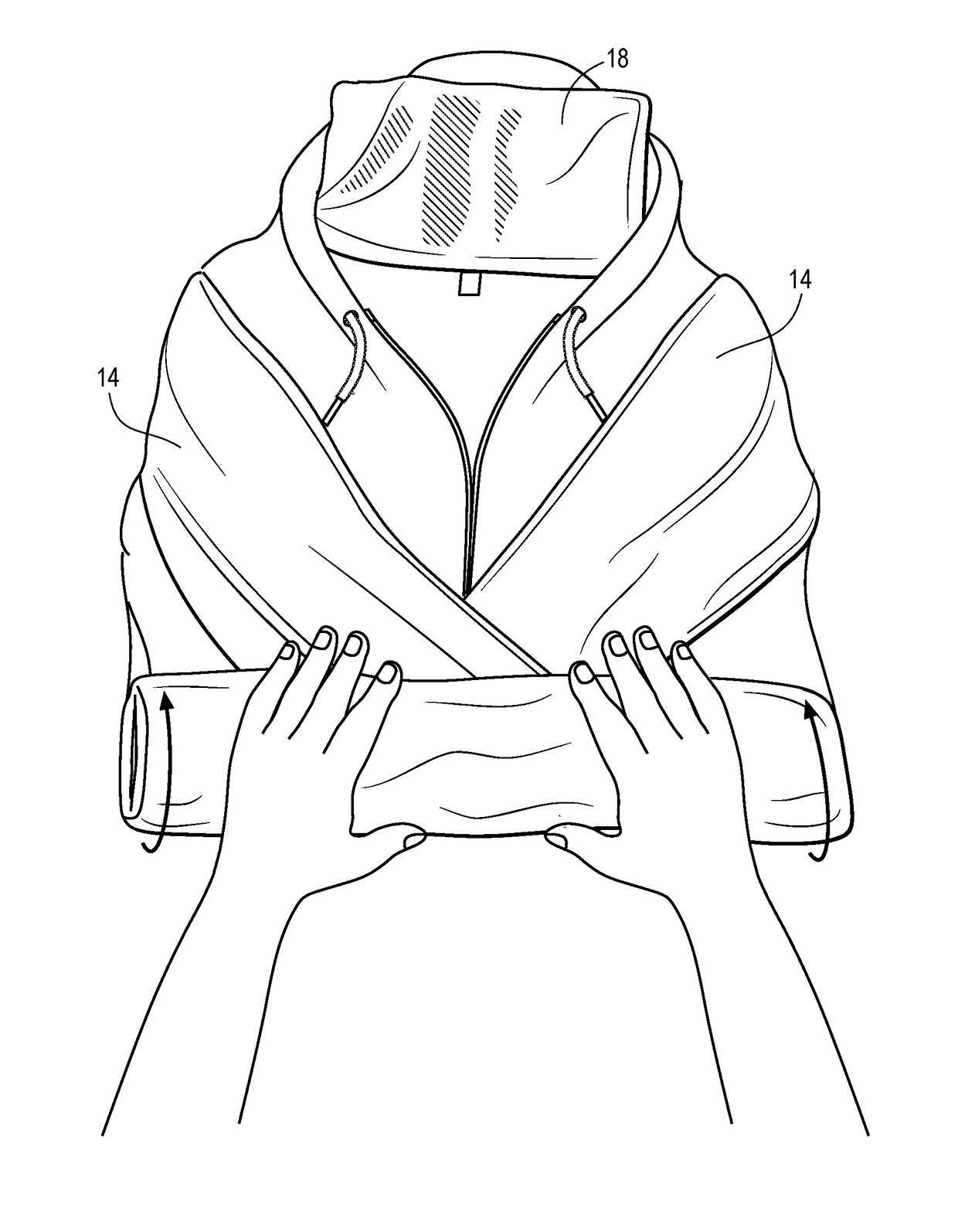

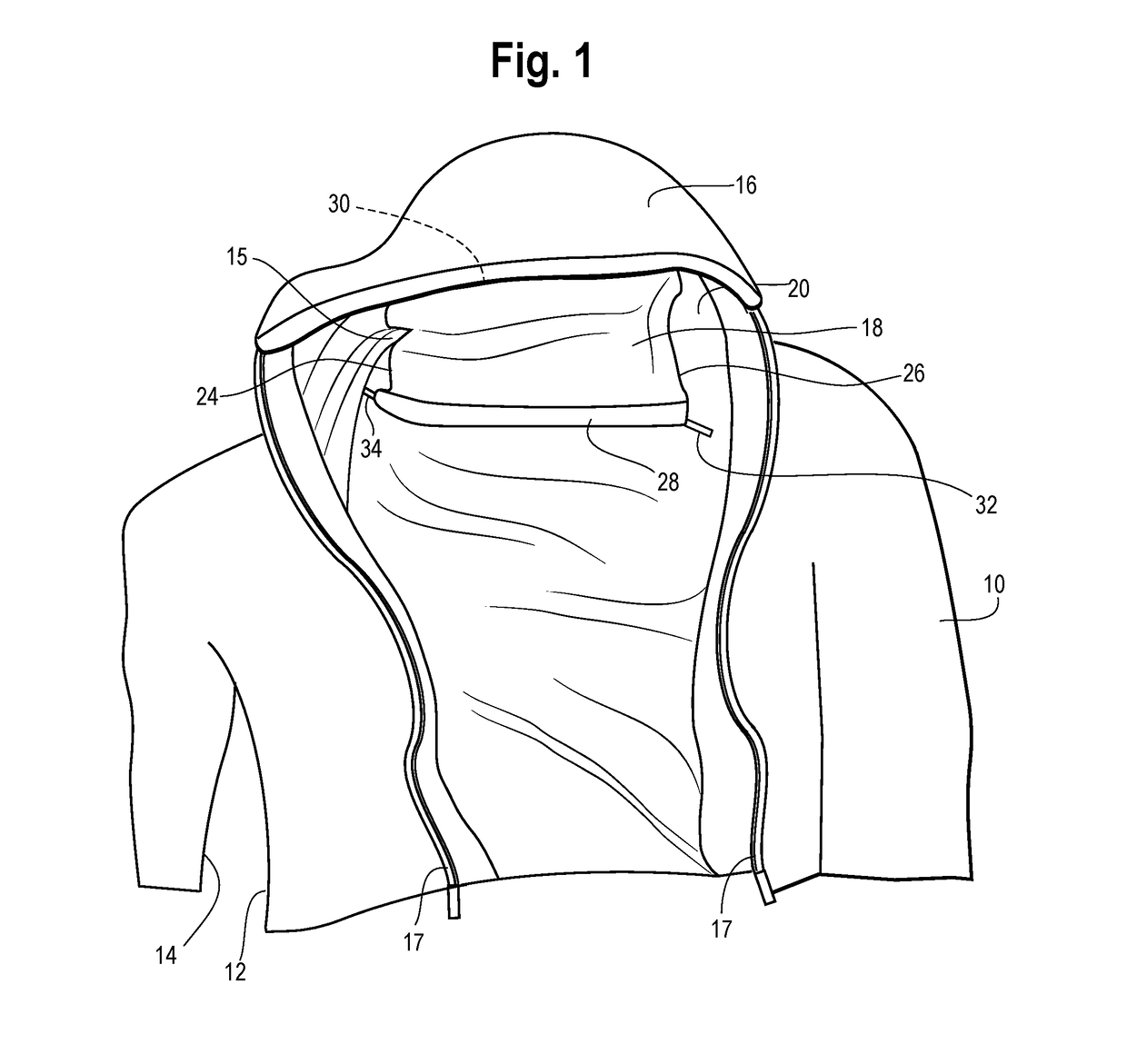

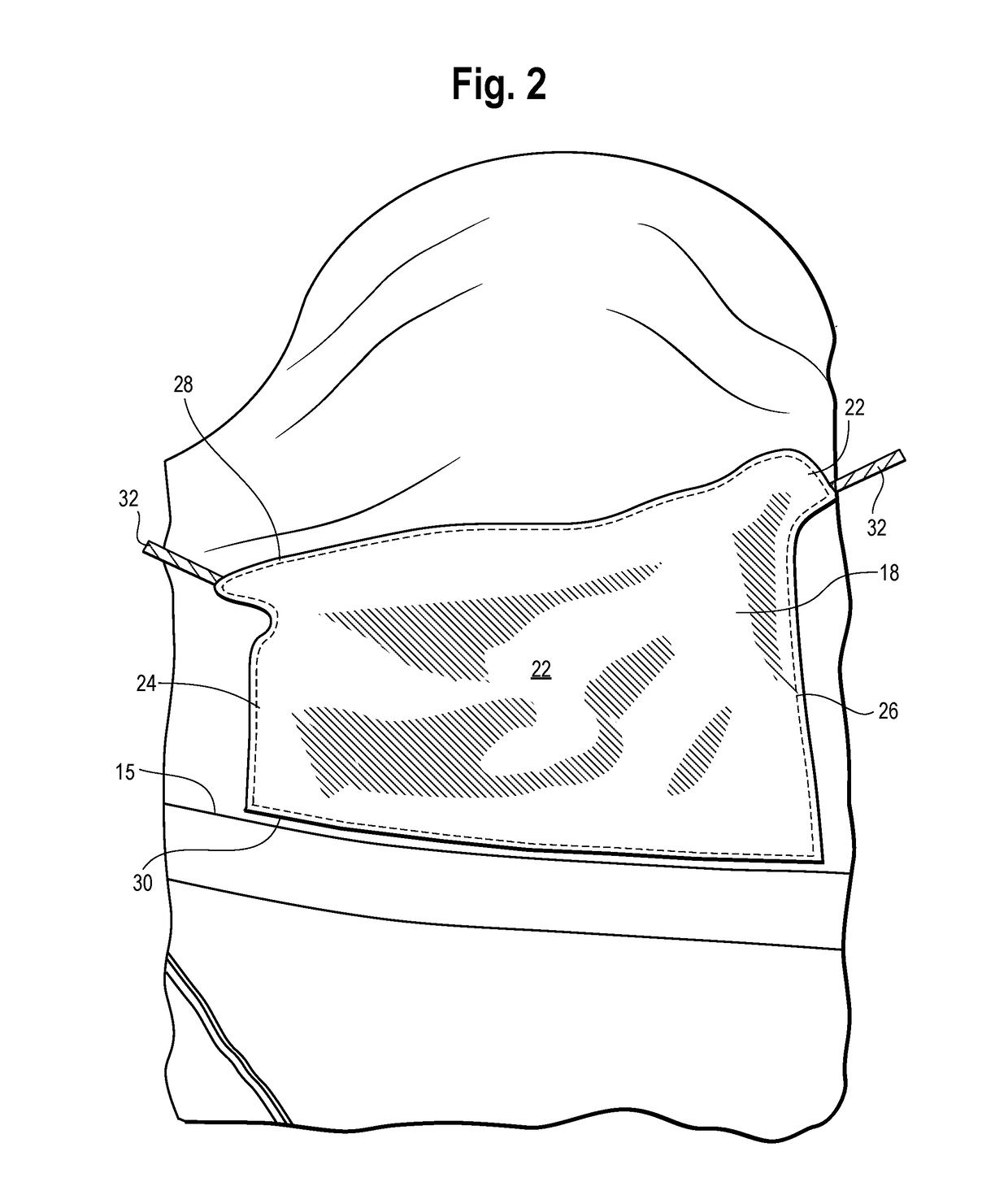

Combination Sweatshirt and Travel Pillow

Owner:LATTA JR ROBERT S

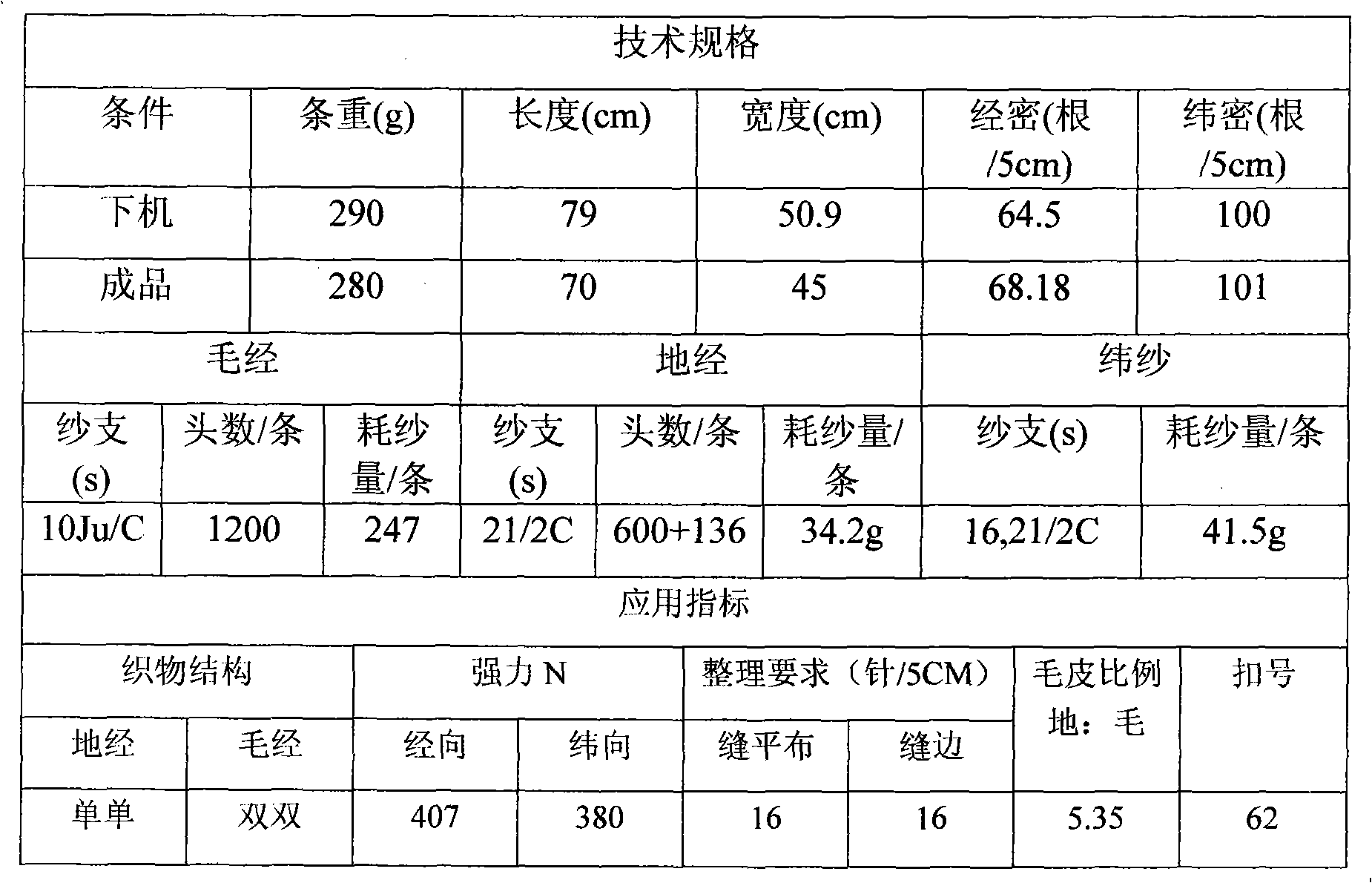

Method for producing jute natural antibiotic bath mat

InactiveCN101260588AGood antibacterialGood antibacterial effectBleaching apparatusDyeing processMoisture absorptionEngineering

The invention relates to a manufacturing method for a jute natural antibacterial floor towel, blending jute and cotton, adequately utilizing the characteristics of the jute such as excellent moisture absorption and moisture wicking, high strength and tensile stretch and good antibacterial and bacteriostatic capability. Jute fibre is humidified before spinning, and the humidified percentage reaches 12-15 percent; the mixture ratio of jute and cotton is 20-50 percent / 50-80 percent during spinning, the relative humidity of spinning environment reaches 83-86 percent, and the relative humidity of textile environment reaches above 85 percent; in order to make up strength and fix short fiber, the sizing ratio is adjusted below 1 percent, and softening treatment and flexible treatment are performed. The manufacturing method for the jute natural antibacterial floor towel changes the jute performance that jute can not be woven, and has the advantages of anti-bacteria, anti-corrosion, anti-wrinkle, moisture absorption, ventilation, flatness and flexibility, good slip resistant and so on.

Owner:石磊

Ink-absorbing quick-drying painting canvas

ActiveCN103741481AImprove antioxidant capacityNot easy to fadeFibre treatmentChemistryEconomic shortage

The invention discloses an ink-absorbing quick-drying painting canvas. The preparation method of the canvas comprises the following steps: (1) painting gel resin on the surface of fabric, drying in an oven with a temperature of 100 to 120 DEG C so as to obtain a gel resin layer; (2) painting prime paint on the gel resin layer, drying in an oven with a temperature of 90 to 100 DEG C so as to obtain a prime paint layer; (3) painting surface paint on the prime paint layer, drying in an oven with a temperature of 70 to 85 DEG C so as to obtain a surface paint layer, wherein during this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute; (4) painting ink-absorbing quick-drying paint on the surface paint layer, drying in an oven with a temperature of 70 to 85 DEG C, wherein in this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute. The ink-absorbing quick-drying painting canvas preserves the unique wash-painting effect of raw Xuan paper, overcomes the inherent shortages of raw Xuan paper, thus enlarges the application range and increases the collection value of wash paintings.

Owner:沭阳凤凰画材有限公司

Sturgeon leather production method and sturgeon leather produced using same

InactiveCN102154529AImprove wrinkle resistanceFeel goodSpecial leather manufactureEngineeringSturgeon

The invention provides a sturgeon leather production method and a sturgeon leather produced using same. The sturgeon leather production method comprises the following steps of: 1) pretreating a sturgeon leather raw material with a bone deck by means of cleaning, soaking and degreasing; 2) sequentially performing primary softening, pickle softening and tanning to the bone deck of the pretreated sturgeon leather by means of cleaning, soaking and degreasing, so that the bone deck is softened; and 3) treating the sturgeon leather with the softened bone deck by means of neutral retanning, dyeing, greasing and drying to obtain the sturgeon leather with the softened bone deck after the bone deck is treated by means of the primary softening, the pickle softening and the tanning. The sturgeon leather produced by the method is soft and ventilate, and has good tear-resistant performance and buckling-resistant performance, so that the special bone deck of the sturgeon is firmly adhered to the surface of the leather without falling off, the bone deck can be bended at 45-90 degrees without breaking off, and each bone deck is distinct in gradation, natural in decorative pattern, beautiful and fashionable.

Owner:李宏强

Terylene, vinylon and cotton fiber blended yarn preparation method

The invention provides a terylene, vinylon and cotton fiber blended yarn preparation method. The blended yarn is formed by the following raw materials in parts by weight: 20-100 parts of terylene fibers, 10-30 parts of vinylon fibers and 10-50 parts of long stapled cotton fibers. The preparation method comprises the following steps: cotton cleaning, cotton carding, drawing, roving, fine spinning and winding. The terylene, vinylon and cotton fiber blended yarn has good advantages of terylene, vinylon and cotton fibers simultaneously, and eliminates defects of the terylene, vinylon and cotton fibers respectively.

Owner:安徽创星实业有限公司

Production method of Newdal-fiber-containing spun wool fabric

InactiveCN103898745AWrinkle resistantReduce disadvantagesBiochemical fibre treatmentAnimal fibresAfter treatmentWorsted

The invention discloses a production method of a Newdal-fiber-containing spun wool fabric. The fabric is spun from wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and Newdal fibers. The production method comprises the following steps: respectively carrying out anti-pilling treatment, enzyme treatment and softening treatment on the wool fibers and cashmere fibers; spinning the wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and Newdal fibers in a weight ratio of (55-75):(12-18):(18-28):(12-15):(5-8) into a fabric; and finally, carrying out after-treatment on the fabric by using a water-soluble polyurethane wool anti-shrinking agent. The method can greatly reduce the damage of the wool fiber product and reduce pilling; and the fabric has the advantages of softer feeling, greatly lower felting shrinkage and better quality.

Owner:汤丽娟

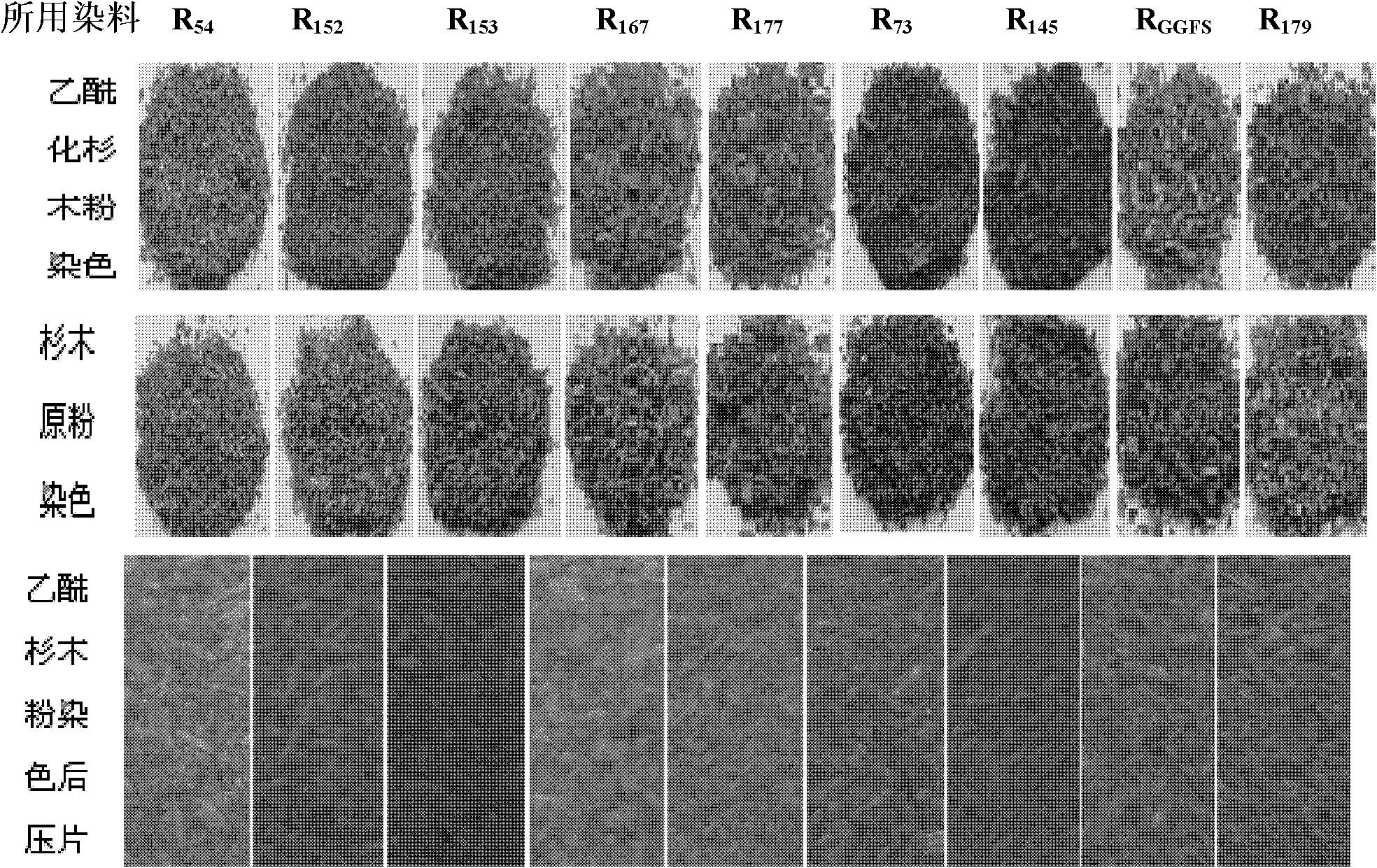

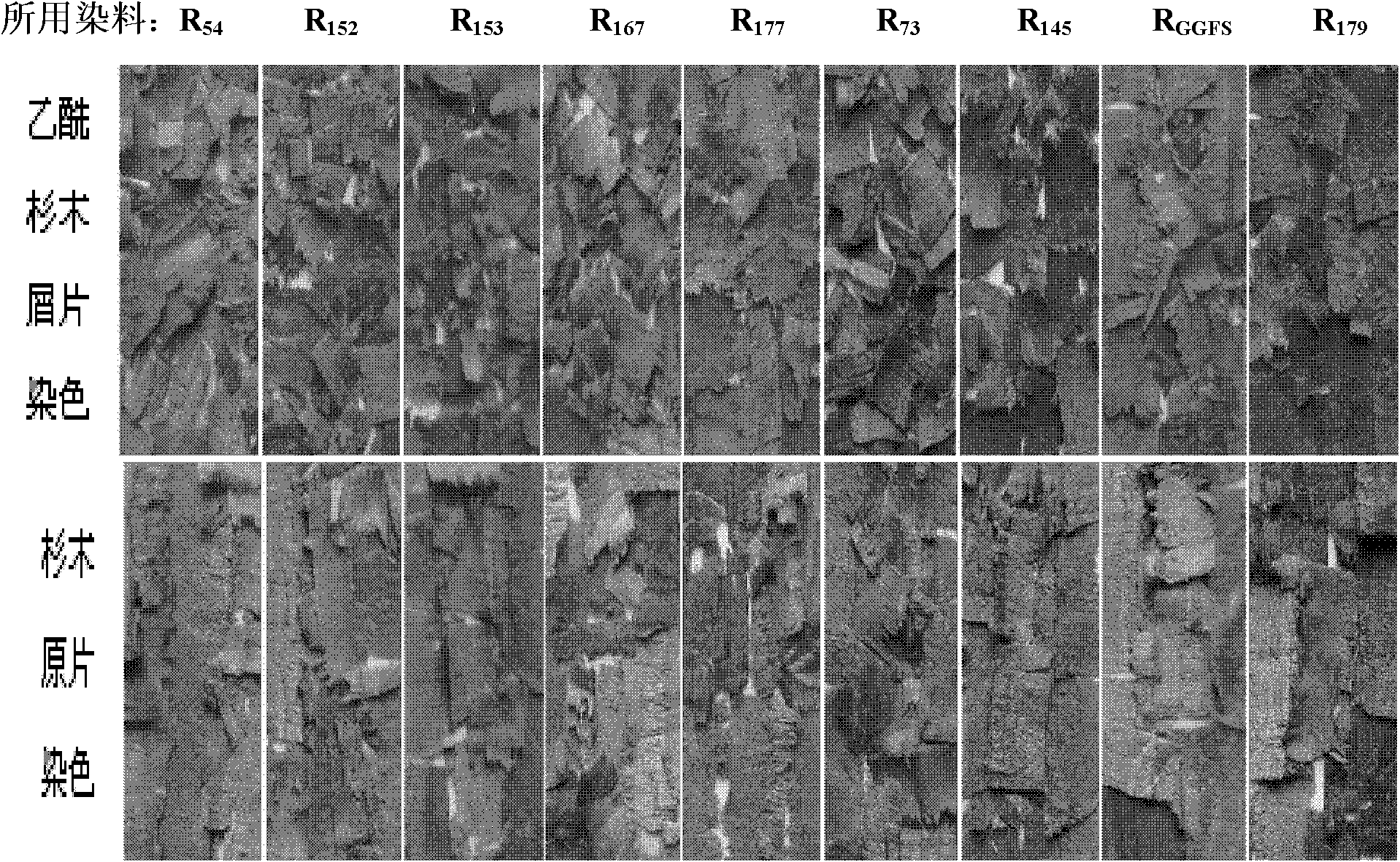

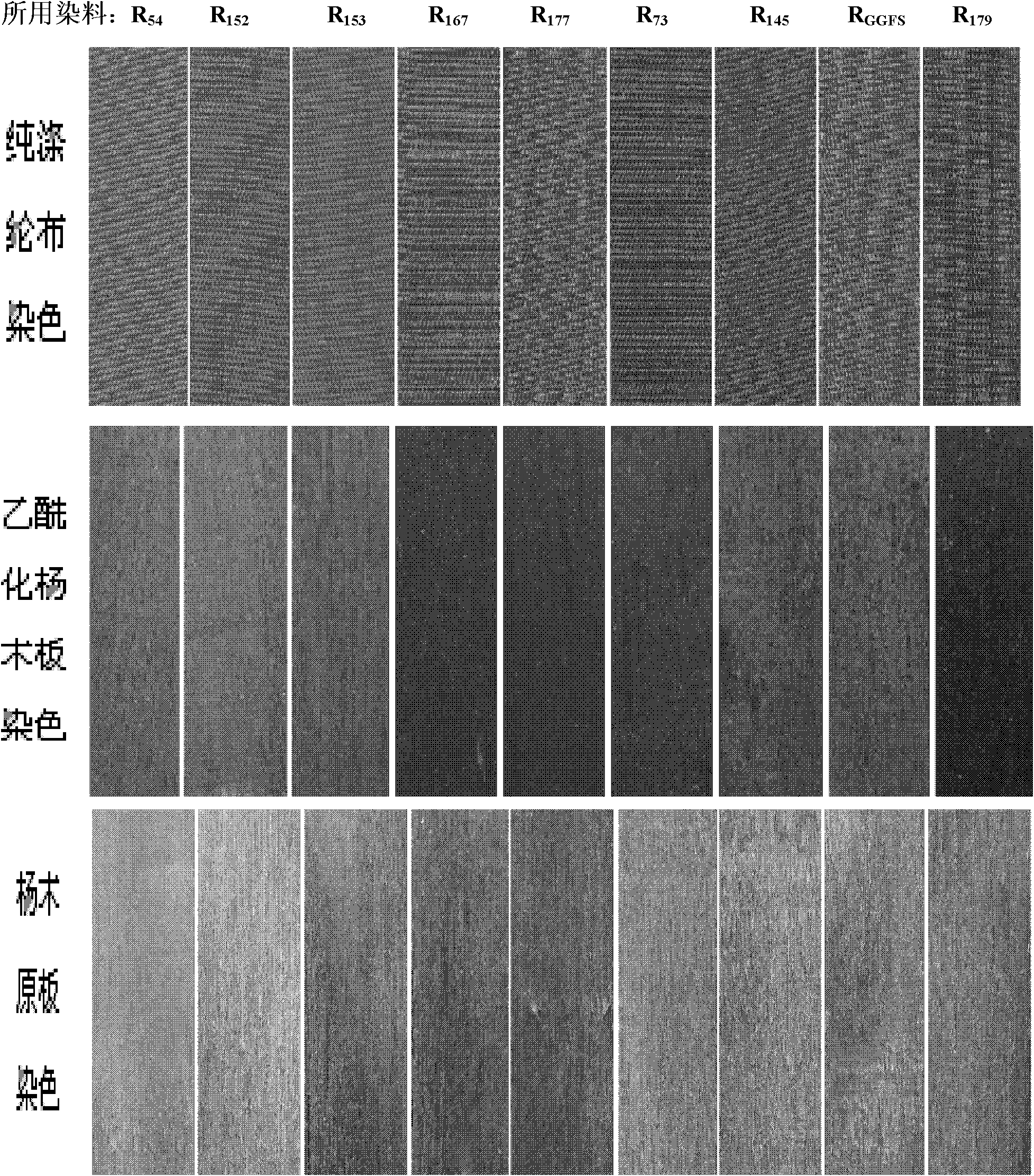

Red washable timber and preparation method thereof

The invention provides red washable timber and a preparation method thereof. According to the method, timber is subjected to an acetylation treatment to obtain acetylation modified timber, then the acetylation modified timber is immersed into water with pH value of 3.0-10.5, azo or anthraquinone red disperse dyestuff with weight of 0.01% to 20% of weight of the timber is added into the water, and the timber is subjected to dyeing in a dyeing tank at a temperature of 60 DEG C to 140 DEG C. After dyeing, the timber is subjected to water rinse and air drying treatments to obtain the red washable timber. Colors of the timber comprises orange, carmine, rhodamine, bright red, violet red, jujube red, pale red, deep red and the like. The timber has the characteristics of washing fastness, anti-insect, anti-corrosion, cracking deformation resistance and the like, and is suitable for manufacture of indoor high-grade floor and simulated redwood high-grade furniture, construction of outdoor high-grade decoration project like archaize building. The timber especially can be used as beauty decoration materials in a wet environment which has a high water resistance requirement to the materials, and has good application prospect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Manufacturing technique of anti-wrinkle woolen fiber

The invention relates to a manufacturing technique of anti-wrinkle woolen fiber. The manufacturing technique of anti-wrinkle woolen fiber weaves a woolen high count frivolous woolen fleece tweed by using woolen yarn with a metric number of 25 / 1. The woolen high count frivolous woolen fleece tweed has the advantages of good binding cohesion and antistatic property. The woolen high count yarn is characterized by balance evenness, high intensity, frivolous and gentle fabric, full handle, smoothness and bonyskinny. The Newer fiber has the advantages of good handle feeling and strong sense of pendant and laundering durability and good wrinkle resistance, which complements the advantage and disadvantage of each fiber. Thus the anti-wrinkle woolen fiber is characterized by stronger intensity of fabric and better water absorption, heat retaining property and stiff and smooth property, which benefits human health and environmental protection.

Owner:JIANGSU SUNSHINE GRP CO LTD

Preparation method of cotton fabric formaldehyde-free crease-resistant finishing agent

InactiveCN107119458AImprove the swelling coefficientImprove water absorptionWrinkle resistant fibresVegetal fibresFiberEnvironmental resistance

The invention discloses a preparation method of a formaldehyde-free crease-resistant finishing agent, and belongs to the technical field of textile finishing. The preparation method comprises the following steps: extracting fibroin from silk, carrying out a cross-linking reaction with itaconic acid, acrylic acid and the like to obtain a reactant for standby use, then mixing and soaking cotton fiber with water, then dropwise adding a sulfuric acid solution and cold water after defibering to obtain a turbid liquid, after mixing with deionized water after centrifugal separation for ultrasonic dispersion, adding acid anhydride for a stirring reaction to obtain a mixture, after centrifugal separation and washing drying, stirring and mixing a cocoanut fatty acid diethanolamide solution and linoleic acid to obtain a mixed liquor A, and then stirring and mixing with a standby reactant and carboxymethylcellulose to obtain the cotton fabric formaldehyde-free crease-resistant finishing agent. The preparation method is simple in preparation steps, the obtained formaldehyde-free crease-resistant finishing agent is free of formaldehyde release and is safe and environmentally-friendly, a fabric after being used does not yellow, the fabric is little in strength damage, and the break strength retention and chromaticity of the fabric can be effectively improved.

Owner:CHANGZHOU LANXU CHEM CO LTD

Production process of colorful, high-elasticity and environment-friendly fabric

InactiveCN106676735AHigh elastic hasMoisture wickingWeft knittingHeating/cooling textile fabricsPolyesterEngineering

The invention discloses a production process of a colorful, high-elasticity and environment-friendly fabric. The fabric is formed by weaving 4-6 150-200 D / 144F net-section dyed polyester silk on a 30-inch 8-12G coarse gauge towel single-face machine, and the production process of the fabric comprises the following steps of weaving, slitting, pre-setting, galling, shearing and finished product setting. The production process of the colorful, high-elasticity and environment-friendly fabric has no step of drying the fabric, accordingly contaminant discharge can be greatly reduced, and the purposes of saving energy and protecting environment are achieved. In addition, the fabric produced by the production process has colorful, high-elasticity, moisture absorption, sweat releasing, stiffening and crease resistance properties, and the color fastness of the fabric can be up to the level 3-4 of the American standard requirements.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

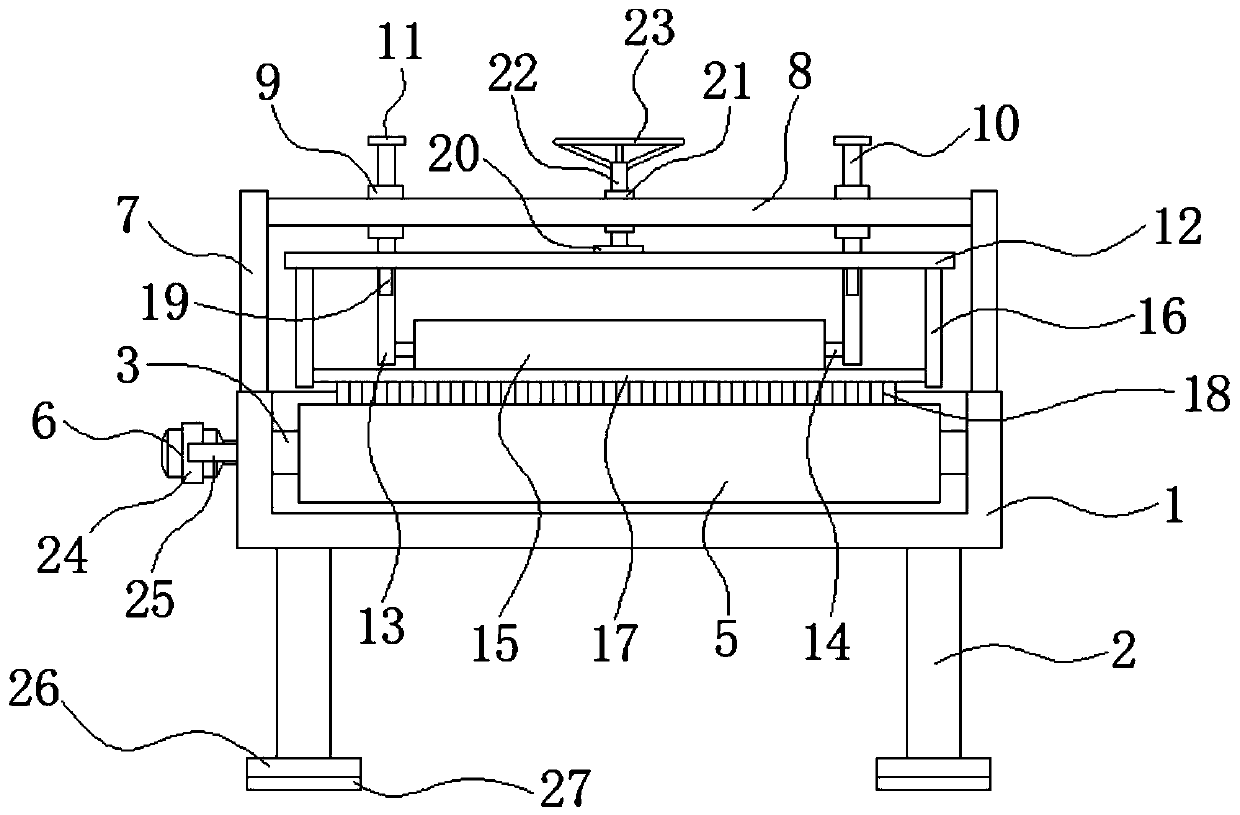

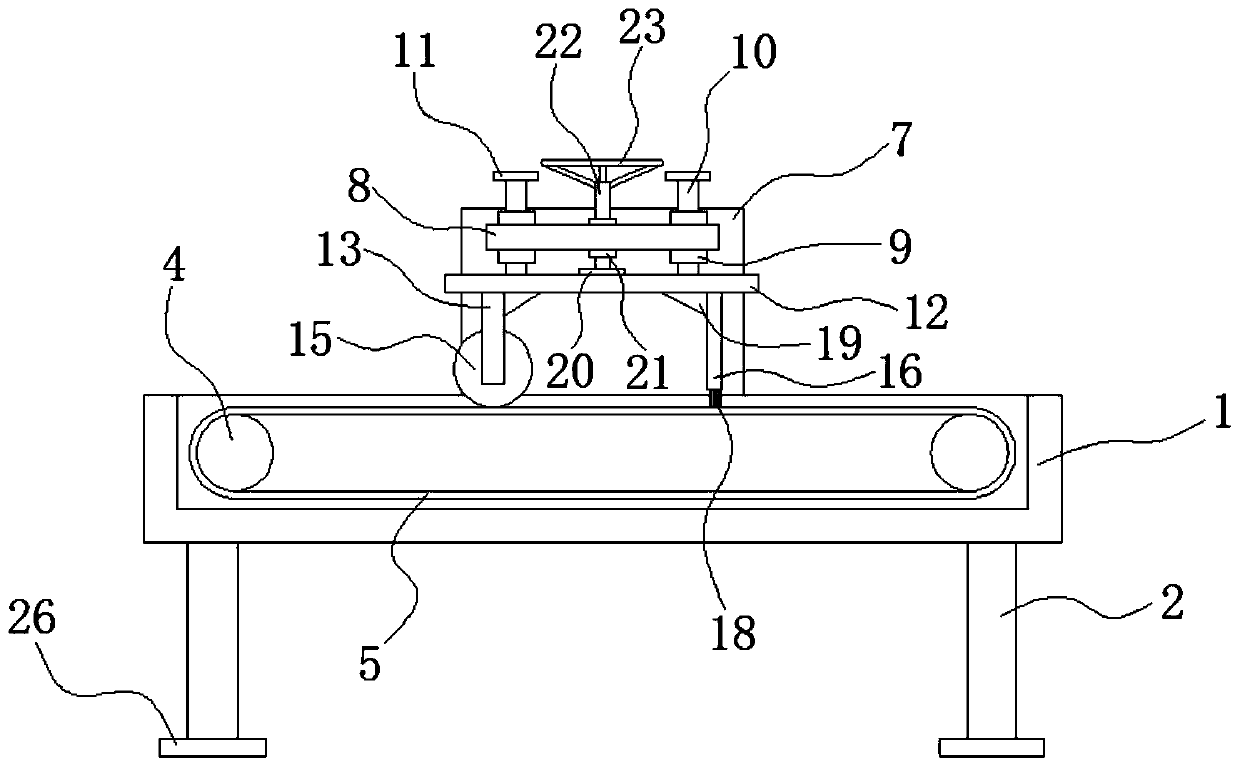

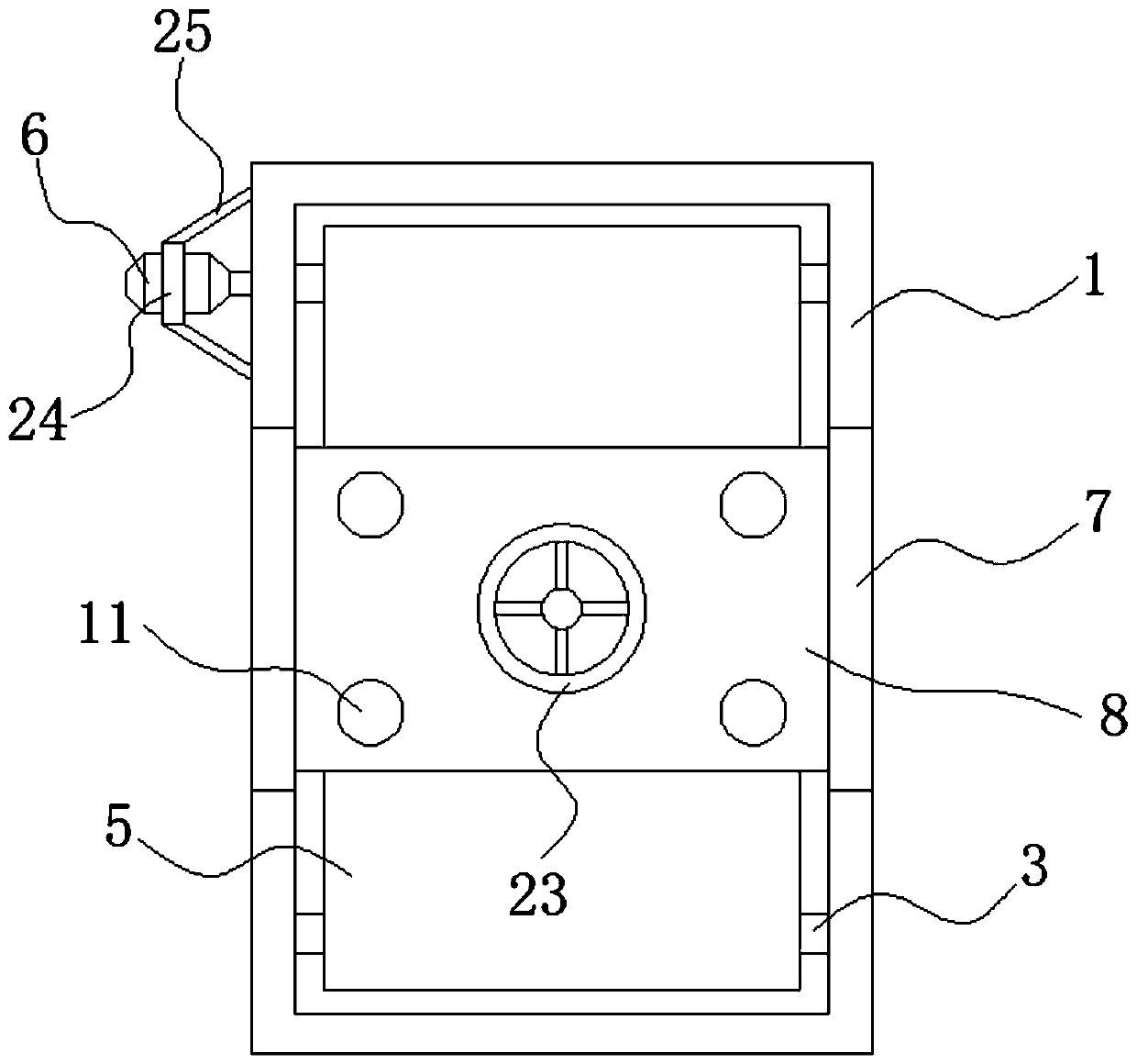

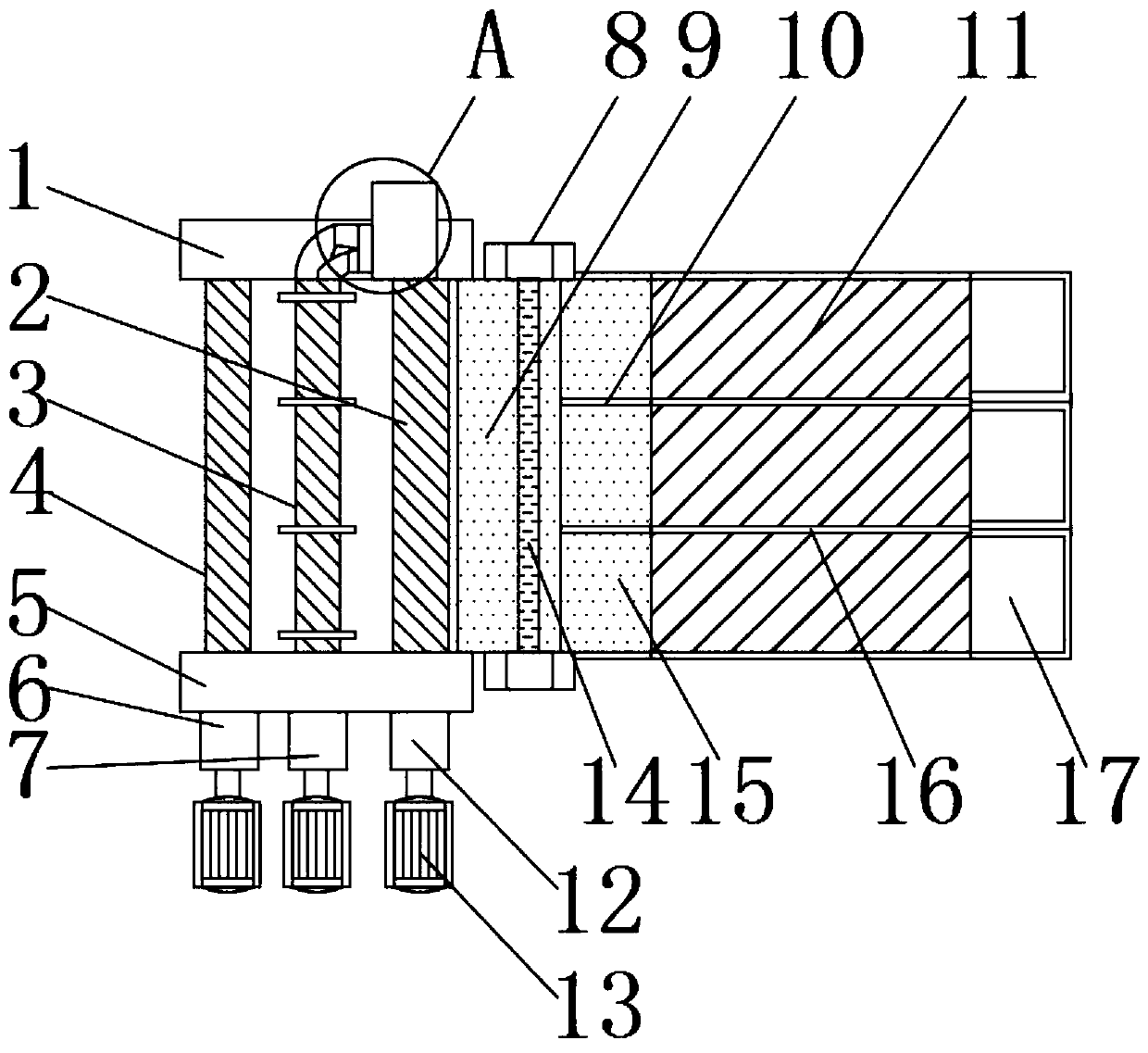

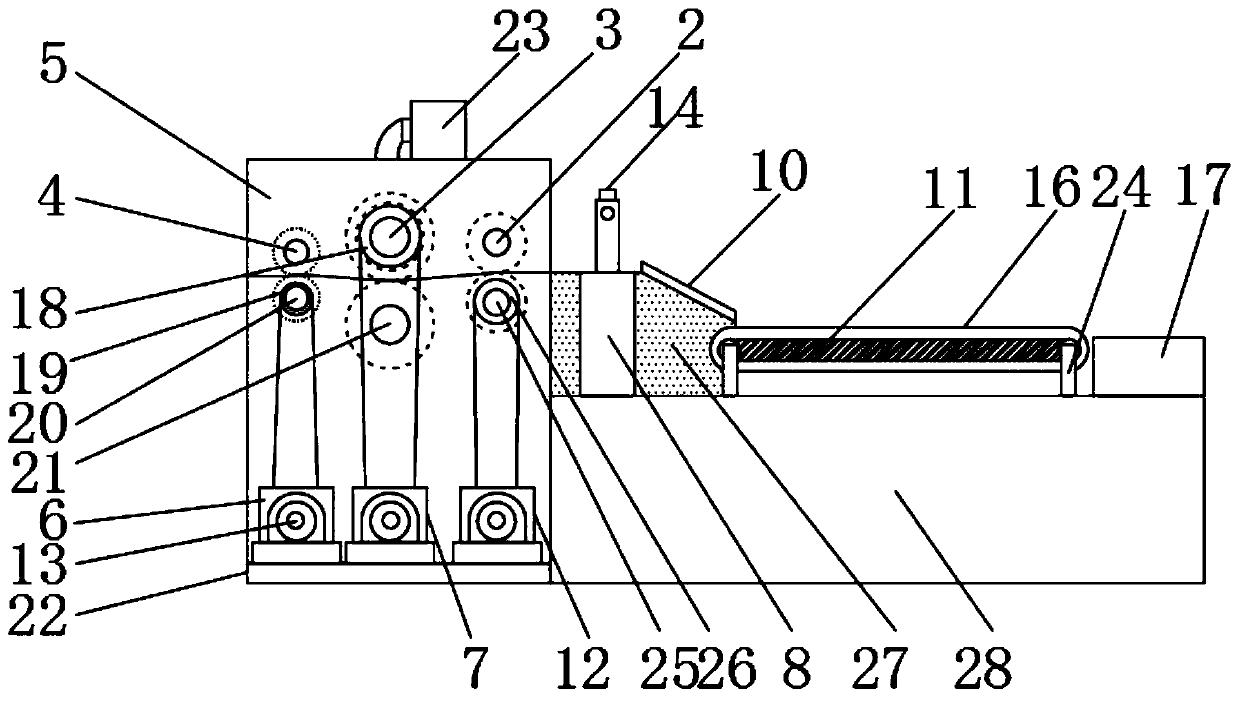

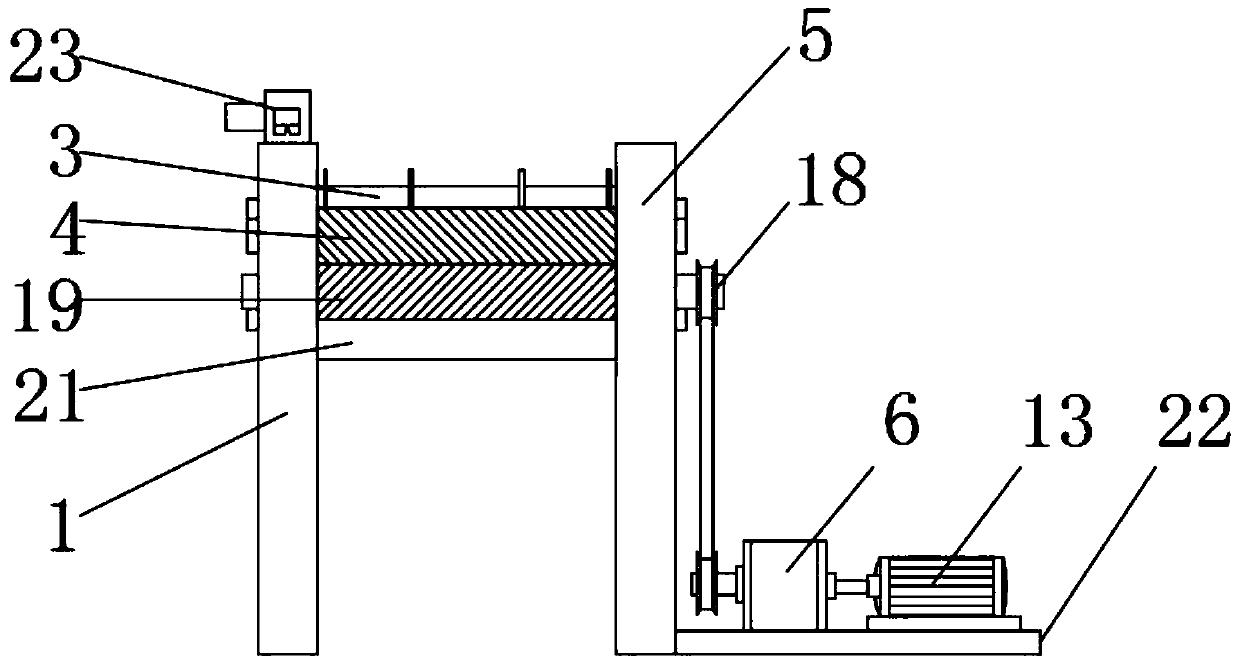

Cotton and linen textile cloth anti-wrinkle conveying device

The invention relates to the technical field of cloth production, in particular to a cotton and linen textile cloth anti-wrinkle conveying device. The cotton and linen textile cloth anti-wrinkle conveying device comprises a conveying groove. Supporting columns are fixedly welded to four corners of the bottom surface of the conveying groove. Two symmetrical supporting round rods are rotatably arranged at the two ends of the interior of the conveying groove. First roller wheels fixedly sleeve the supporting round columns. A belt is arranged between the two first roller wheels in a sleeving mode.One ends of the supporting round rods penetrate through the conveying grove and extend out of the conveying groove. A driving motor is mounted outside the conveying groove through a fixing mechanism.Due to the arrangement of a second roller wheel and a brush, when cotton and linen on the belt are extruded by the second roller wheel and the brush, the belt drives cotton and linen cloth and the second roller wheel to move together, the position of the cotton and linen cloth relative to the belt is unchanged under the action of the belt and the second roller wheel, and the cotton and linen cloth can be laid flat on the belt under the action of the brush. Due to the arrangement, the conveying device has an anti-wrinkle effect, and is convenient to operate, strong in practicability and suitable for popularization.

Owner:HUBEI XINYUANDONG FIBER

Preparation method and application of novel modified organic silicon softening agent

The invention discloses a preparation method and application of a novel modified organic silicon softening agent, and belongs to the technical field of textile chemical industry. The preparation method comprises the catalyst preparing process and the softening agent preparing process, wherein zinc sulfate and D-sodium gluconate solids are added into 100 ml of water to be mixed to prepare a catalyst solution, polysiloxane, butyl methacrylate and n-butyl acrylate are mixed and stirred, the catalyst solution is added after the temperature is increased, and a temperature increasing reaction is performed to obtain the modified organic silicon softening agent. The invention further discloses application of the organic silicon softening agent in a flax fabric finishing technology. The preparation method is simple, convenient, easy to operate, low in cost and suitable for the large-scale industrialized production requirement; after the novel modified organic silicon softening agent is applied to flax fabric finishing, the good flexibility and wrinkle resistance are given to flax fabric fiber, the smoothness and brightness are also excellent, and the extremely high market promotion value is achieved.

Owner:SUZHOU INSILK CO LTD

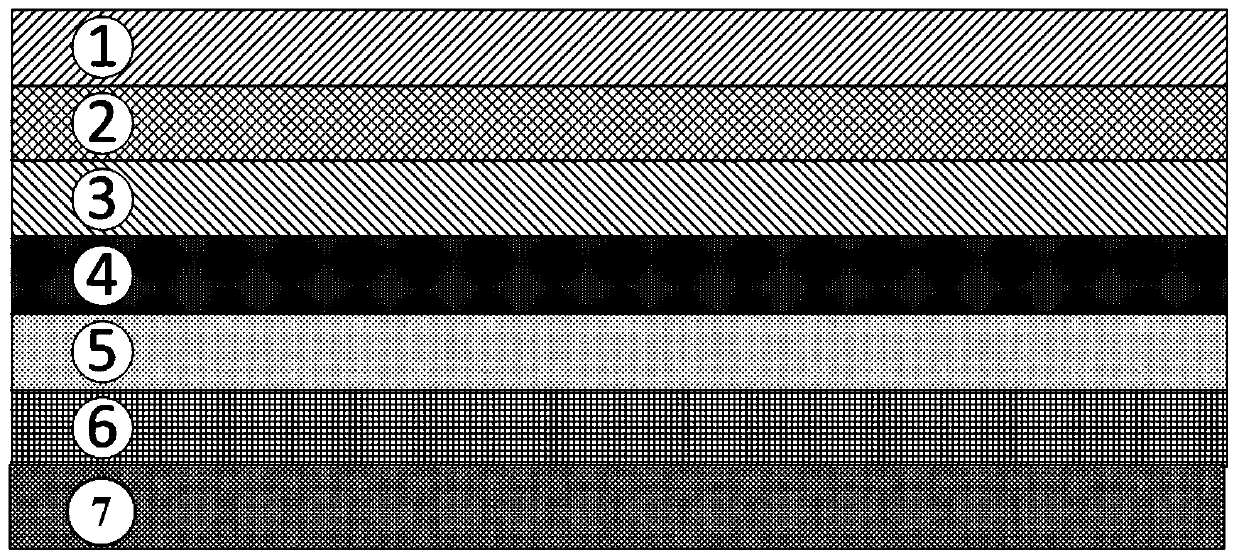

Wear-resistant and crease-resistant fabric

ActiveCN110341255AReasonable structureImprove comfortSynthetic resin layered productsCellulosic plastic layered productsPolyesterCarbon fibers

The invention provides a wear-resistant and crease-resistant fabric. The wear-resistant and crease-resistant fabric comprises a lining layer, a base cloth layer, a crease-resistant layer, a non-wovenfabric layer, a thermoplastic polyurethane (TPU) film layer and a nylon grid layer which are sequentially stacked from inside to outside. The lining layer is made of a cotton-plaited polyester woven fabric; the base cloth layer is a double-layer plain-weave fabric woven by carbon fiber yarn; the crease-resistant layer is a single-layer plain-weave fabric woven by linen yarn; and the nylon grid layer is of a grid structure woven by nylon wires. The cotton-plaited polyester woven fabric is used as the lining layer, so that the comfort performance is good, and moisture absorption performance, sweat releasing performance and air permeability are excellent; the base cloth layer is a double-layer plain-weave fabric woven by carbon fiber yarn, so that the base cloth layer has good structural strength and tear resistance and has certain crease resistance, and good crease resistance is achieved with the match of the crease-resistant layer through internal stress of a plain weave structure; theTPU film layer endows the fabric with certain elasticity, toughness, cold resistance and water resistance; and the nylon grid layer can effectively improve wear resistance of the surface of a TPU film, and the service life is prolonged.

Owner:JIANGYIN XIANGFEI APPAREL +1

Graphene composite PVA fiber and preparation method

InactiveCN107604459AFix unstable performanceWrinkle resistantElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentOrganic acidFiber

The invention belongs to the field of preparation of composite fiber, and in particular relates to graphene composite PVA fiber and a preparation method, the graphene composite PVA fiber includes thefollowing materials by weight: graphene, microcrystalline cellulose, a solvent, a filler, hydrophobic amino acids and an organic acid, the solvent is water, ethanol or acetone, the filler is a hydrophobic filler; or functional filler fiber powder; the graphene is 3-10 layers of graphene. The comprehensive performance of the PVA fiber can be effectively improved.

Owner:SHAOXING BIAODIAN TEXTILE TECH

Process for producing stripe-style blended fabric with high elasticity and good environmental protection

ActiveCN106521781AWith whipped styleHigh elastic performanceWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses a process for producing a blended fabric with high elasticity and high elasticity. The fabric is made of 32S-45ST polyester yarn and color yarn network silk which is added 20-40D spandex woven. Yarn wire network silk consists of 50-65% 32-40S bamboo fiber, 20-25% viscose and 15-25% lyocell network. The production process of the fabric is as follows: weaving, cutting, shaping, preshrinking and finished products (1) in the weaving, wherein the double rib machine is used for weaving, so that the fabric has a pumping style; (2) in the shaping, where in a long chain aliphatic softener or amino modified silicone softener is used, shaping temperature is 140 - 160 DEG C, the speed is 18 -0 26m / min, shaping setting upper position is 115 - 120% super, lower position is 100-110%, fan function is 95-100%;(3) in the preshrinking, the preshrinking temperature is 100-120 DEG C, the speed is 2-25m / min, the tension is 0.5-0.8N, and the super position is 20-30%. The fabric which is produced by the process for producing blended fabric with high elasticity and good environmental protection has the advantages of stiff anti-wrinkle, antibacterial activity, moisture absorption, soft and smooth and anti-ultraviolet.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

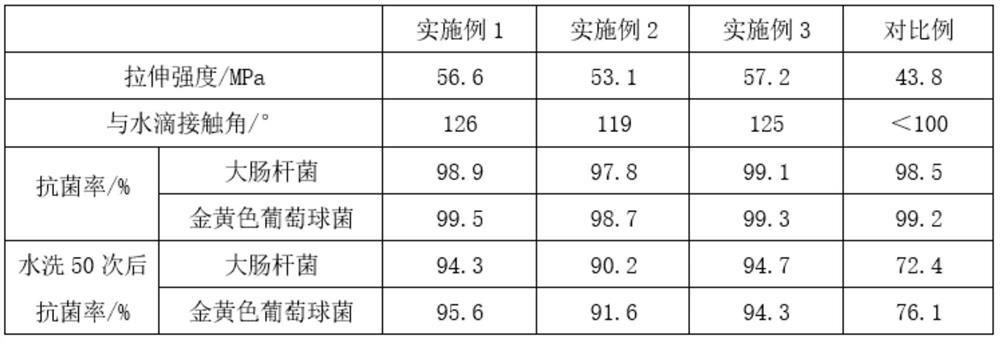

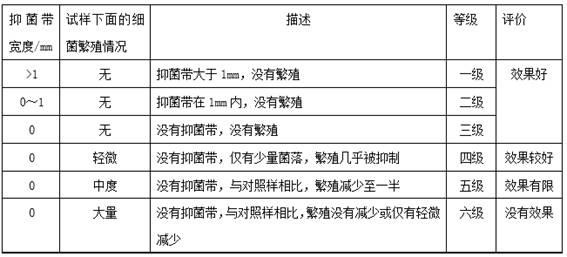

Composite nano antibacterial fiber gauze fabric and preparation process thereof

InactiveCN112522832AHigh mechanical strengthImprove waterproof performanceBiochemical fibre treatmentFibre typesCotton fibrePolyester

The invention relates to a composite nano antibacterial fiber gauze fabric and a preparation process thereof. The gauze fabric is formed by weaving warp yarns and weft yarns, the warp yarns are formedby blending antibacterial fibers and cotton fibers, the weft yarns are formed by blending bamboo fibers and polyurethane fibers, and the antibacterial fibers are obtained by modifying polyester fibers with a composite nano material. The problems that in the research field of antibacterial textiles, a fabric after-finishing method is mainly adopted in a preparation method of the antibacterial textiles, so that an antibacterial layer is formed on the surface of a textile material, but an antibacterial fabric in the prior art is not long in service life and not ideal in antibacterial effect aresolved. The prepared antibacterial fibers and the cotton fibers with high air permeability are blended to form the warp yarns, the waterproof and anti-aging bamboo fibers and the polyurethane fibers with high elasticity are blended to form the weft yarns, and then the warp yarns and the weft yarns are woven to form the gauze fabric. The prepared gauze fabric has the advantages of being high in antibacterial property and lasting in antibacterial property.

Owner:ANHUI HEBANG TEXTILE TECH CO LTD

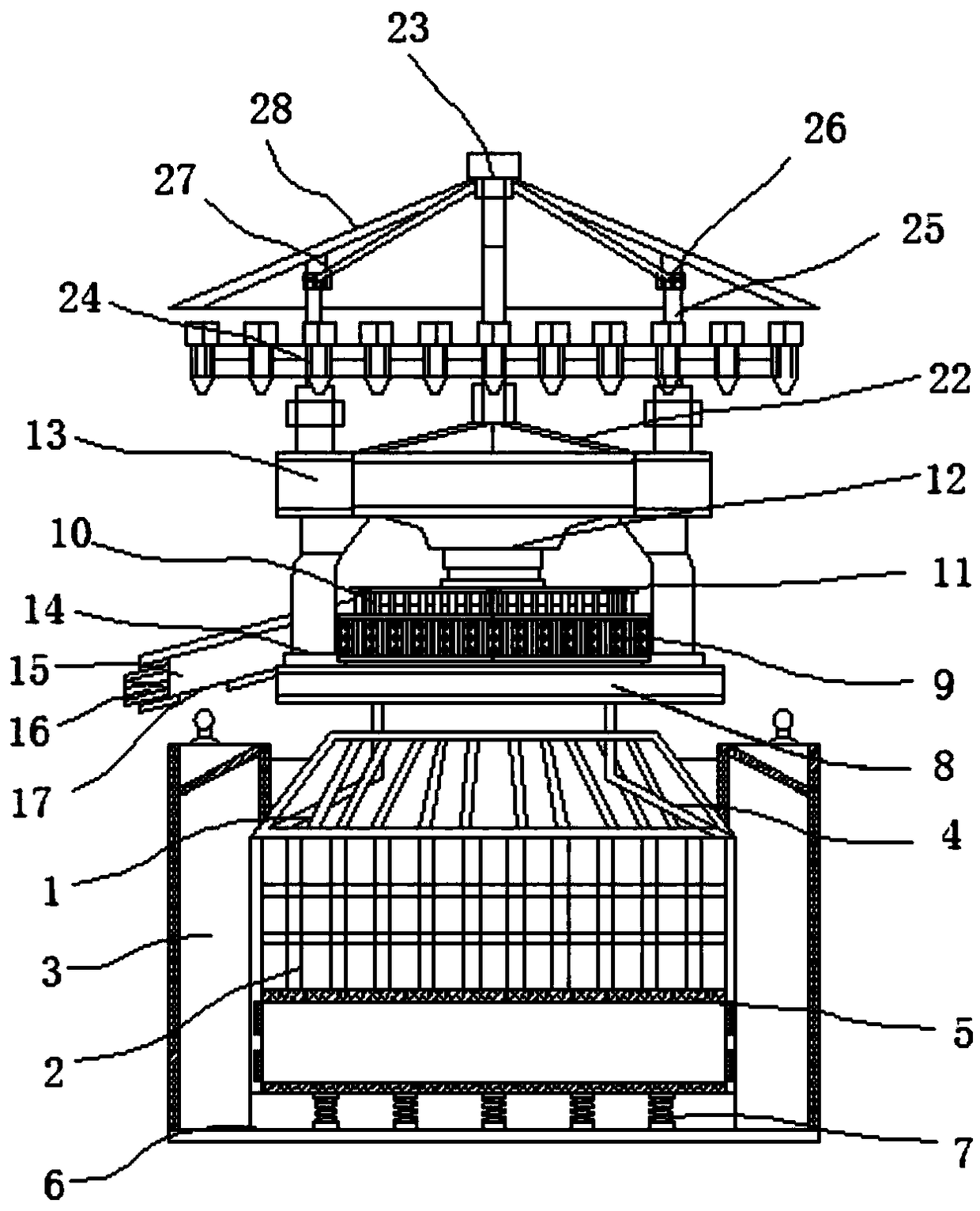

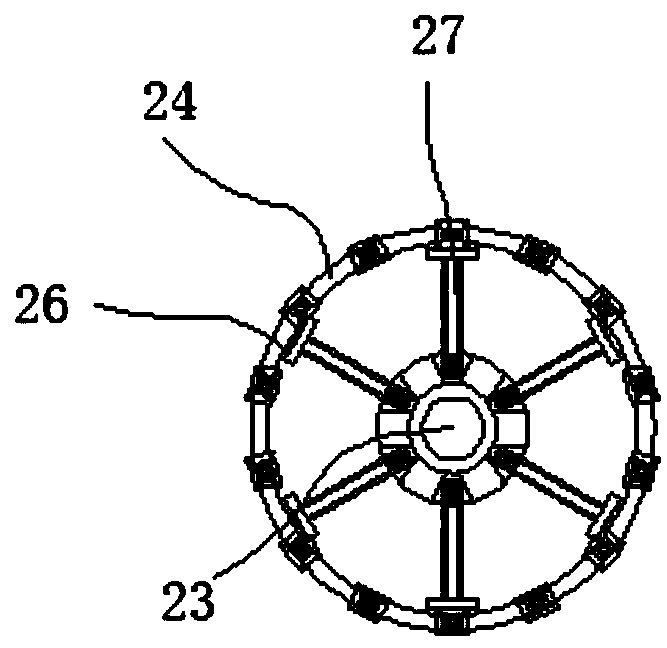

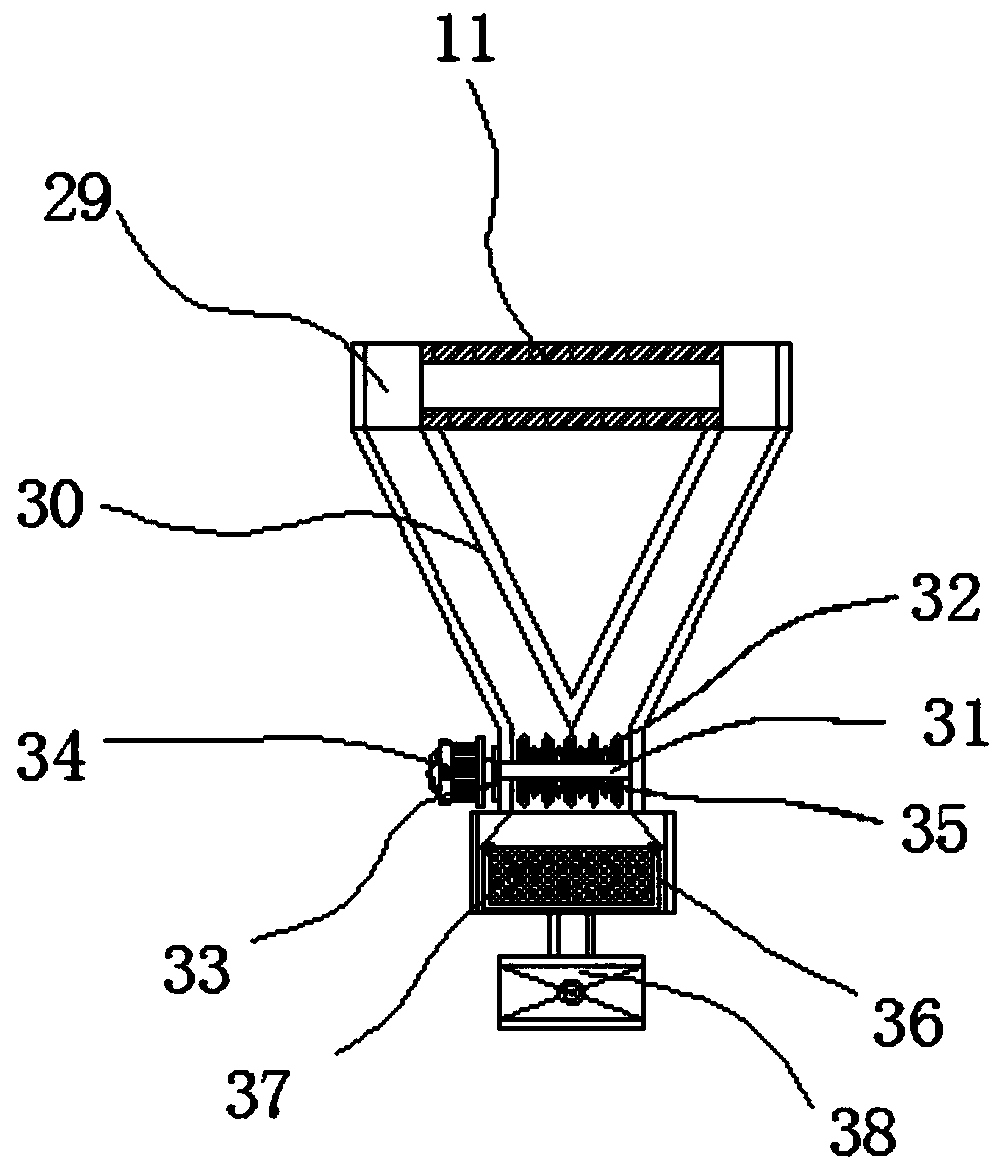

Anti-wrinkle high-speed numerically-controlled knitting device facilitating scrap removal

InactiveCN109355790AAvoid cloggingEasy to clean upNon-rotating vibration suppressionCircular knitting machinesYarnEngineering

The invention relates to an anti-wrinkle high-speed numerically-controlled knitting device facilitating scrap removal. The anti-wrinkle high-speed numerically-controlled knitting device comprises a driving bin, a knitting disc and a support platform, a main grid fence is welded and fixedly installed at the outer side of the driving bin, and control bins are arranged at the left and right ends of the driving bin; an operating plate is installed at the top of the driving bin, a yarn guide disc is arranged at the top of the operating plate, the knitting disc is arranged over the yarn guide disc,and an annular groove is formed in the top of the knitting disc. The anti-wrinkle high-speed numerically-controlled knitting device facilitating scrap removal has the advantages that through the adoption of a scrap sliding-out pipe and a dust collection net bag in cooperation with operative extraction of an air suction pump, scraps can draw close in the direction of the dust collection net bag through a scrap guide port of a hollow structure and the scrap sliding-out pipe; in the process of sliding down, the scraps are smashed and refined by a main crushing blade and a subsidiary smashing blade, the crushed and refined scraps slide out of the scrap sliding-out pipe and enter the dust collection net bag, and the whole scrap removal work is convenient and efficient.

Owner:广州亿骏科技有限公司

Cotton fiber, polyurethane fiber and polyester fiber interwoven fabric and production method

The invention discloses a cotton fiber, polyurethane fiber and polyester fiber interwoven fabric and a production method. The interwoven fabric comprises a double-layer fabric composed of a first fabric and a second fabric, and the first fabric and the second fabric are connected through connecting filaments, wherein the first fabric is obtained by interweaving cotton fibers and polyurethane fibers, the second fabric is obtained by weaving modified polyester fibers, and the connecting filaments are made of polyester fiber silk threads. The interwoven fabric prepared by the method is smooth and fine in outer surface, full in velvet feeling, comfortable and warm-keeping, and the inner surface of the interwoven fabric is close to the skin. The interwoven fabric product has the characteristics of being natural, environment-friendly, moisture-absorbing, warm-keeping, fluffy and good in resilience, and is very suitable for being used as a fabric for children.

Owner:衣拉拉集团股份有限公司

Novel composite fiber with anti-wrinkle effect and processing technique thereof

A novel composite fiber with the anti-wrinkle effect is characterized by being formed by compositing silk and chemical fiber silk according to a certain mixing ratio.

Owner:青岛同盈家纺有限公司

Far-infrared thermal fabric

InactiveCN108576984AAnti-wrinkleWrinkle-resistantGarment special featuresMonocomponent synthetic polymer artificial filamentWrinkle skinWear resistant

The invention discloses a far-infrared thermal fabric. The far-infrared thermal fabric is made by blending of the following materials of, by weight, 20-30 parts of special spandex, 45-55 parts of cornfiber and 35-45 parts of bamboo fiber; and the special spandex contains the following components of, by weight, 40-50 parts of polyurethane, 2-3 parts of tourmaline powder, 1-2 parts of glass beads,1-3 parts of magnet powder, 2-4 parts of magnesium oxide, 1-2 parts of zinc oxide, 1-2 parts of salvia miltiorrhiza, 1-3 parts of angelica, 1-2 parts of melia toosendan, 1-3 parts of twotooth achyranthes root, 1-3 parts of common bletilla pseudobulb, 1-2 parts of rubia cordifolia and 1-2 parts of charred typha pollen. The far-infrared thermal fabric has the beneficial effects that natural fiber and rayon are organically combined, after deep processing of the rayon, the far-infrared thermal fabric is soft, wrinkle-resistant, wear-resistant, non-toxic, durable and anti-infrared, the far-infraredthermal fabric is provided with the magnetic field to clear and activate channels and collaterals, and the far-infrared thermal fabric is further provided with negative ions and drug components to promote blood circulation.

Owner:何韵苗

Antibacterial wet tissue for human body and preparation method of antibacterial wet tissue

PendingCN110772431AWrinkle resistantConformalCosmetic preparationsToilet preparationsPolyesterGlycerol

The invention discloses an antibacterial wet tissue for a human body and a preparation method of the antibacterial wet tissue. The antibacterial wet tissue for the human body is obtained by soaking ablocky non-woven fabric into antibacterial liquid; the non-woven fabric comprises the following raw materials: viscose and polyester; the antibacterial liquid is prepared from the following raw materials: a degerming agent, a preservative, glycerol, an antibacterial agent, a natural preservative, olive oil, citric acid and deionized water; the antibacterial wet tissue for the human body is good inantibacterial performance and high in safety; according to a non-woven fabric slitting device for slitting the blocky non-woven fabric, a process of automatically slitting a large non-woven fabric into a plurality of blocky non-woven fabrics is completed, the automation degree is high, and the working efficiency is improved; the non-woven fabric slitting device can be cut into different quantities of blocky non-woven fabrics with different sizes, and is wide in application range and high in practical performance; and according to the non-woven fabric slitting device, little noise pollution isgenerated during working, the influence of noise on the body health of workers is avoided, and interference on life and work of surrounding people is avoided.

Owner:铜陵麟安生物科技股份有限公司

Aronia melanocarpa collagen beverage and preparation method thereof

PendingCN111869804AAntioxidantWrinkle resistantFood ingredient functionsOligosaccharide food ingredientsBiotechnologyFood additive

The invention discloses an aronia melanocarpa collagen beverage. The aronia melanocarpa collagen beverage is prepared by adding 4-6g of collagen peptide, 2.5-3.5 g of fructo-oligosaccharide, 0.150-0.170 g of tannase and 0.0150-0.0180 g of a food additive into 55ml of aronia melanocarpa normal juice. The aronia melanocarpa collagen beverage provided by the invention is good in taste and rich in nutrients.

Owner:杨涛

Novel PP ultrathin thermal insulation shell fabric and production method thereof

InactiveCN105386221AReduce consumptionNothing producedWeft knittingTextile shapingFiberThermal insulation

The invention discloses a novel PP ultrathin thermal insulation shell fabric and a production method thereof. The production method comprises the steps that firstly, 75D or 8.3tex ultrafine-denier PP and novel 42D XLA comfortable and elastic fibers are interwoven; secondly, shaping and longitudinal and transverse drawing are performed at the temperature between 120 DEG C and 130 DEG C; thirdly, the dyeing and finishing process is performed; fourthly, processing and aftertreatment are performed. The shell fabric produced through the method is high in dimensional stability and heat loss and light and thin in texture, has the functions of keeping warm, being breathable, carrying anions and so on, is light and thin, soft in handfeel, good in fluffing and pilling resistance and light, attractive and comfortable to wear, can free people from past bloat in winter and achieves perfect combination of science and technology, fashion and functions, and the shrinkage rate is less than 2%.

Owner:GAOMI FUYUAN PRINTING & DYEING

Snake gall facial mask and preparation method thereof

InactiveCN107397712AHave metabolismPromote growthCosmetic preparationsToilet preparationsSkin complexionSkin elasticity

The invention relates to a snake gall facial mask and a preparation method thereof. The effective constituents of the snake gall facial mask are prepared from the following raw materials of, by weight, 80-90 parts of deionized water, 6-12 parts of butanediol, 2-8 parts of glycerinum, 6-16 parts of propylene glycol, 0.02-0.06 part of sodium hyaluronate, 0.1-0.7 part of allantoin, 0.4-1 part of polyglycerylmetharylate and propylene glycol, 4-12 parts of rose hydrosol, 0.1-0.6 part of camellia oil, 0.2-1 part of a snake gall extracting solution, 0.8-2.2 parts of aloe gel and 0.2-1 part of PE9010. The snake gall facial mask is capable of repairing damaged skin rapidly, increasing the water content of the skin, moistening the skin, improving dim complexion, enhancing the skin elasticity, compacting the skin and achieving whitening and freckle-removing, and has the characteristics of resisting and preventing wrinkles, preventing acne, removing scars, achieving sun protection and after-sun repair and the like.

Owner:广西小燕蛇业有限公司

Sturgeon leather production method and sturgeon leather produced using same

The invention provides a sturgeon leather production method and a sturgeon leather produced using same. The sturgeon leather production method comprises the following steps of: 1) pretreating a sturgeon leather raw material with a bone deck by means of cleaning, soaking and degreasing; 2) sequentially performing primary softening, pickle softening and tanning to the bone deck of the pretreated sturgeon leather by means of cleaning, soaking and degreasing, so that the bone deck is softened; and 3) treating the sturgeon leather with the softened bone deck by means of neutral retanning, dyeing, greasing and drying to obtain the sturgeon leather with the softened bone deck after the bone deck is treated by means of the primary softening, the pickle softening and the tanning. The sturgeon leather produced by the method is soft and ventilate, and has good tear-resistant performance and buckling-resistant performance, so that the special bone deck of the sturgeon is firmly adhered to the surface of the leather without falling off, the bone deck can be bended at 45-90 degrees without breaking off, and each bone deck is distinct in gradation, natural in decorative pattern, beautiful and fashionable.

Owner:李宏强

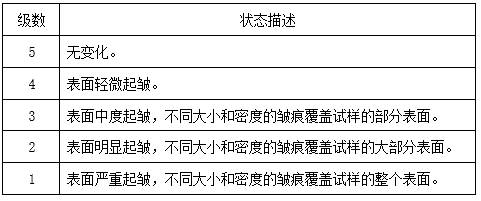

Preparation method of anti-wrinkle glossy cotton and linen fabric

InactiveCN113337933AHigh glossImprove silky feelingBiochemical fibre treatmentWoven fabricsPolymer sciencePlant Gums

The prepared fabric is made of natural fibers, is nontoxic and harmless to the human body and has certain benefits to the skin. Milk protein fibers are added and blended with cotton and linen fibers, so that the softness and the skin-friendly performance of the fabric are improved, and the glossiness and the silky feeling of the fabric are improved. The fibers are modified, so that the fabric made of the modified fibers is smooth and not prone to wrinkling; and negative ion powder is added, so that the fabric has the sterilization and health care effects. Doubling threads are soaked in a solution containing a fixing agent, so that the doubling threads are not prone to wrinkling and shrinking; and the fixing agent adopts propolis, gum, glycerin and the like as adhesive substances and is harmless to the human body. The fabric made of the cotton and linen fibers is prone to wool sticking, and the milk fibers are poor in heat resistance and acid and alkali resistance; in order to prevent pilling of the fabric, a protective layer coats the fabric to protect the fabric; and insect wax in a protective agent serves as a coating film, and vegetable gum forms the protective layer, so that the fabric is comfortable, skin-friendly and free of itching feeling.

Owner:美雅(龙南)服饰有限公司

Crease-resistant finishing method of polyester-cotton blended shirt

InactiveCN111074620AWrinkle resistantOvercome the defect of hard feelingHeating/cooling textile fabricsWrinkle resistant fibresPolyesterPolymer science

The invention relates to a crease-resistant finishing method of a polyester-cotton blended shirt. A composition applied to crease-resistant finishing comprises the following components in parts by weight: 90-100 parts of polyurethane crease-resistant resin, 30-60 parts of hydrophilic finishing agents, 20-40 parts of strong protective agents, 10-15 parts of catalysts, 2-4 parts of penetrating agents and 4-6 parts of crack resistant agents. A crease-resistant after-finishing technology comprises the steps: alkaline washing, stacking, dosing, preparing, immersing in a prepared liquid, extruding,drying to fixed humidity, shaping and press-ironing, baking and shaping, slow cooling and rewetting, and cleaning. The technology is simple, greatly reduces the after-finishing time of the clothes, improves the utilization rate of a workshop, and can fully meet environmental protection and natural needs of customers.

Owner:江阴创杰佳服装有限公司

Composition for crease-resistant finishing of polyester cotton garment

InactiveCN111074584AShorten soaking timeEasy to reuseLiquid/gas/vapor article treatmentLiquid/gas/vapor removalChemistryPolyester

The invention provides a composition for crease-resistant finishing of a polyester cotton garment. The composition is prepared by taking deionized water as a solvent and comprises 90-100g / L of polyterpene resin, 80-130g / L of polyether modified organic silicon finishing agent, 7-40g / L of organic silicon cross-linking agent and 0.5-1.5 g / L of organic acid. The crease-resistant finishing compositionis combined with the special auxiliary tool for medicine soaking and the medicine soaking circulating pool so that a better crease-resistant effect can be achieved, and the economic cost and the timecost of production can be reduced for enterprises. The polyester cotton garment obtained by adopting the crease-resistant after-finishing method does not contain formaldehyde and is good in size and shape stability and can completely meet the requirements of customers for pursuing environmental protection and nature. The crease-resistant finishing agent is green and environment-friendly, the process is simple and reliable, and the requirements of energy conservation and emission reduction of dyeing plants are met.

Owner:江阴创杰佳服装有限公司

Production technology of blended high-elastic and environmentally friendly double-sided fabric with drawstring style

ActiveCN106521781BWrinkle-resistantAntibacterial health careWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses a process for producing a blended fabric with high elasticity and high elasticity. The fabric is made of 32S-45ST polyester yarn and color yarn network silk which is added 20-40D spandex woven. Yarn wire network silk consists of 50-65% 32-40S bamboo fiber, 20-25% viscose and 15-25% lyocell network. The production process of the fabric is as follows: weaving, cutting, shaping, preshrinking and finished products (1) in the weaving, wherein the double rib machine is used for weaving, so that the fabric has a pumping style; (2) in the shaping, where in a long chain aliphatic softener or amino modified silicone softener is used, shaping temperature is 140 - 160 DEG C, the speed is 18 -0 26m / min, shaping setting upper position is 115 - 120% super, lower position is 100-110%, fan function is 95-100%;(3) in the preshrinking, the preshrinking temperature is 100-120 DEG C, the speed is 2-25m / min, the tension is 0.5-0.8N, and the super position is 20-30%. The fabric which is produced by the process for producing blended fabric with high elasticity and good environmental protection has the advantages of stiff anti-wrinkle, antibacterial activity, moisture absorption, soft and smooth and anti-ultraviolet.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

Superfine-denier antistatic polyester fiber

InactiveCN104499074AAnti-wrinkleConformalElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentMetal fiberPolyester

The invention discloses a superfine-denier antistatic polyester fiber. The superfine-denier antistatic polyester fiber comprises a polyester component and an antistatic component, and is prepared by fusing the polyester component and the antistatic component at high temperature and spinning in a spinneret plate, wherein the pore diameter of a spinneret hole in the spinneret plate is 0.1mm-0.3mm; and the antistatic component is formed by mixing the following components by mass percent: 30%-40% of metal fibers, 15%-25% of bamboo charcoal master batches and 35%-55% of silicon dioxide. With the adoption of the manner, the superfine-denier antistatic polyester fiber has original wrinkle resistance and shape preserving property of polyester fibers and also has the antistatic, antibacterial, heat-preservation and comfortable properties; and meanwhile, the self diameters of the fibers are thin and are soft, so that the comfort is greatly improved.

Owner:CHANGSHU POLYESTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com