Patents

Literature

31results about How to "High elastic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

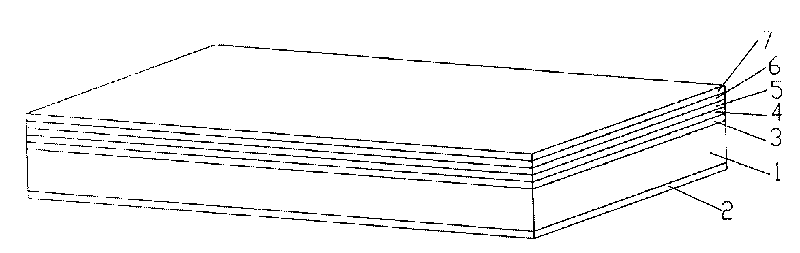

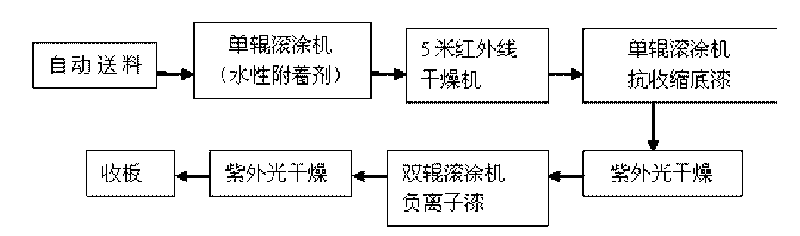

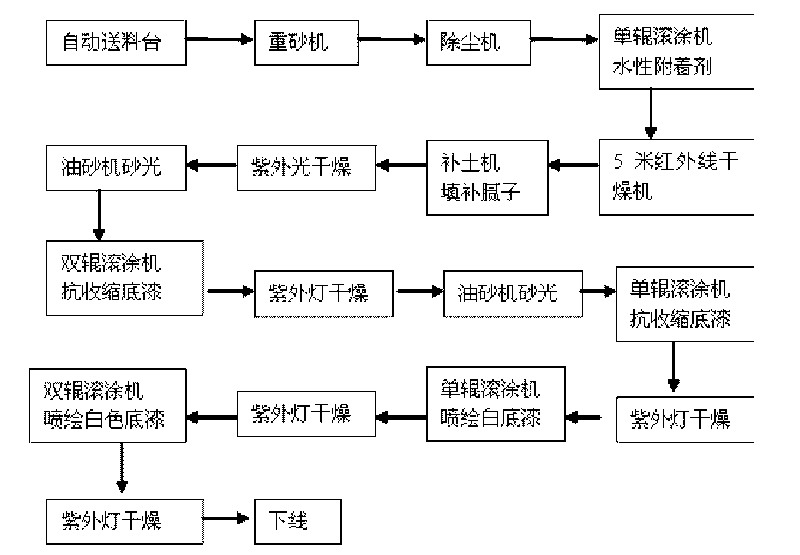

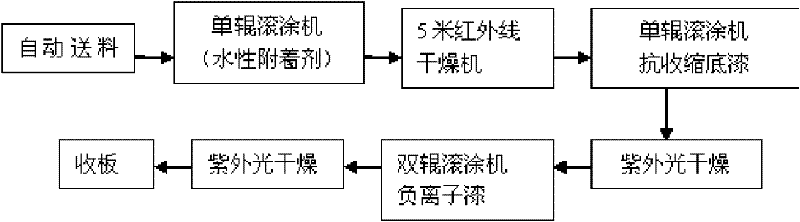

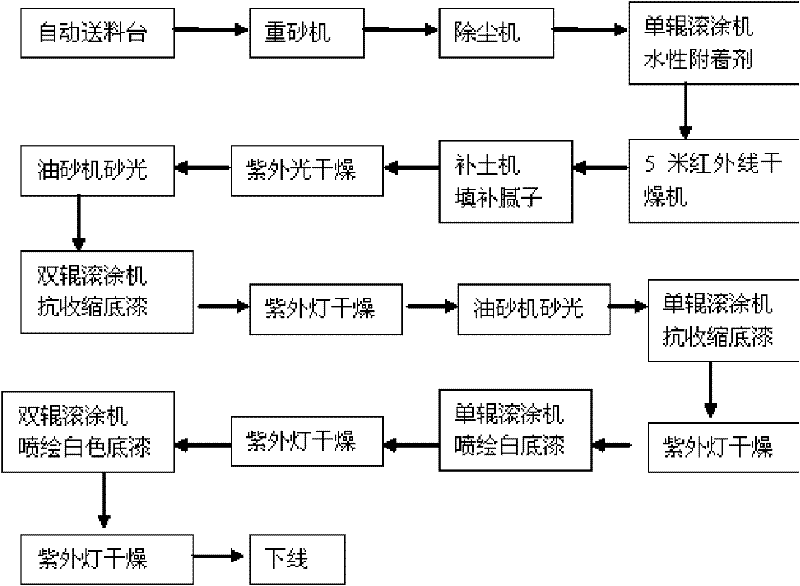

Elastic floor and production method thereof

ActiveCN101691806AProtection from bruisesProtect against damagePolyurea/polyurethane coatingsFlooringSolid woodSurface finish

The invention belongs to the technical field of wood floors, and in particular relates to an elastic floor and a production method thereof. The elastic floor comprises a floor substrate; and the surface of the floor substrate is coated with a high-elasticity UV paint layer which is formed by using large molecular weight flexible polymers and a large molecular weight active diluent as main film forming materials. The floor substrate is made of pure soft wood with a density between 0.35 and 0.55 or a medium and high density laminated plate with a density of 0.8. The production method for the elastic floor comprises the following steps: a) performing surface finish on the floor substrate; and b) coating the high-elasticity UV paint layer which is formed by using the large molecular weight flexible polymers and the large molecular weight active diluent as the main film forming materials. The elastic floor adopts the high-elasticity UV paint as finishing paint of the floor to prevent children from physical injuries because of falling, and has high elasticity after being coated with elastic pain despite that the substrate is made of the pure soft wood or the medium and high density plate.

Owner:广西柏景地板有限公司

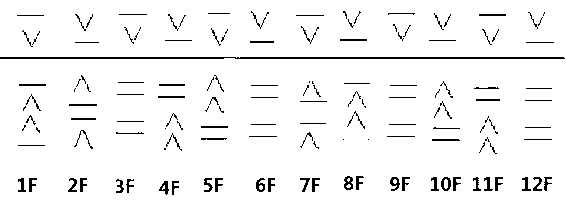

Intelligent temperature-adjustment comfortable knitting fabric and weaving method thereof

Owner:QINGDAO XUEDA GRP

High-elastic TPU thin film and preparation method thereof

The invention relates to a high-elastic TPU thin film and a preparation method thereof. The method includes: according to ratio, performing three-stage mixing on prepared TPU granules, foamed siliconemaster batches, and modified nano-SiO2 master batches; feeding the mixture to a casting machine through an automatic conveying system; and extruding the mixture to form the thin film. The TPU thin film is high in elasticity and can be widely applied to the fields, such as: damping materials, packaging and toys, children's toys, sports equipment, aero-models, heat insulation materials, and automobile trim materials, etc.

Owner:SUZHOU XIONGLIN NEW MATERIAL SCI & TECH CO LTD

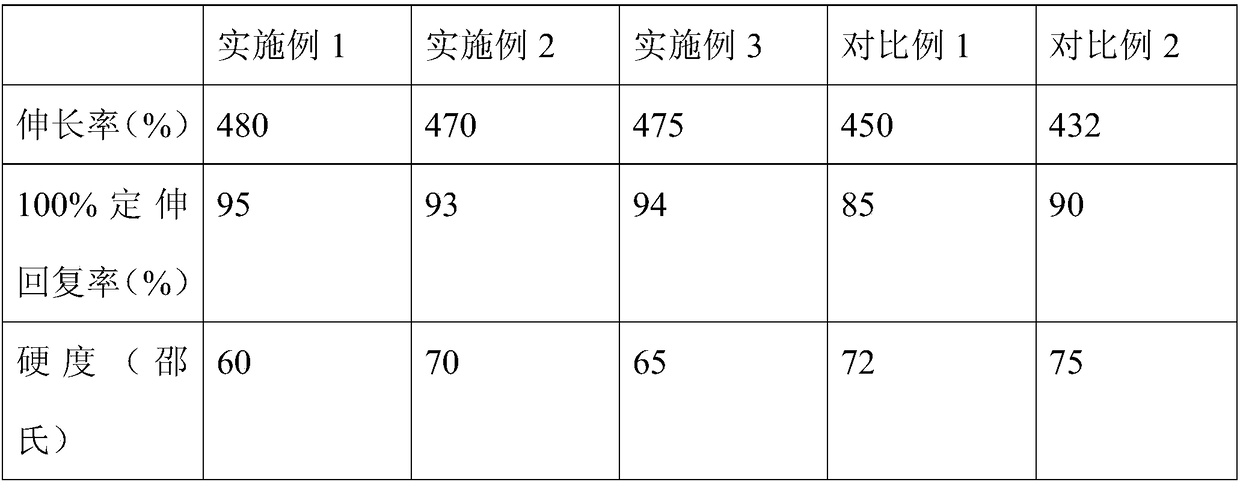

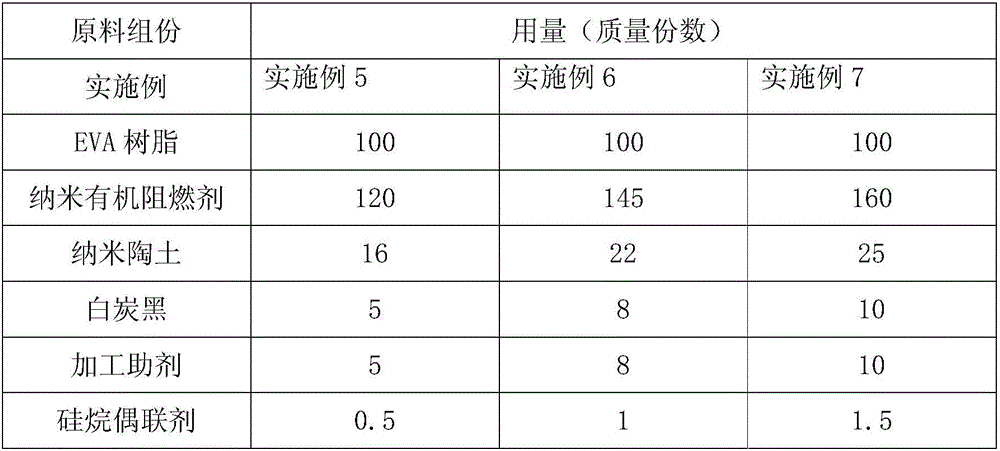

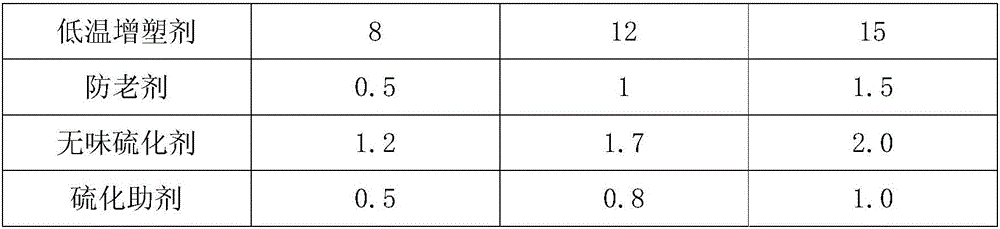

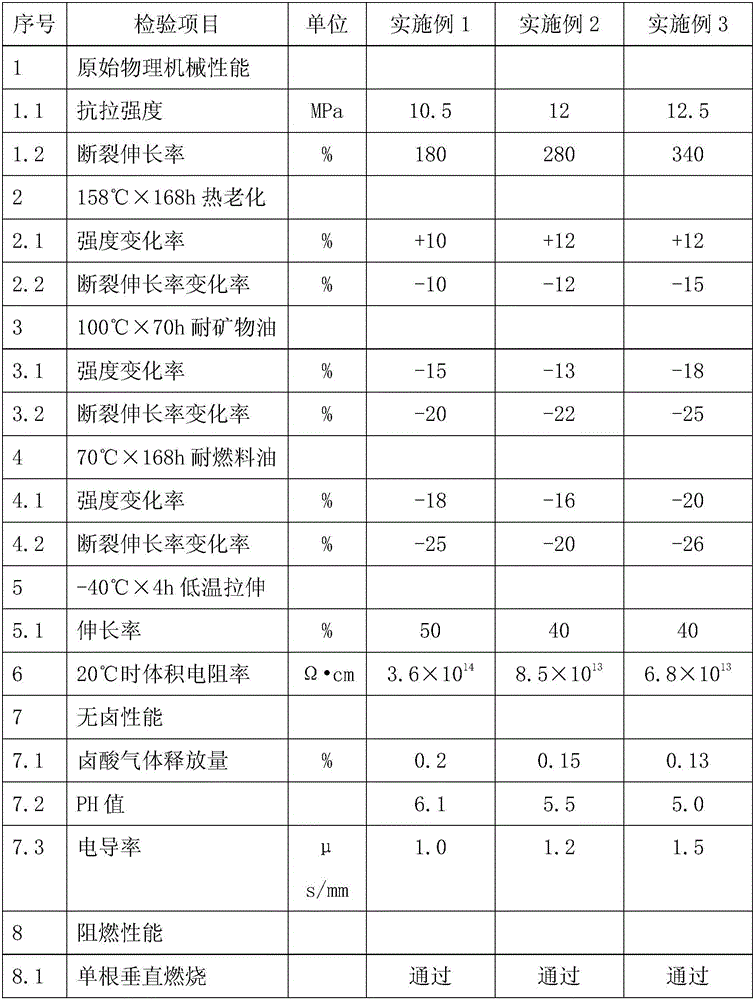

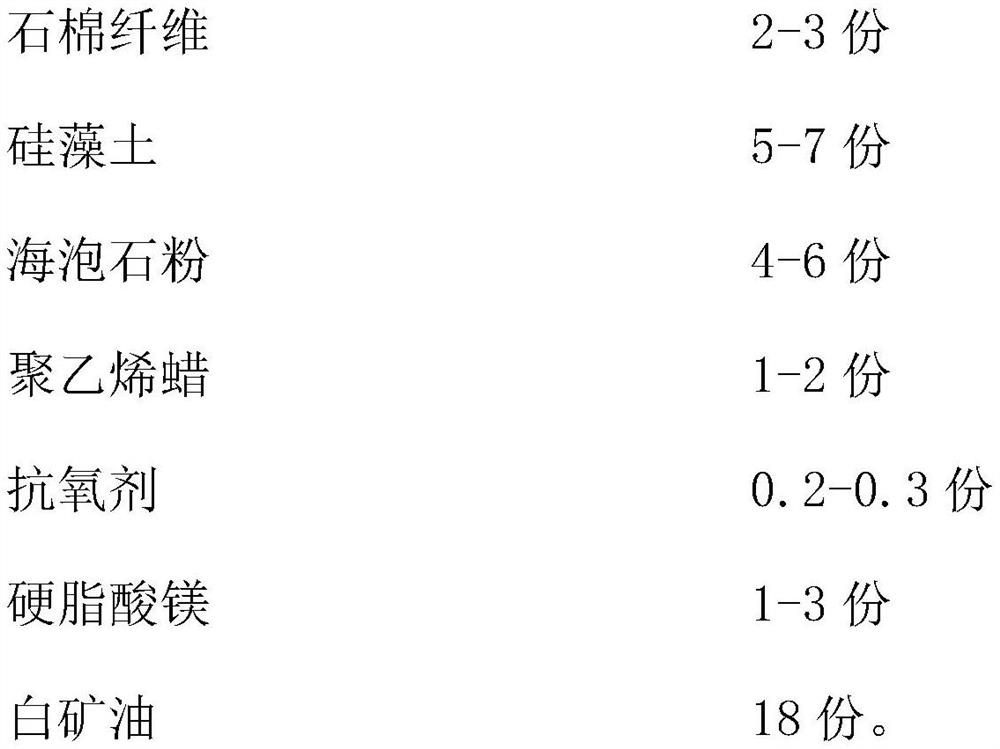

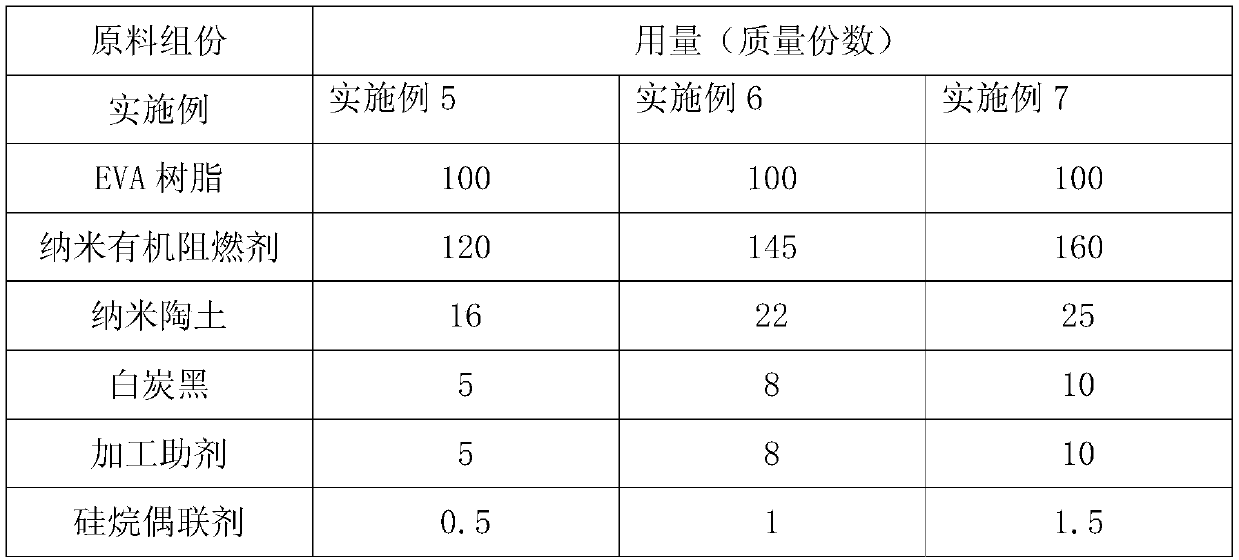

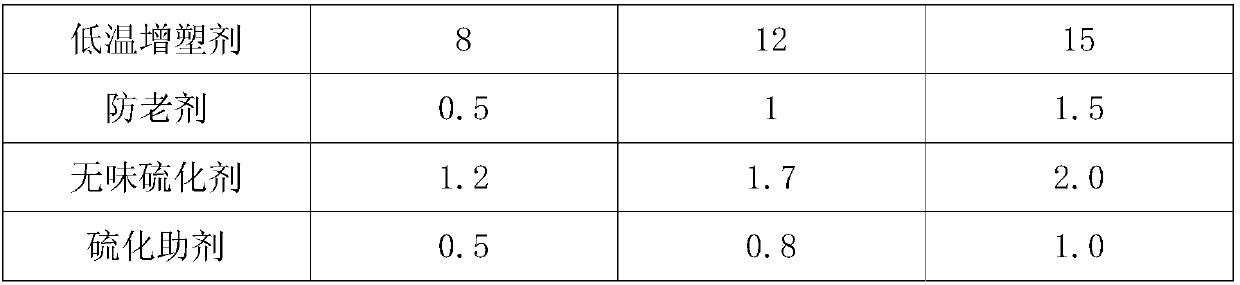

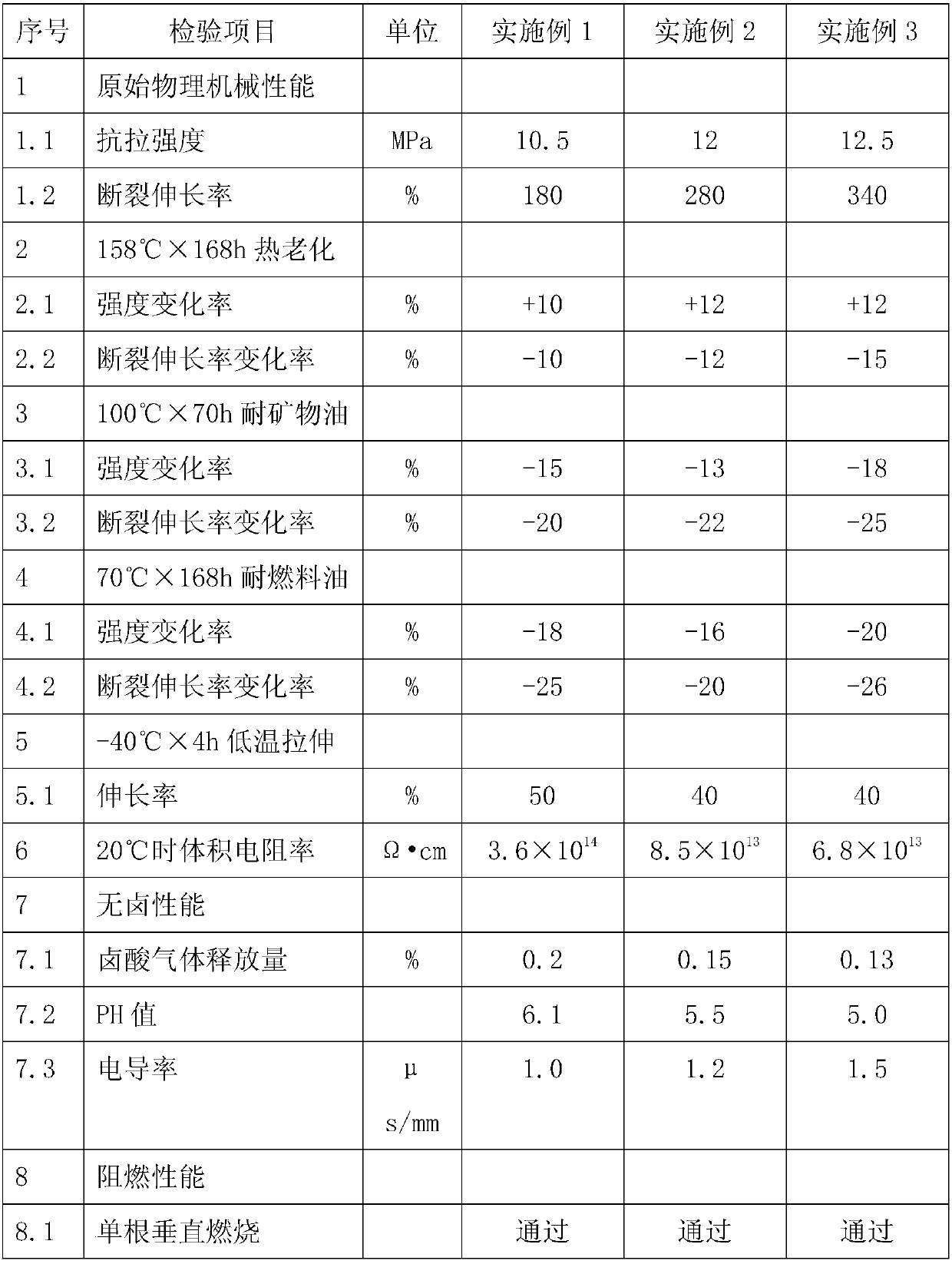

Oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material and preparation method thereof

ActiveCN106220985ASolve flame retardancyAddress mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePower cable

The invention relates to an oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material and a preparation method thereof, and belongs to the technical field of power cables. The oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material is prepared from the following components in parts by weight: 90 to 110 parts of EVA resin, 100 to 160 parts of a nanoscale organic flame retardant, 5 to 10 parts of white carbon black, 15 to 25 parts of nano-pottery clay, 5 to 10 parts of a processing auxiliary agent, 0.5 to 2 parts of a silane coupling agent, 8 to 15 parts of a low-temperature plasticizer, 0.5 to 1.5 parts of an anti-ageing agent, 1.2 to 2.0 parts of a tasteless vulcanizing agent and 0.5 to 1.0 part of a vulcanizing auxiliary agent. The preparation method comprises the following steps: 1, plastifying: plastifying EVA resin particles for 5 to 8 minutes in an internal mixer, scrolling down and allowing standing still; 2, mixing: plastifying the primarily plastified EVA resin for 0.5 to 1.5 minutes; adding the processing auxiliary agent, the silane coupling agent, the nano-pottery clay and the white carbon black and mixing for 4 to 6 minutes; adding the nanoscale organic flame retardant, the low-temperature plasticizer and the anti-ageing agent and mixing for 5 to 7 minutes; adding the tasteless vulcanizing agent and the vulcanizing auxiliary agent in a later period. The invention has the advantages that the oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material has excellent fire resistance, high mechanical property, high insulating property and high elasticity; the process is simple, the operation is convenient, the control is accurate, and the product is stable.

Owner:天津金山电线电缆股份有限公司

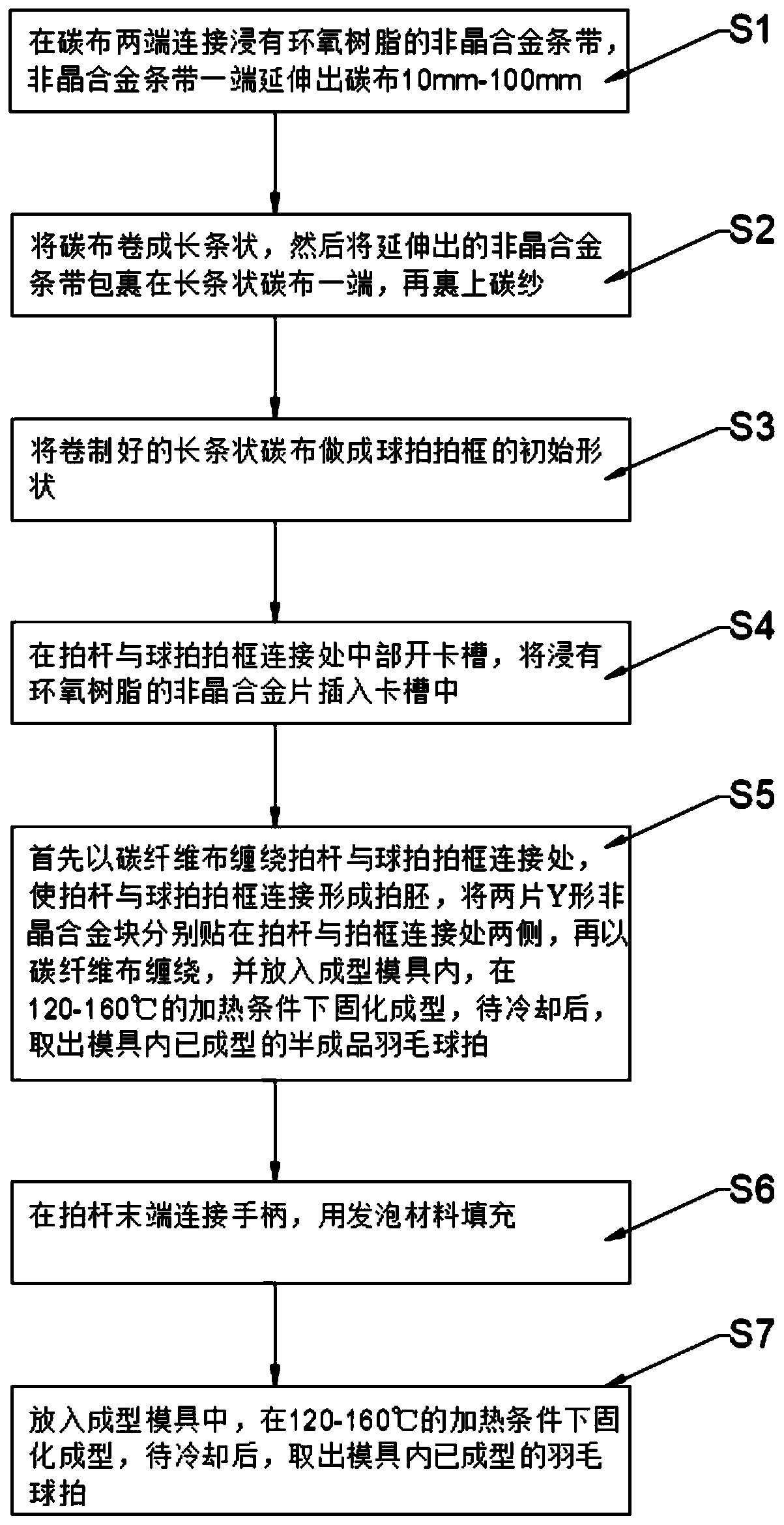

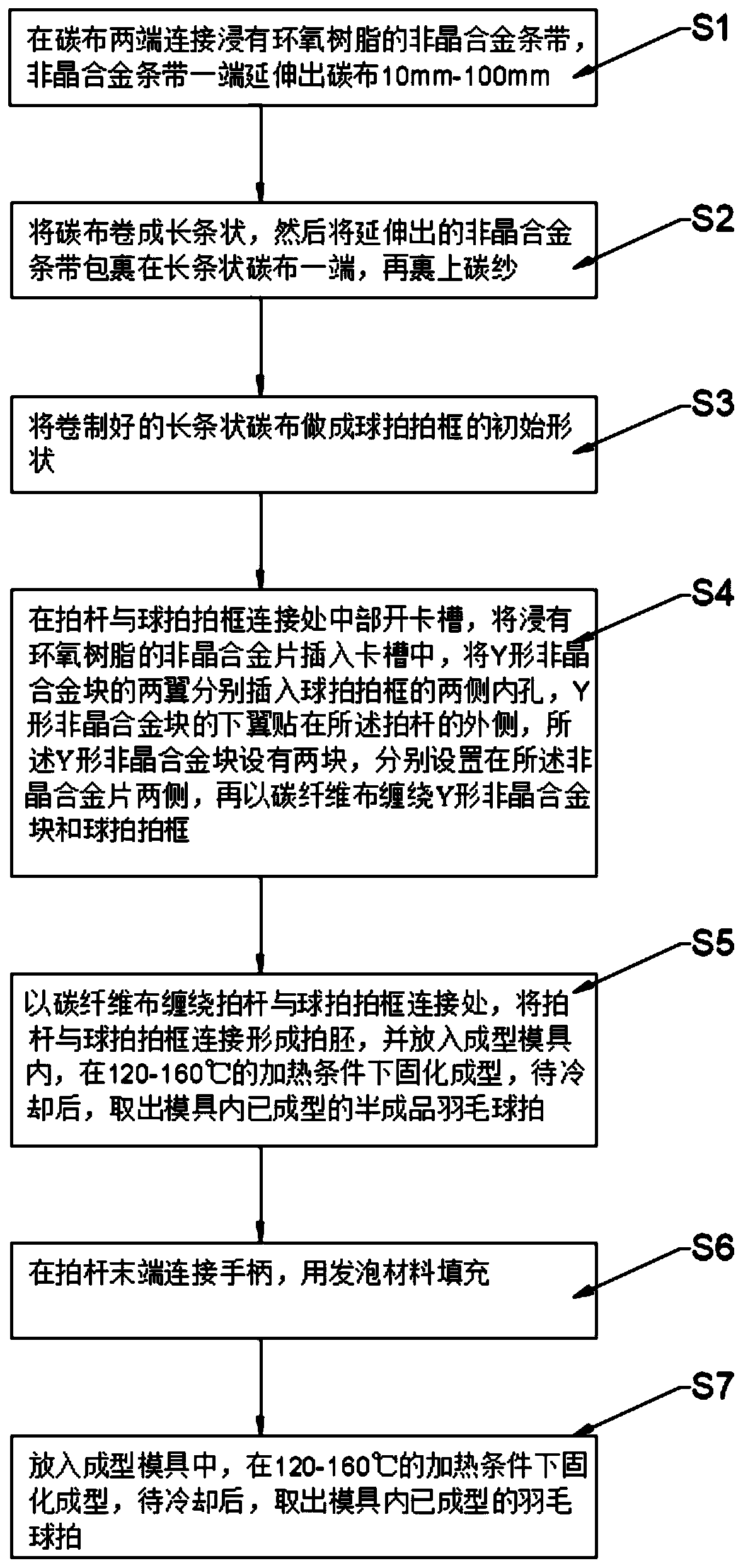

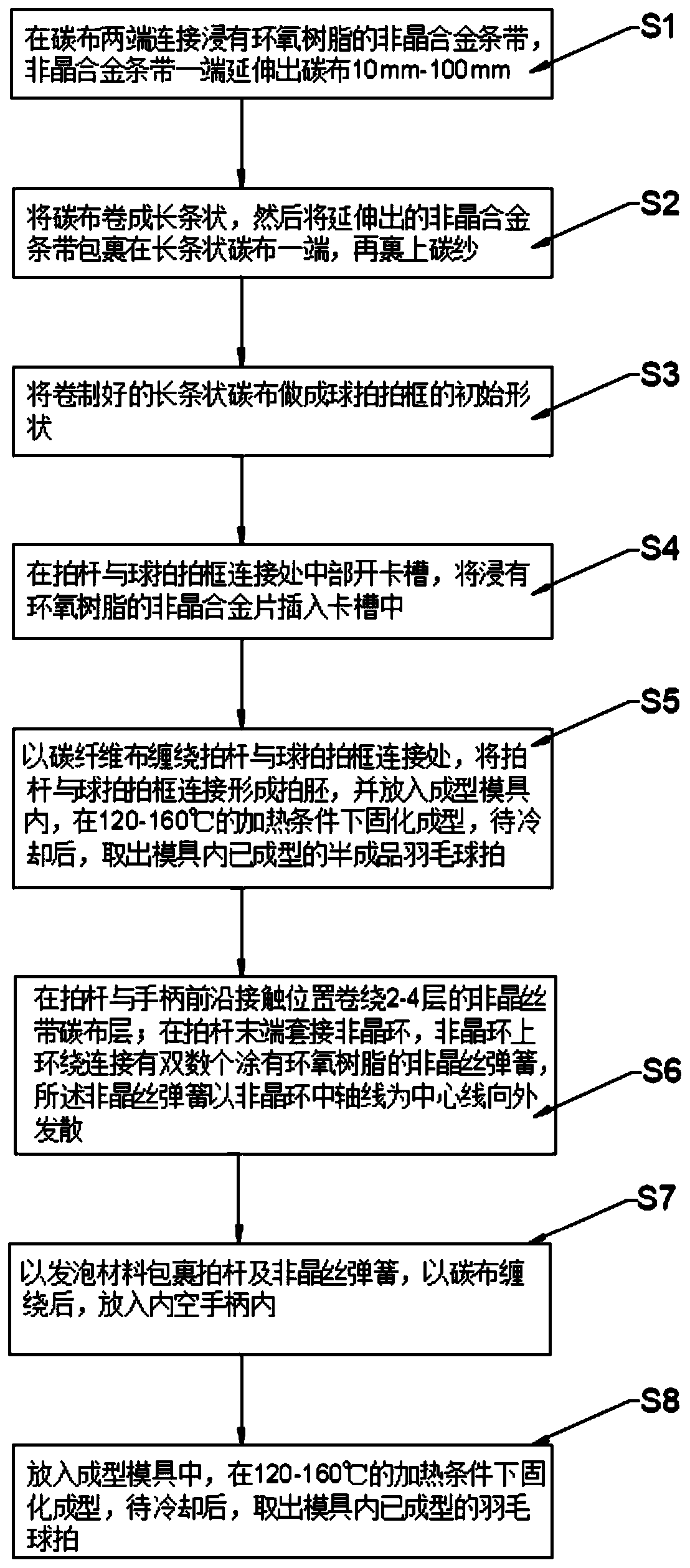

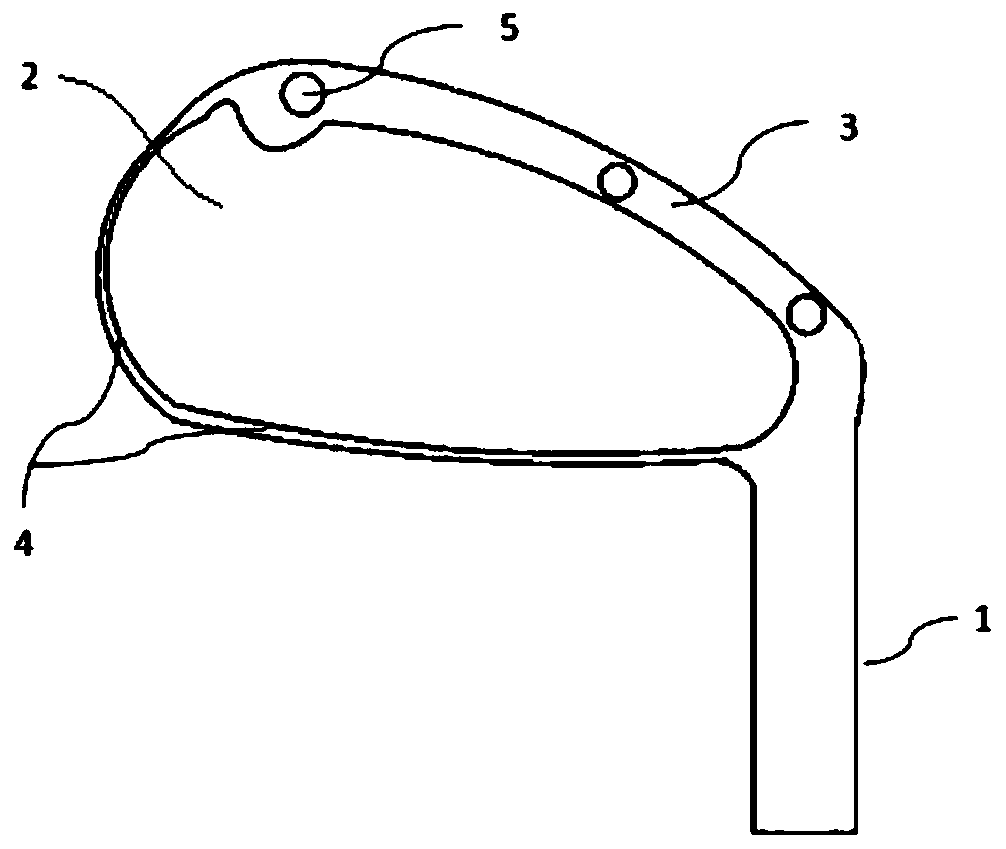

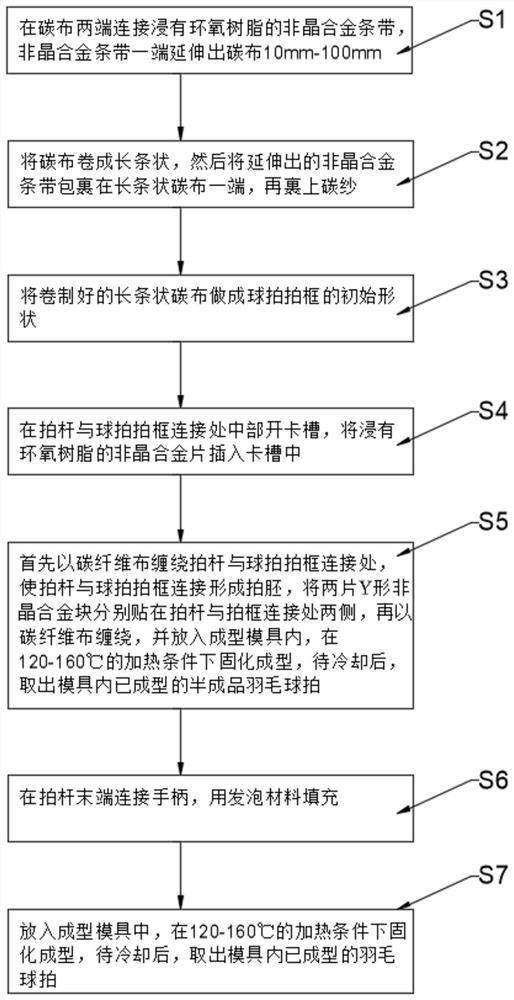

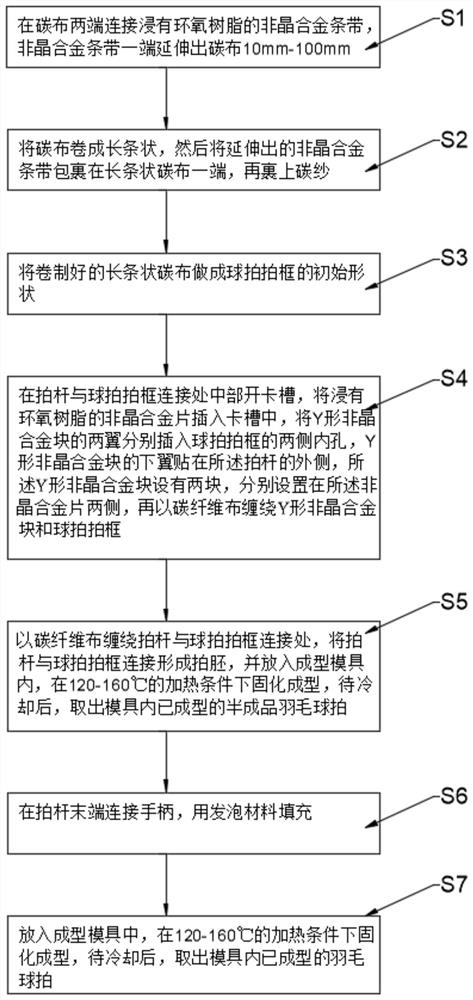

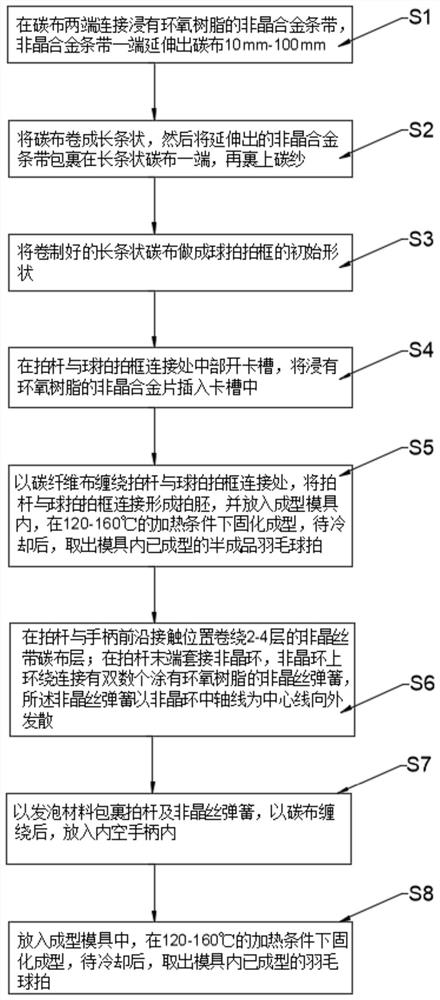

Amorphous alloy enhanced racket and preparation method thereof

The invention discloses a preparation method for an amorphous alloy enhanced racket. The method comprises the steps that S1, amorphous alloy strips are connected with two ends of carbon cloth, and oneend of each amorphous alloy strip extends outside of the carbon cloth by 10 mm-100 mm; S2, the carbon cloth is rolled into a long strip shape, the extended amorphous alloy strips are packaged by oneend of the long strip-shaped carbon cloth and then are wrapped by carbon yarns; S3, the rolled long strip-shaped carbon cloth is made into an initial shape of a racket frame; S4, a clamping slot is set at the middle part of a connection part of a racket stick and the racket frame, and an amorphous alloy plate is inserted into the clamping slot; and S5, the connection part of the racket stick and the racket frame is intertwined by carbon fiber cloth, the racket stick and the racket frame are connected to form a racket blank, the racket blank is placed into a shaping mould, the racket blank is cured and shaped under a heating condition of 120-160 DEG C, and after cooling is carried out, a shaped semi-finished product badminton racket is taken out from the mould. According to the method, through utilization of excellent performance such as high strength, high elasticity, high hardness and light weight of an amorphous alloy material, strength at the connection part of the racket frame andthe racket stick is enhanced, and a fracture risk at the part is reduced.

Owner:SHENZHEN UNIV

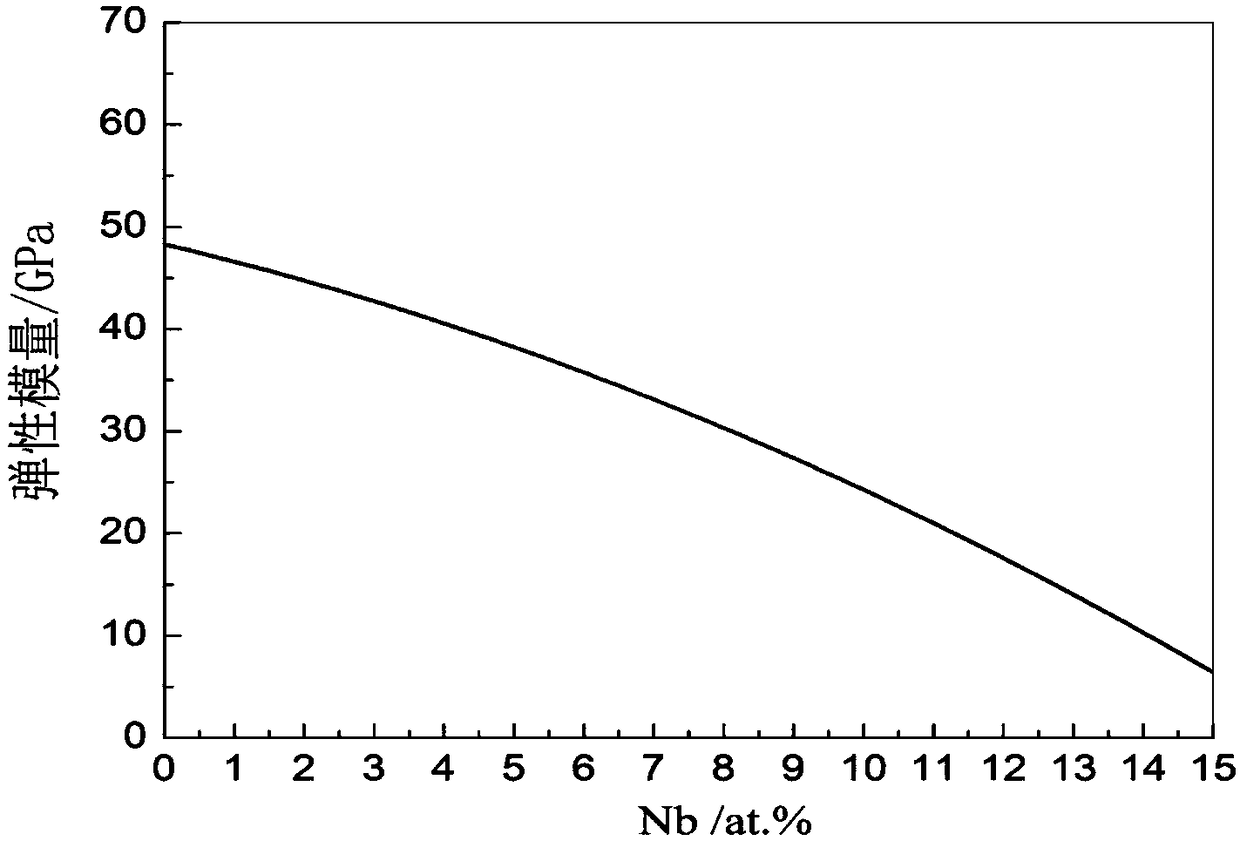

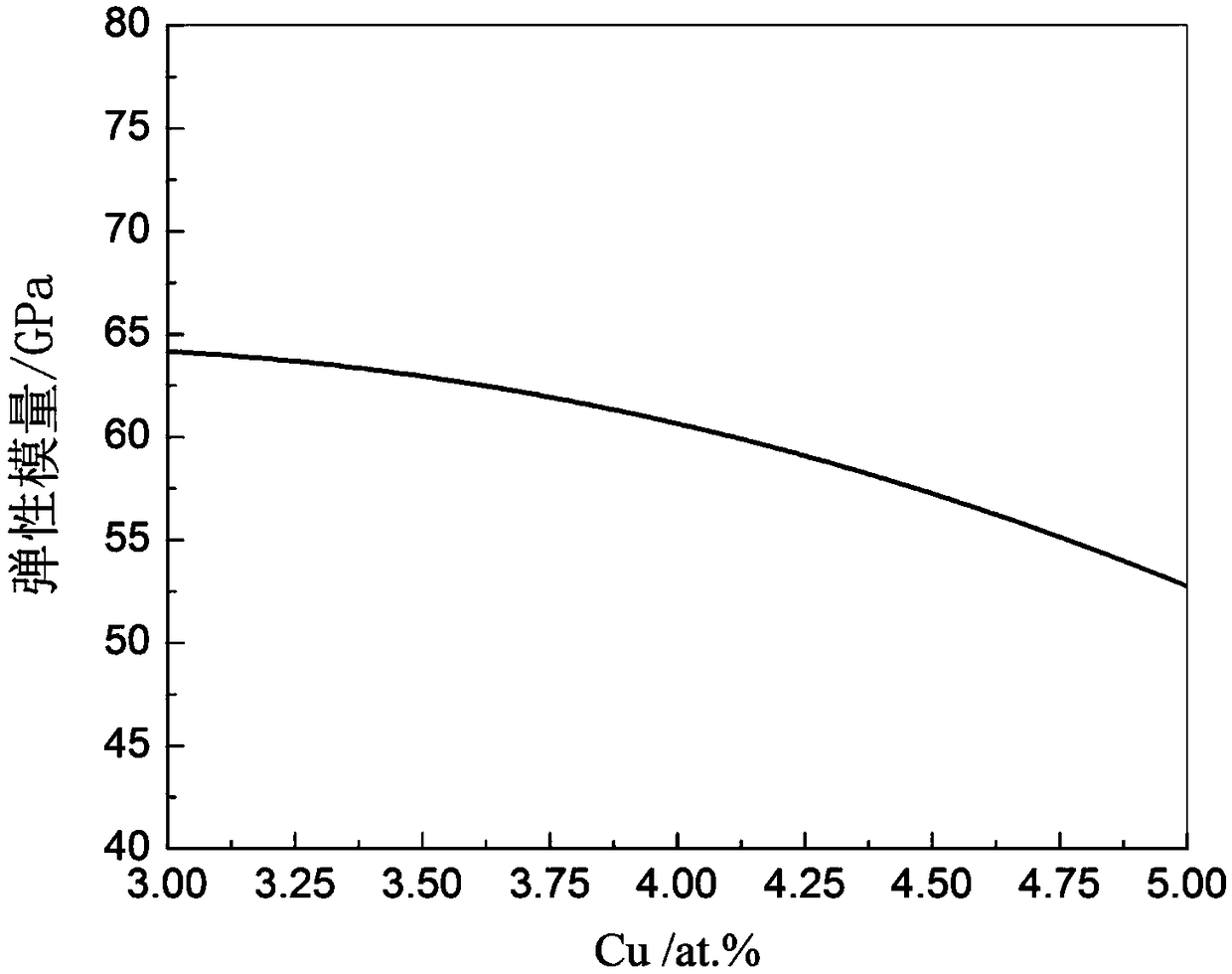

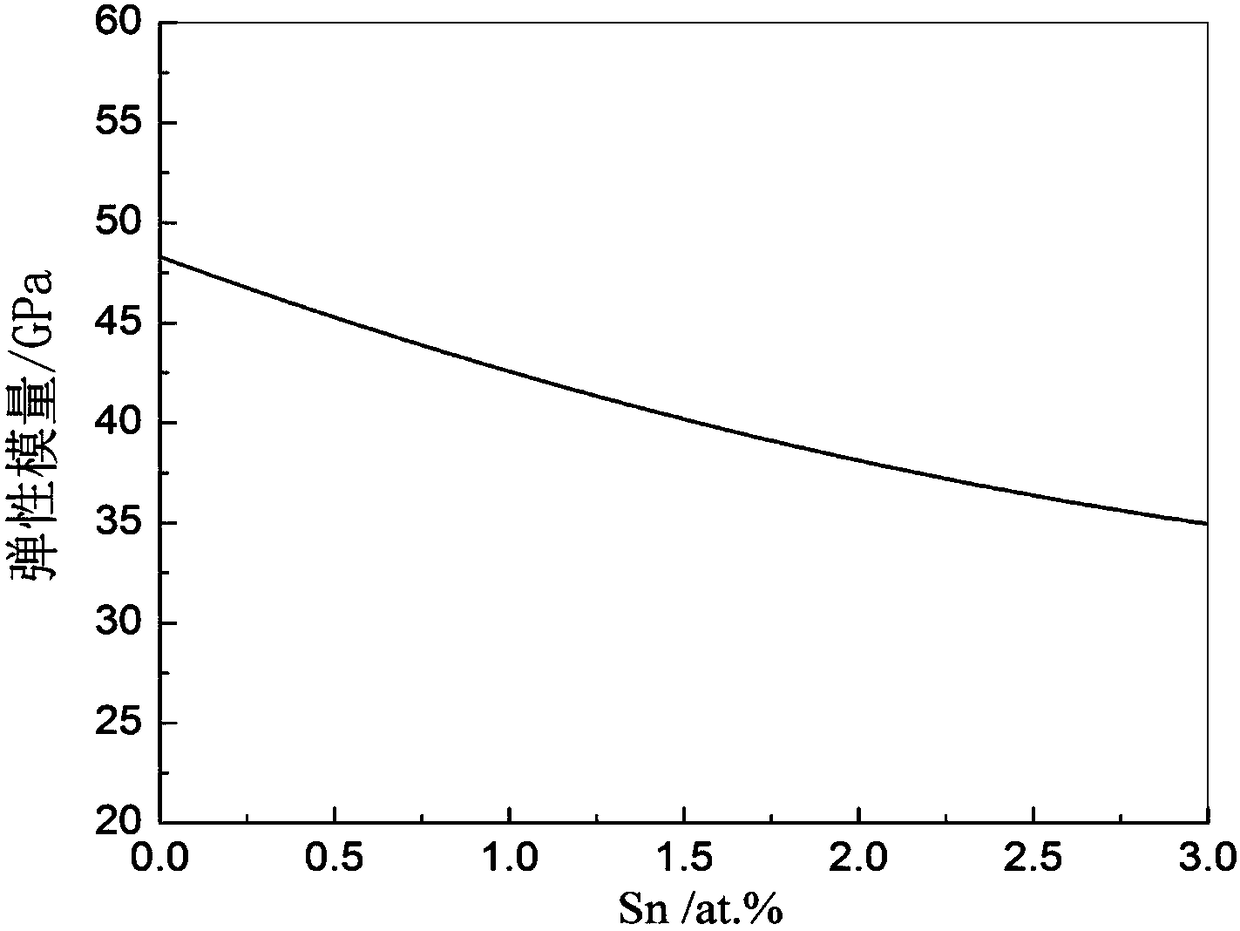

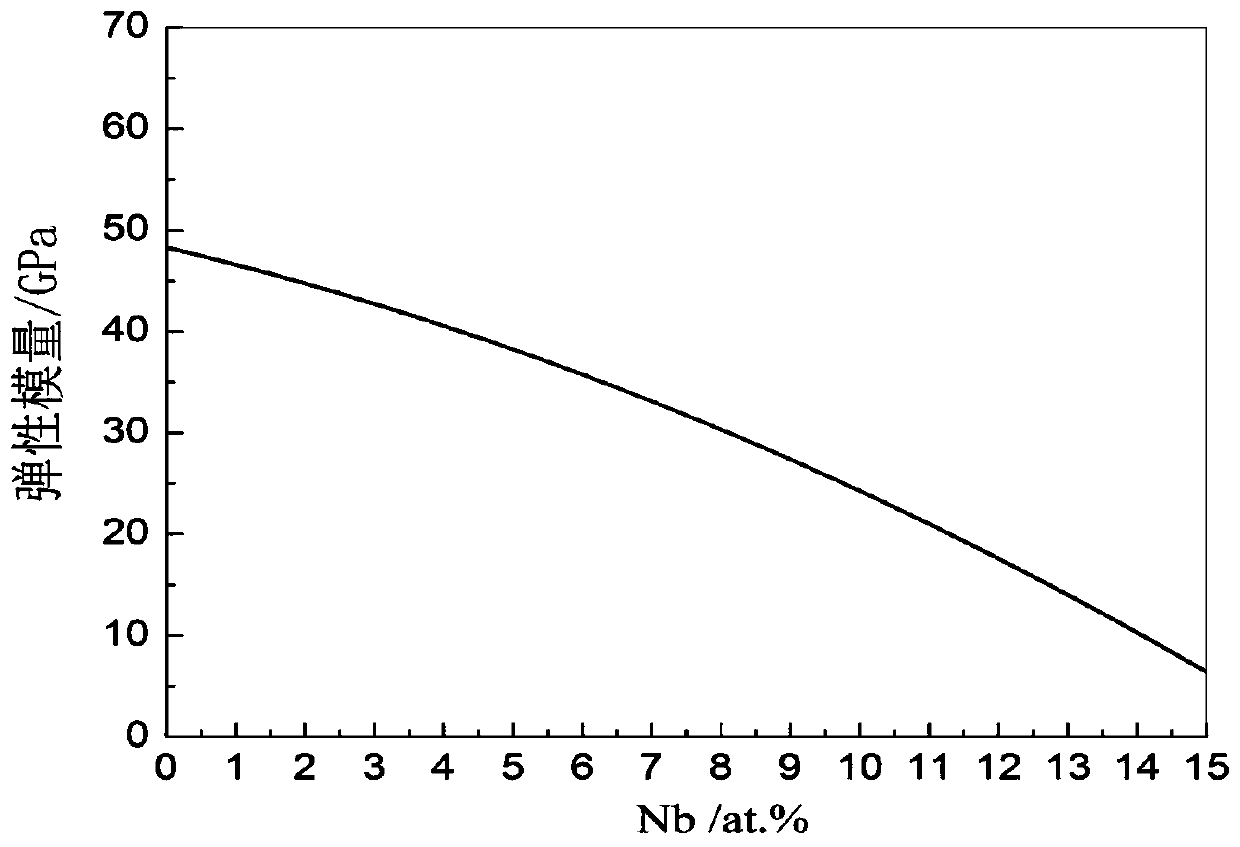

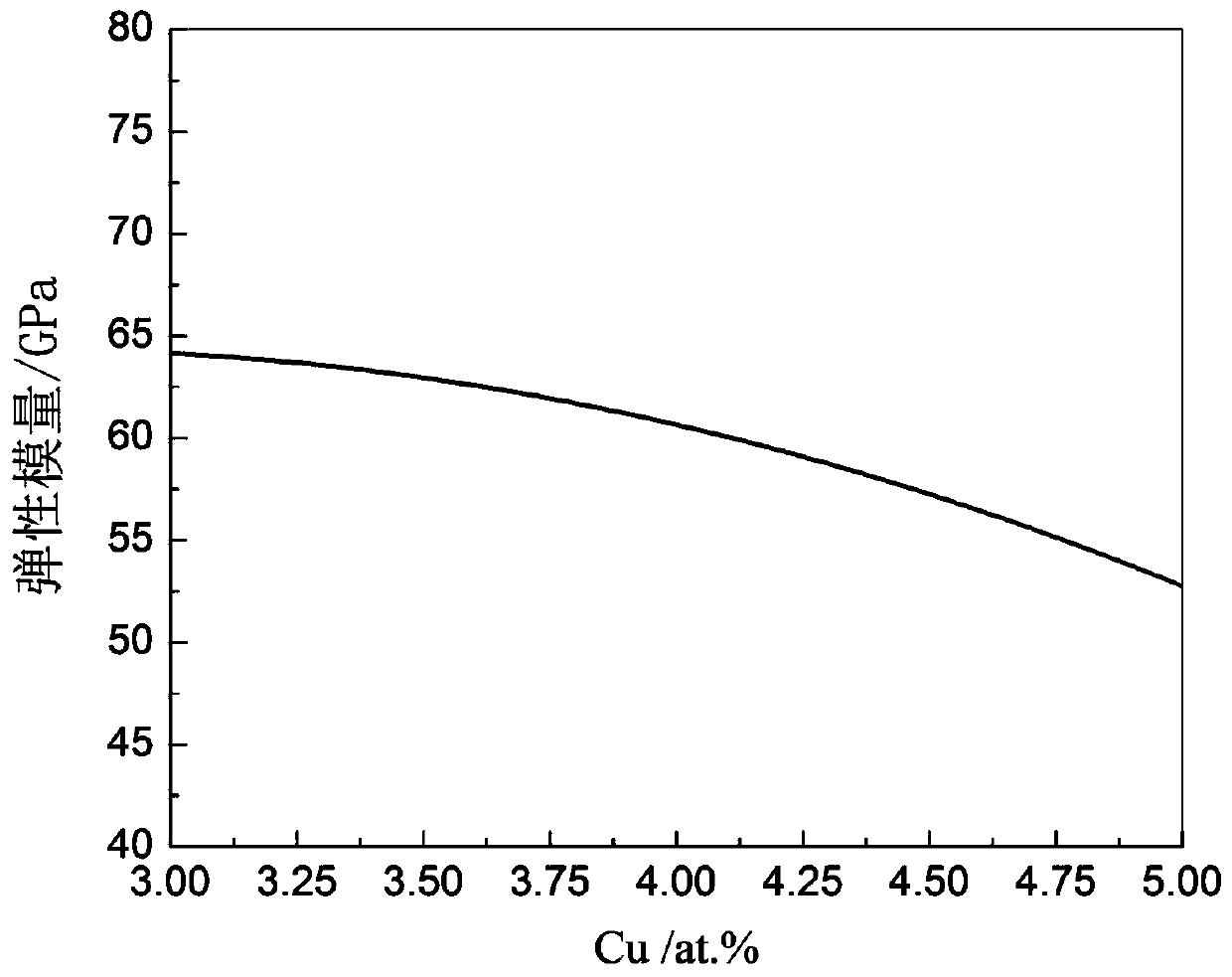

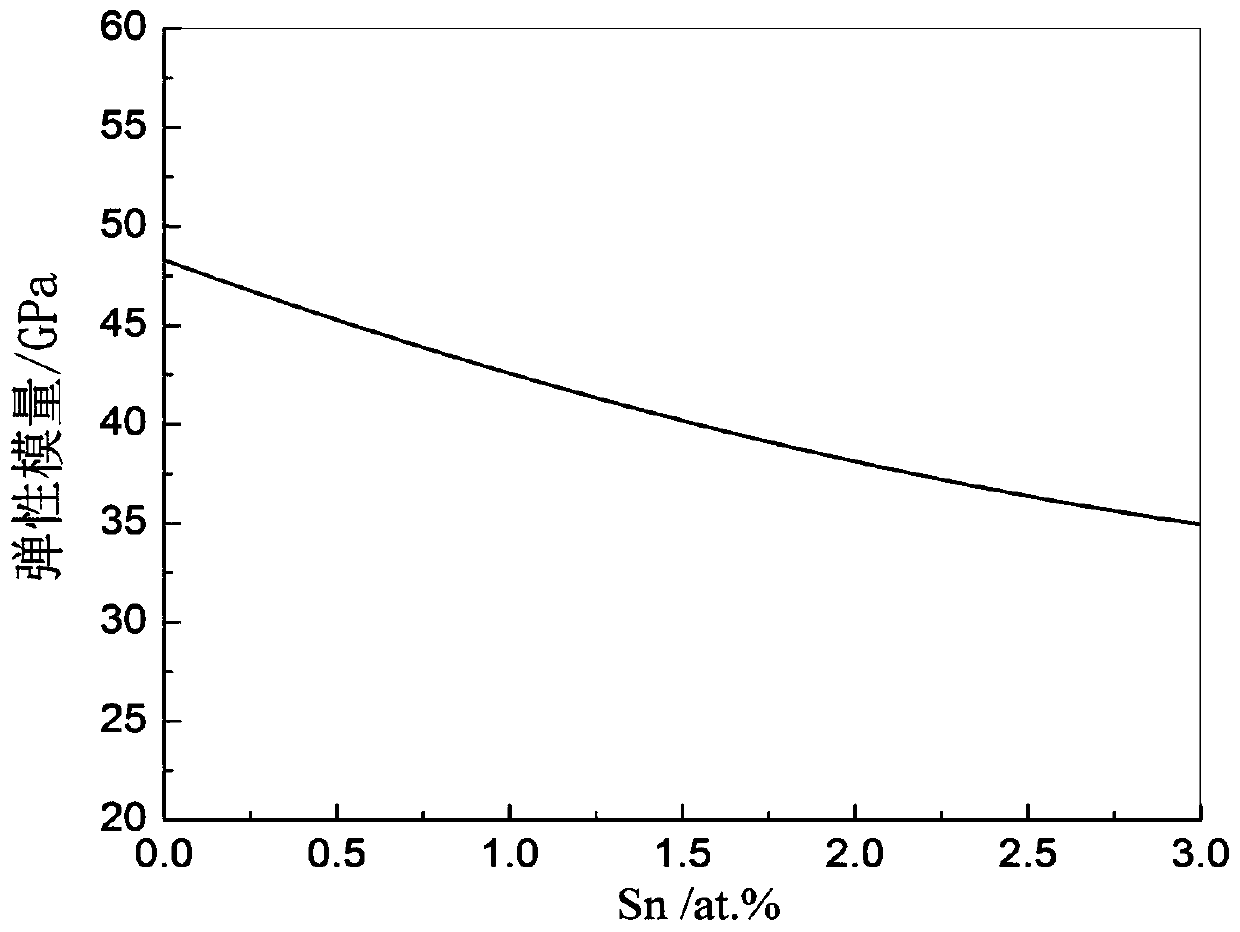

Low elasticity modulus novel medical zirconium alloy and designing method thereof

ActiveCN108411157AHigh modulus of elasticityElastic Modulus Performance OptimizationMathematical modelNiobium

The invention discloses low elasticity modulus novel medical zirconium alloy and a designing method thereof. The low elasticity modulus novel medical zirconium alloy disclosed by the invention is prepared from the raw materials in atomic percent: 0.1at.% to 3at.% of tin, 3at.% to 5at.% of copper, 0.1at.% to 15at.% of niobium and the balance of zirconium. The designing method of the low elasticitymodulus novel medical zirconium alloy comprises the steps: utilizing a quadratic regression orthogonal rotation combination design to perform ingredient design to obtain an experiment scheme; then converting atomic percent of all alloy elements in the scheme into weight percentage to obtain a weight ratio scheme; performing alloy preparation, a compression experiment and further phase analysis anda microscopic structure observing experiment according to the weight ratio scheme obtained from the combination design; then utilizing SPSS to analyze experiment results and finally obtaining a mathematic model of alloy performance and alloy elements. The zirconium alloy designed out according to the mathematic model has the advantages of low elastic modulus, moderate compression strength and yield strength, high elastic energy and ability in meeting a requirement of clinical medicine to an implant material.

Owner:GUANGXI UNIV

Process for producing stripe-style blended fabric with high elasticity and good environmental protection

ActiveCN106521781AWith whipped styleHigh elastic performanceWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses a process for producing a blended fabric with high elasticity and high elasticity. The fabric is made of 32S-45ST polyester yarn and color yarn network silk which is added 20-40D spandex woven. Yarn wire network silk consists of 50-65% 32-40S bamboo fiber, 20-25% viscose and 15-25% lyocell network. The production process of the fabric is as follows: weaving, cutting, shaping, preshrinking and finished products (1) in the weaving, wherein the double rib machine is used for weaving, so that the fabric has a pumping style; (2) in the shaping, where in a long chain aliphatic softener or amino modified silicone softener is used, shaping temperature is 140 - 160 DEG C, the speed is 18 -0 26m / min, shaping setting upper position is 115 - 120% super, lower position is 100-110%, fan function is 95-100%;(3) in the preshrinking, the preshrinking temperature is 100-120 DEG C, the speed is 2-25m / min, the tension is 0.5-0.8N, and the super position is 20-30%. The fabric which is produced by the process for producing blended fabric with high elasticity and good environmental protection has the advantages of stiff anti-wrinkle, antibacterial activity, moisture absorption, soft and smooth and anti-ultraviolet.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

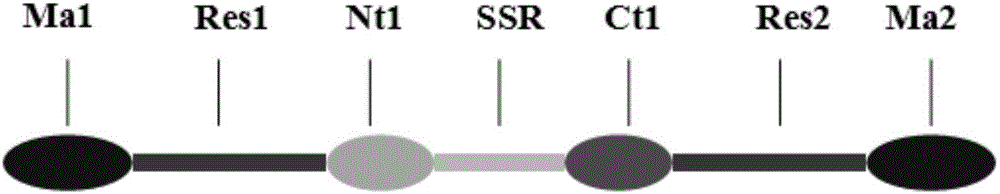

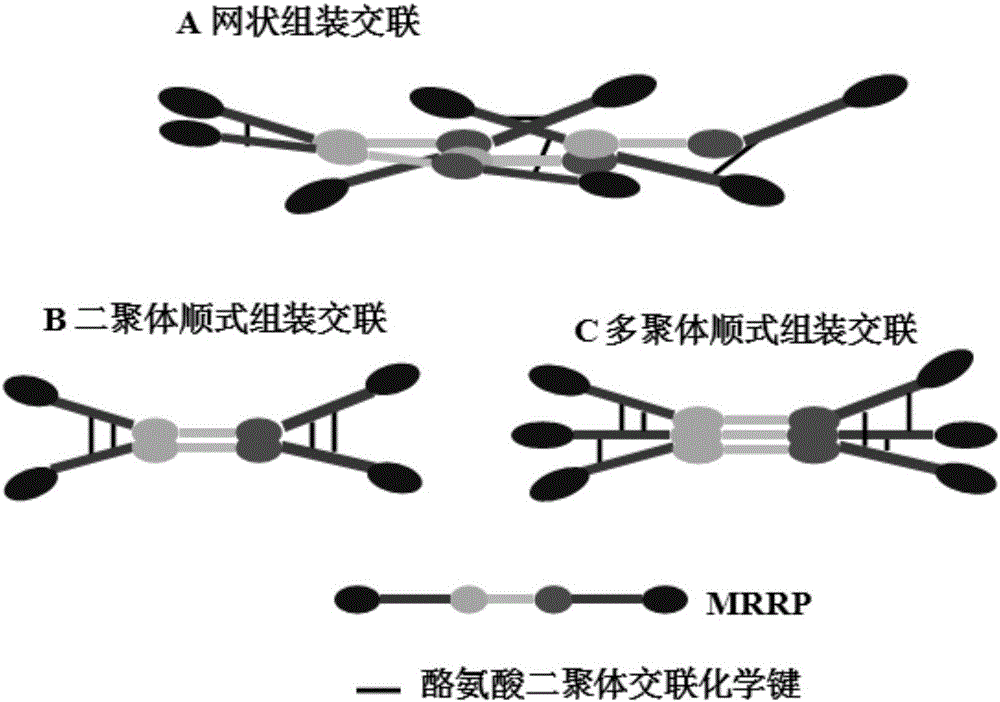

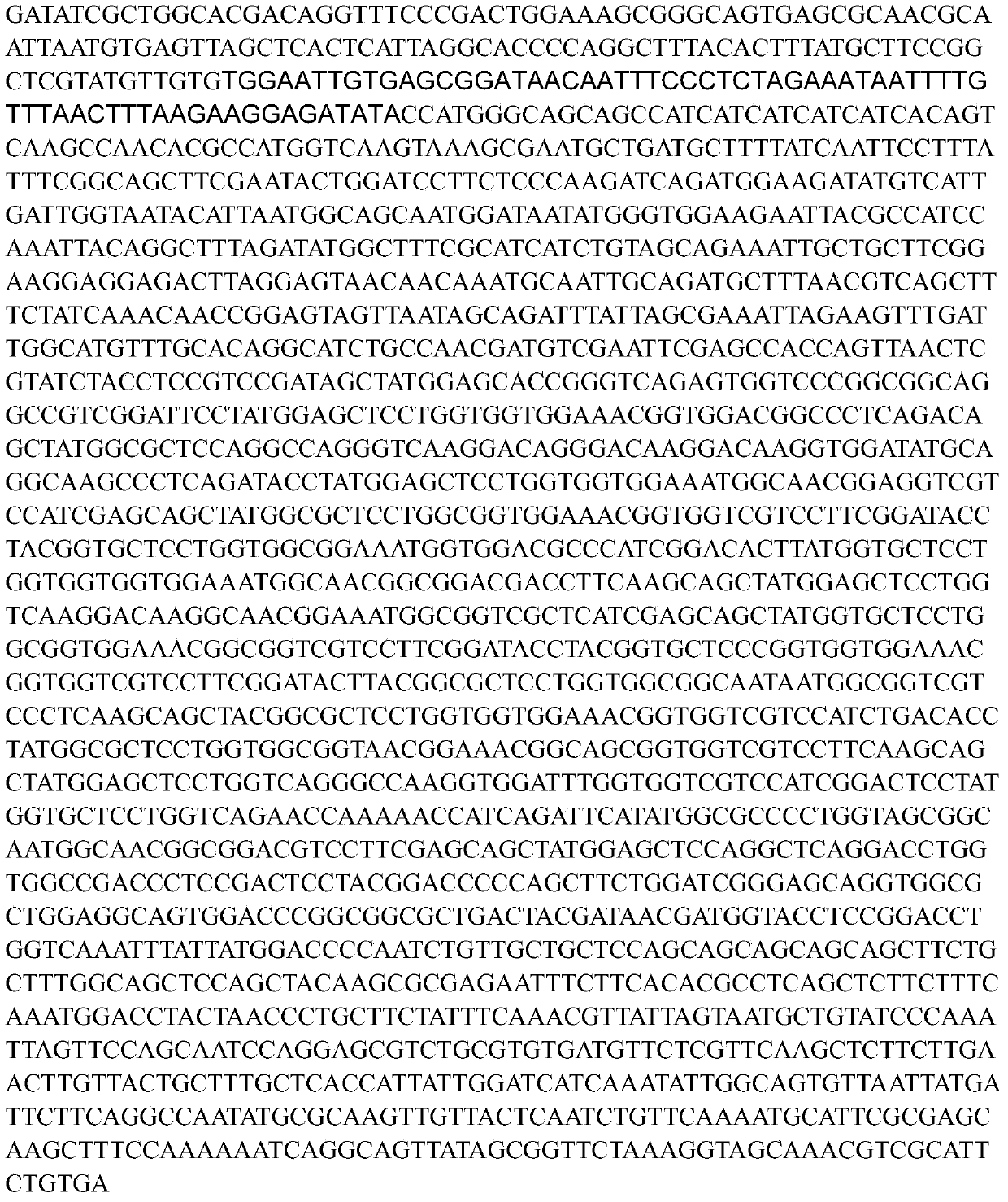

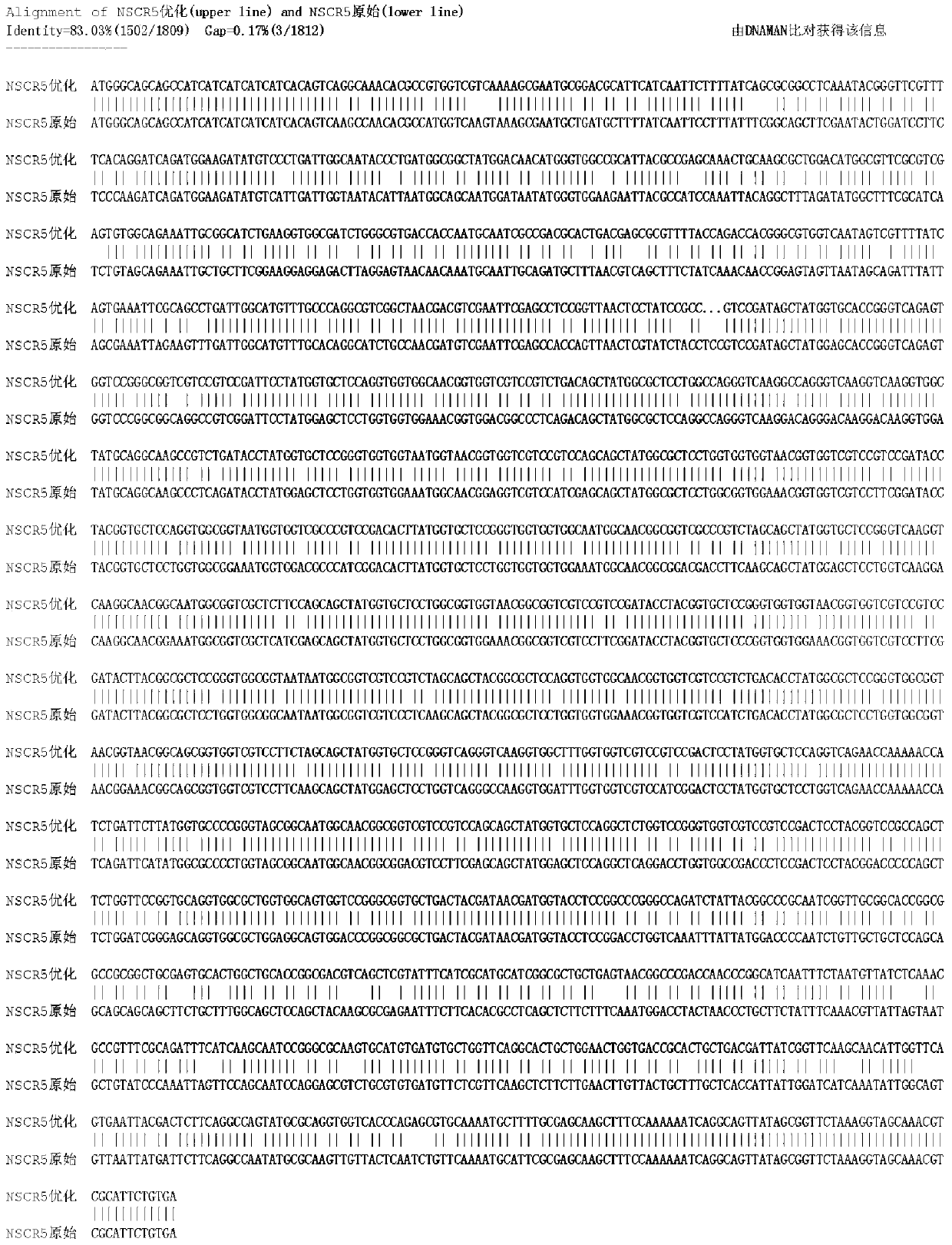

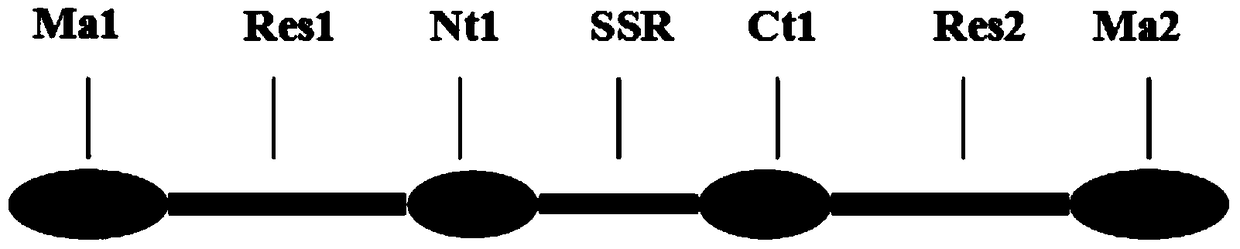

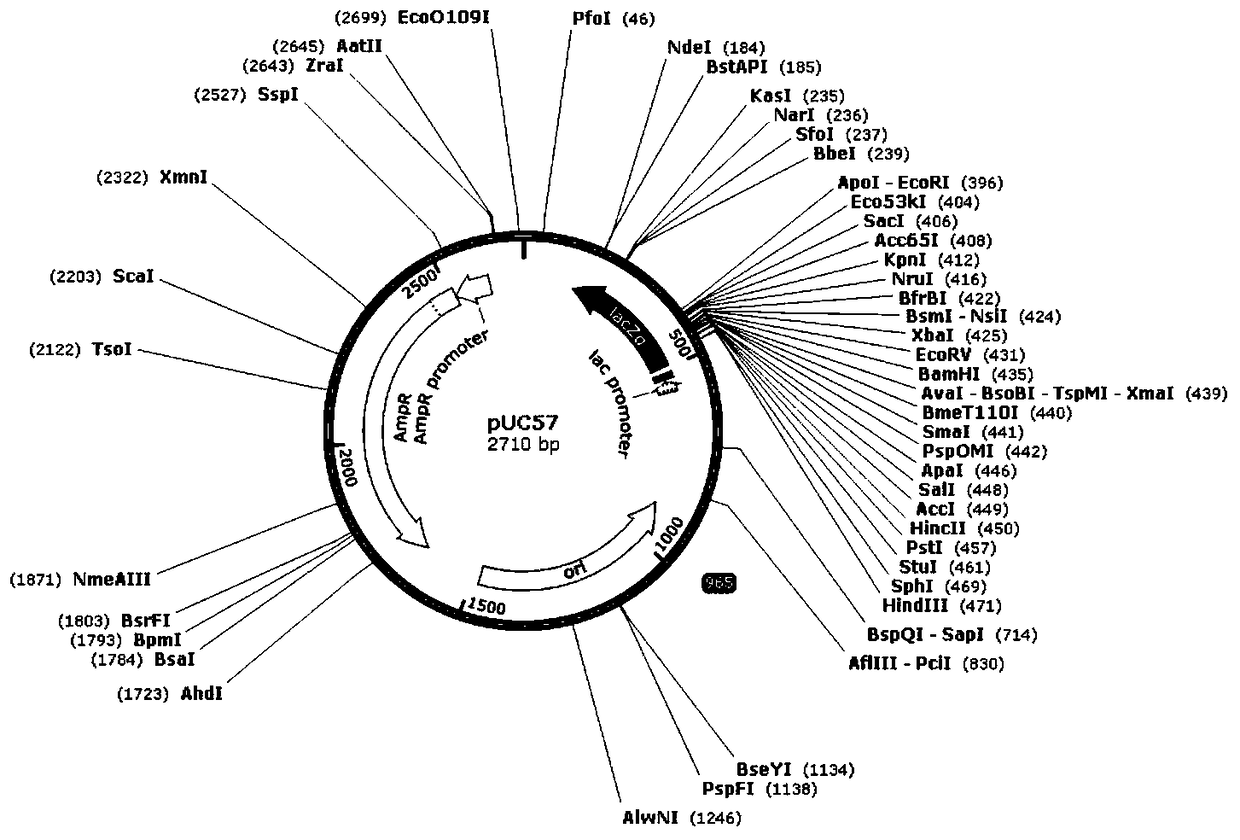

MRRP protein, gene, carrier, engineering bacteria and application thereof

ActiveCN105085685AImprove manufacturing yieldSelf-assembly properties haveBacteriaPeptide/protein ingredientsAttachment proteinBiology

The invention discloses MRRP protein, a gene, a carrier, engineering bacteria and application of the MRRP protein, the gene, the carrier and the engineering bacteria to preparation of wound healing medicine. The MRRP protein is formed by sequentially connecting mussel attachment protein Ma1, elastic drosophila melanogaster protein Res1, a spider silk protein nitrogen end sequence Nt1, a spider silk protein middle-piece repetitive sequence SSR, a spider silk protein carbon end sequence Ct1, elastic drosophila melanogaster protein Res2 and mussel attachment protein Ma2. The MRRP protein integrates self-assembling performance of spider silk protein, high elasticity of the elastic drosophila melanogaster protein and high viscosity of the mussel attachment protein, comprehensive performance is excellent, lengths are uniform, the MRRP protein can be biodegraded completely, the yield is high by adopting a microorganism method for preparing, and chemical pollution is avoided; the MRRP protein has high elasticity, and can bond wounds, so that the wounds are bonded without using lines.

Owner:山东润土节能环保工程有限公司

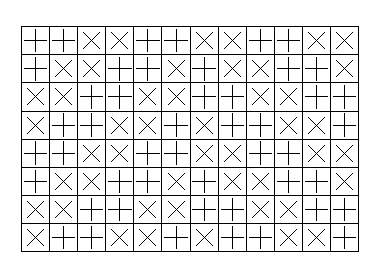

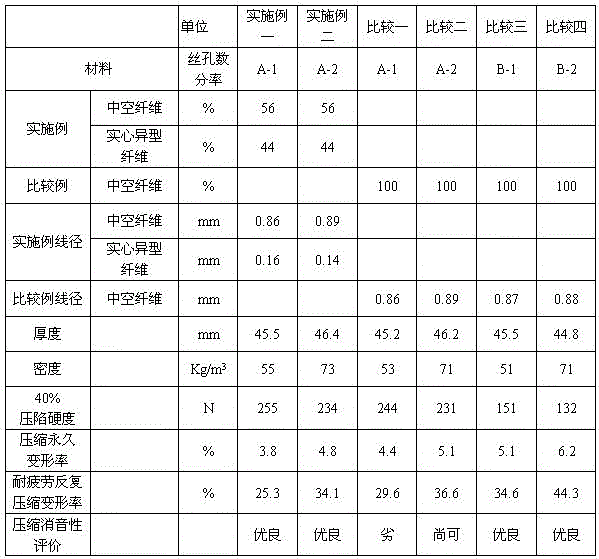

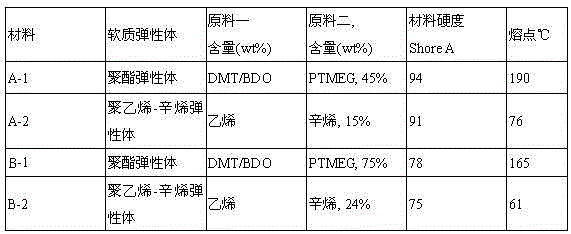

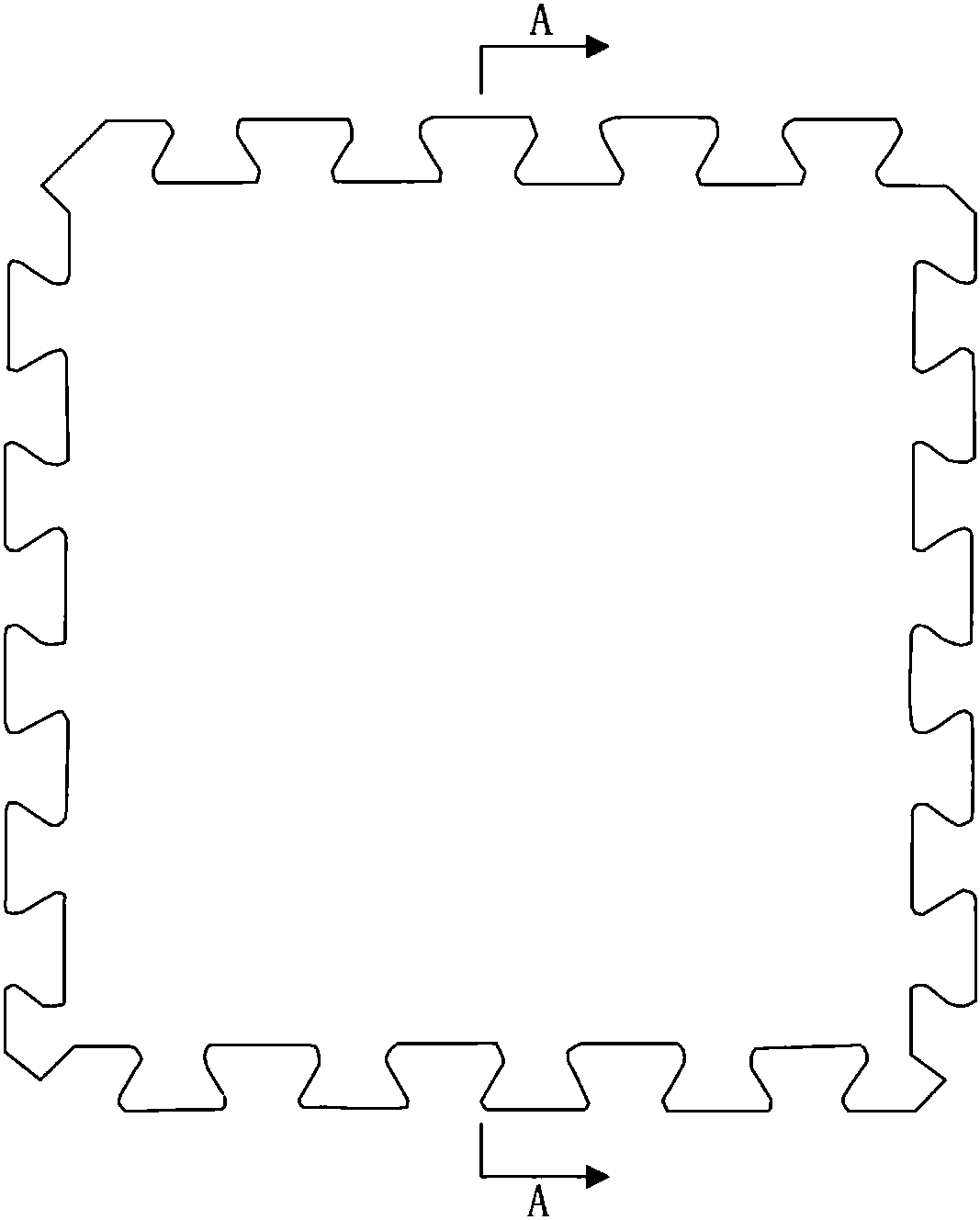

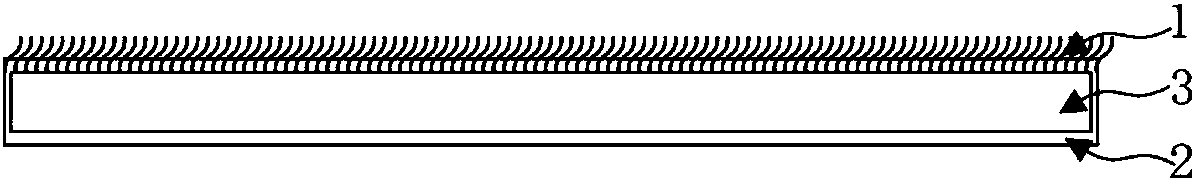

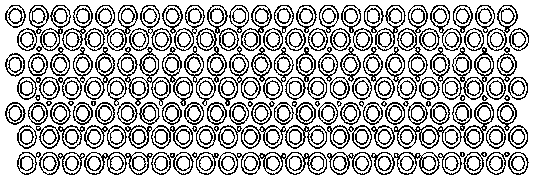

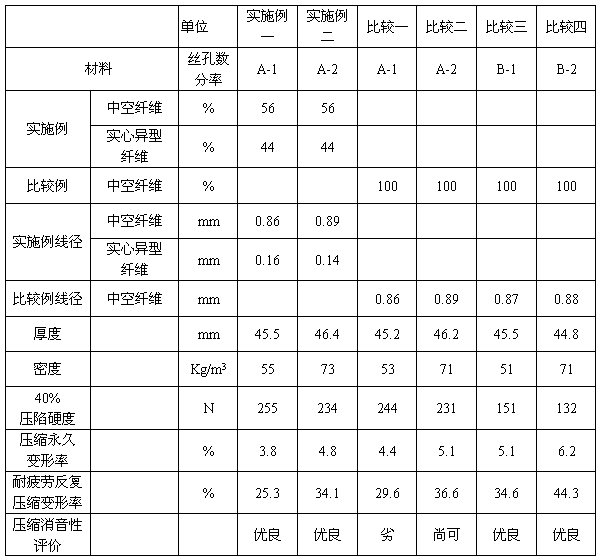

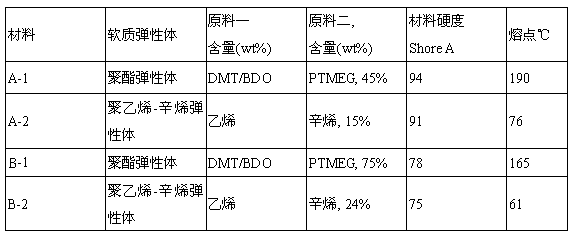

Three-dimensional net structure with sound attenuation and high elasticity performance

ActiveCN105839296AMeet the use requirementsImprove suitabilityNon-woven fabricsUltrasound attenuationFiber

The invention relates to a three-dimensional net structure with sound attenuation and high elasticity performance. The structure is made of a thermoplastic elastomer, the material hardness is in a range of 80-98 A, the density of the three-dimensional net structure is 20-100 kg / m<3>, and the structure is made of two different types of fibers including (1) hollow fibers which have the wire diameter of 0.3-2 mm and account for 40%-95% of all hole counts and (2) solid special-shaped fibers which have the wire diameter of 0.05-0.6 mm and account for 5%-60% of all hole counts. The compressive deformation durability, resilience, adaptability and sound attenuation performance of a support product are improved, so that the three-dimensional net structure has the longer service life and sound attenuation comfort when used as a buffer material.

Owner:JIANGYIN HETRON ELASTOMER NEW MATERIALS TECHNOLOGY CO LTD +1

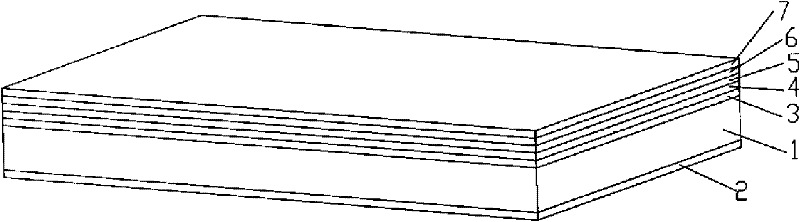

High-elasticity flame-retardant floor mat and preparation method thereof

InactiveCN108586988ASimple preparation processInhibit flammabilitySynthetic resin layered productsLaminationPolyvinyl chlorideAcrylonitrile

The invention discloses a high-elasticity flame-retardant floor mat and a preparation method thereof. The high-elasticity flame-retardant floor mat comprises a chenille fabric composite layer, a rubber layer and a foamed rubber layer, wherein the foamed rubber layer is arranged in a sealing structure of the chenille fabric composite layer and the rubber layer; the chenille fabric composite layer is a composite structure of rubber having a thickness of 0.4-0.8 mm formed at the root of the chenille fabric; the foamed plastic layer comprises the following raw materials: polyvinyl chloride, ethylene-vinyl acetate copolymer, phenolic resin, EVA toughened resin, peroxy lauryl, a plasticizer, a foaming agent, a flame retardant and a color master batch; the rubber layer comprises the following rawmaterials: natural rubber, stearic acid, solution polymerized styrene-butadiene rubber, chlorinated butyl rubber, butadiene-acrylonitrile rubber, sulfur, an elastic modifier and a scorch retarder color master batch.

Owner:SICHUAN PROVINCIAL PEOPLES HOSPITAL

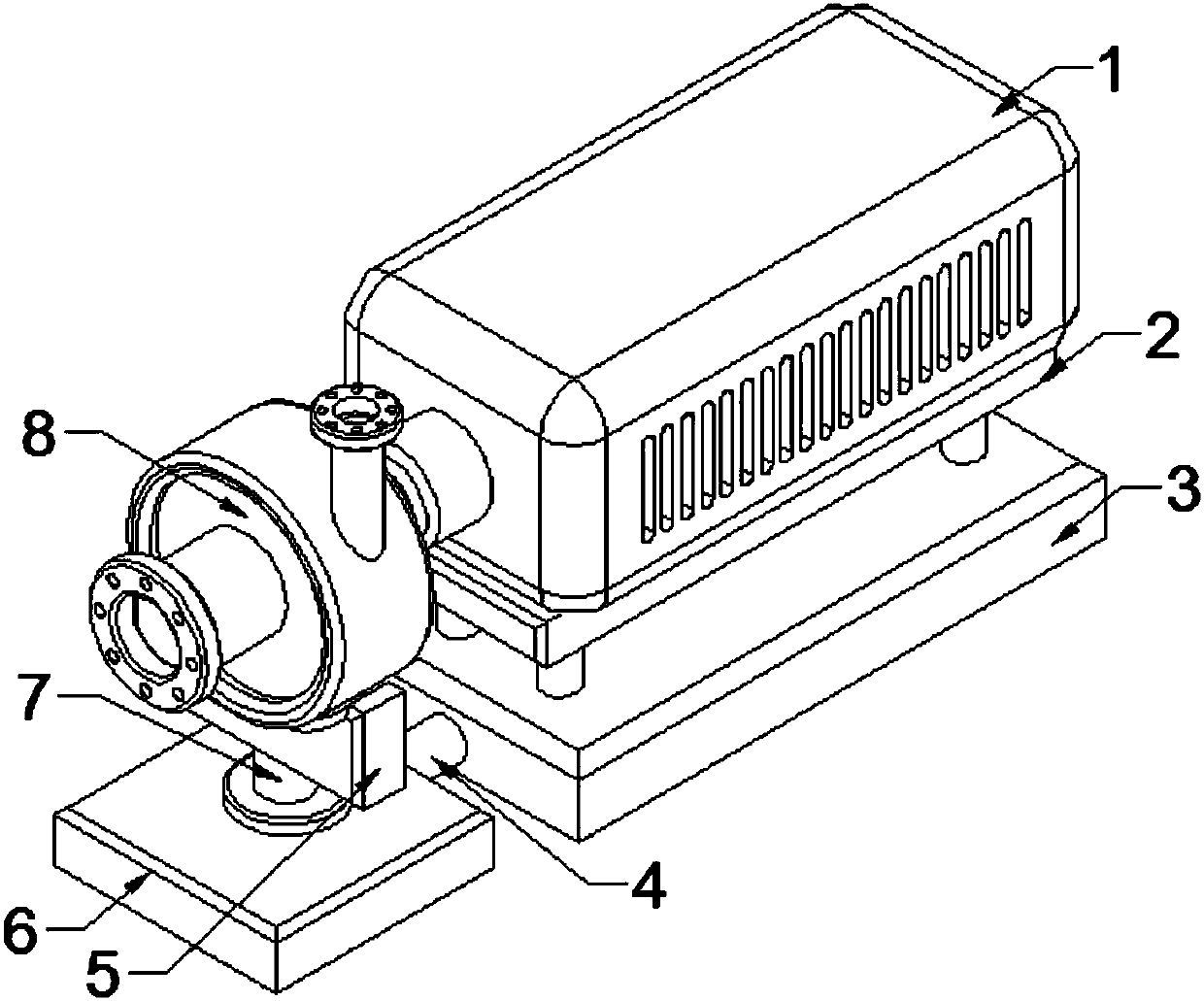

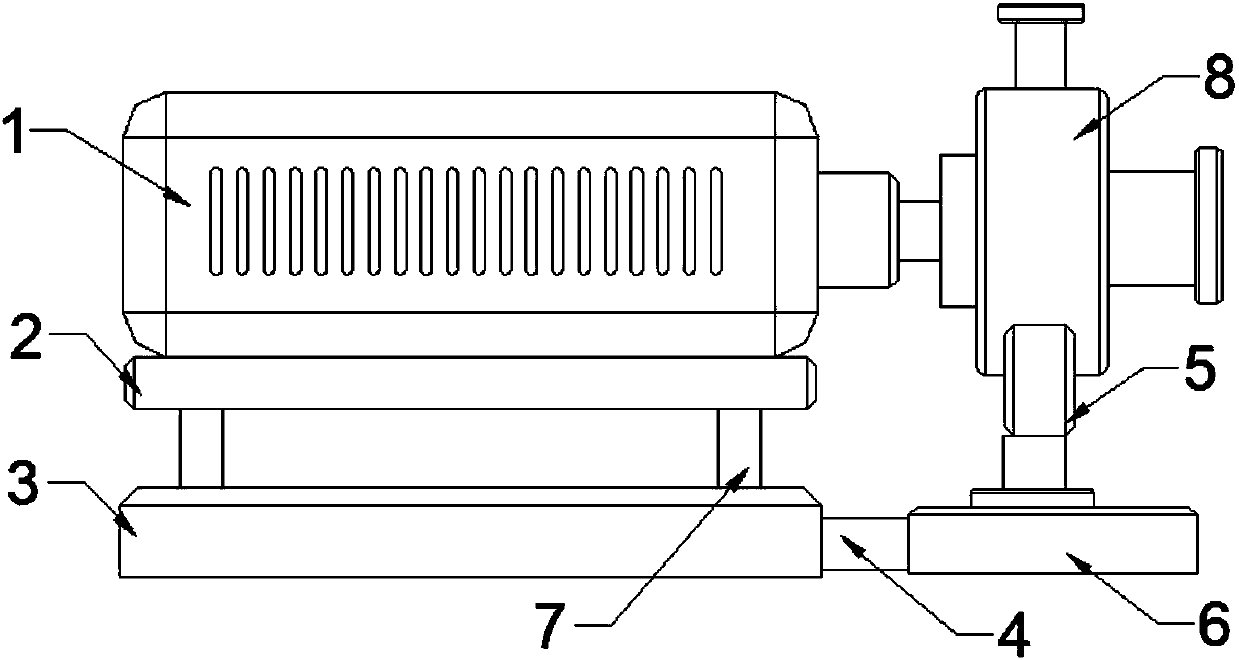

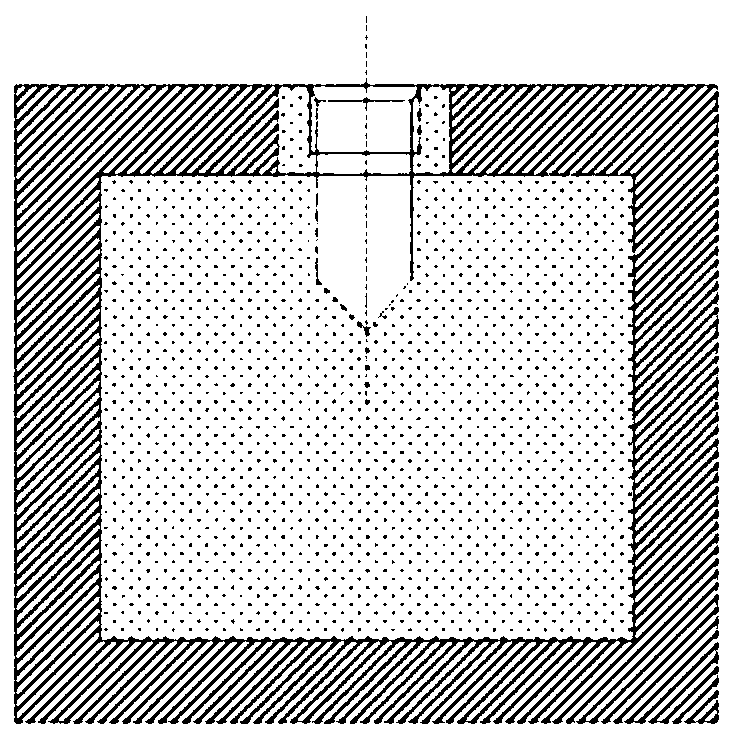

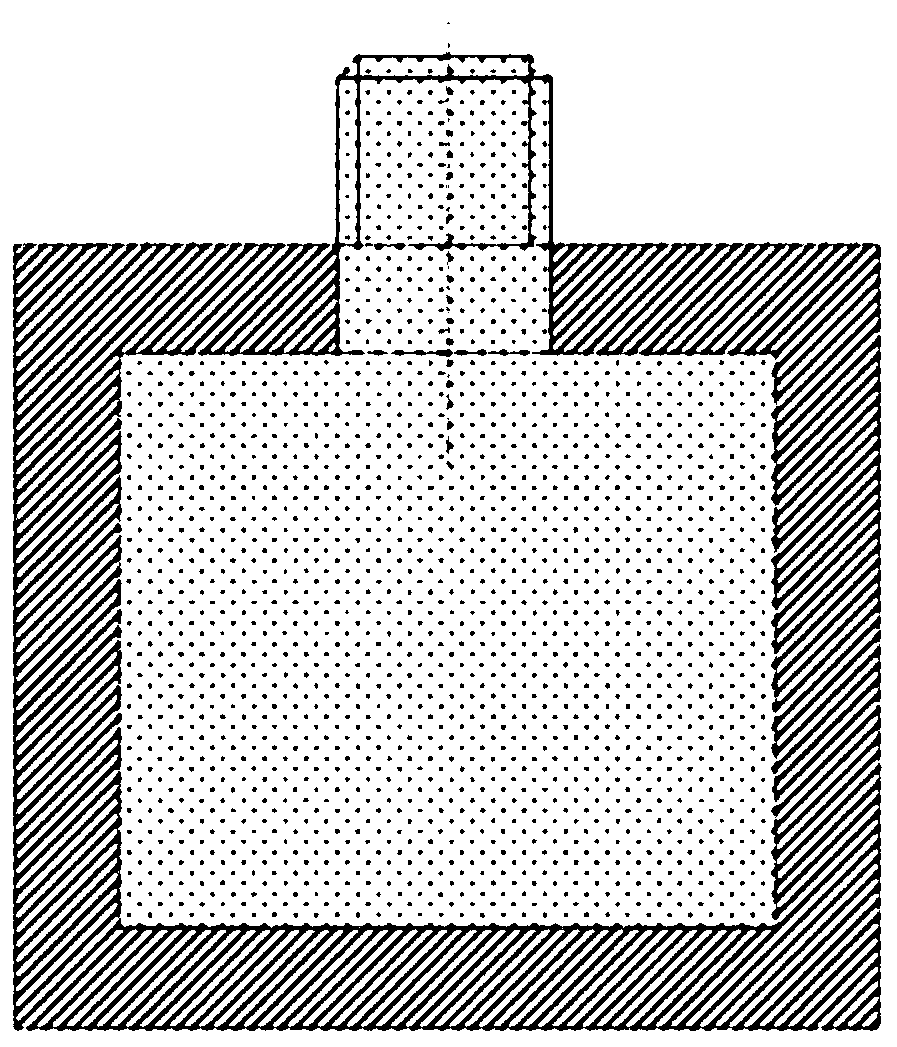

Preparation method for height-adjustable centrifugal pump

InactiveCN107605749AReduce vibrationGood buffer protectionPump componentsPump installationsPulp and paper industryCentrifugal pump

The invention provides a preparation method for a height-adjustable centrifugal pump. The height-adjustable centrifugal pump comprises a pump body, the lower end of the pump body is fixedly provided with a pump body supporting frame, and the bottom end of the pump body supporting frame is fixedly connected with a lifting supporting column body. The bottom end of the supporting column body is fixedly provided with a pump body supporting base, the side end face of the pump body is fixedly connected with a transmission rod, and the tail end of the transmission rod is fixedly provided with a motorfor providing operation power of the pump body. The lower end of the motor is fixedly provided with a motor mounting table. The lower end of the motor mounting table is provided with a plurality of supporting column bodies with the tail ends fixedly connected with a mounting base, and the upper end faces of the motor mounting table and the pump body supporting frame are provided with damping cushions correspondingly. The preparation method for the height-adjustable centrifugal pump has the beneficial effects that by arranging the lifting supporting column bodies on the lower end faces of thepump body supporting frame and the motor mounting table correspondingly, the height positions of the pump body and the motor can be effectively adjusted and controlled, a long delivering water pipe does not need to be mounted at a water inlet and a water outlet of the pump body by workers, the labor intensity is relieved, and the water delivering efficiency is improved.

Owner:TIANJIN MINGAO PUMP CO LTD

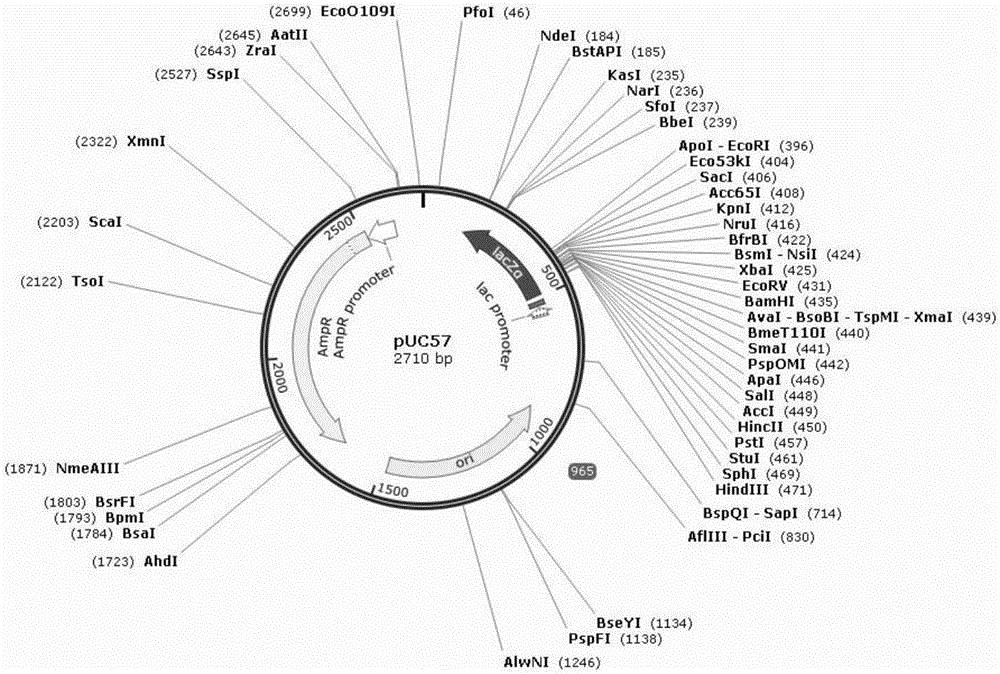

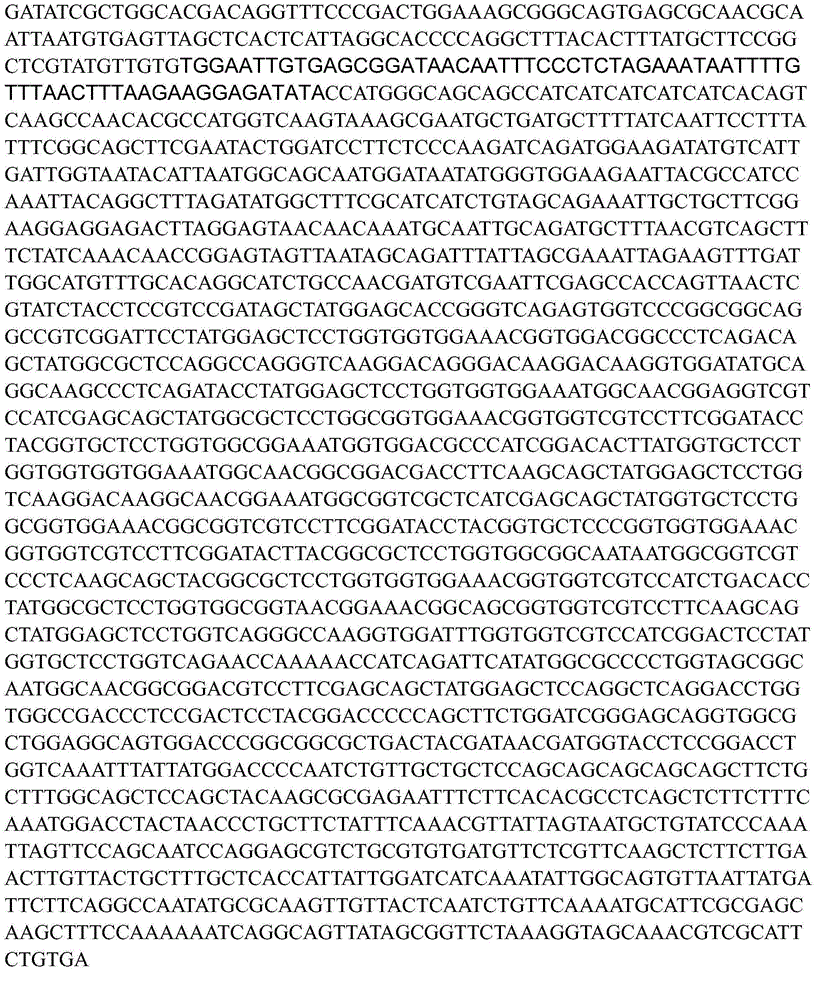

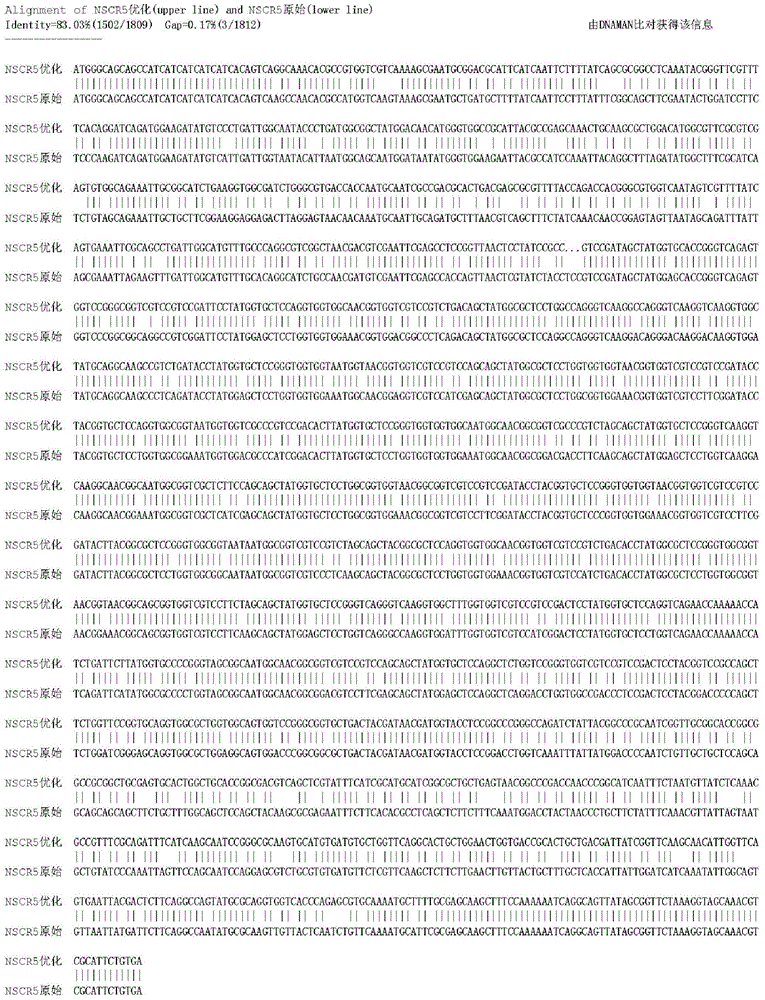

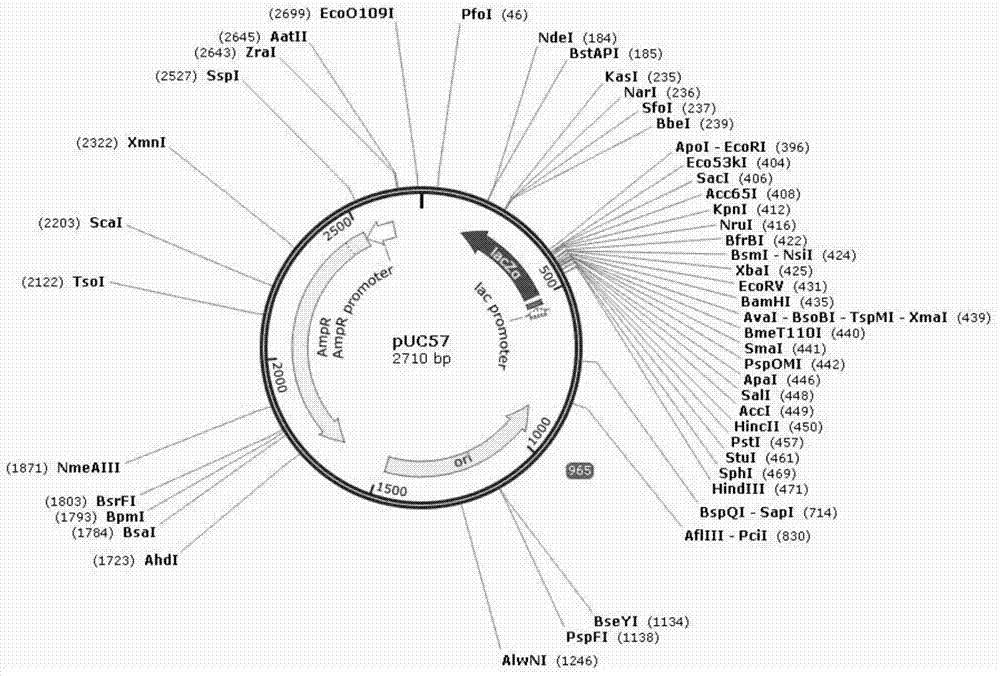

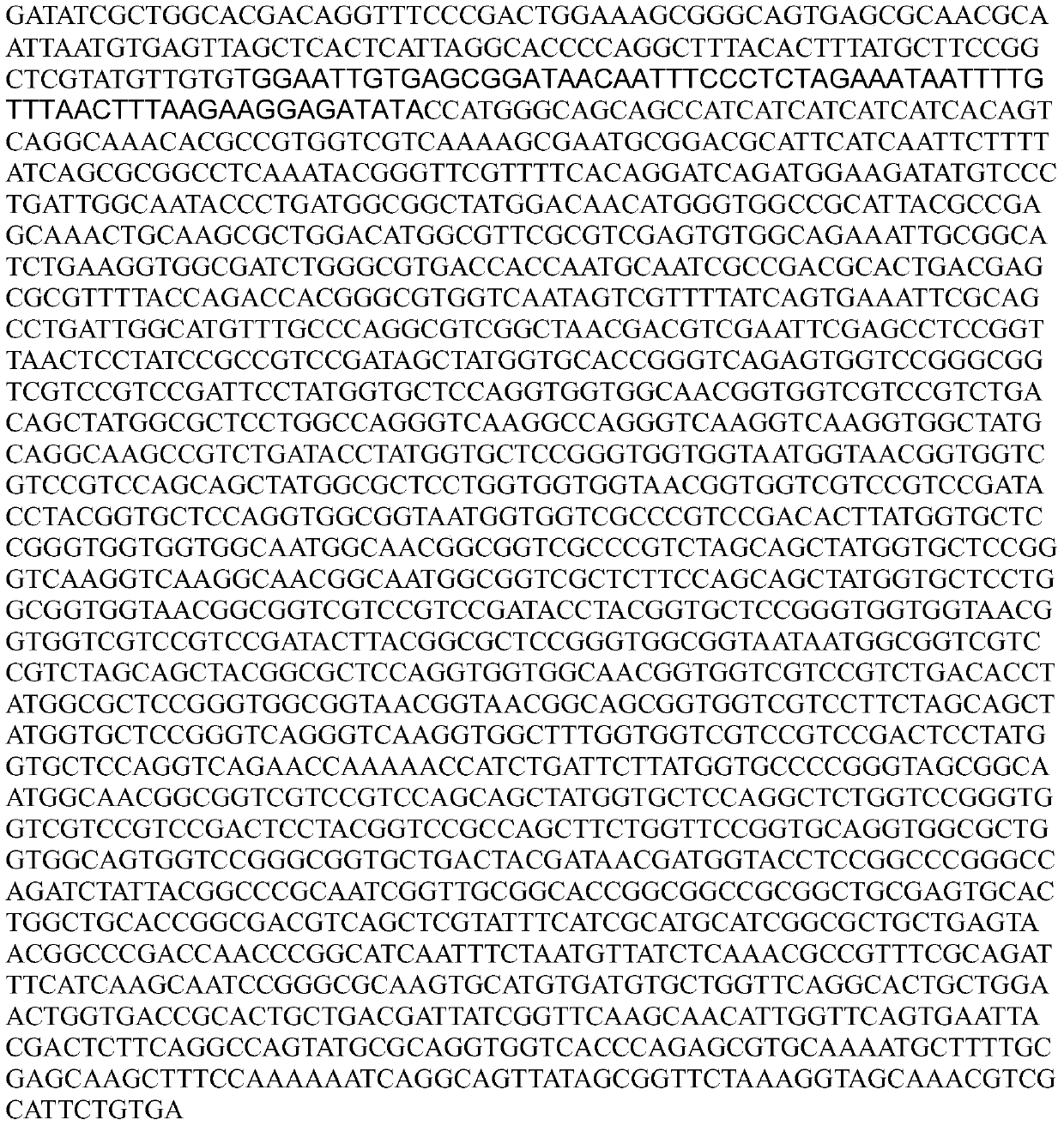

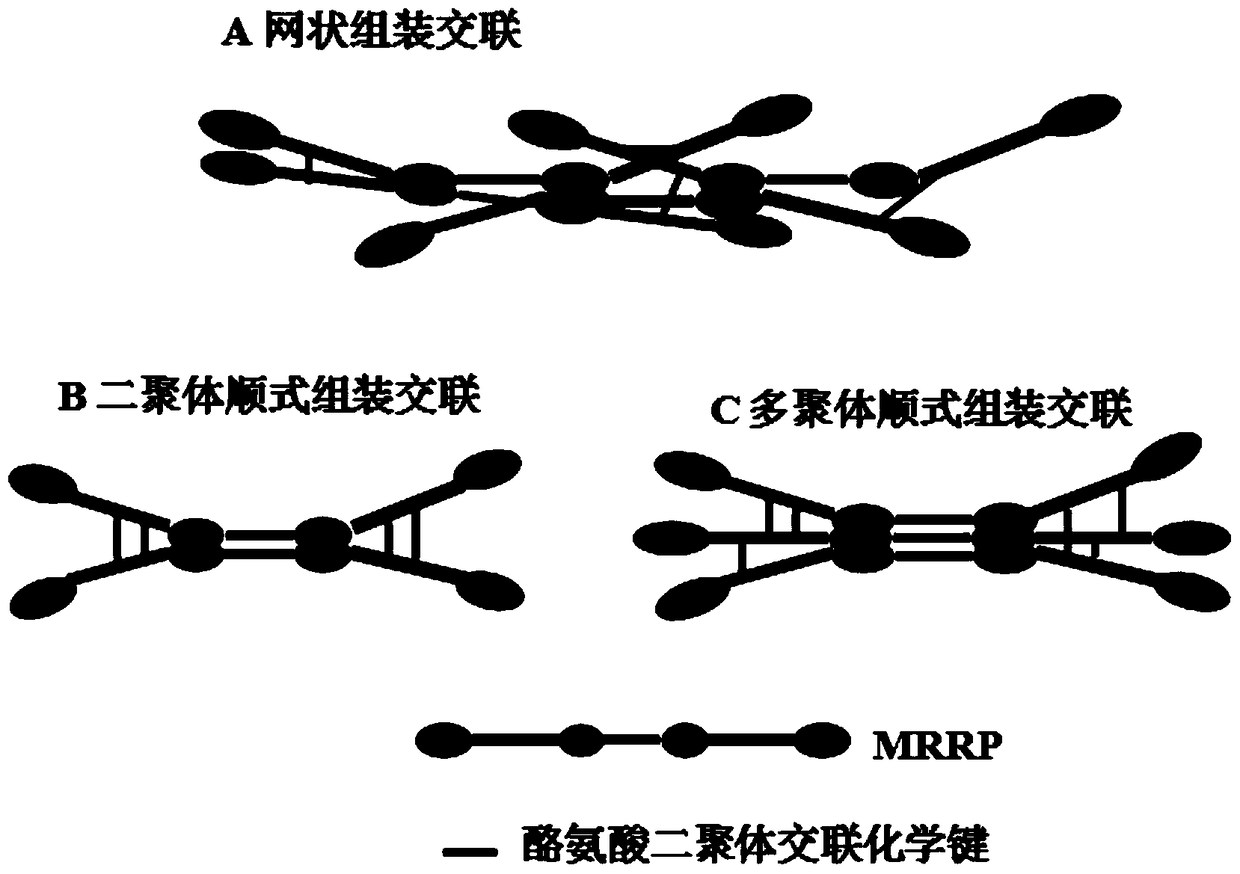

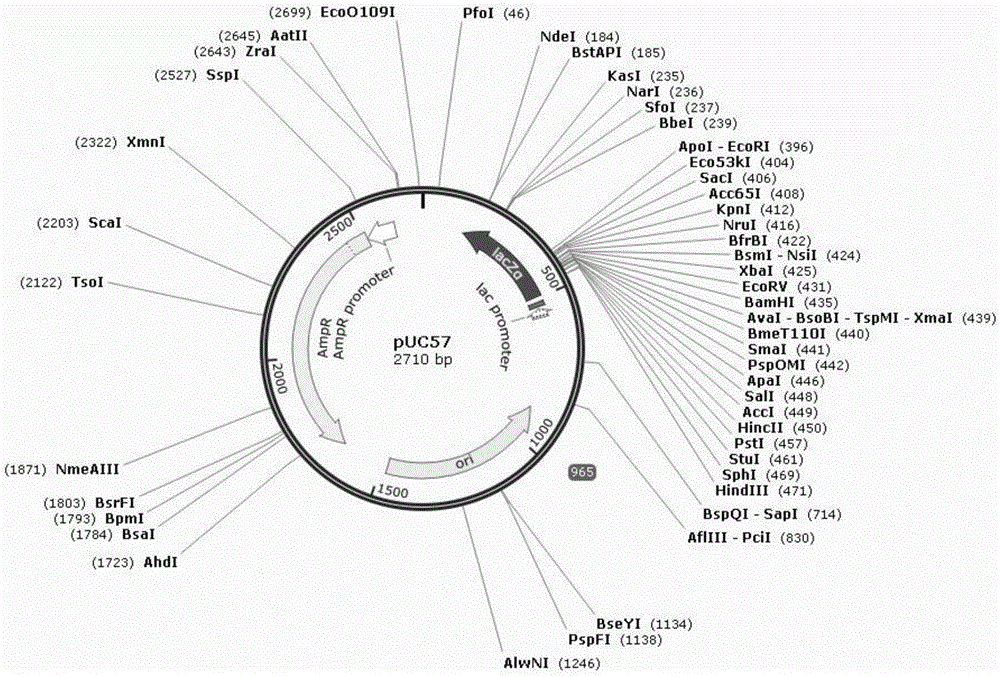

Novel fusion protein NSCR5 and preparation method thereof

InactiveCN104877031AHigh self-assembly performanceHigh elastic performanceHybrid peptidesVector-based foreign material introductionSynthesis methodsFermentation

The invention provides novel fusion protein NSCR5 and a preparation method thereof. The novel fusion protein NSCR5 is characterized in that the fusion protein NSCR5 is formed by sequential connection of four sections including 6 poly histidine labels (6X His), a spider silk protein amino terminal sequence (NT), drosophila Resilin, a spider silk protein carbon terminal sequence (CT) and diatom silicon deposition peptide (R5) and the like; the novel fusion protein NSCR5 is as long as 602 amino acid residues and is obtained by a whole-genome synthesis method, and codon compositions are optimized. The fusion protein NSCR5 can be used for producing 70-1200mg / L of fermentation liquor with purity ranging from 82-95%. The novel fusion protein NSCR5 has photocatalysis crosslinking, highly elastic, self-assembling and silicon depositing characteristics and has a broad application prospect in the biomedical field.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

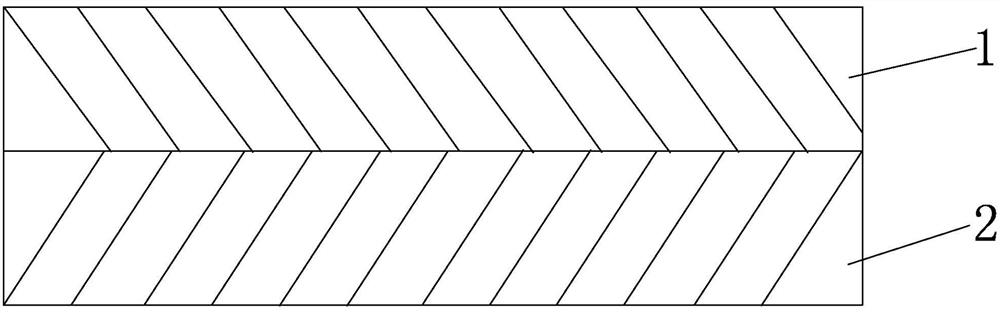

High-elasticity polyvinyl chloride fabric-art tablecloth

ActiveCN109591418AChange the boring and monotonous phenomenonCloth fits tightlyLamination ancillary operationsDomestic upholsteryYarnPolyvinyl chloride

The invention discloses high-elasticity polyvinyl chloride fabric-art tablecloth. The tablecloth comprises a PVC layer and a yarn layer, wherein the PVC layer is prepared through calendering, and theyarn layer is an environment-friendly degradable yarn layer; and the high-elasticity polyvinyl chloride fabric-art tablecloth is prepared by the steps of laminating double-surface embosses of the PVClayer and the yarn layer, printing, and reeling. The prepared high-elasticity polyvinyl chloride fabric-art tablecloth is high in flexibility, high in tear resistance and easy to clean, has anti-sliding performance and high elasticity and is relatively environment-friendly and relatively long in service life, and patterns and embosses can be printed on the prepared high-elasticity polyvinyl chloride fabric-art tablecloth.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

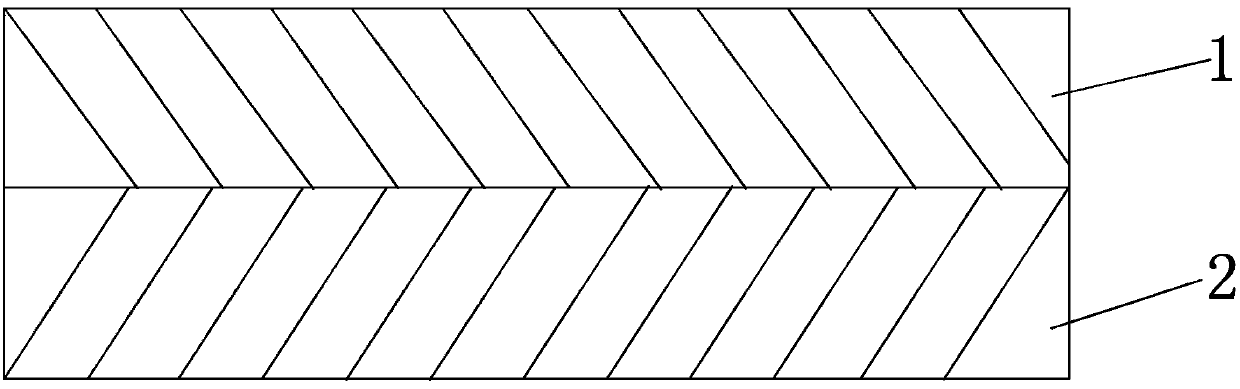

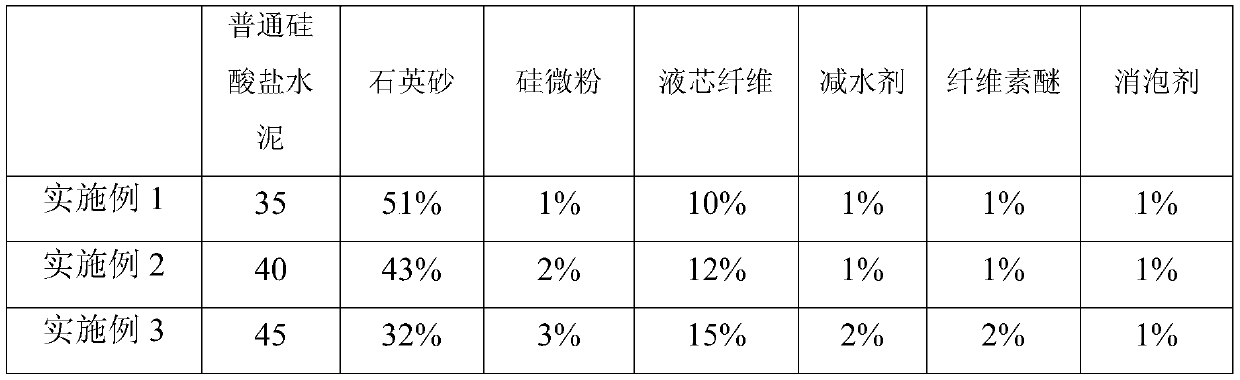

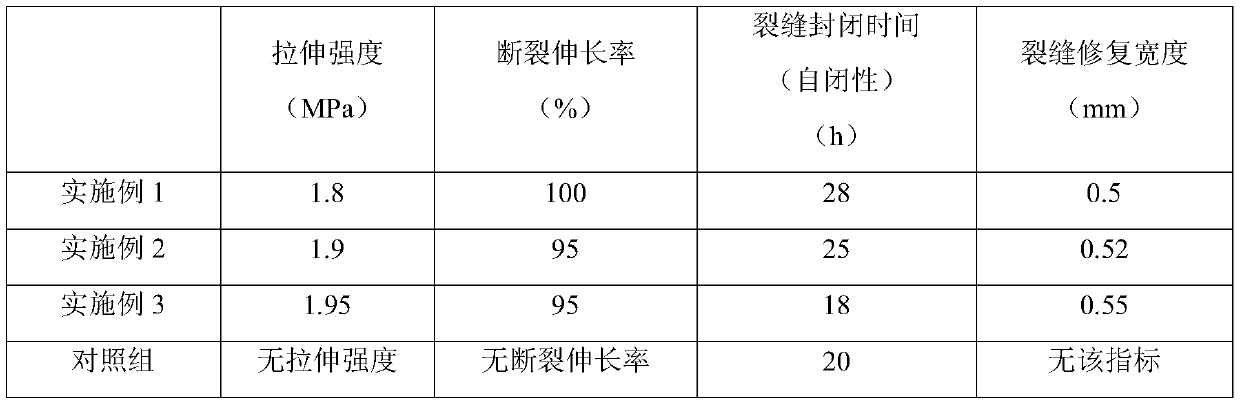

Two-component self-repairing polymer cement waterproof coating based on liquid core optical fiber method and preparation method of two-component self-repairing polymer cement waterproof coating

The invention discloses a two-component self-repairing polymer cement waterproof coating based on a liquid core optical fiber method. The coating comprises a liquid material and a powder material. Onthe basis, a corresponding preparation method of the product is established. The waterproof coating is a two-component coating composed of liquid and powder, is an intelligent high-elasticity waterproof coating, has higher elongation and structural cracking resistance, and has self-healing capability structurally. The coating can be self-repaired by support of a repair agent with a tubular fiber,damage caused by long-term mechanical action of the coating can be repaired, and accordingly, self-repair after cracks of the waterproof coating and restoration of the waterproof function are achieved. During use, the liquid material and the powder material are uniformly mixed for forming in the mass ratio of 1:1, the obtained coating has high elasticity, and cracks with water after water seepagecaused by cracking can be self-repaired. Accordingly, the problem that waterproof treatment is required to be performed again after a waterproof layer is damaged is solved, and the coating has higherpractical application value.

Owner:广东青龙建筑工程有限公司

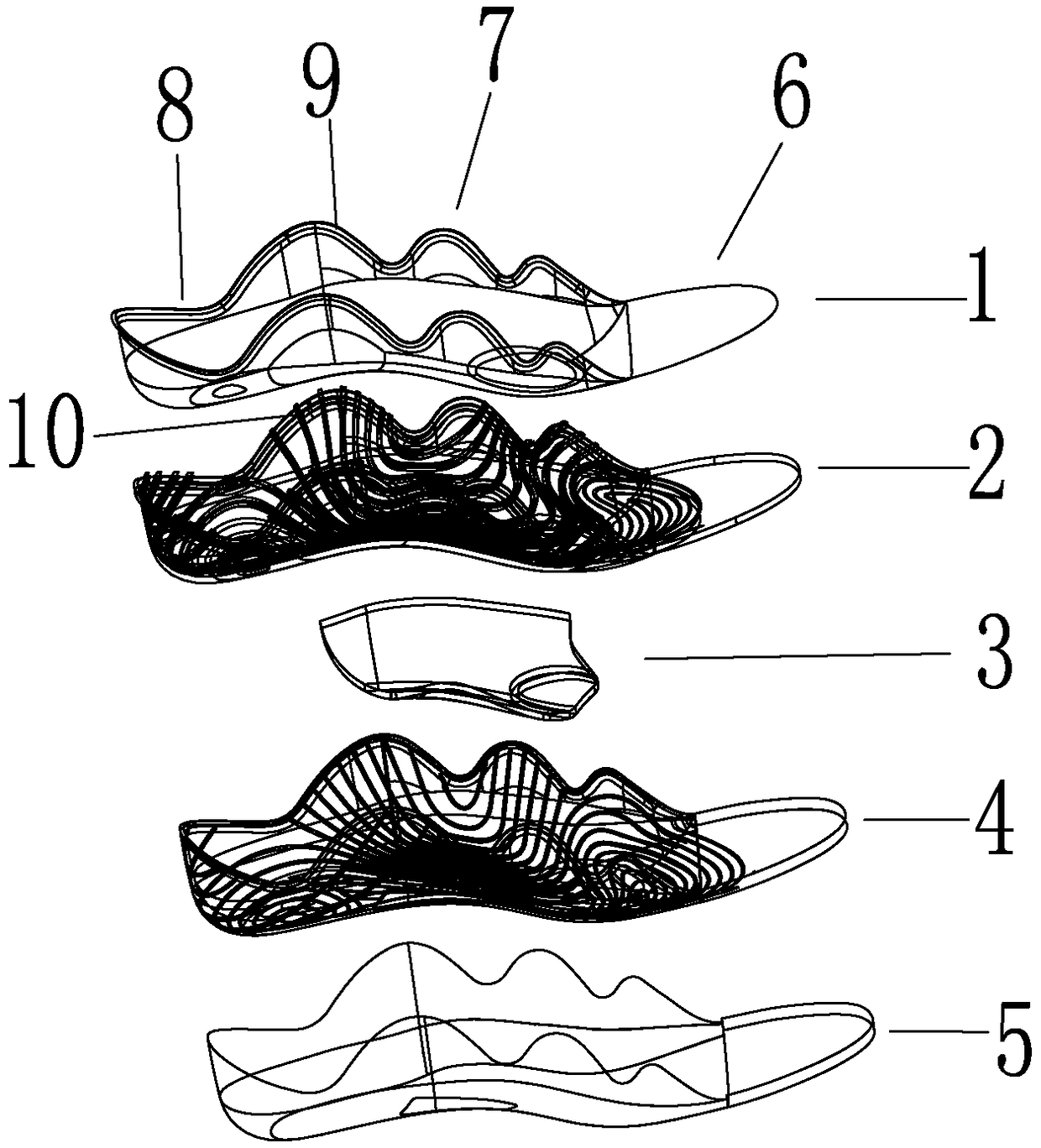

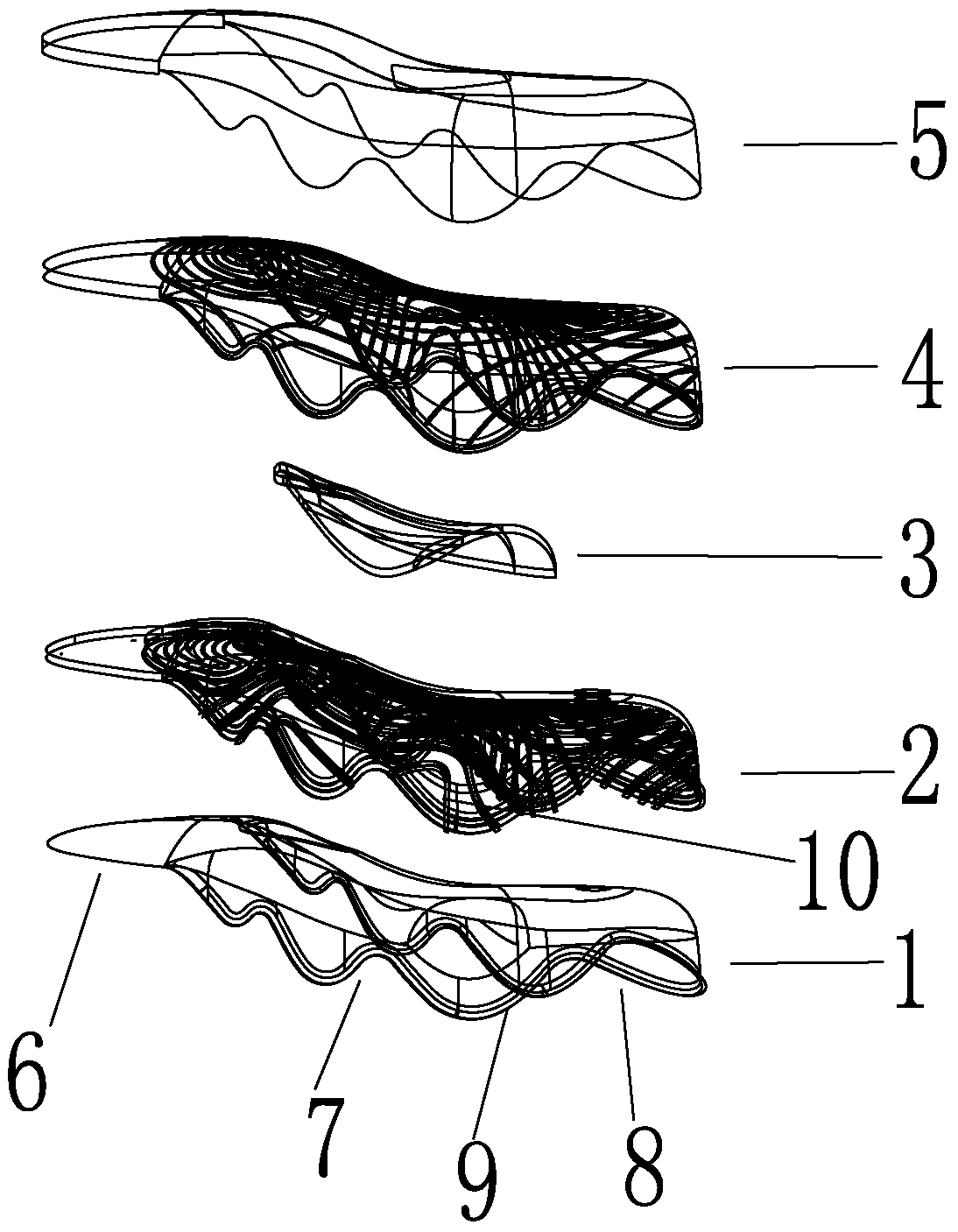

Sock-insole two-in-one insole

The invention discloses a sock-insole two-in-one insole. The insole comprises an insole body, and the insole body comprises a first nano bamboo carbon fiber layer, a first polyurethane foamed plasticlayer, a supporting cushion block, a second polyurethane foamed plastic layer and a second nano bamboo carbon fiber layer from top to bottom in sequence; the supporting cushion block is located at theportion corresponding to the arch part of the human body and jacks upwards, and accordingly an arch protrusion part corresponding to the supporting cushion bock is formed at the upper side of the insole body; an insole half-sole part, an insole waistline part and an insole heel part are arranged from the front end to the rear end of the insole body in sequence, and wave-shaped edges which tilt upwards are arranged on the insole waistline part and the insole heel part respectively. According to the sock-insole two-in-one insole, the rigidity difference of the insole and the sole is small, theinsole is good in elasticity, the demand of modern people for comfortable feet can be well met, and the insole fits the foot stably, does not easily slide, and has the double effects of socks and insoles; damping and foot protection in the motion process can be achieved, the pressure of the arch can be effectively improved, sweat and air are discharged, the insole is cool and has a good effect, and the effects of sterilization, bacterium inhibition and deodorization are effectively achieved.

Owner:DONGGUAN SHUNFENG SPORTS EQUIP CO LTD

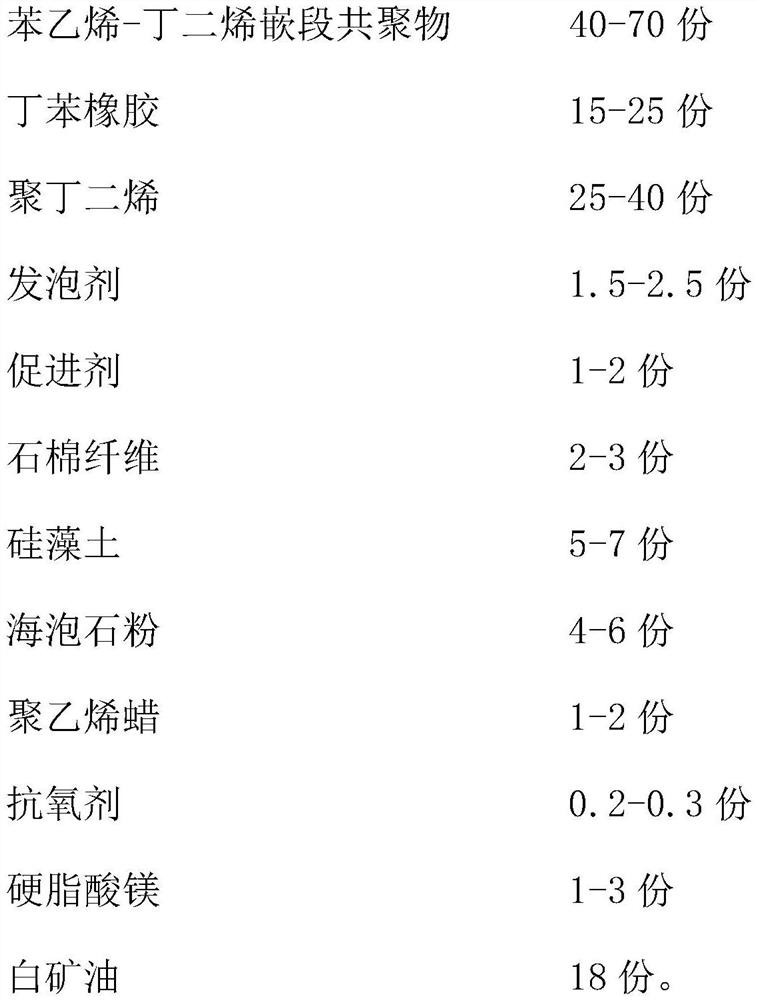

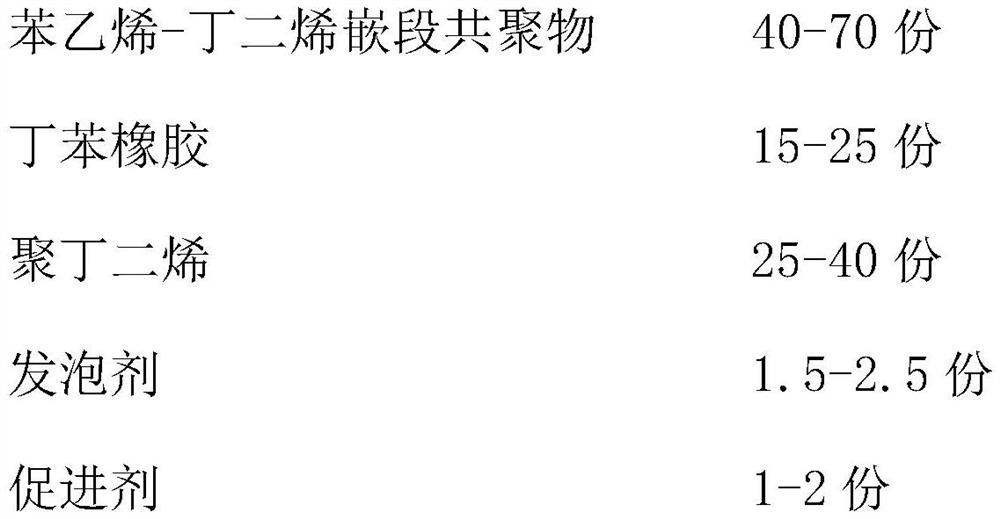

Light folding-resistant thermoplastic rubber sole, thermoplastic elastomer composition and preparation method thereof

Owner:MAOTAI FUJIAN SOLES CO LTD +1

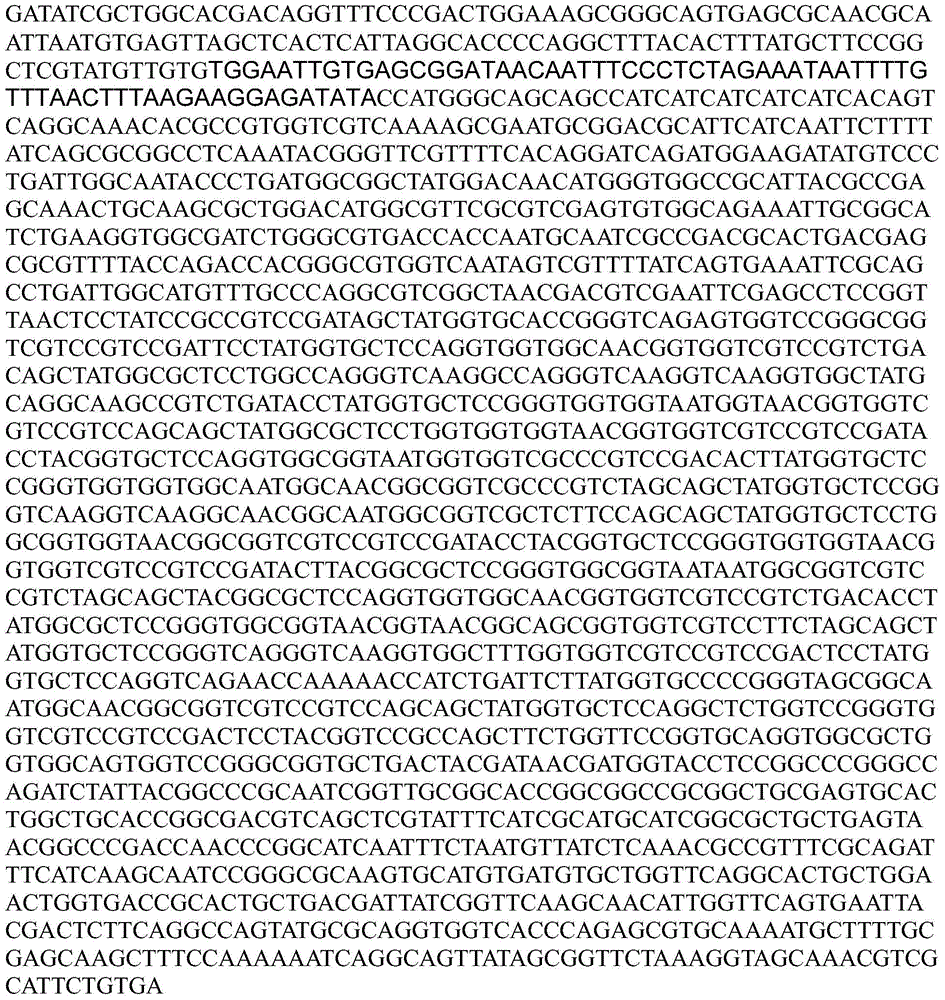

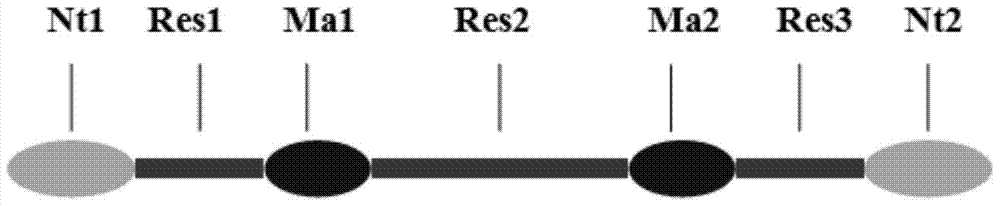

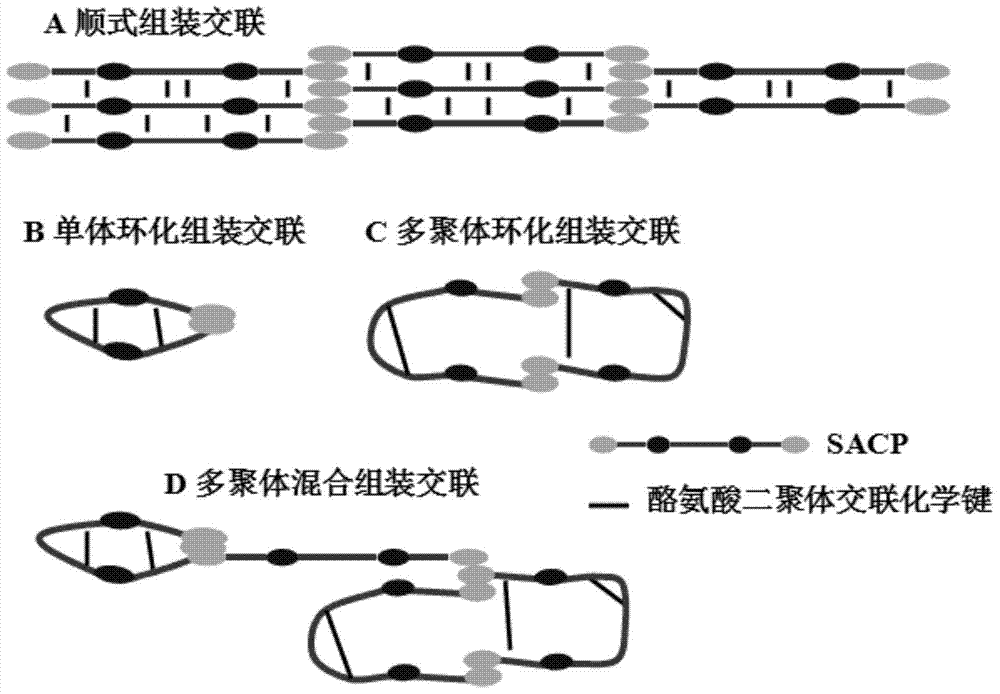

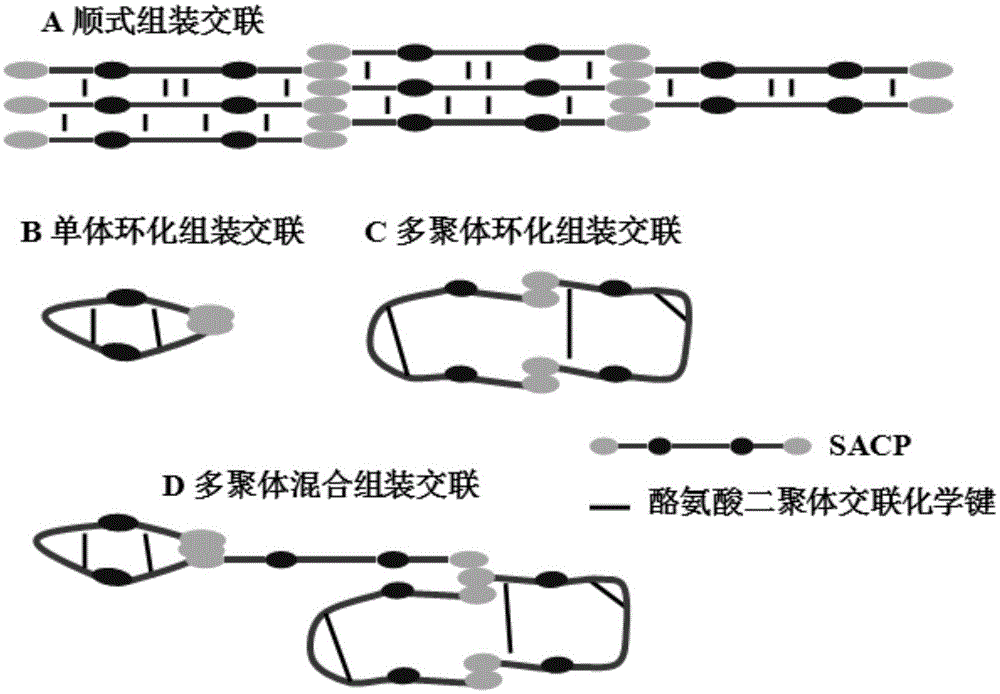

A fusion protein sacp, encoding gene, engineering bacteria and application thereof

ActiveCN105037556BHas high elastic propertiesHigh elastic performanceBacteriaMicroorganism based processesDrosophila ornatifronsBiopolymer

The invention discloses a fusion protein SACP, an encoding gene, an engineering bacterium and an application thereof in preparing wound dressing medicines. The fusion protein is composed of a spider silk protein nitrogen terminal sequence Nt1, fruit fly elastin Res1, Protein Ma1, Drosophila elastin Res2, mussel adhesion protein Ma2, Drosophila elastin Res3 and spider silk protein nitrogen-terminal sequence Nt2 are sequentially connected to form a total of 7 blocks; the novel biopolymer-fusion protein SACP of the present invention, Integrating the self-assembly performance of spider silk protein, the high elastic performance of Drosophila elastin and the high viscosity performance of mussel adhesion protein, the comprehensive performance is excellent, and the length is uniform, and it can be completely biodegraded. Pollution; Wound dressing drugs made of SACP can adhere to skin and wounds efficiently, and have excellent ductility, and have outstanding application performance in wound dressing.

Owner:山东润土节能环保工程有限公司

Amorphous alloy golf club head and manufacturing method thereof

ActiveCN110314353AHigh tensile strengthHigh elastic performanceGolf clubsMetallic materialsNeck parts

Owner:NANJING YOUTIAN METAL TECH

A novel fusion protein nscr5 and its preparation method

InactiveCN104877031BHigh self-assembly performanceHigh elastic performanceHybrid peptidesVector-based foreign material introductionSynthesis methodsFermentation

The invention provides novel fusion protein NSCR5 and a preparation method thereof. The novel fusion protein NSCR5 is characterized in that the fusion protein NSCR5 is formed by sequential connection of four sections including 6 poly histidine labels (6X His), a spider silk protein amino terminal sequence (NT), drosophila Resilin, a spider silk protein carbon terminal sequence (CT) and diatom silicon deposition peptide (R5) and the like; the novel fusion protein NSCR5 is as long as 602 amino acid residues and is obtained by a whole-genome synthesis method, and codon compositions are optimized. The fusion protein NSCR5 can be used for producing 70-1200mg / L of fermentation liquor with purity ranging from 82-95%. The novel fusion protein NSCR5 has photocatalysis crosslinking, highly elastic, self-assembling and silicon depositing characteristics and has a broad application prospect in the biomedical field.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

A kind of mrrp protein, gene, carrier, engineering bacteria and application thereof

ActiveCN105085685BHigh elastic performanceImprove manufacturing yieldBacteriaPeptide/protein ingredientsRepetitive SequencesAttachment protein

The invention discloses MRRP protein, a gene, a carrier, engineering bacteria and application of the MRRP protein, the gene, the carrier and the engineering bacteria to preparation of wound healing medicine. The MRRP protein is formed by sequentially connecting mussel attachment protein Ma1, elastic drosophila melanogaster protein Res1, a spider silk protein nitrogen end sequence Nt1, a spider silk protein middle-piece repetitive sequence SSR, a spider silk protein carbon end sequence Ct1, elastic drosophila melanogaster protein Res2 and mussel attachment protein Ma2. The MRRP protein integrates self-assembling performance of spider silk protein, high elasticity of the elastic drosophila melanogaster protein and high viscosity of the mussel attachment protein, comprehensive performance is excellent, lengths are uniform, the MRRP protein can be biodegraded completely, the yield is high by adopting a microorganism method for preparing, and chemical pollution is avoided; the MRRP protein has high elasticity, and can bond wounds, so that the wounds are bonded without using lines.

Owner:山东润土节能环保工程有限公司

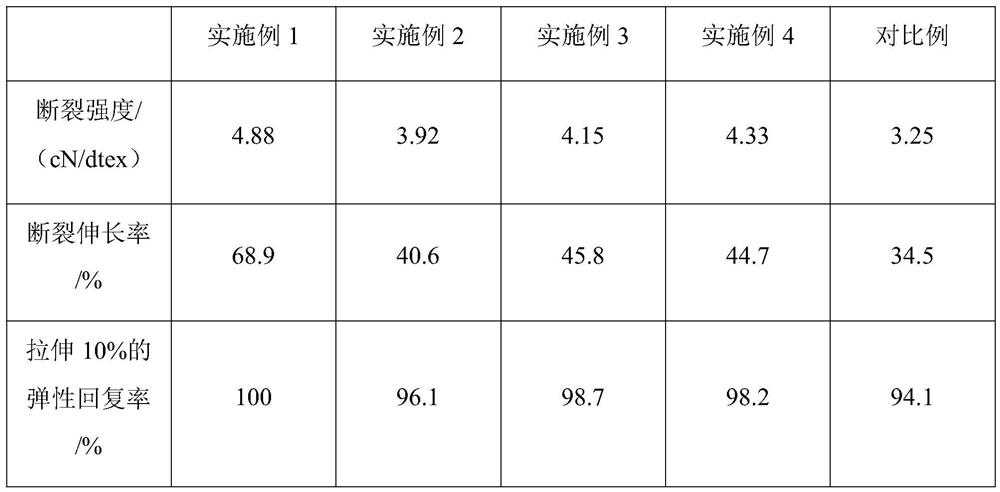

Fiber with relatively high stretch rate and preparation method thereof

ActiveCN112779630AGood compatibilityGuaranteed StrengthFibre typesConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate glycol

The invention discloses fiber with relatively high stretch rate and a preparation method thereof, and relates to the technical field of textile materials. The preparation method comprises the following steps of firstly drying polytrimethylene terephthalate slices and polyethylene glycol terephthalate slices, and carrying out melt extrusion to obtain a polytrimethylene terephthalate spinning material and a polyethylene glycol terephthalate spinning material; adding the polytrimethylene terephthalate spinning material and the polyethylene glycol terephthalate spinning material into a composite spinning assembly according to a mass ratio of 1: 1, performing spinning to obtain fibril, then stretching the fibril in a stretching bath containing esterified polysiloxane and pretreated silicon dioxide to obtain a fiber blank; and finally, soaking the fiber blank in dispersion liquid of a modified linear styrene-butadiene-styrene block copolymer, and performing curing in a light curing machine to obtain the high-stretch-rate fiber. The high-stretch-rate fiber prepared by the method has excellent elasticity and relatively high stretch rate.

Owner:WUXI HONGDOU SPORTSWEAR CO LTD

A high-elastic polyvinyl chloride cloth tablecloth

ActiveCN109591418BChange the boring and monotonous phenomenonCloth fits tightlyLamination ancillary operationsDomestic upholsteryYarnPolymer science

The invention discloses a high-elastic polyvinyl chloride cloth art tablecloth, which comprises a PVC layer and a yarn layer. The PVC layer is made by calendering. The polyvinyl chloride fabric tablecloth is obtained by laminating the PVC layer and the yarn layer with double-sided embossing, printing and winding. The high-elastic polyvinyl chloride cloth art tablecloth prepared by the invention has high softness and high tear resistance, can print patterns and embossing patterns, is non-slip and easy to clean, has high elasticity, is more environmentally friendly and has a longer service life.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Elastic floor and production method thereof

ActiveCN101691806BProtection from bruisesProtect against damagePolyurea/polyurethane coatingsFlooringSolid woodSurface finish

The invention belongs to the technical field of wood floors, and in particular relates to an elastic floor and a production method thereof. The elastic floor comprises a floor substrate; and the surface of the floor substrate is coated with a high-elasticity UV paint layer which is formed by using large molecular weight flexible polymers and a large molecular weight active diluent as main film forming materials. The floor substrate is made of pure soft wood with a density between 0.35 and 0.55 or a medium and high density laminated plate with a density of 0.8. The production method for the elastic floor comprises the following steps: a) performing surface finish on the floor substrate; and b) coating the high-elasticity UV paint layer which is formed by using the large molecular weight flexible polymers and the large molecular weight active diluent as the main film forming materials. The elastic floor adopts the high-elasticity UV paint as finishing paint of the floor to prevent children from physical injuries because of falling, and has high elasticity after being coated with elastic pain despite that the substrate is made of the pure soft wood or the medium and high density plate.

Owner:广西柏景地板有限公司

A new type of low elastic modulus medical zirconium alloy and its design method

ActiveCN108411157BHigh modulus of elasticityElastic Modulus Performance OptimizationUltimate tensile strengthZirconium alloy

The invention discloses low elasticity modulus novel medical zirconium alloy and a designing method thereof. The low elasticity modulus novel medical zirconium alloy disclosed by the invention is prepared from the raw materials in atomic percent: 0.1at.% to 3at.% of tin, 3at.% to 5at.% of copper, 0.1at.% to 15at.% of niobium and the balance of zirconium. The designing method of the low elasticitymodulus novel medical zirconium alloy comprises the steps: utilizing a quadratic regression orthogonal rotation combination design to perform ingredient design to obtain an experiment scheme; then converting atomic percent of all alloy elements in the scheme into weight percentage to obtain a weight ratio scheme; performing alloy preparation, a compression experiment and further phase analysis anda microscopic structure observing experiment according to the weight ratio scheme obtained from the combination design; then utilizing SPSS to analyze experiment results and finally obtaining a mathematic model of alloy performance and alloy elements. The zirconium alloy designed out according to the mathematic model has the advantages of low elastic modulus, moderate compression strength and yield strength, high elastic energy and ability in meeting a requirement of clinical medicine to an implant material.

Owner:GUANGXI UNIV

A three-dimensional mesh structure with sound-absorbing and high-elastic properties

ActiveCN105839296BHigh elastic performanceImprove pressure set durabilityNon-woven fabricsUltrasound attenuationFiber

The invention relates to a three-dimensional net structure with sound attenuation and high elasticity performance. The structure is made of a thermoplastic elastomer, the material hardness is in a range of 80-98 A, the density of the three-dimensional net structure is 20-100 kg / m<3>, and the structure is made of two different types of fibers including (1) hollow fibers which have the wire diameter of 0.3-2 mm and account for 40%-95% of all hole counts and (2) solid special-shaped fibers which have the wire diameter of 0.05-0.6 mm and account for 5%-60% of all hole counts. The compressive deformation durability, resilience, adaptability and sound attenuation performance of a support product are improved, so that the three-dimensional net structure has the longer service life and sound attenuation comfort when used as a buffer material.

Owner:JIANGYIN HETRON ELASTOMER NEW MATERIALS TECHNOLOGY CO LTD +1

Fusion protein SACP, coding gene, engineering bacterium and application of fusion protein SACP

ActiveCN105037556AExcellent overall performanceUniform lengthBacteriaMicroorganism based processesChemistryChemical pollution

The invention discloses a fusion protein SACP, a coding gene, an engineering bacterium and application of the fusion protein SACP to preparation of wound dressing medicines. The fusion protein is formed by sequentially connecting 7 blocks, namely spider silk protein N terminal sequence Nt1, drosophila elastin Res1, mussel adhesive protein Ma1, drosophila elastin Res2, mussel adhesive protein Ma2, drosophila elastin Res3 and spider silk protein N terminal sequence Nt2. The novel biomacromolecule-fusion protein SACP integrates the self-assembly property of spider silk protein, the high elasticity property of drosophila elastin and the high viscosity property of mussel adhesive protein, is excellent in comprehensive performance and equal in length, can be completely biodegraded, and is high in yield and free of chemical pollution due to the microbiological preparation method; the wound dressing medicine prepared from SACP can be efficiently adhered to the skin and a wound, meanwhile, has favorable ductility and has outstanding application performance for wound dressing.

Owner:山东润土节能环保工程有限公司

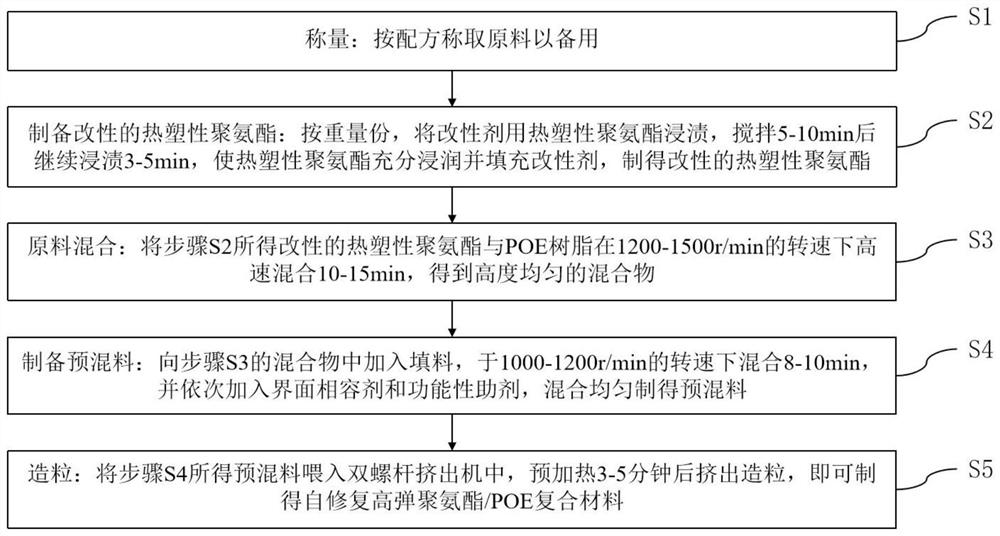

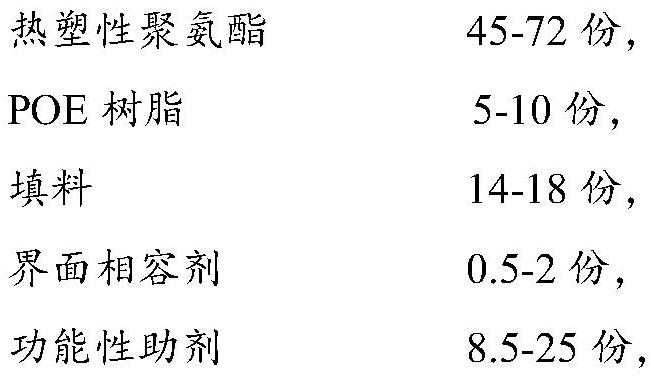

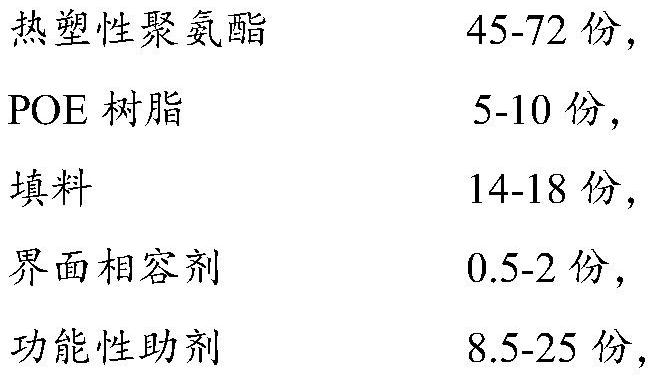

Self-repairing high-elastic polyurethane/POE (Polyolefin Elastomer) composite material and preparation method thereof

The invention belongs to the technical field of composite materials, and particularly relates to a self-repairing high-elastic polyurethane / POE composite material, which comprises, by weight, 45-72 parts of thermoplastic polyurethane, 5-10 parts of POE resin, 14-18 parts of a filler, 0.5-2 parts of an interfacial compatibilizer, and 8.5-25 parts of a functional auxiliary agent, the sum of the parts by weight of the components is 100, the thermoplastic polyurethane comprises a modifier, and the POE resin comprises a silane coupling agent. The modifier accounts for 5-25% of the thermoplastic polyurethane by weight, and the modifier is one or more of tetrafluoroethylene, carbon fiber or a porous nano material; the invention also provides a preparation method of the self-repairing high-elastic polyurethane / POE composite material. The advantages of thermoplastic polyurethane and POE resin are fully exerted, the self-repairing performance and high elasticity of the composite material are remarkably improved, the preparation process is simple, energy is not consumed, complex reactions are not involved, volatile by-products are not generated, and energy and cost are saved.

Owner:合肥中科凯辰新材料有限公司

A kind of amorphous alloy reinforced racket and its preparation method

A method for preparing an amorphous alloy reinforced racket, comprising steps: step S1: connect amorphous alloy strips to both ends of the carbon cloth, one end of the amorphous alloy strip extends out of the carbon cloth by 10mm-100mm; step S2: connect the carbon cloth The cloth is rolled into a long strip, and then the extended amorphous alloy strip is wrapped around one end of the long strip of carbon cloth, and then wrapped with carbon yarn; Step S3: Make the rolled long strip of carbon cloth into the frame of the racket Initial shape; Step S4: Open a card slot in the middle of the joint between the racket shaft and the racket frame, insert the amorphous alloy sheet into the slot; Step S5: Wrap the joint between the racket shaft and the racket frame with carbon fiber cloth, and connect the racket shaft to the racket frame. The racket frame is connected to form a racket embryo, which is put into the molding mold, solidified and formed under the heating condition of 120-160°C, and after cooling, the semi-finished badminton racket that has been formed in the mold is taken out. The invention utilizes the high strength, high elasticity, high hardness, light weight and other excellent properties of the amorphous alloy material to enhance the strength of the joint between the racket frame and the racket shaft, and reduce the risk of fracture here.

Owner:SHENZHEN UNIV

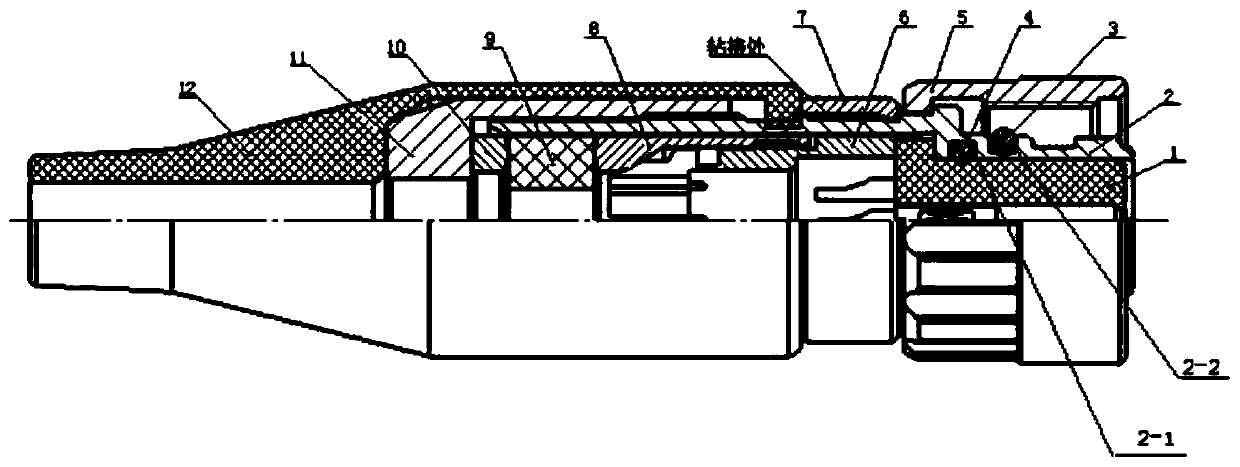

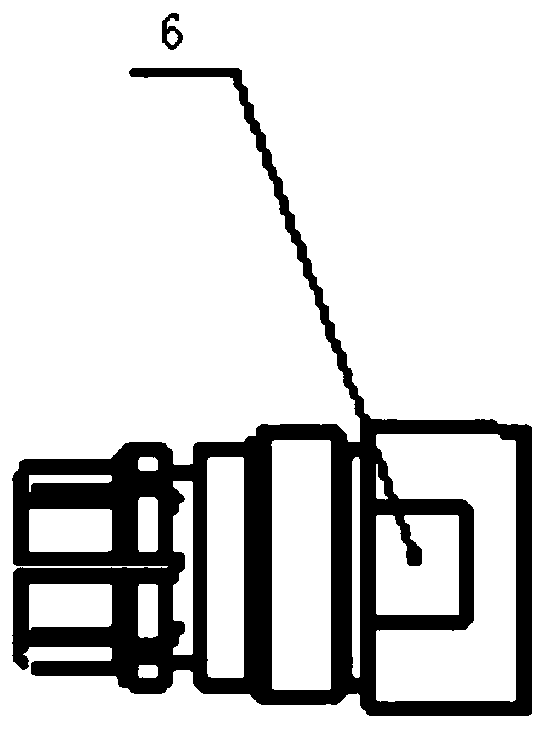

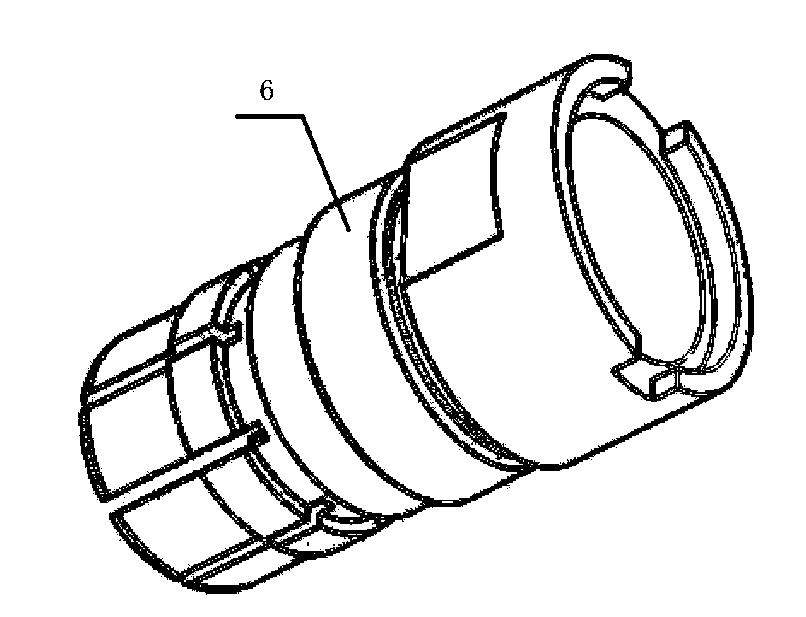

Mechanical watertight connector

PendingCN109980426AGood resistance to seawater corrosionIncrease productivityEngagement/disengagement of coupling partsRelieving strain on wire connectionCushionEngineering

The invention provides a mechanical watertight connector, and solves the problem that ocean equipment can not be repaired since the sealing structure of an existing watertight connector or other connectors can not be disassembled. The watertight connector comprises a jack insulator component, a plug shell, a connection nut, a line clamping barrel, a spacing nut, a line clamping barrel nut, a waterproof cushion, a retainer ring, a tail nut and a rubber sleeve. When the tail nut is loosened, extrusion force is lost, after the tail nut is loosened, the retainer ring, the waterproof cushion, the line clamping barrel nut and the line clamping barrel are detachable, the cable can be disassembled and replaced, and the electrical connection of the ocean equipment in a deep sea environment and themaintenance and the repairing of equipment can be guaranteed.

Owner:沈阳兴华航空电器有限责任公司

A kind of oil resistant low temperature flame retardant polyolefin rubber cable material and preparation method thereof

ActiveCN106220985BNo smellGood dispersionPlastic/resin/waxes insulatorsInsulated cablesPower cableProcedure Agents

The invention relates to an oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material and a preparation method thereof, and belongs to the technical field of power cables. The oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material is prepared from the following components in parts by weight: 90 to 110 parts of EVA resin, 100 to 160 parts of a nanoscale organic flame retardant, 5 to 10 parts of white carbon black, 15 to 25 parts of nano-pottery clay, 5 to 10 parts of a processing auxiliary agent, 0.5 to 2 parts of a silane coupling agent, 8 to 15 parts of a low-temperature plasticizer, 0.5 to 1.5 parts of an anti-ageing agent, 1.2 to 2.0 parts of a tasteless vulcanizing agent and 0.5 to 1.0 part of a vulcanizing auxiliary agent. The preparation method comprises the following steps: 1, plastifying: plastifying EVA resin particles for 5 to 8 minutes in an internal mixer, scrolling down and allowing standing still; 2, mixing: plastifying the primarily plastified EVA resin for 0.5 to 1.5 minutes; adding the processing auxiliary agent, the silane coupling agent, the nano-pottery clay and the white carbon black and mixing for 4 to 6 minutes; adding the nanoscale organic flame retardant, the low-temperature plasticizer and the anti-ageing agent and mixing for 5 to 7 minutes; adding the tasteless vulcanizing agent and the vulcanizing auxiliary agent in a later period. The invention has the advantages that the oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material has excellent fire resistance, high mechanical property, high insulating property and high elasticity; the process is simple, the operation is convenient, the control is accurate, and the product is stable.

Owner:天津金山电线电缆股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com