Elastic floor and production method thereof

A technology of elastic flooring and production methods, applied in coating, construction, building construction, etc., can solve problems such as human injury, children, elderly wrestling, high price, etc., and achieve the effect of good softness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The elastic floor and its production method of the present invention will be further described in detail below in conjunction with specific embodiments.

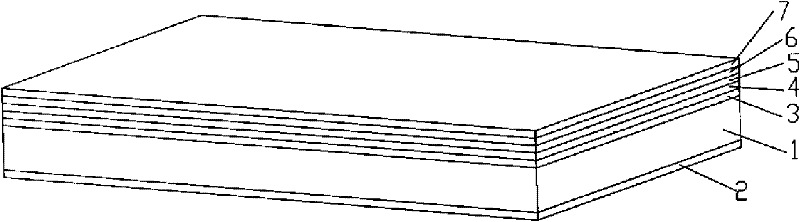

[0026] Such as figure 1 Shown is the resilient floor of the present invention, comprising a floor substrate 1, the back of the floor substrate is coated with an anion paint 2, and the surface of the floor substrate 1 is coated with an anti-shrinkage paint layer 3 formed by a flexible polymer composition. The shrinkage paint layer 3 is coated with a white primer 4, the pattern 5 is painted on the white primer 4, and the surface of the pattern 5 is coated with an anti-shrinkage paint layer 6 formed by a flexible polymer composition, and the shrinkage-resistant paint layer 6 is coated High elastic UV paint layer7.

[0027] The elastic floor of the present invention adopts pure soft solid wood with a density of 0.35 to 0.55 as the base material of the children's floor; or adopts a medium-high density laminated board with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com