Light folding-resistant thermoplastic rubber sole, thermoplastic elastomer composition and preparation method thereof

A thermoplastic rubber, thermoplastic elastomer technology, applied in the thermoplastic elastomer composition and its preparation, in the field of lightweight and folding-resistant thermoplastic rubber soles, can solve the problems of unreachable requirements, reduced tortuosity resistance, rough surface and the like, Achieve the effect of meeting production requirements, low shrinkage, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A light-weight and folding-resistant thermoplastic rubber sole, which is injection-molded with a thermoplastic elastomer composition. Specifically, the preparation method includes: adding the thermoplastic composition into a hopper of a disc injection molding machine, feeding the material automatically, and mixing and melting through a screw. , extruded into a sealed sole mold for injection molding, the screw temperature is 145-160° C., cooled, and the mold is opened to obtain a thermoplastic rubber sole.

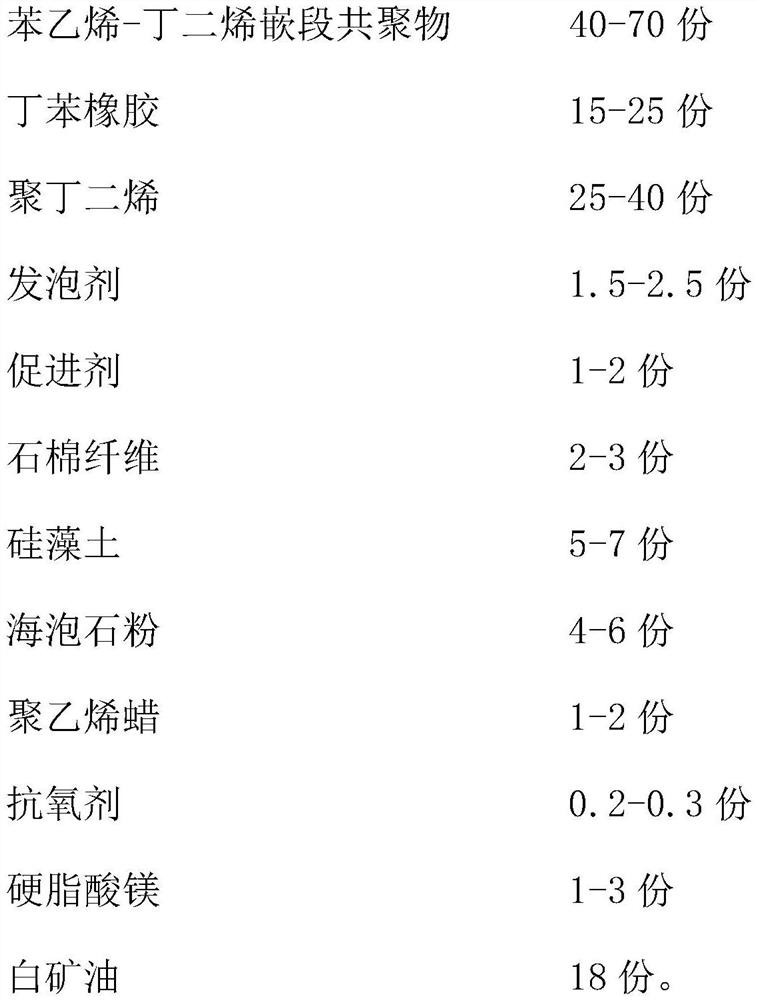

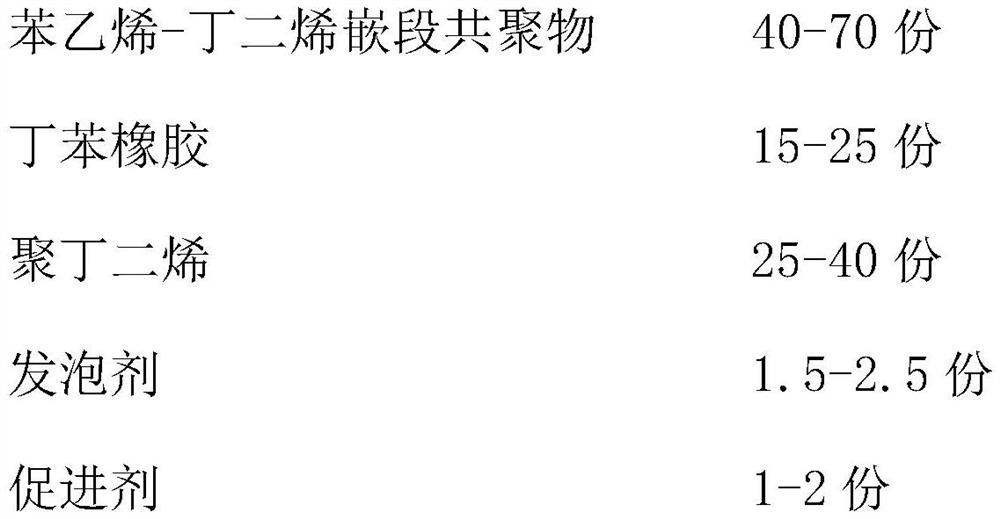

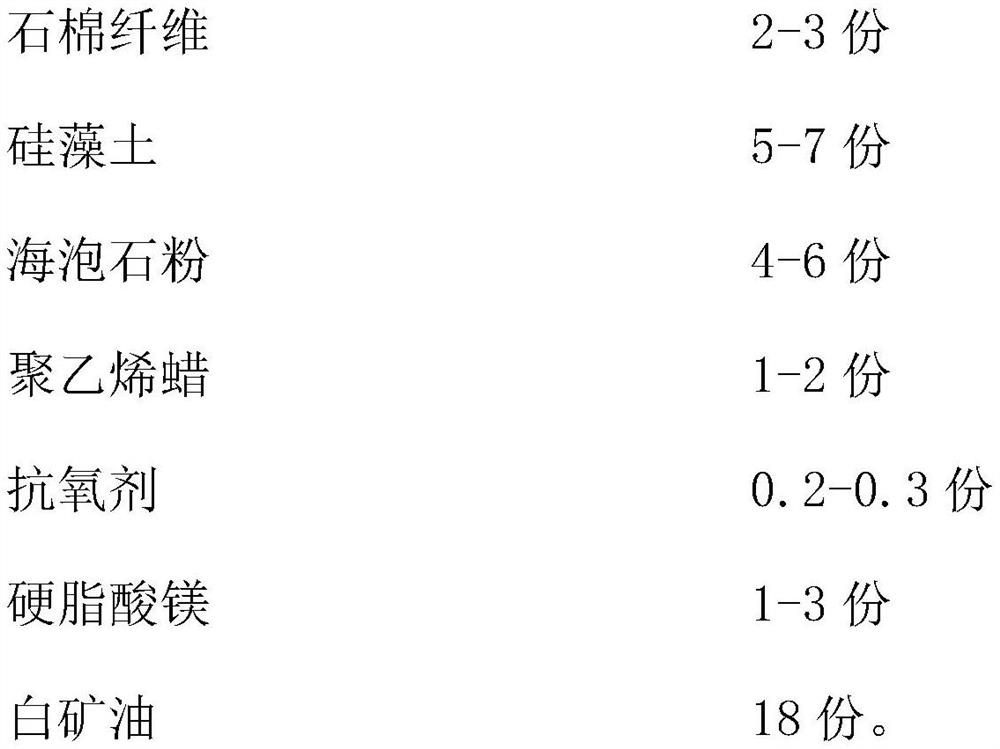

[0025] Thermoplastic elastomer composition, comprising the following raw materials in parts by weight:

[0026]

[0027] Wherein, the accelerator is composed of dibenzoyl peroxide and thiol in a mass ratio of 1:0.56-0.72.

[0028] Its preparation method comprises the following steps:

[0029] Step 1, premix the styrene-butadiene block copolymer of the required weight portion in a high-speed mixer for 10-15min, then add the styrene-butadiene rubber of the required...

Embodiment 1

[0033] A light-weight and folding-resistant thermoplastic rubber sole, which is injection-molded with a thermoplastic elastomer composition. Specifically, the preparation method includes: adding the thermoplastic composition into a hopper of a disc injection molding machine, feeding the material automatically, and mixing and melting through a screw. , extruded into a sealed sole mold for injection molding, the screw temperature was 145° C., cooled, and the mold was opened to obtain a thermoplastic rubber sole.

[0034] Thermoplastic elastomer composition, comprising the following raw materials in parts by weight:

[0035]

[0036]

[0037] Wherein, the accelerator is composed of dibenzoyl peroxide and thiol in a mass ratio of 1:0.56.

[0038] Its preparation method comprises the following steps:

[0039] Step 1, premix the styrene-butadiene block copolymer of the required weight portion in a high-speed mixer for 10 minutes, then add the styrene-butadiene rubber of the r...

Embodiment 2

[0043] A light-weight and folding-resistant thermoplastic rubber sole, which is injection-molded with a thermoplastic elastomer composition. Specifically, the preparation method includes: adding the thermoplastic composition into a hopper of a disc injection molding machine, feeding the material automatically, and mixing and melting through a screw. , extruded into a sealed sole mold for injection molding, the screw temperature is 160° C., cooled, and the mold is opened to obtain a thermoplastic rubber sole.

[0044] Thermoplastic elastomer composition, comprising the following raw materials in parts by weight:

[0045]

[0046]

[0047] Wherein, the accelerator is composed of dibenzoyl peroxide and thiol in a mass ratio of 1:0.72.

[0048] Its preparation method comprises the following steps:

[0049] Step 1, premix the styrene-butadiene block copolymer of the required weight portion in a high-speed mixer for 15 minutes, then add the styrene-butadiene rubber of the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com