Self-repairing high-elastic polyurethane/POE (Polyolefin Elastomer) composite material and preparation method thereof

A composite material, polyurethane technology, applied in the field of composite materials, to achieve the effect of enhancing self-healing performance, good stability, improving toughness and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

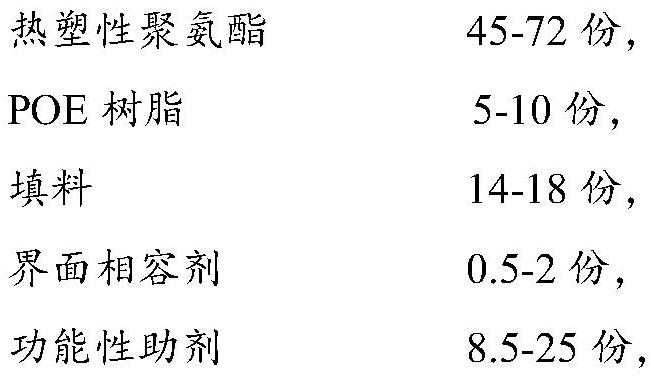

[0030] In this embodiment, the sum of each component is 100 parts, and the specific formula by weight is:

[0031] raw material Content (parts by weight) thermoplastic polyurethane 72 servings POE resin 5 servings filler 14 servings interfacial compatibilizer 0.5 servings Functional additives 8.5 servings

[0032] Among them, the thermoplastic polyurethane contains 5% of the modifier, and the modifier is tetrafluoroethylene.

[0033] The POE resin is an ethylene-octene copolymer, and the octene content in the POE resin is 20%; the filler is quartz powder, and the average particle size of the filler is 1 μm; and the interface compatibilizer is a silane coupling agent.

[0034] The functional additives in this example include 3.5 parts of antioxidants and 5 parts of heat stabilizers in parts by weight. Wherein, the antioxidant is composed of antioxidant 1010 and antioxidant 168 in a weight portion of 1:1; the thermal stabilizer...

specific Embodiment 2

[0041] In this embodiment, the sum of each component is 100 parts, and the specific formula by weight is:

[0042]

[0043]

[0044] Among them, thermoplastic polyurethane contains 25% of modifier, which is carbon fiber.

[0045] Among them, the POE resin is a copolymer of ethylene-octene, and the octene content in the POE resin is 30%; the filler is white carbon black, and the average particle size of the filler is 8 μm; the interface compatibilizer is dodecylbenzene Sodium sulfonate.

[0046]The functional additives in this embodiment include 9 parts by weight of plasticizer, 7 parts of antioxidant and 9 parts of heat stabilizer. Wherein, the plasticizer is glycerol; the antioxidant is composed of antioxidant 1010 and antioxidant 168 in a weight portion of 1:3; and the heat stabilizer is calcium stearate.

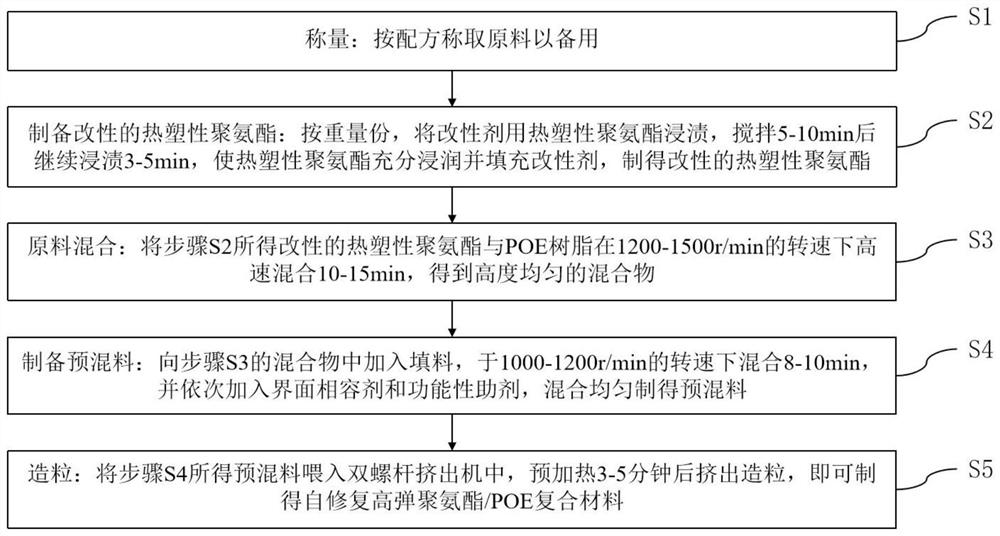

[0047] figure 1 It is a schematic flowchart of a preparation method of a self-healing high-elasticity polyurethane / POE composite material of the present inventio...

specific Embodiment 3

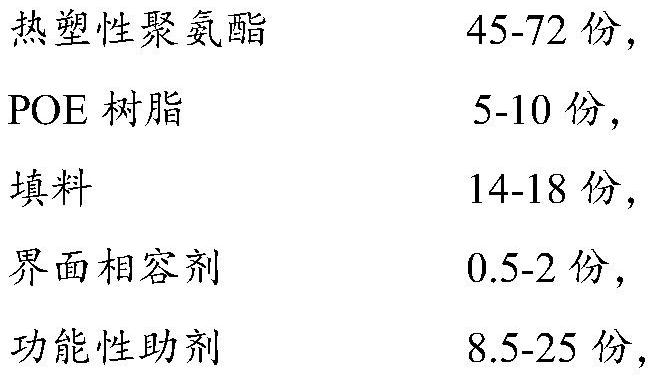

[0053] In this embodiment, the sum of each component is 100 parts, and the specific formula by weight is:

[0054]

[0055]

[0056] Wherein, the thermoplastic polyurethane contains 15% of a modifier, and the modifier is a porous nano material, and the porous nano material is nano calcium carbonate with an average particle size of 10 nm.

[0057] Among them, the POE resin is a copolymer of ethylene-octene, and the octene content in the POE resin is 25%; the filler is a mixture of quartz powder and calcium sulfate whiskers, and the average particle size of the filler is 5 μm; the interface compatibilizer It is a mixture of silane coupling agent and lauric acid.

[0058] The functional additives in this embodiment include, in parts by weight, 4 parts of plasticizer, 5 parts of antioxidant and 6 parts of heat stabilizer. Wherein, the plasticizer is polyethylene wax; the antioxidant is composed of antioxidant 1010 and antioxidant 168 in a weight portion of 1:2; and the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com