A kind of amorphous alloy reinforced racket and its preparation method

An amorphous alloy and reinforced technology, which is applied to the field of amorphous alloy reinforced rackets and their preparation, can solve the problems such as the inability to hit the ball by the athlete, the fracture of the connection between the racket shaft and the racket frame, and the asynchronous distortion and deformation. To achieve the effect of convenient control of hitting and landing points, reducing the risk of injury and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

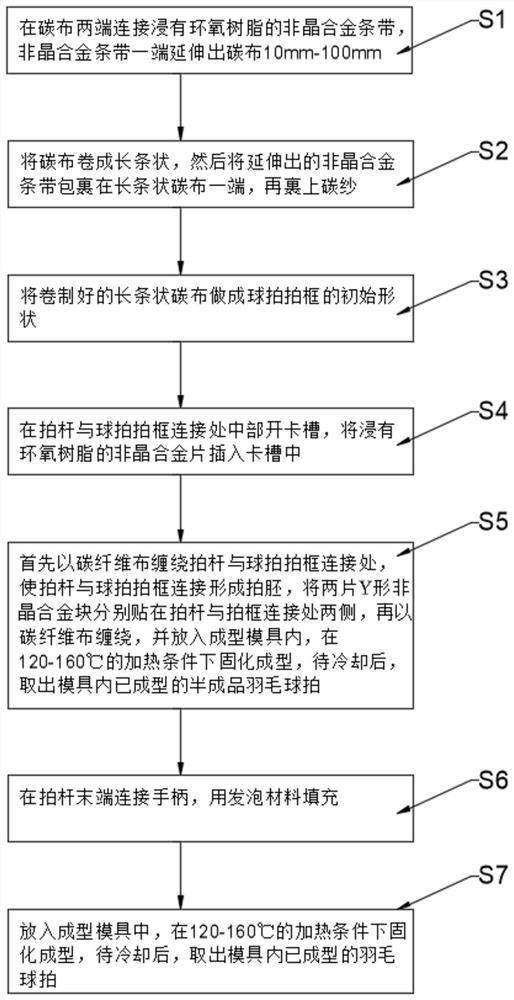

[0043] Such as figure 1 Shown, a kind of preparation method of amorphous alloy reinforced racket comprises steps:

[0044] Step S1: Connecting amorphous alloy strips impregnated with epoxy resin at both ends of the carbon cloth, one end of the amorphous alloy strip extends out of the carbon cloth by 10mm-100mm;

[0045] Step S2: Roll the carbon cloth into a long strip, then wrap the extended amorphous alloy strip on one end of the long carbon cloth, and then wrap it with carbon yarn;

[0046] Step S3: Make the rolled strip carbon cloth into the initial shape of the racket frame;

[0047] Step S4: Open a card slot in the middle of the connection between the racket shaft and the racket frame, and insert the amorphous alloy sheet impregnated with epoxy resin into the card slot;

[0048] Step S5: Wrap the joint between the racket shaft and racket frame with carbon fiber cloth, connect the racket shaft and racket frame to form a racket embryo, put it into the molding mold, solidi...

Embodiment 2

[0068] The difference between this embodiment and the first embodiment above is:

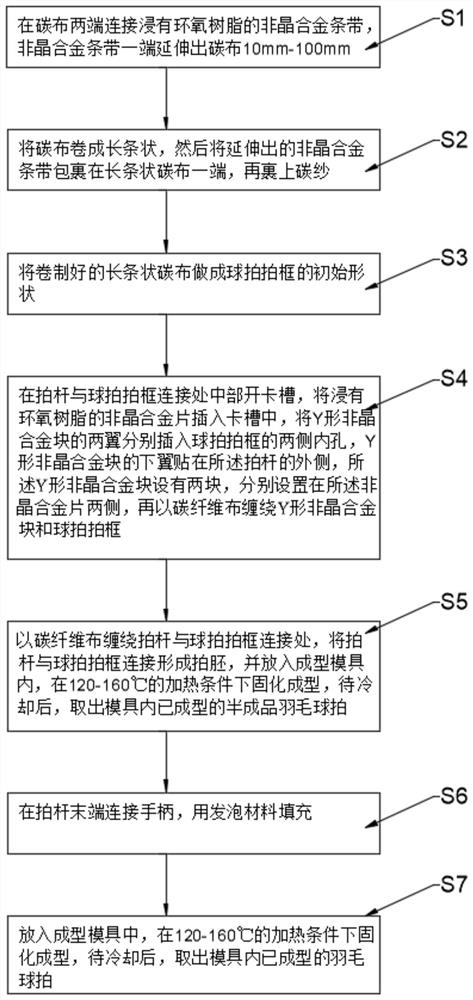

[0069] Such as figure 2 Shown, a kind of preparation method of amorphous alloy reinforced racket comprises steps:

[0070] Step S1: Connecting amorphous alloy strips impregnated with epoxy resin at both ends of the carbon cloth, one end of the amorphous alloy strip extends out of the carbon cloth by 10mm-100mm;

[0071] Step S2: Roll the carbon cloth into a long strip, then wrap the extended amorphous alloy strip on one end of the long carbon cloth, and then wrap it with carbon yarn;

[0072] Step S3: Make the rolled strip carbon cloth into the initial shape of the racket frame;

[0073] Step S4: Open a card slot in the middle of the connection between the racket shaft and the racket frame, and insert the amorphous alloy sheet impregnated with epoxy resin into the card slot;

[0074] Step S5: Wrap the joint between the racket shaft and the racket frame with carbon fiber cloth, connect the ra...

Embodiment 3

[0082] The difference between this embodiment and the above-mentioned embodiment one or embodiment two is:

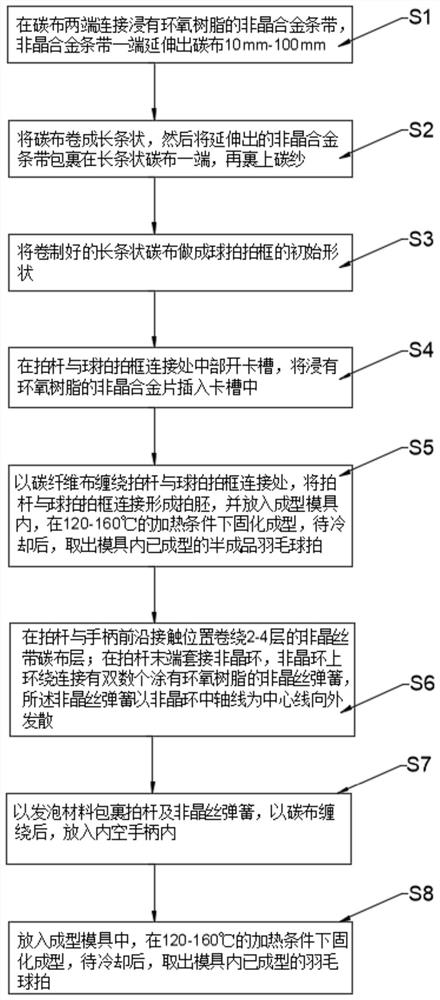

[0083] Such as image 3 Shown, a kind of preparation method of amorphous alloy reinforced racket comprises steps:

[0084] Step S1: Connecting amorphous alloy strips impregnated with epoxy resin at both ends of the carbon cloth, one end of the amorphous alloy strip extends out of the carbon cloth by 10mm-100mm;

[0085] Step S2: Roll the carbon cloth into a long strip, then wrap the extended amorphous alloy strip on one end of the long carbon cloth, and then wrap it with carbon yarn;

[0086] Step S3: Make the rolled strip carbon cloth into the initial shape of the racket frame;

[0087] Step S4: Open a card slot in the middle of the connection between the racket shaft and the racket frame, and insert the amorphous alloy sheet impregnated with epoxy resin into the card slot;

[0088] Step S5: Wrap the joint between the racket shaft and the racket frame with carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com