High-elastic TPU thin film and preparation method thereof

A film and high-elastic technology, applied in the field of high-elastic TPU film and its preparation, can solve the problems of TPU performance degradation, poor TPU hydrolysis resistance, low-density TPU foam beads, etc., to improve structural properties, easy blending and dispersion , excellent elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

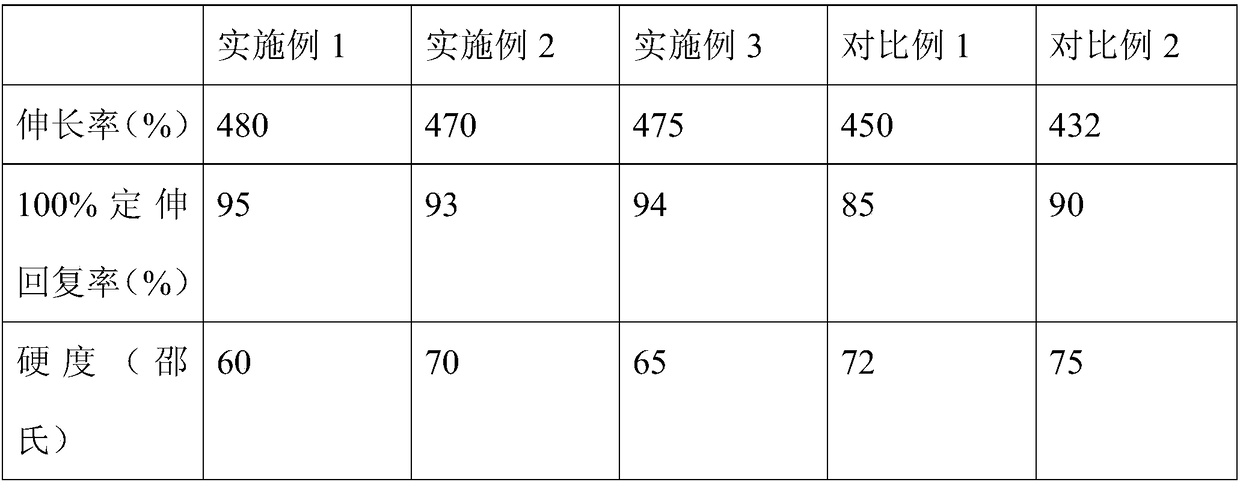

Examples

Embodiment 1

[0049] A kind of preparation method of high elasticity TPU film, it comprises the following steps:

[0050] (1) Preparation of TPU particles:

[0051] Step 1: Premix the thermoplastic polyurethane elastomer, melt viscosity regulator, filler and anti-aging agent in the high-speed mixer according to the ratio of 100:15:12, mix them evenly and put them into the extruder for melting and kneading, water Down cutting pelletizes to obtain thermoplastic polyurethane blended particles;

[0052] The thermoplastic polyurethane elastomer is a mixture of polyester type and polyether type, and the proportion of the two is 20:50; the density of the polyester type or polyether type thermoplastic polyurethane elastomer is 1.2g / cm 3 , the hardness is Shore A 70; the melt viscosity modifier is a mixture of ethylene-vinyl acetate copolymer and acrylonitrile-butadiene-styrene copolymer, and the ratio of the two is 1:10; the filler is calcium carbonate;

[0053] The second step: add the thermopl...

Embodiment 2

[0060] A kind of preparation method of high elasticity TPU film, it comprises the following steps:

[0061] (1) Preparation of TPU particles:

[0062] Step 1: Premix the thermoplastic polyurethane elastomer, melt viscosity regulator, filler and anti-aging agent in a high-speed mixer according to the ratio of 100:5:2, and put it into the extruder to melt and knead after mixing evenly. Down cutting pelletizes to obtain thermoplastic polyurethane blended particles;

[0063] The thermoplastic polyurethane elastomer is a mixture of polyester type and polyether type, and the proportion of the two is 30:70; the density of the polyester type or polyether type thermoplastic polyurethane elastomer is 1.1g / cm 3 , the hardness is Shore A 80; the melt viscosity modifier is a mixture of ethylene-vinyl acetate copolymer and acrylonitrile-butadiene-styrene copolymer, and the proportion of the two is 5:20; the filler is calcium carbonate;

[0064]The second step: add the thermoplastic polyu...

Embodiment 3

[0071] A kind of preparation method of high elasticity TPU film, it comprises the following steps:

[0072] (1) Preparation of TPU particles:

[0073] Step 1: Premix the thermoplastic polyurethane elastomer, melt viscosity regulator, filler and anti-aging agent in a high-speed mixer according to the ratio of 100:5:5, mix them evenly and put them into the extruder for melting and kneading, water Down cutting pelletizes to obtain thermoplastic polyurethane blended particles;

[0074] Described thermoplastic polyurethane elastomer is polyester type; The density of described polyester type or polyether type thermoplastic polyurethane elastomer is 1.0g / cm 3 , the hardness is Shore A 60; the melt viscosity modifier is a mixture of ethylene-vinyl acetate copolymer and acrylonitrile-butadiene-styrene copolymer, and the proportion of the two is 3:20; the filler is calcium carbonate;

[0075] The second step: add the thermoplastic polyurethane blend particles obtained in the above st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com