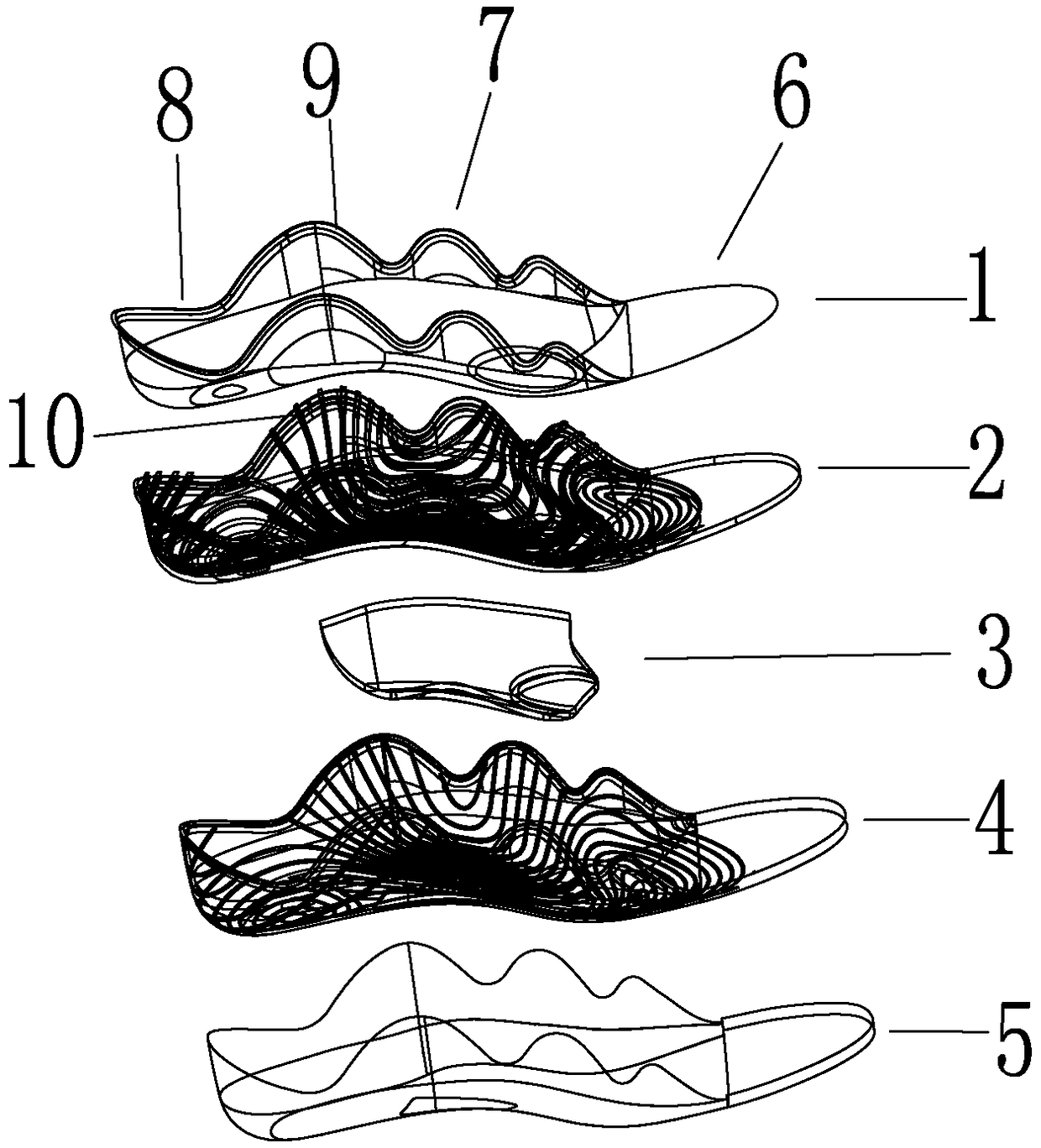

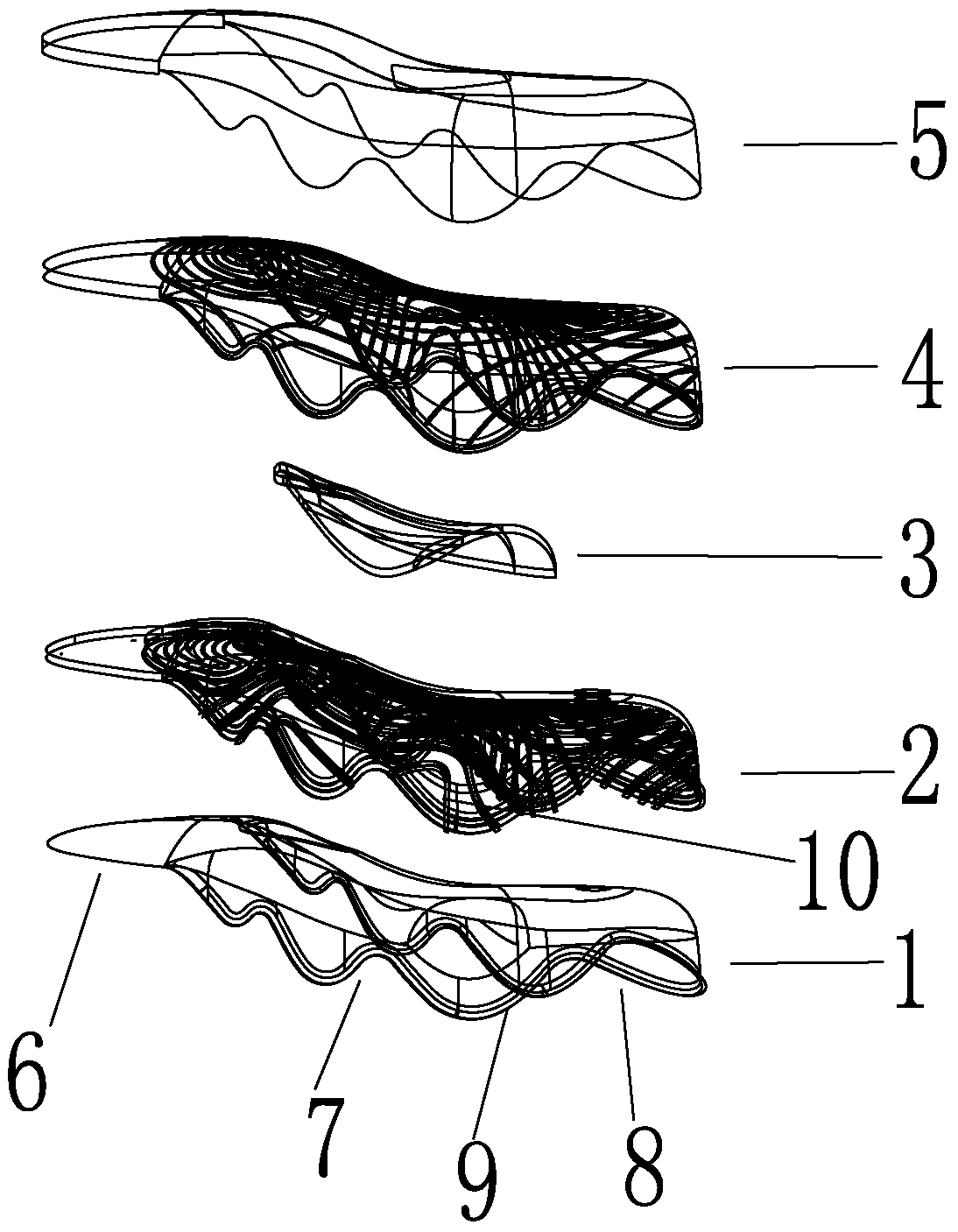

Sock-insole two-in-one insole

A two-in-one, insole technology, applied in the field of insoles, can solve the problems of small differences in hardness and achieve moderate hardness, improved comfort, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare the first nanometer bamboo charcoal fiber layer 1 and the second nanometer bamboo charcoal fiber layer 5:

[0029] Weigh the following components by weight: 6 parts of corn fiber, 70 parts of nano-bamboo charcoal fiber, 0.5 part of polypropylene fiber, 1.5 parts of nylon cotton, 1.3 parts of tocopherol, 3-heptyl-2-heptylthio-4-methyl 0.2 parts of thiazol-3-ium iodide salt, 0.8 parts of chitin, 0.9 parts of poria cocos, 0.45 parts of safflower, 0.8 parts of aloe, 0.7 parts of benzethonium chloride, and 1.5 parts of 1,2-propylene glycol. The first nanometer bamboo charcoal fiber layer 1 and the second nanometer bamboo charcoal fiber layer 5 are obtained by spinning.

[0030] Other structural components of the insole are obtained from existing materials through common methods.

Embodiment 2

[0032] Prepare the first nanometer bamboo charcoal fiber layer 1 and the second nanometer bamboo charcoal fiber layer 5:

[0033] Weigh the following components by weight:

[0034] 9 parts of corn fiber, 85 parts of nano-bamboo charcoal fiber, 4 parts of polypropylene fiber, 3.5 parts of nylon cotton, 2.8 parts of tocopherol, 3-heptyl-2-heptylthio-4-methylthiazol-3-ium iodide salt 0.45 parts, chitin 1.5 parts, Poria 1.0 parts, safflower 0.55 parts, aloe vera 1.1 parts, benzethonium chloride 1.3 parts, 1,2-propanediol 4.5 parts. The first nanometer bamboo charcoal fiber layer 1 and the second nanometer bamboo charcoal fiber layer 5 are obtained by spinning.

[0035] Other structural components of the insole are obtained from existing materials through common methods.

Embodiment 3

[0037] Prepare the first polyurethane foam layer 2 and the second polyurethane foam layer 4:

[0038] The raw materials for the preparation of the first polyurethane foam layer 2 are: 40 parts of isophorone diisocyanate; 40 parts of diphenylmethane diisocyanate; 10 parts of polyether polyol; 0.5 part of phosphoric acid; 0.5 part of N,N-dimethylcyclohexylamine; 0.5 part of crosslinking agent; 3 parts of cooling agent; 4 parts of foaming agent; 0.2 part of stabilizer; share;

[0039] The cooling agent is prepared from L-menthol and N,2,3-trimethyl-2-isopropylbutanamide at a weight ratio of 2-5:1; the foaming agent is n-heptane; The cross-linking agent is a mixture of ethylenediamine, triethylene glycol and dipropylene glycol; the stabilizer is cyclodextrin, methylcellulose, pectin, gelatin hydrolyzate, carrageenan, gellan gum, red A mixture made of alginate, alginic acid, enzymatically decomposed lecithin, casein, xanthan gum and other components; the antibacterial agent is po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com