High-grade structural steel with bainitic structure, forged part produced therefrom and method for producing a forged part

A technology of microstructure and structural steel, applied in the field of forgings, can solve problems such as inapplicability, and achieve the effect of small residual stress and small difference in hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Next, the present invention will be further described according to the examples.

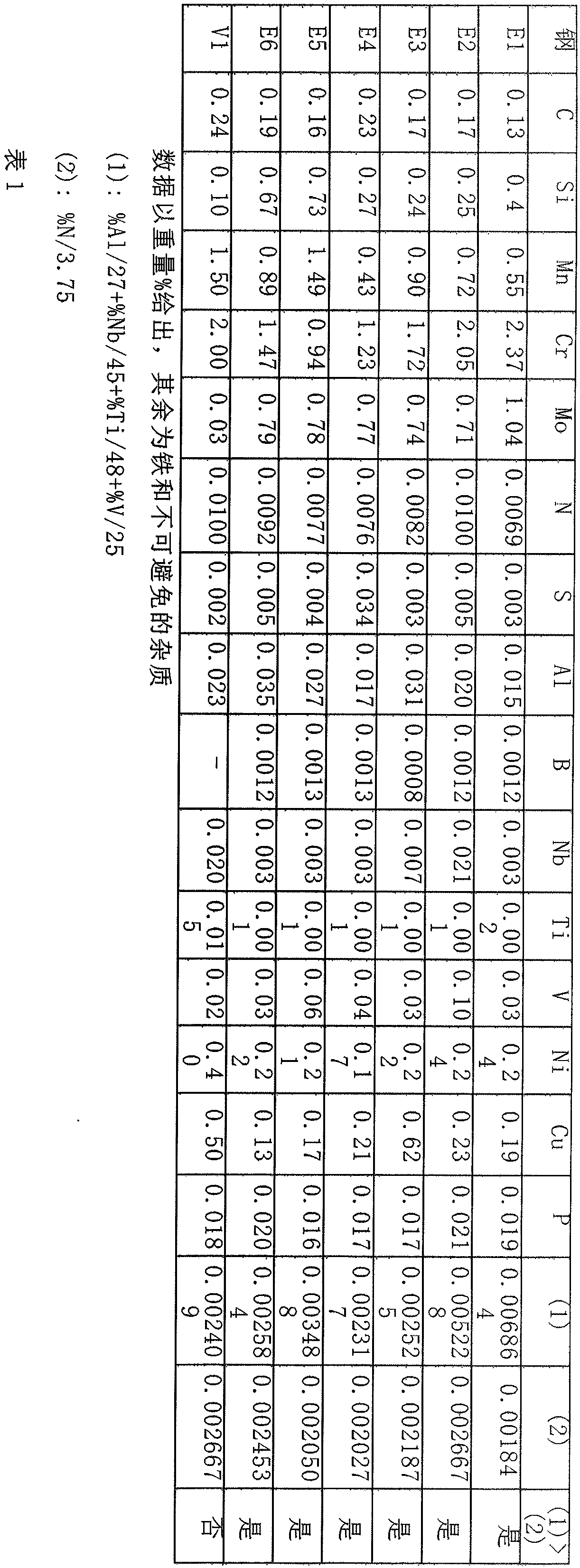

[0056] The molten steels E1-E6 according to the invention and the comparative melt V1 with the composition shown in Table 1 were melted and cast into semi-finished products which are ingots as they are usually provided for further processing in forging technology.

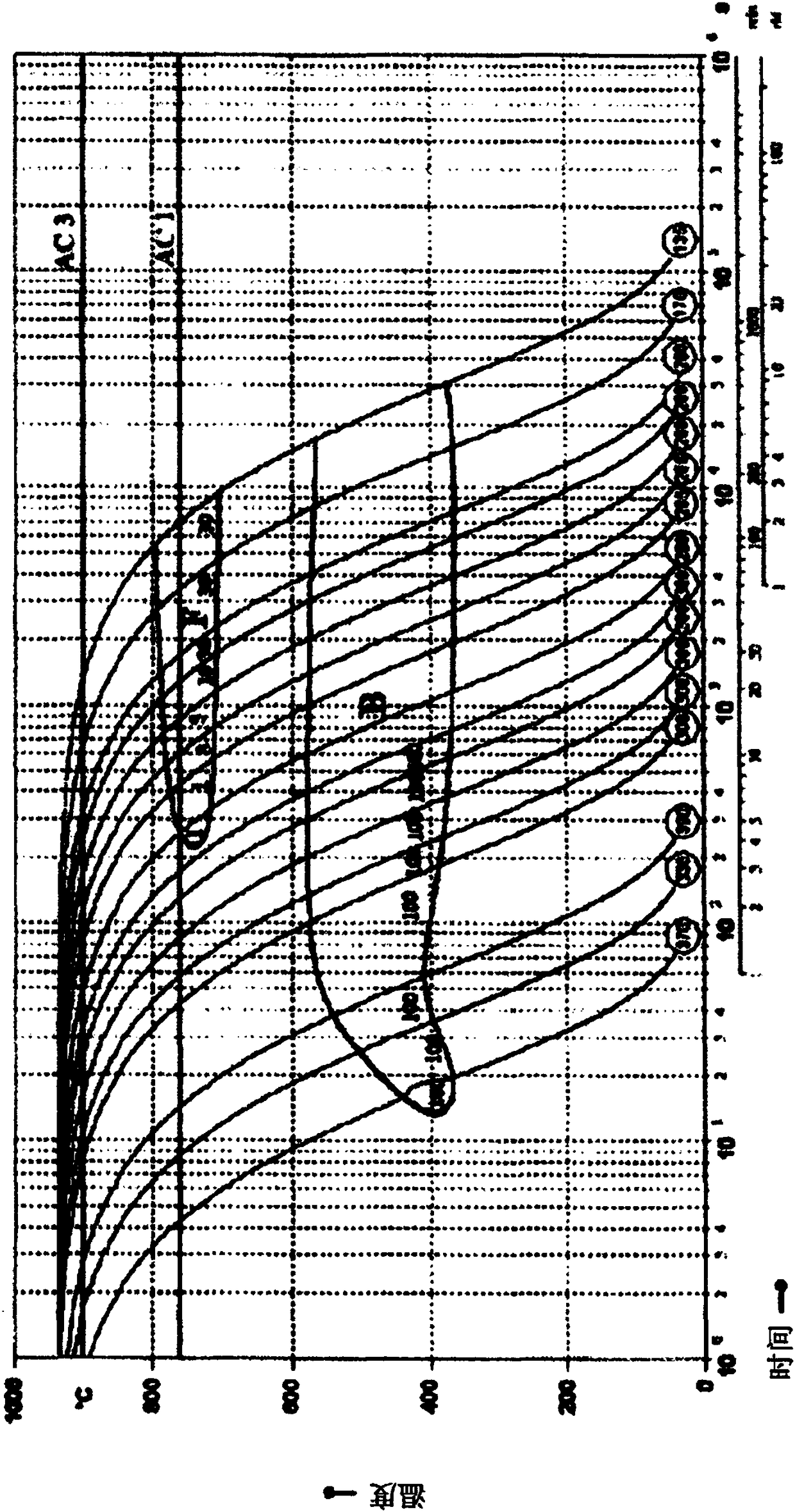

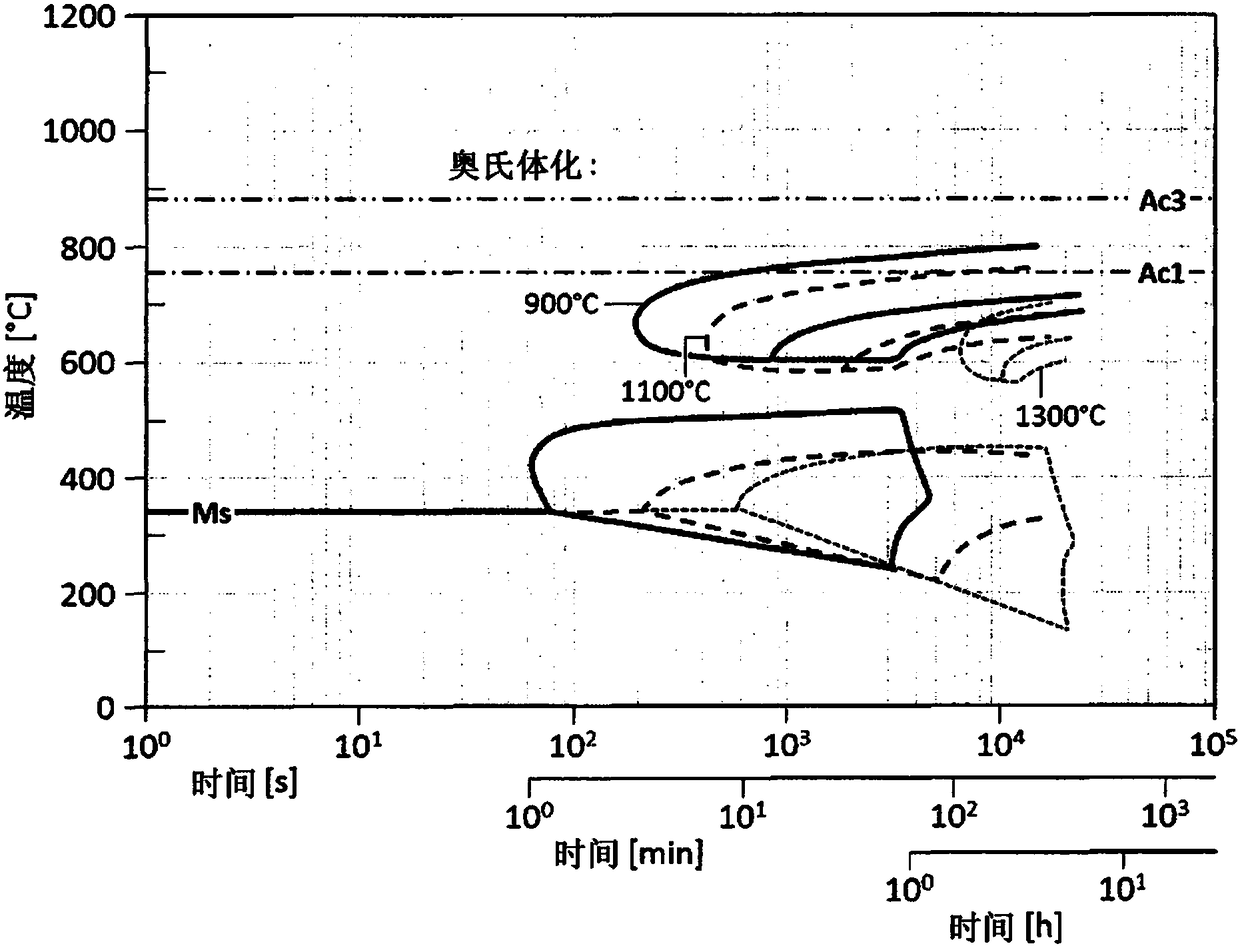

[0057] The semi-finished product is fully heated to the heating temperature for forging, and then hot-formed into a forged workpiece by die forging in a traditional way and then cooled to room temperature in air. Some of the forgings produced were subsequently tempered.

[0058] Table 2 shows the heating temperature Tw applied in the example, the t8 / 5 time necessary for passing through the critical temperature range of 800-500 °C, the temperature of the tempering treatment and the temperature of the tempering treatment if carried out Duration, as well as the proportion of bainite in the microstructure, the tensile strength Rm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com