Alloyed hot dip galvanizing double-phase steel and preparation method thereof

A technology of alloying and hot-dip galvanizing, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of inability to obtain martensitic phase, hinder the cooling process of strip steel, and reduce the cooling rate, etc. Achieve the effect of improving bendability, improving hardenability and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

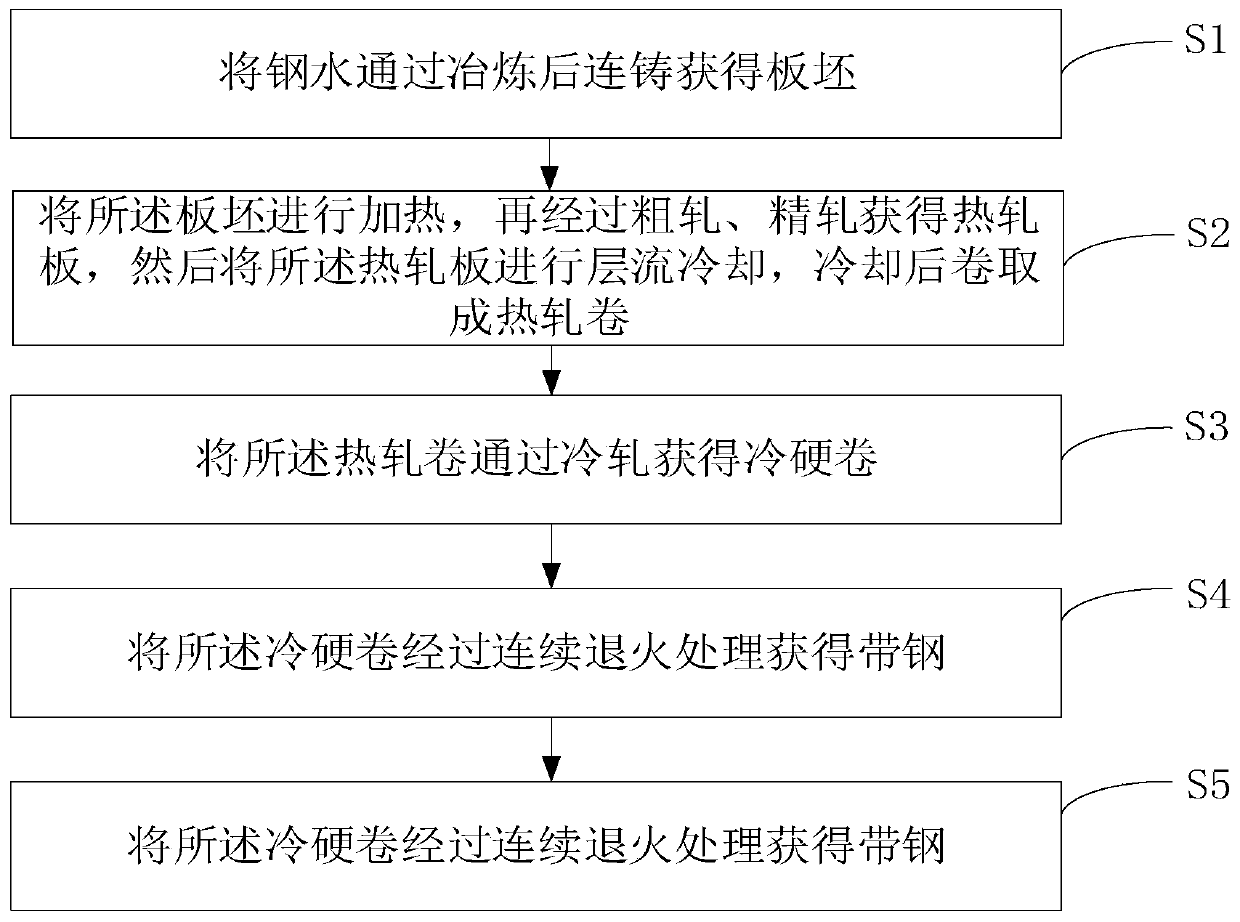

Method used

Image

Examples

Embodiment Construction

[0023] The embodiment of the present application solves the defects of the existing hot-dip galvanized dual-phase steel in terms of mechanical properties and preparation methods by providing an alloyed hot-dip galvanized dual-phase steel and a preparation method thereof.

[0024] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

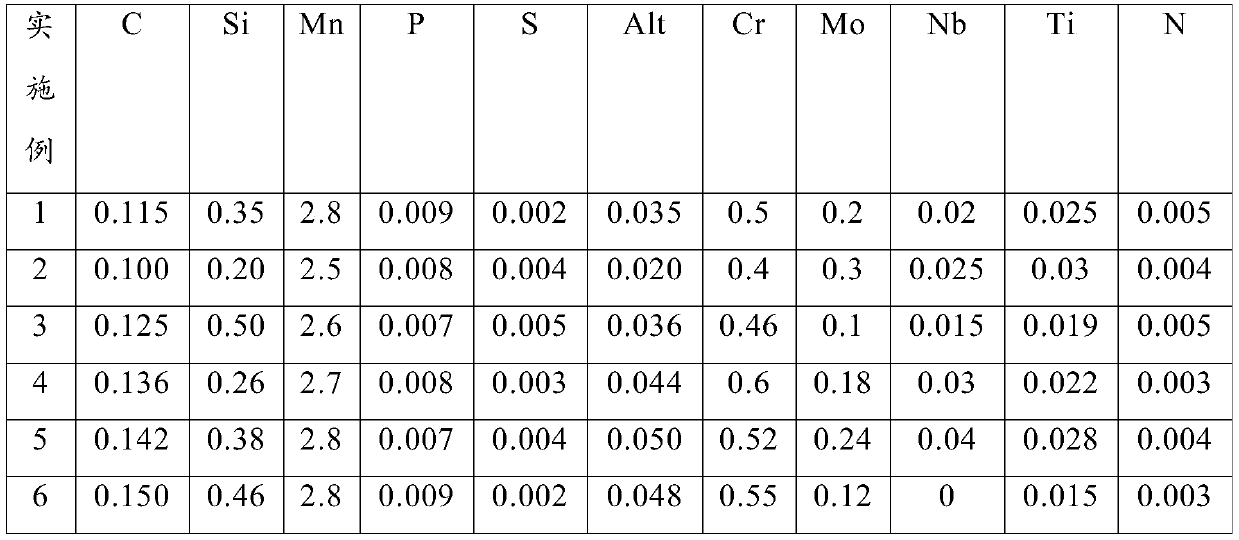

[0025] The alloyed hot-dip galvanized dual-phase steel in the embodiment of the present invention includes the following chemical components in weight percent:

[0026] Carbon C: 0.10% to 0.15%, silicon Si: 0.2% to 0.5%, manganese Mn: 2.5% to 2.9%, all aluminum Alt: 0.02% to 0.05%, titanium Ti: 0.015% to 0.03%, niobium Nb: 0.015 %~0.03%, chromium Cr: 0.4%~0.6%, molybdenum Mo: 0.1%~0.3%, phosphorus P≤0.01%, sulfur S≤0.01%, nitrogen N≤0.004%, the balance is Fe and unavoidable impurities element.

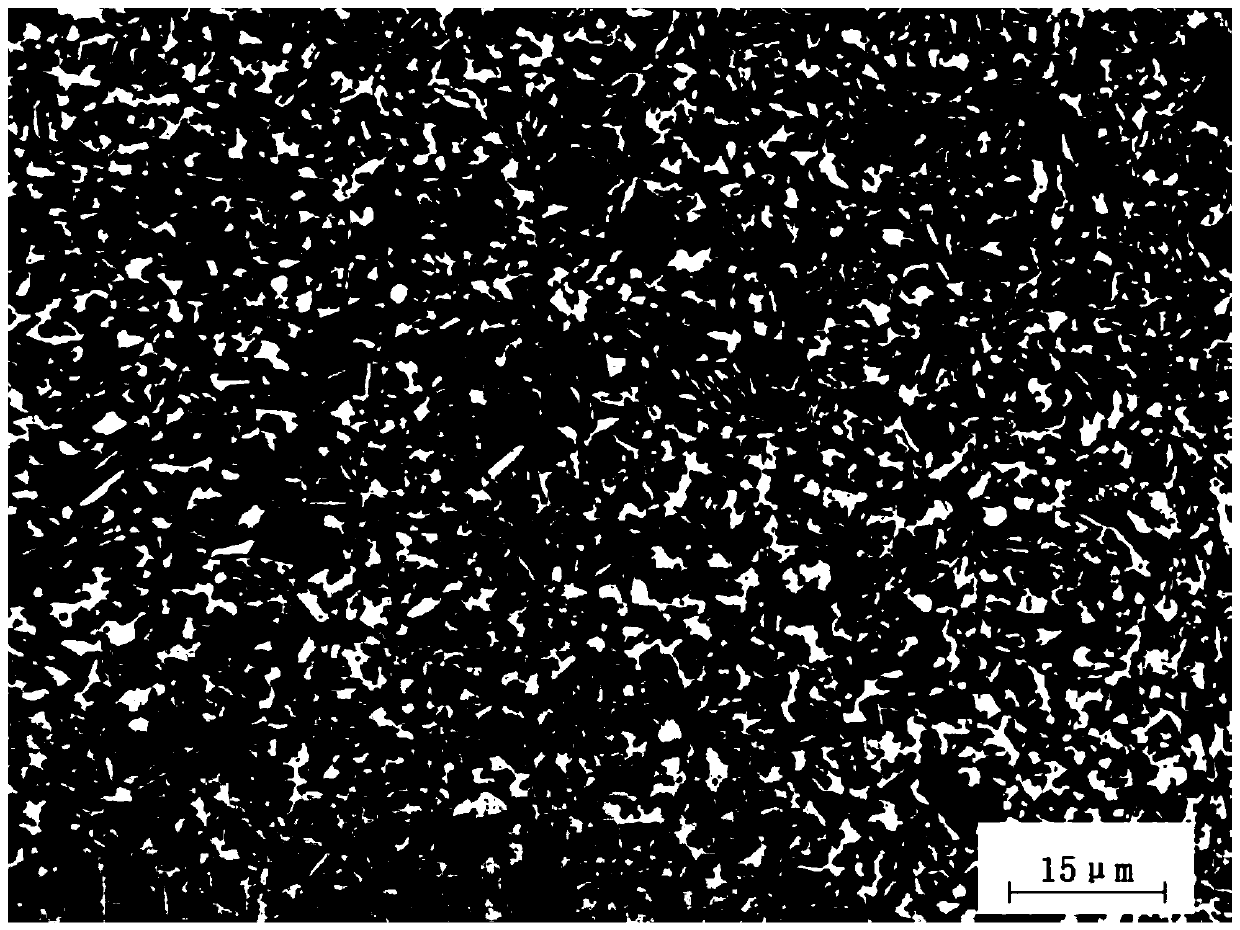

[0027] figure 2 The microstructure photo of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com