A three-dimensional mesh structure with sound-absorbing and high-elastic properties

A three-dimensional mesh, elastomer technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as uncontrollable indentation hardness, and achieve the effect of enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

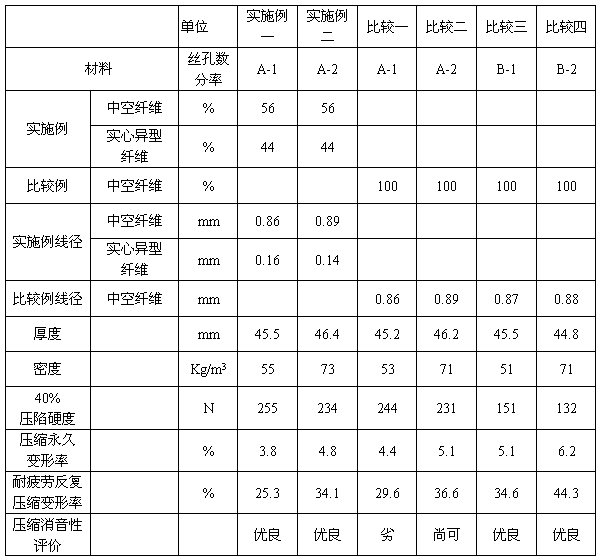

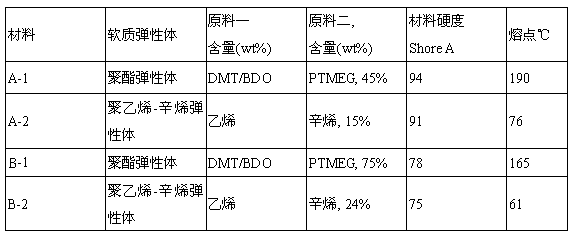

Embodiment 1

[0022] A three-dimensional network structure with sound-absorbing and high-elastic properties. The spinneret type of the structure includes hollow fibers and solid special-shaped fibers interlaced. The hole ratio of hollow fiber and solid special-shaped fiber is 56:44. The specific preparation method is that the A-1 raw material is fed into the extruder, heated to a molten state of 230°C in the extruder, and then transported to the spinneret after being metered by a metering pump. Infrared heat preservation is used between the spinneret and the water tank to avoid The thinner solid special-shaped fibers are solidified early before interlacing, and the woven fibers are compressed into a mold in warm water at 50°C to obtain a three-dimensional network structure. By controlling the traction rate, the density of the three-dimensional network structure is controlled at 55kg / m3. The compression hardness of the network structure is 255N after 40% compression, the permanent deformatio...

Embodiment 2

[0024] The specific preparation method is similar to that of Example 1. The heating temperature is set to 210°C in a molten state, and it is transported to the spinneret by a metering pump. Infrared heat insulation is used between the spinneret and the water tank to avoid early solidification of thinner solid shaped fibers before interlacing. , the woven fibers are molded in cold water at 20°C to obtain a three-dimensional network structure. By controlling the traction rate, the density of the three-dimensional network structure is controlled at 73kg / m3, and the compression hardness of the three-dimensional network structure is 234N at 40% compression. The compression set rate is 4.8%, and the hardness loss rate after fatigue-resistant repeated compression is 34.1%. When the compression test is repeated, the sound is quite small, and the noise reduction evaluation is rated as excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com