High-elasticity polyvinyl chloride fabric-art tablecloth

A polyvinyl chloride and high-elastic technology, applied in tablecloths, lamination, applications, etc., can solve the problems of softness and hand feeling inferior to fabric products, cumbersome production process, and not environmentally friendly, etc., to achieve strong three-dimensional patterns, rich colors, Eco-friendly effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

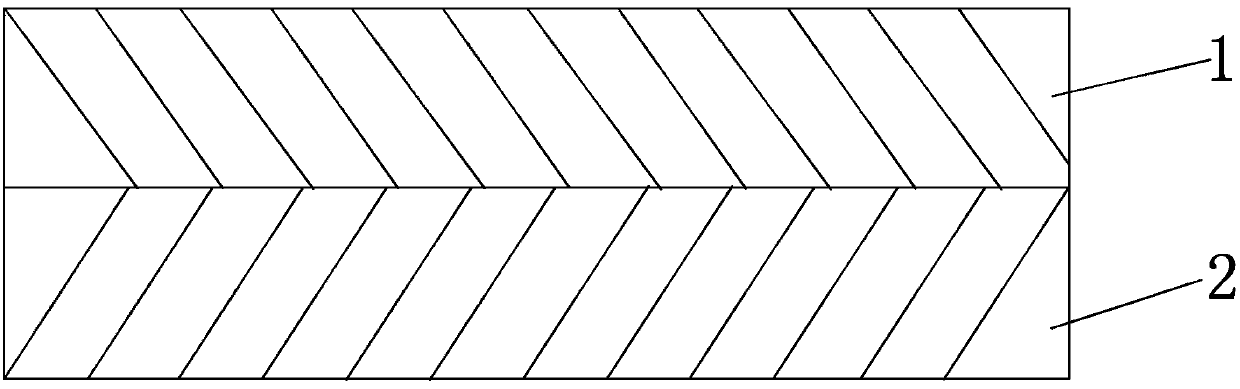

[0026] Embodiment 1: The present invention is a high-elastic polyvinyl chloride cloth art tablecloth, comprising a PVC layer 1 and a yarn layer 2, the yarn layer 2 is an environmentally friendly and degradable yarn layer 2, and the high-elastic polyvinyl chloride cloth art The tablecloth includes the following process steps:

[0027] S1: making the PVC layer 1 through a calendering process;

[0028] S2: using a PVC printing machine to print patterns on the PVC layer 1;

[0029] S3: double-sided embossing is carried out by contacting the high-temperature patterned cylinder with the yarn layer 2;

[0030] S4: The PVC layer 1 and the yarn layer 2 are hot-pressed together by using rubber wheels and embossing rollers;

[0031] S5: Rewinding.

[0032] The PVC layer 1 includes the following components: 50 parts of polyvinyl chloride resin powder, 20 parts of diisononyl phthalate, 0.5 part of stabilizer, 0.005 part of PVC color masterbatch, 3 parts of epoxy soybean oil, smooth and ...

Embodiment 2

[0038] Embodiment 2: The present invention is a high-elastic polyvinyl chloride cloth art tablecloth, comprising a PVC layer 1 and a yarn layer 2, the yarn layer 2 is an environmentally friendly and degradable yarn layer 2, and the high-elastic polyvinyl chloride cloth art The tablecloth includes the following process steps:

[0039] S1: making the PVC layer 1 through a calendering process;

[0040] S2: using a PVC printing machine to print patterns on the PVC layer 1;

[0041] S3: double-sided embossing is carried out by contacting the high-temperature patterned cylinder with the yarn layer 2;

[0042] S4: The PVC layer 1 and the yarn layer 2 are hot-pressed together by using rubber wheels and embossing rollers;

[0043]S5: Rewinding.

[0044] The PVC layer 1 includes the following components: 75 parts of polyvinyl chloride resin powder, 40 parts of diisononyl phthalate, 2.5 parts of stabilizer, 0.15 parts of PVC color masterbatch, 5 parts of epoxy soybean oil, smooth and ...

Embodiment 3

[0050] Embodiment 3: The present invention is a high-elastic polyvinyl chloride cloth art tablecloth, comprising a PVC layer 1 and a yarn layer 2, the yarn layer 2 is an environmentally friendly and degradable yarn layer 2, and the high-elastic polyvinyl chloride cloth art The tablecloth includes the following process steps:

[0051] S1: making the PVC layer 1 through a calendering process;

[0052] S2: using a PVC printing machine to print patterns on the PVC layer 1;

[0053] S3: double-sided embossing is carried out by contacting the high-temperature patterned cylinder with the yarn layer 2;

[0054] S4: The PVC layer 1 and the yarn layer 2 are hot-pressed together by using rubber wheels and embossing rollers;

[0055] S5: Rewinding.

[0056] The PVC layer 1 includes the following components: 55 parts of polyvinyl chloride resin powder, 30 parts of diisononyl phthalate, 1.5 parts of stabilizer, 0.08 parts of PVC color masterbatch, 4 parts of epoxy soybean oil, smooth and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com