Fiber with relatively high stretch rate and preparation method thereof

A stretch rate and fiber technology, applied in the field of fiber and its preparation, can solve the problems of insufficient stretch rate of elastic fibers, etc., and achieve the effect of not easy to split, strength and spinnability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

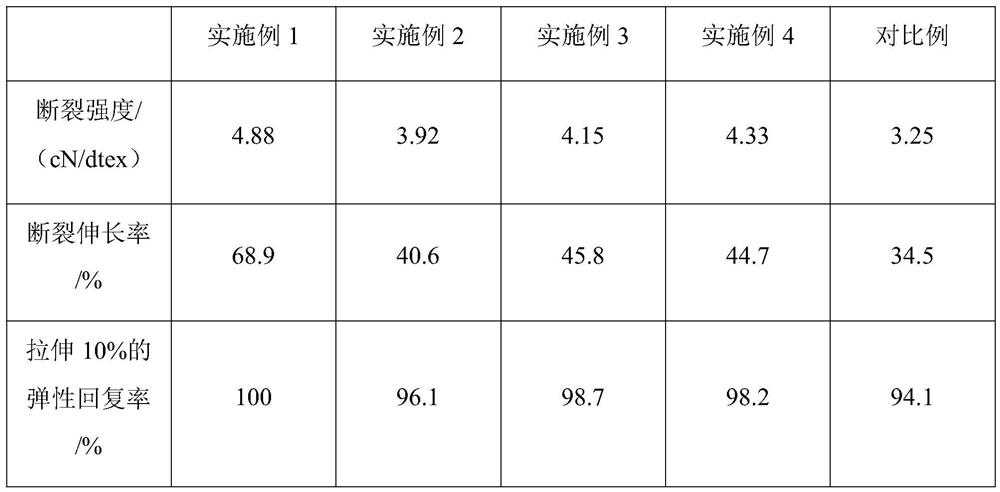

Examples

Embodiment 1

[0030] A kind of fiber with higher elongation rate, in parts by weight, mainly includes: 50 parts of polytrimethylene terephthalate chips, 50 parts of polyethylene terephthalate chips, 20 parts of esterified polysiloxane alkane, 6 parts pretreated silica, 6 parts modified linear styrene-butadiene-styrene block copolymer, and 4 parts methyl benzoylformate.

[0031]A kind of preparation method of the fiber with higher draw rate, the preparation method of the higher fiber of described draw rate mainly comprises following preparation steps:

[0032] (1) After drying the polytrimethylene terephthalate chip and the polyethylene terephthalate chip respectively, melt and extrude them respectively to obtain polytrimethylene terephthalate spinning stock and polyethylene terephthalate Glycol ester spinning material, polytrimethylene terephthalate spinning material and polyethylene terephthalate spinning material are added to the composite spinning assembly at a mass ratio of 1:1 for spin...

Embodiment 2

[0041] A fiber with higher elongation, mainly comprising: 50 parts of polytrimethylene terephthalate chips, 50 parts of polyethylene terephthalate chips, 6 parts of pretreated silicon dioxide in parts by weight , 6 parts of modified linear styrene-butadiene-styrene block copolymer and 4 parts of methyl benzoylformate.

[0042] A kind of preparation method of the fiber with higher draw rate, the preparation method of the higher fiber of described draw rate mainly comprises following preparation steps:

[0043] (1) After drying the polytrimethylene terephthalate chip and the polyethylene terephthalate chip respectively, melt and extrude them respectively to obtain polytrimethylene terephthalate spinning stock and polyethylene terephthalate Glycol ester spinning material, polytrimethylene terephthalate spinning material and polyethylene terephthalate spinning material are added to the composite spinning assembly at a mass ratio of 1:1 for spinning to obtain fibrils ;

[0044] (...

Embodiment 3

[0052] A kind of fiber with higher elongation rate, in parts by weight, mainly includes: 50 parts of polytrimethylene terephthalate chips, 50 parts of polyethylene terephthalate chips, 20 parts of esterified polysiloxane alkane, 6 parts of nano-silica, 6 parts of modified linear styrene-butadiene-styrene block copolymer and 4 parts of methyl benzoylformate.

[0053] A kind of preparation method of the fiber with higher draw rate, the preparation method of the higher fiber of described draw rate mainly comprises following preparation steps:

[0054] (1) After drying the polytrimethylene terephthalate chip and the polyethylene terephthalate chip respectively, melt and extrude them respectively to obtain polytrimethylene terephthalate spinning stock and polyethylene terephthalate Glycol ester spinning material, polytrimethylene terephthalate spinning material and polyethylene terephthalate spinning material are added to the composite spinning assembly at a mass ratio of 1:1 for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com