Composite nano antibacterial fiber gauze fabric and preparation process thereof

A technology of nano-antibacterial fibers and composite nano-materials, which is applied in the field of fiber fabrics, can solve the problems of short use time of antibacterial fabrics and unsatisfactory antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

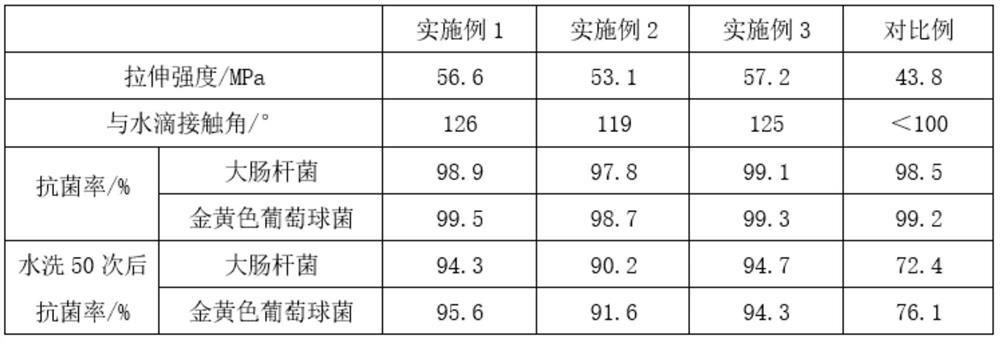

Embodiment 1

[0042] A composite nano antibacterial fiber gauze fabric, the gauze fabric is woven from warp yarns and weft yarns; the warp yarns are blended from antibacterial fibers and cotton fibers; the weft yarns are blended from bamboo fibers and polyurethane fibers;

[0043] The antibacterial fiber is obtained by modifying polyester fiber with composite nano material.

[0044] The weight ratio of the antibacterial fiber to the cotton fiber in the warp is 0.6:1.

[0045] The weight ratio of bamboo fiber and polyurethane fiber in the weft yarn is 1:0.1.

[0046] The composite nanomaterial is composed of organic copper / bismuth nano microspheres and natural antibacterial substances coated on the surface of the organic copper / bismuth nano microspheres.

[0047] The natural antibacterial substance is hinokitiol.

[0048] The preparation method of described organocopper / bismuth nano microspheres is:

[0049] S1. Weigh copper acetylacetonate and add it to N,N-dimethylformamide, stir until ...

Embodiment 2

[0073] A composite nano antibacterial fiber gauze fabric, the gauze fabric is woven from warp yarns and weft yarns; the warp yarns are blended from antibacterial fibers and cotton fibers; the weft yarns are blended from bamboo fibers and polyurethane fibers;

[0074] The antibacterial fiber is obtained by modifying polyester fiber with composite nano material.

[0075] The weight ratio of the antibacterial fiber to the cotton fiber in the warp is 0.2:1.

[0076] The weight ratio of bamboo fiber and polyurethane fiber in the weft yarn is 1:0.05.

[0077] The composite nanomaterial is composed of organic copper / bismuth nano microspheres and natural antibacterial substances coated on the surface of the organic copper / bismuth nano microspheres.

[0078] The natural antibacterial substance is hinokitiol.

[0079] The preparation method of described organocopper / bismuth nano microspheres is:

[0080] S1. Weigh copper acetylacetonate and add it to N,N-dimethylformamide, stir until...

Embodiment 3

[0104] A composite nano antibacterial fiber gauze fabric, the gauze fabric is woven from warp yarns and weft yarns; the warp yarns are blended from antibacterial fibers and cotton fibers; the weft yarns are blended from bamboo fibers and polyurethane fibers;

[0105] The antibacterial fiber is obtained by modifying polyester fiber with composite nano material.

[0106] The weight ratio of the antibacterial fiber to the cotton fiber in the warp is 1:1.

[0107] The weight ratio of bamboo fiber and polyurethane fiber in the weft yarn is 1:0.2.

[0108] The composite nanomaterial is composed of organic copper / bismuth nano microspheres and natural antibacterial substances coated on the surface of the organic copper / bismuth nano microspheres.

[0109] The natural antibacterial substance is hinokitiol.

[0110] The preparation method of described organocopper / bismuth nano microspheres is:

[0111] S1. Weigh copper acetylacetonate and add it to N,N-dimethylformamide, stir until comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com