Patents

Literature

30results about How to "Self-catalyzed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of surface-modified ZTA ceramic particle reinforced steel based composite material

ActiveCN109706438AEnhanced interface bindingHigh yield strengthLiquid/solution decomposition chemical coatingAl powderNi cr alloy

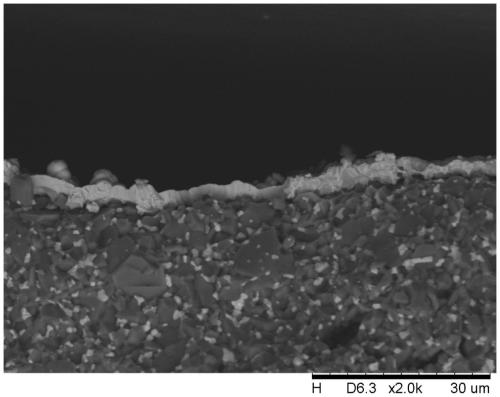

The invention discloses a preparation method of a surface-modified ZTA ceramic particle reinforced steel based composite material. The preparation method comprises the steps that sensitization and activation treatment is conducted on ZTA particles, surface plating is conducted, the ZTA particles are plated with nickel and chromium to achieve surface metallization by controlling the components andthe proportion of a plating solution, the ZTA particles plated with Cr-Ni layers, Ni-Cr alloy powder and Al powder are put into a graphite mold to be made into a preform which is of a honeycomb structure through vacuum sintering, molten metal is poured by adopting a casting infiltration method, and after cooling is conducted, the reinforced steel based composite material is obtained. According tothe preparation method of the surface-modified ZTA ceramic particle reinforced steel based composite material, the ZTA particles are plated with nickel and chromium to achieve surface metallization bycontrolling the components and the proportion of the plating solution, the wet problem with a metal matrix is solved, and then the mechanical property of the composite material is improved; and meanwhile, the technology is easy to operate, the cost is reduced to a large extent, no toxicity or pollution is generated, the great potential on increasing the economic benefit and the social benefit isachieved, and the good prospect of being applied to the harsh abrasive wear condition is achieved.

Owner:XI AN JIAOTONG UNIV +1

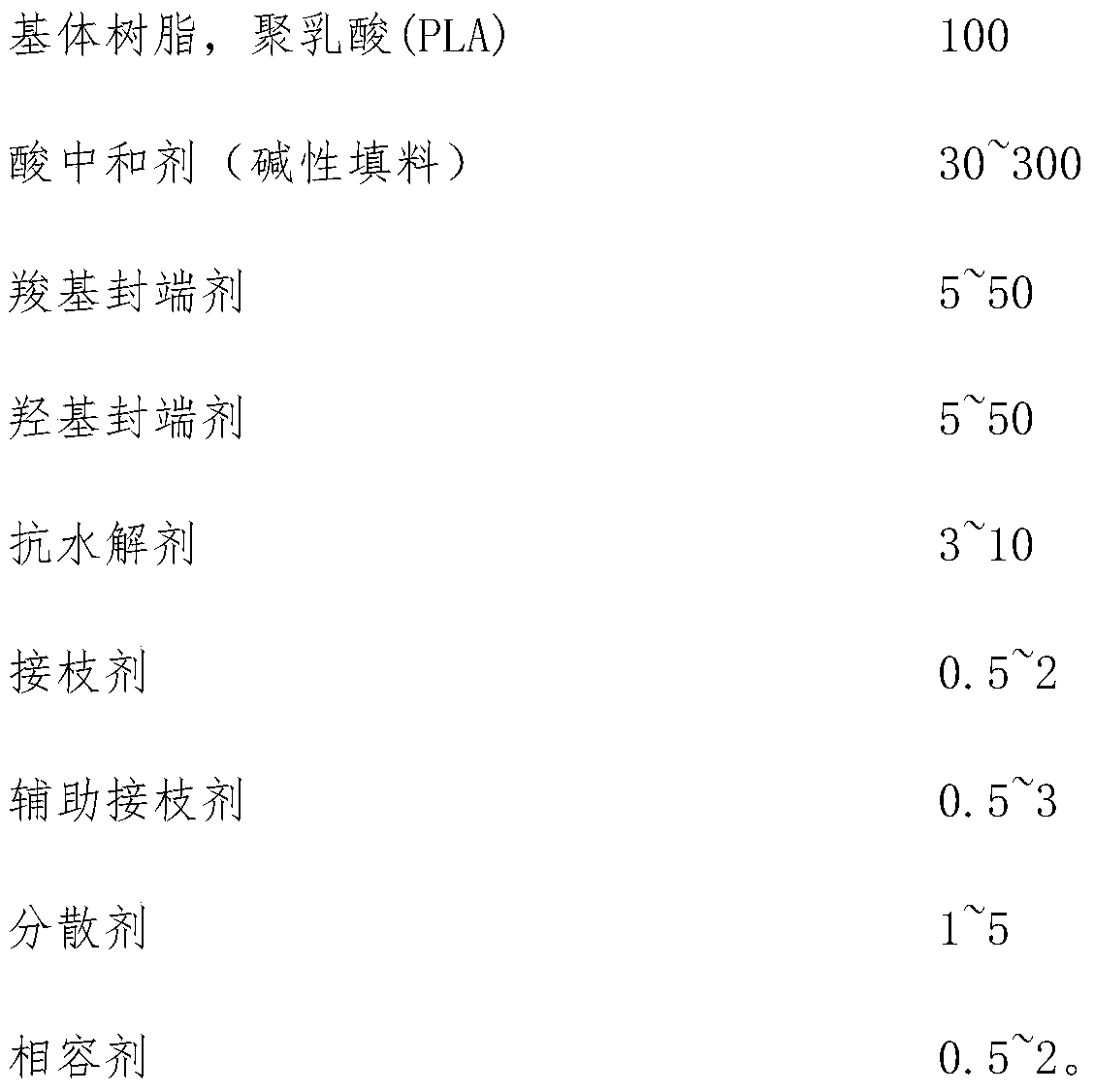

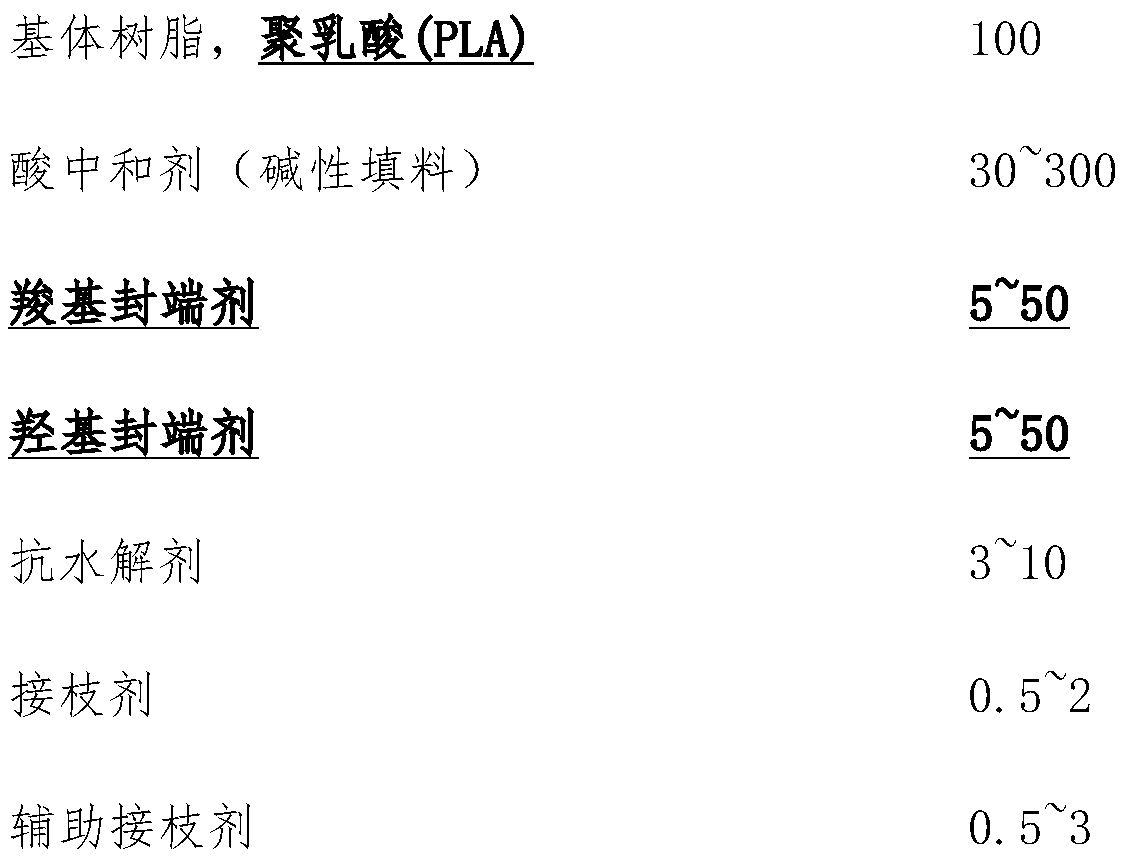

Master batch for improving durability of polyglycolide (PGA) and preparation method of master batch

The invention relates to a master batch for improving durability of polyglycolide (PGA). The master batch is prepared from the following components in parts by mass: 100 parts of matrix resin, 30-300parts of an acid neutralizer, 5-50 parts of a carboxyl end-capping reagent, 5-50 parts of a hydroxyl end-capping reagent, 3-10 parts of an anti-hydrolysis agent, 0.5-2 parts of a grafting agent, 0.5-3parts of an auxiliary grafting agent, 1-5 parts of a dispersing agent and 0.5-2 parts of a compatilizer. The master batch for improving the durability of polyglycollide has the characteristics of convenience in processing and use and small addition amount, can be mixed with polyglycollide particles for injection molding or extrusion processing, and has an excellent effect in improving the durability and shelf life of a polyglycollide product in a room-temperature environment.

Owner:JIANGSU JINJU ALLOY MATERIAL

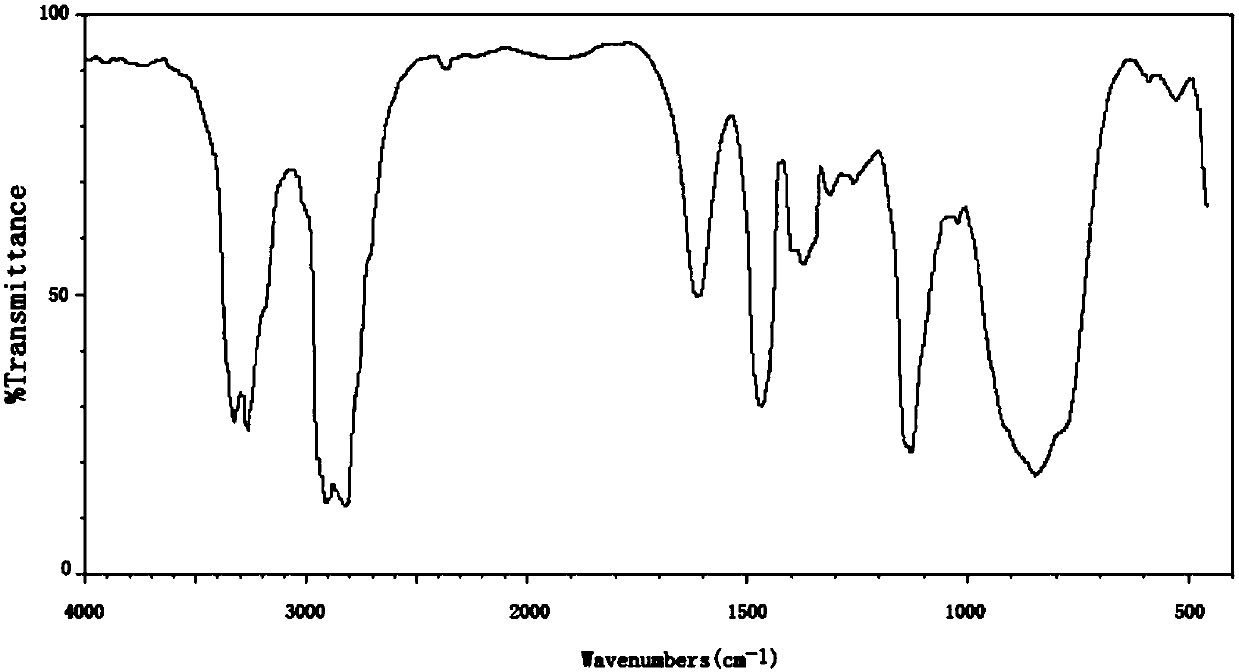

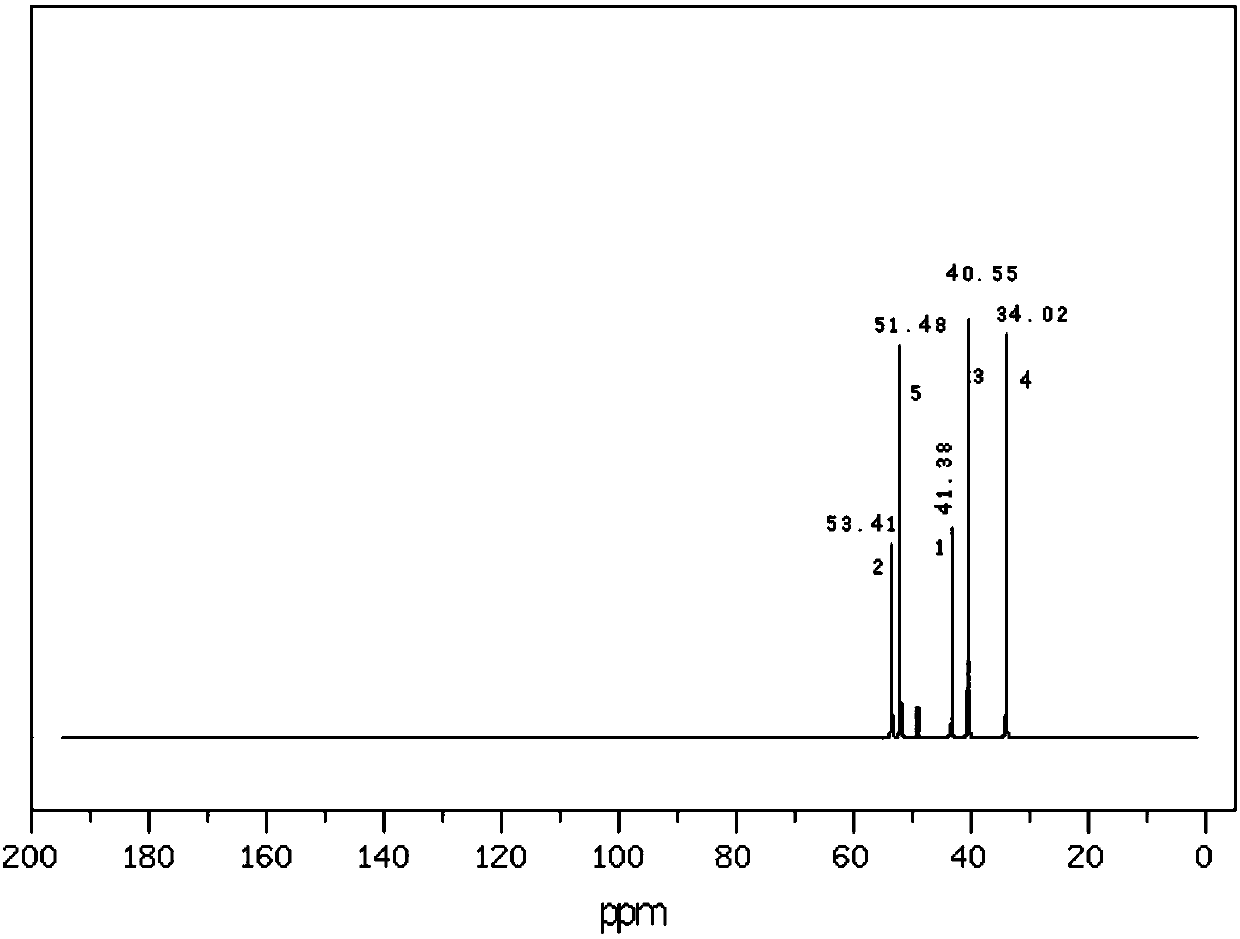

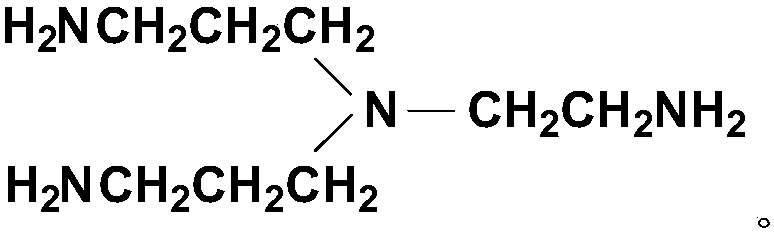

Phenol formaldehyde amine epoxy curing agent and preparation method thereof

ActiveCN105646845AHigh hardnessHigh strengthOrganic compound preparationEpoxy resin adhesivesTemperature resistanceChemistry

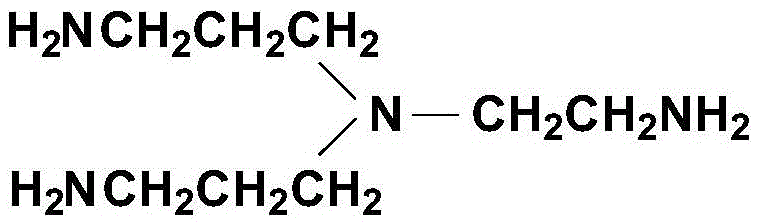

The invention discloses a phenol formaldehyde amine epoxy curing agent which is prepared from the following raw materials in parts by weight: 30-60 parts of N,N-di(3-aminopropyl)ethylenediamine, 5-30 parts of formyl compound and 20-60 parts of phenolic group compound. The combination of the curing agent and the epoxy resin has the advantages of very high scratch resistance, high wear resistance and high temperature resistance.

Owner:雅安市弘利展化工有限公司

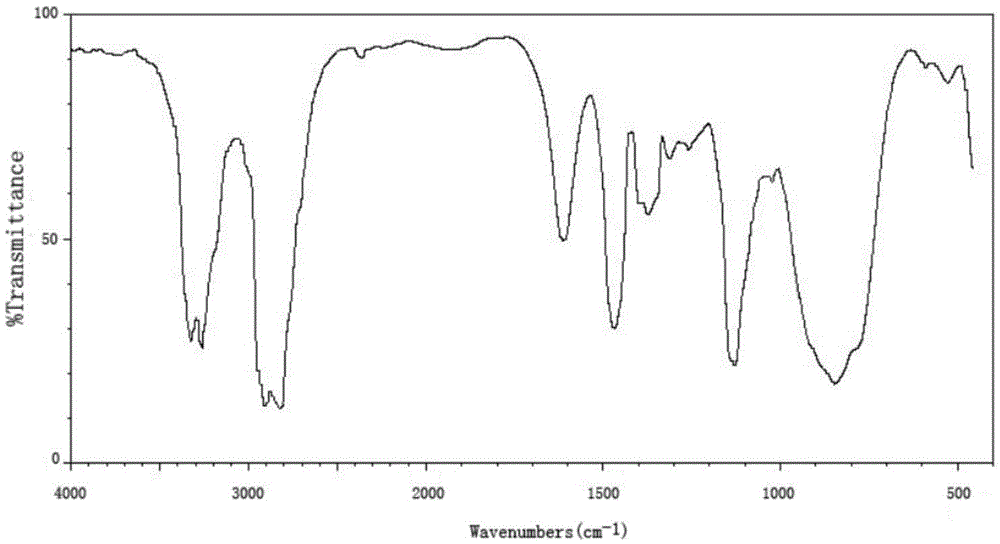

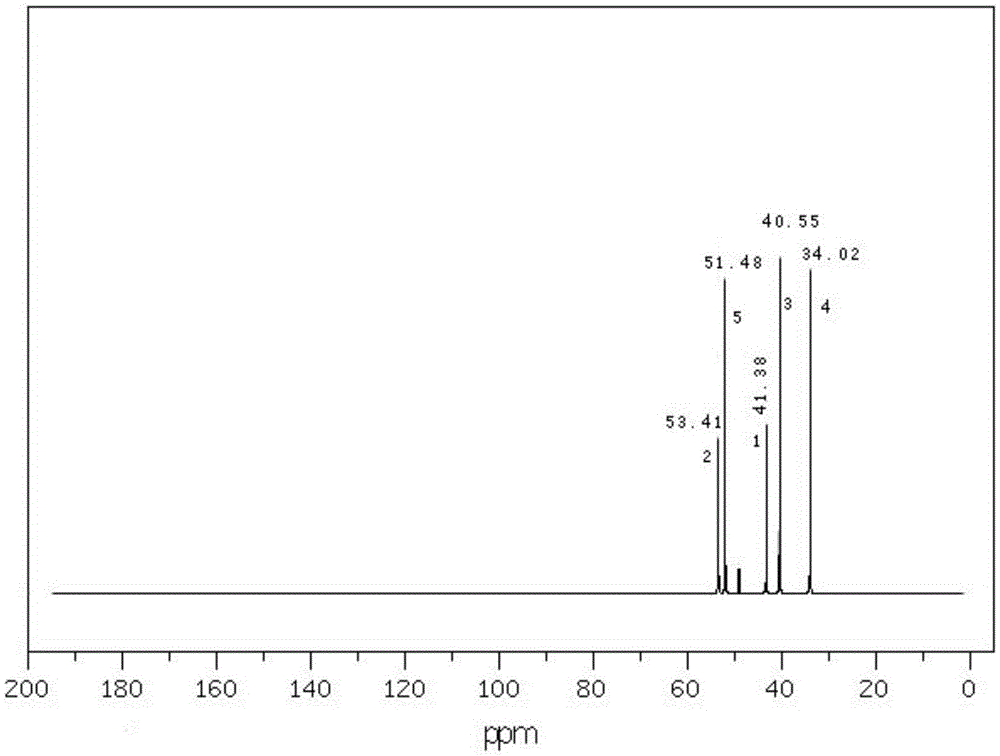

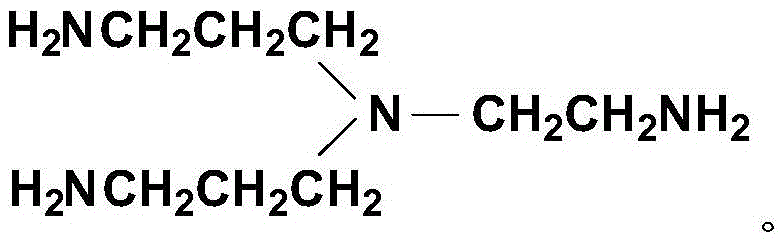

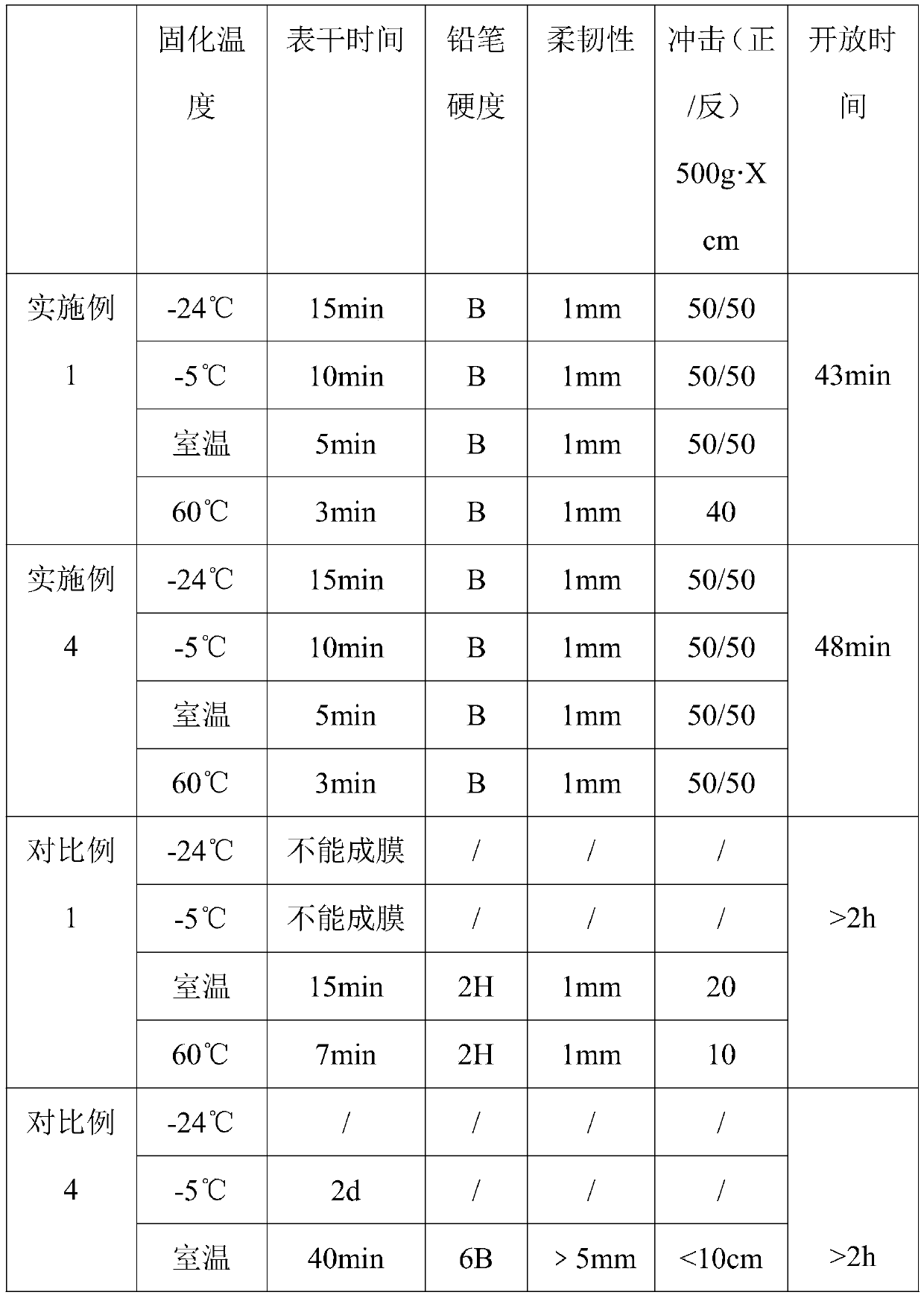

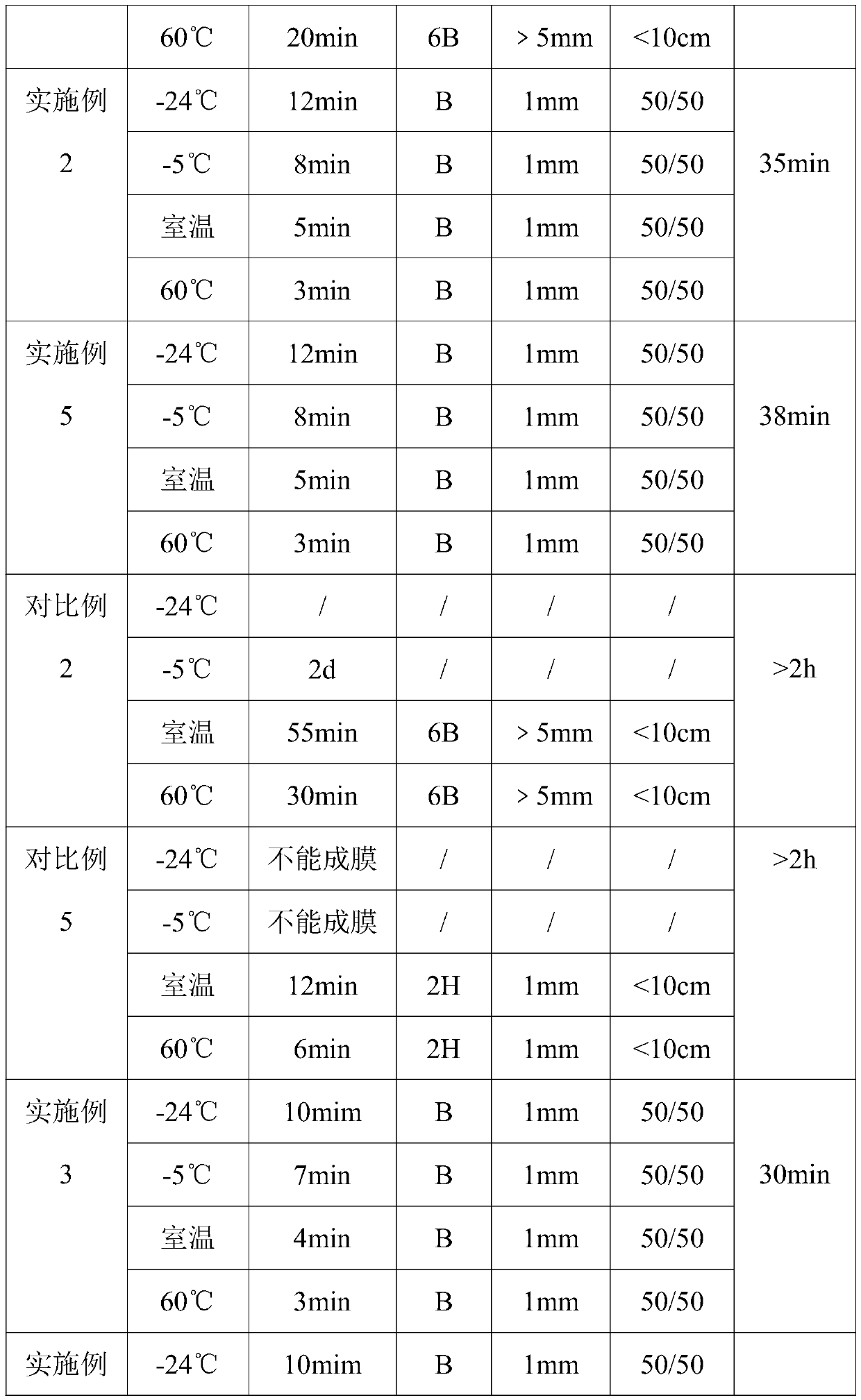

Epoxy resin curing agent, synthesis method and curing method

ActiveCN105646846AHigh activityHigh catalytic efficiencyCarboxylic acid nitrile preparationOrganic compound preparationEpoxySynthesis methods

The invention provides an epoxy resin curing agent, a synthesis method and a curing method and belongs to the field of curing agent products. The epoxy resin curing agent is N,N'-bis(3-aminopropyl) ethanediamine and is synthesized from raw materials including ethanediamine, ketone, acrylonitrile and the like through multi-step reactions. The epoxy resin curing agent has high curing strength, wear resistance and scratch resistance and has a higher curing speed at a low temperature, a surface after curing is bright, is not prone to oxidation and has excellent yellowing resistance. The synthesis method of the epoxy resin curing agent is simple in process and convenient to control.

Owner:雅安市弘利展化工有限公司

Epoxy curing agent

The invention relates to a waterborne epoxy curing agent for waterborne epoxy resin as well as a preparation method and an application method of the waterborne epoxy curing agent. Mercapto and amino groups are taken as curing reaction groups of the waterborne epoxy curing agent, a curing agent structure comprises a tertiary amine structure which can be dispersed or dissolved in water. Compared with a polyamine curing agent, the prepared quick-drying curing agent is faster in curing and better in impact resistance and can realize low-temperature curing; compared with a thiol curing agent, the prepared quick-drying curing agent is faster in curing, and hardness, bending performance and impact resistance of a film are improved remarkably.

Owner:SUZUKA INTERNATIONAL (SHANGHAI) CO LTD

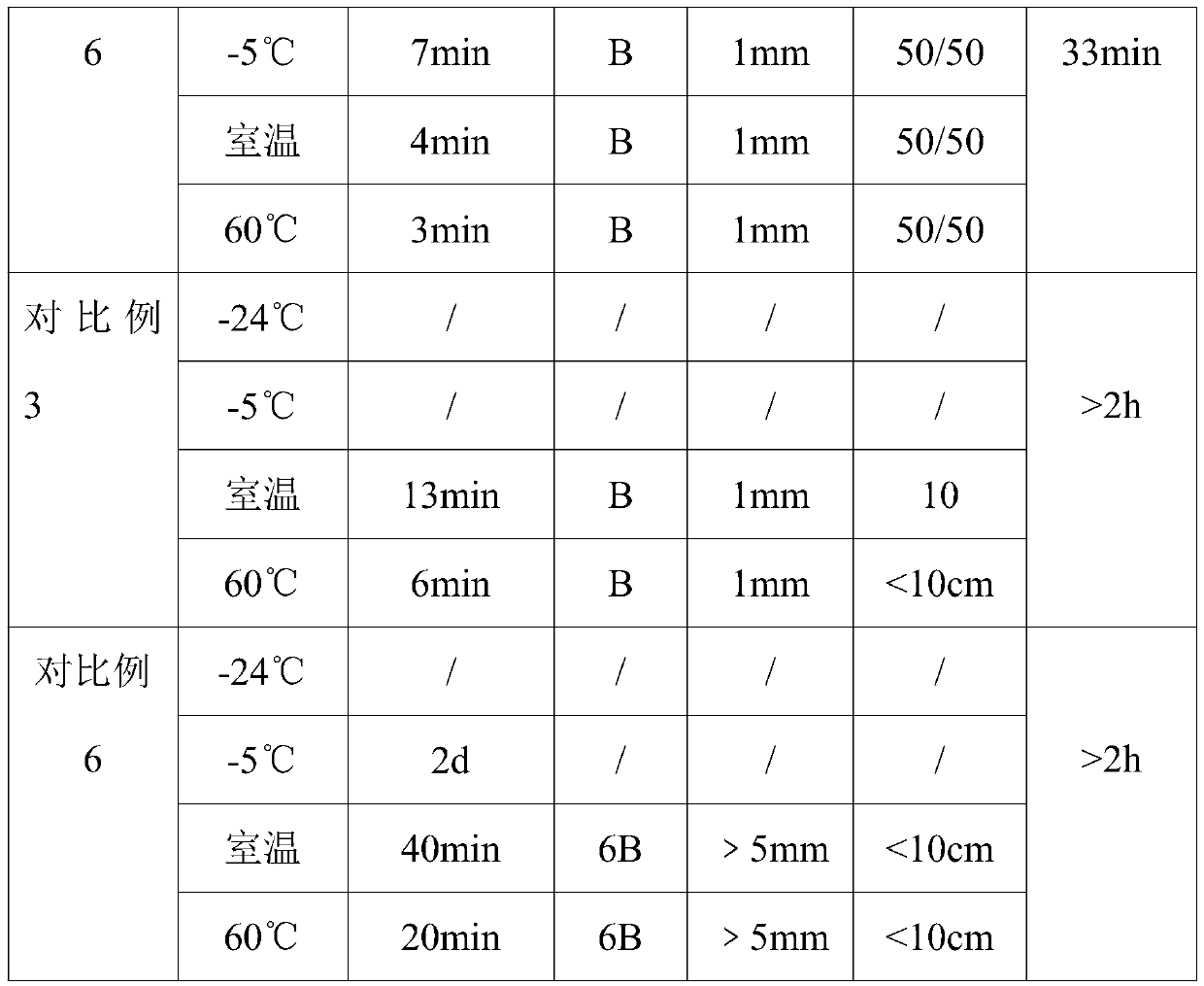

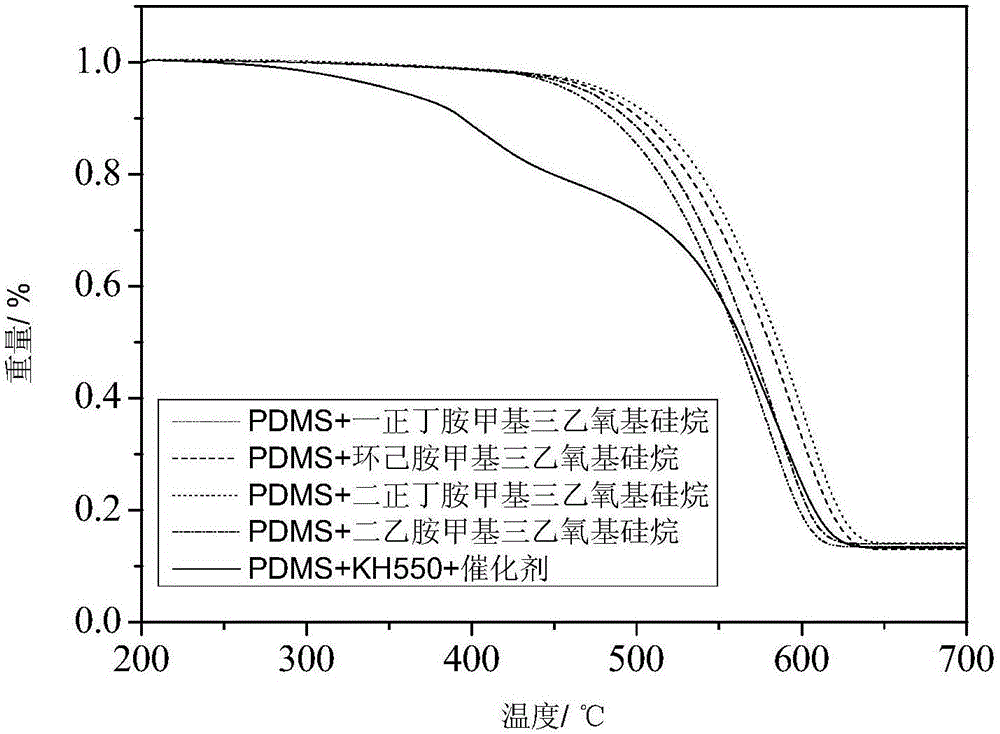

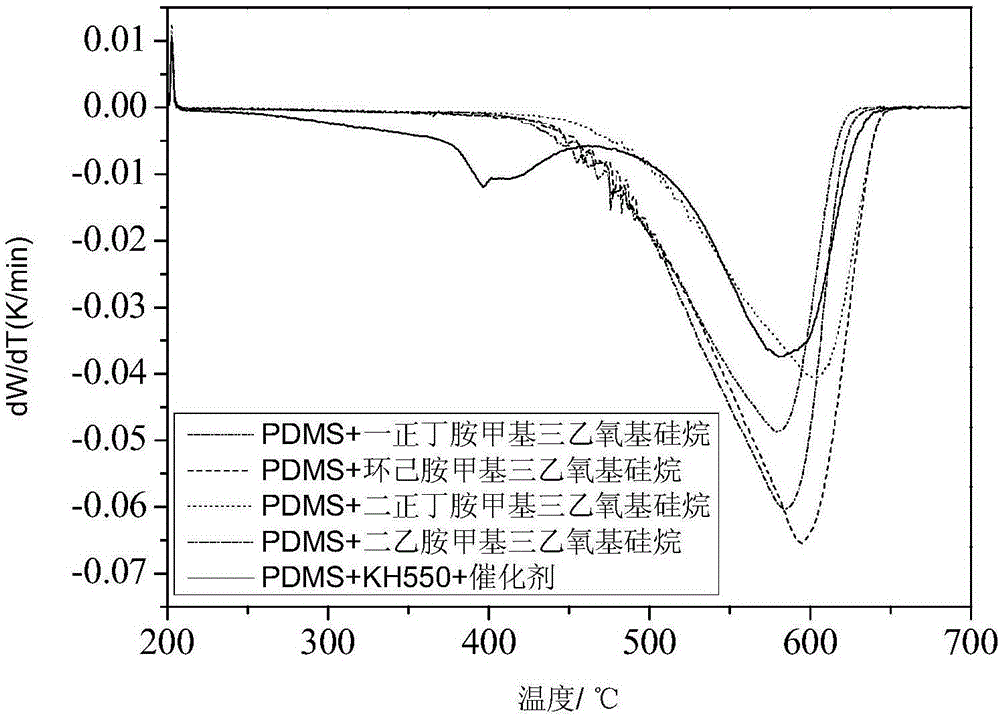

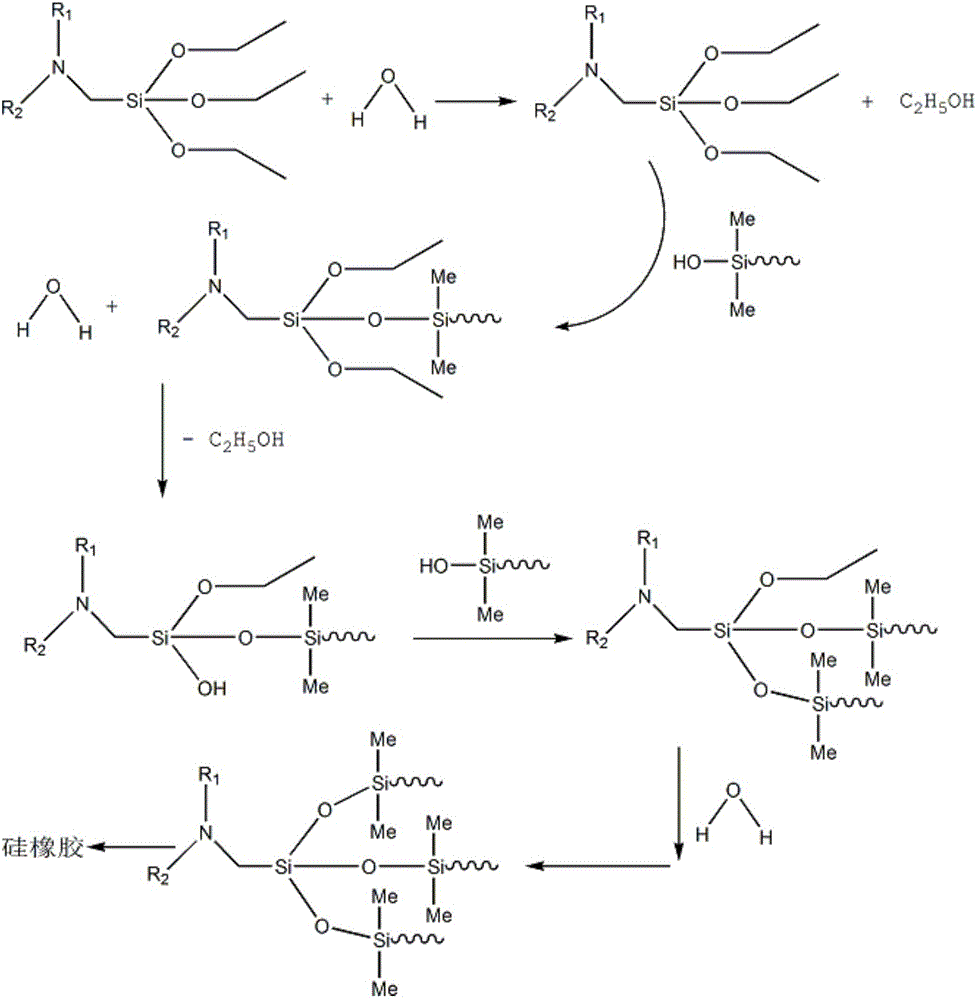

Autocatalytic and dealcoholized room-temperature vulcanized silicone rubber and preparation method thereof

InactiveCN106634803AHigh electronegativityFast curingNon-macromolecular adhesive additivesCross-linkPolymer science

The invention relates to autocatalytic and dealcoholized room-temperature vulcanized silicone rubber and a preparation method thereof. The room-temperature vulcanized silicone rubber is prepared from, by mass, 50-100 parts of terminal hydroxyl polydimethylsiloxane, 5-25 parts of filler and 0.3-5 parts of cross-linking agent. The room-temperature vulcanized silicone rubber can be rapidly cured without organo-tin compounds and other catalysts, the cost is reduced, the harm of the used organo-tin compound to the environment and organisms is also avoided, and therefore the application field of the silicone rubber. The room-temperature vulcanized silicone rubber using alpha-amine methyl triethoxysilane as a cross-linking agent is high in curing speed, good in mechanical property and excellent in thermal performance and has the advantages of being free of corrosion, low in energy consumption and free of pollution.

Owner:SHANDONG UNIV

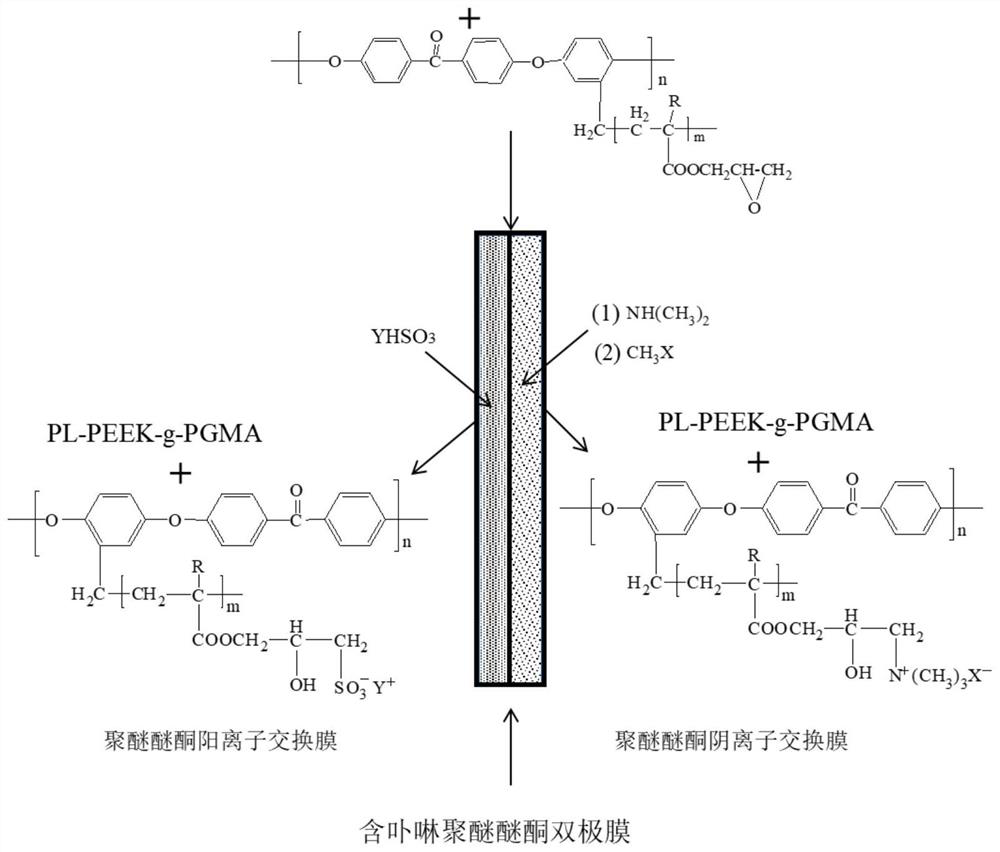

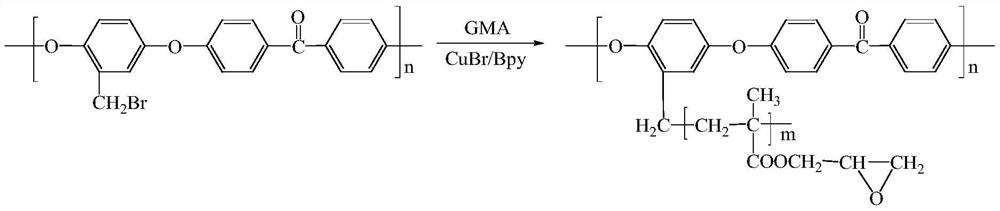

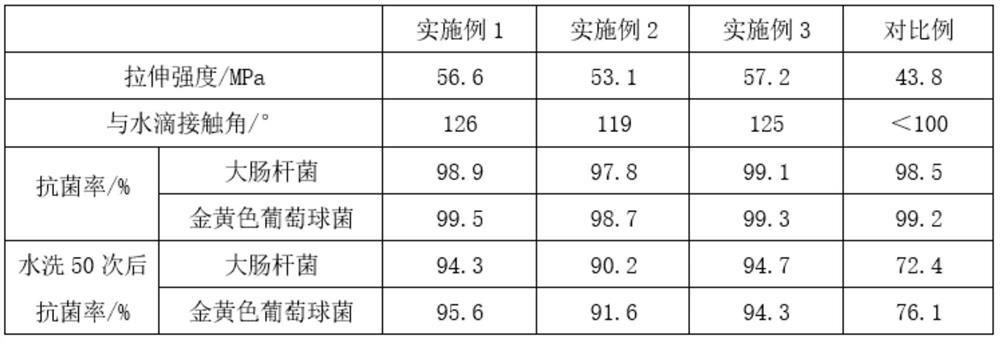

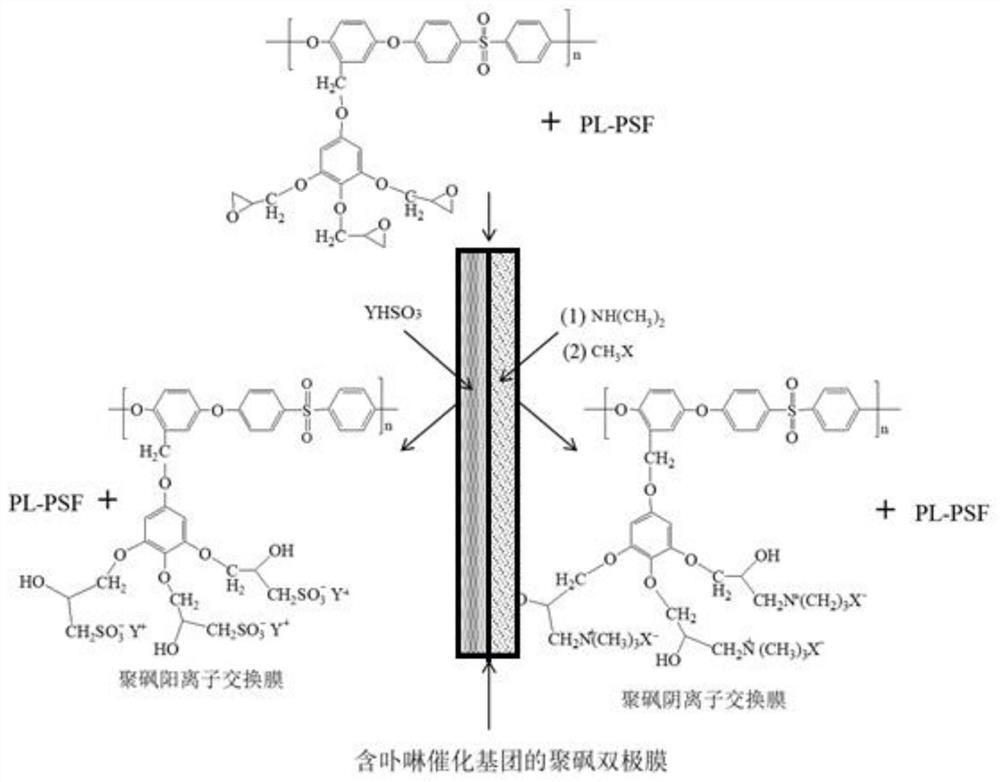

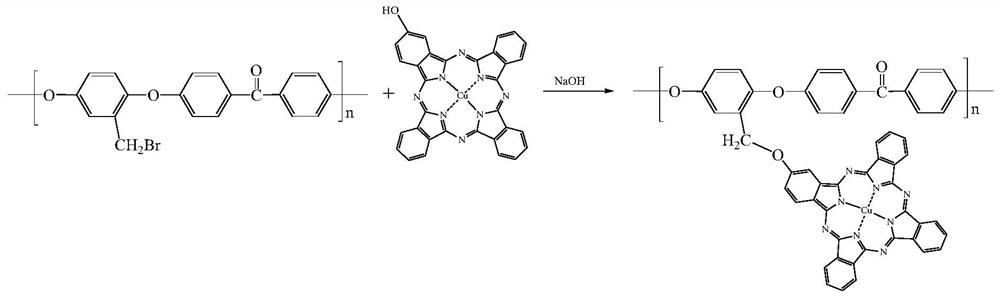

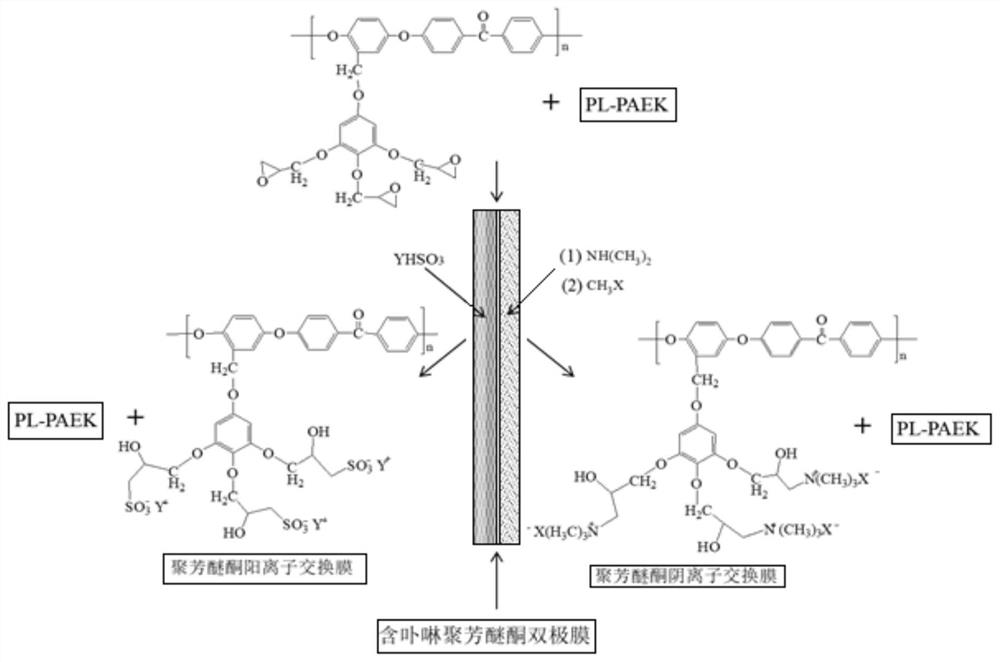

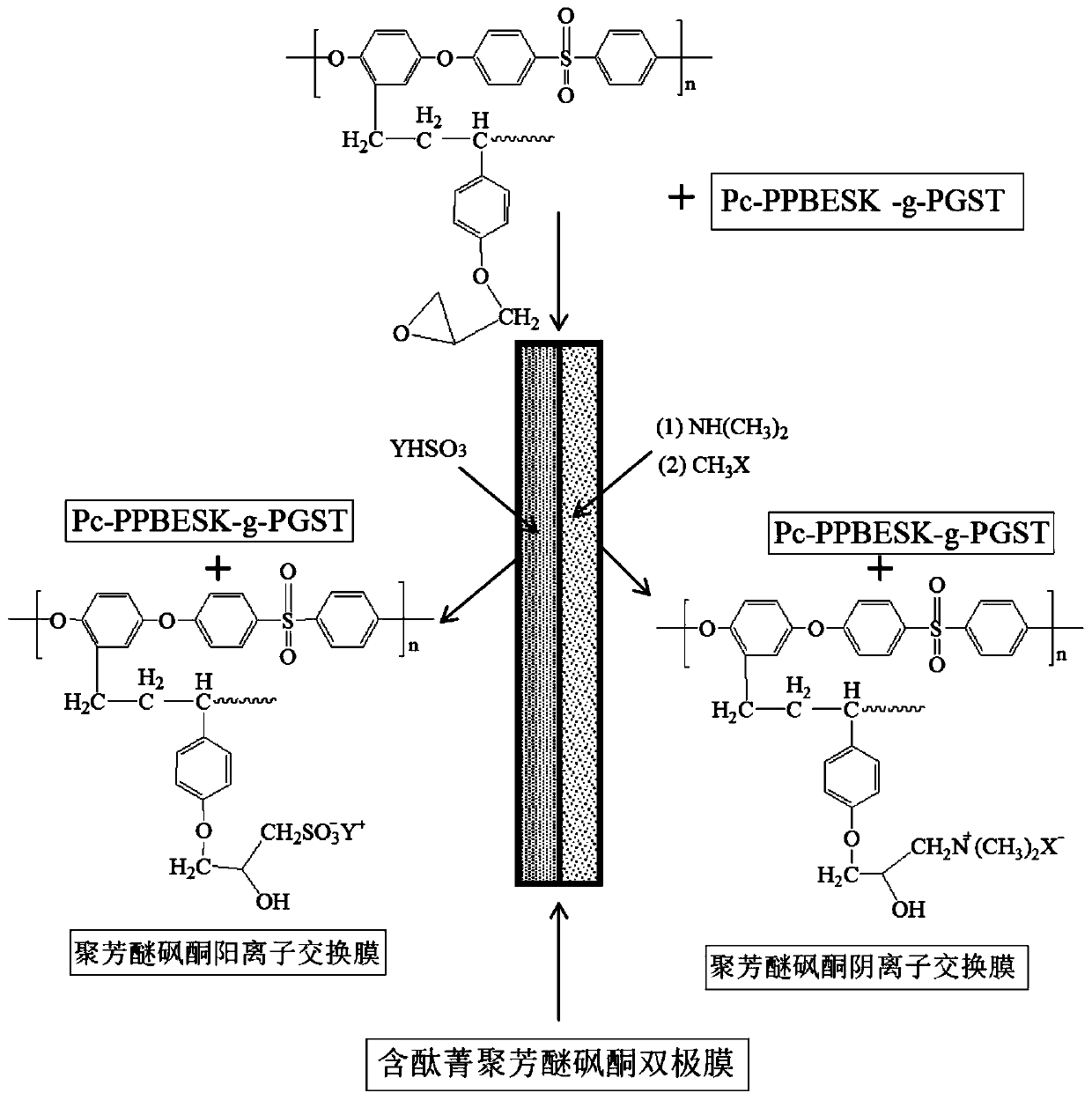

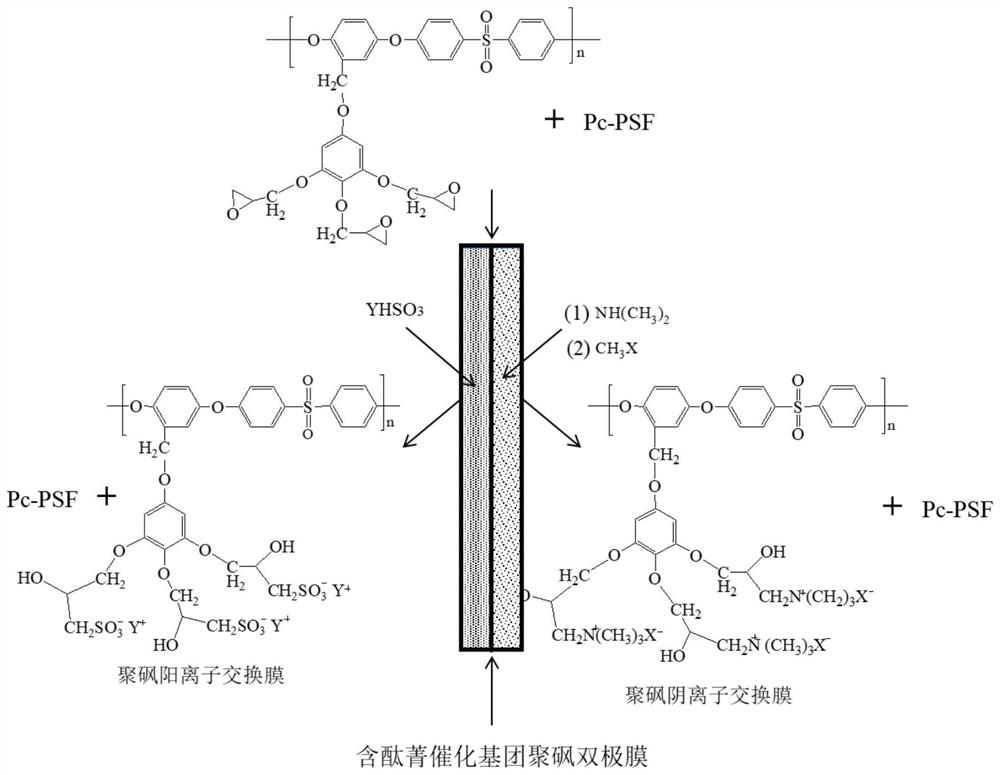

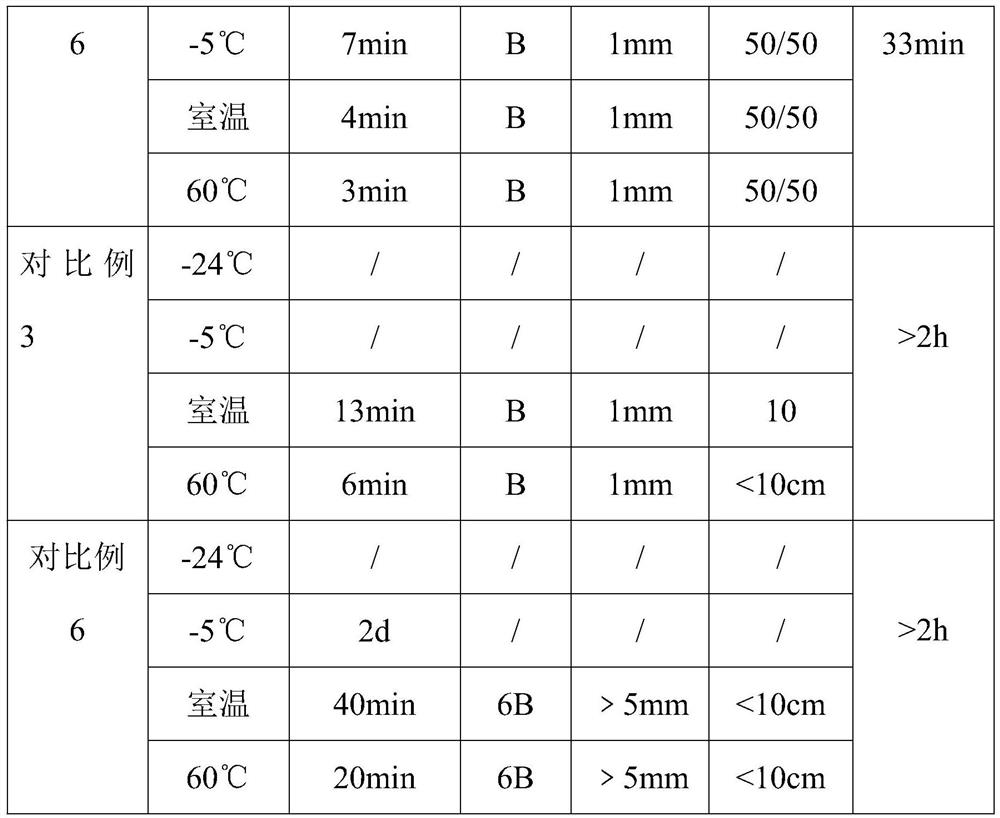

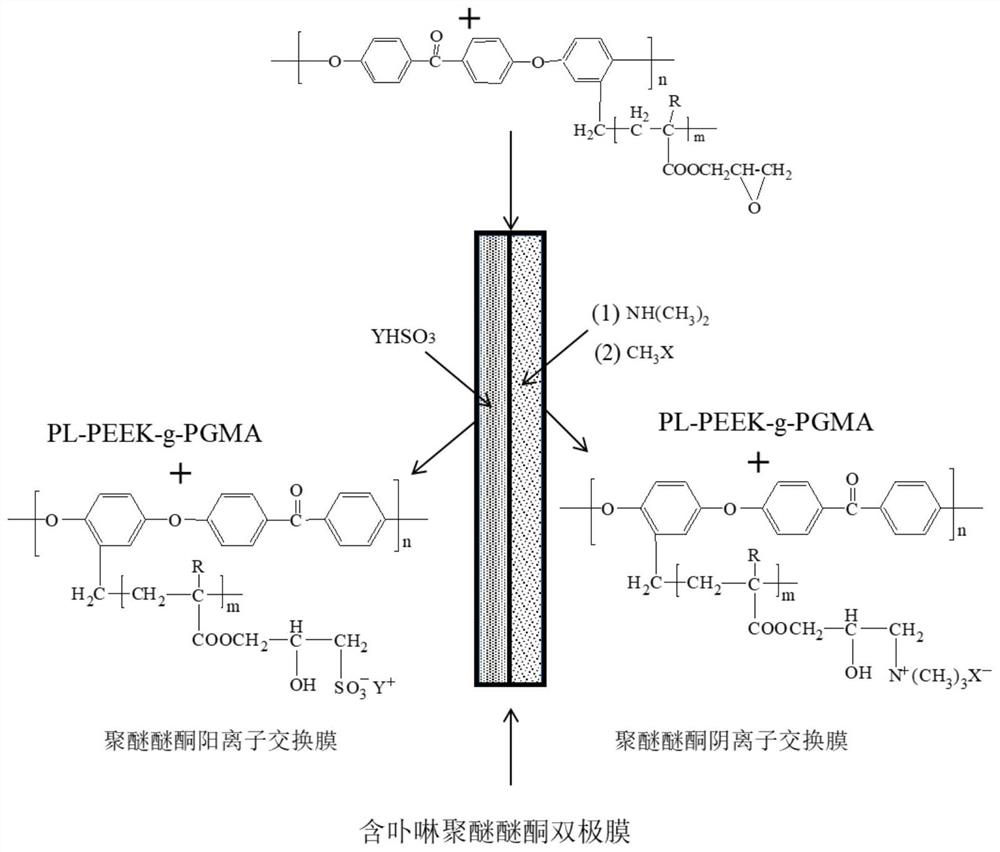

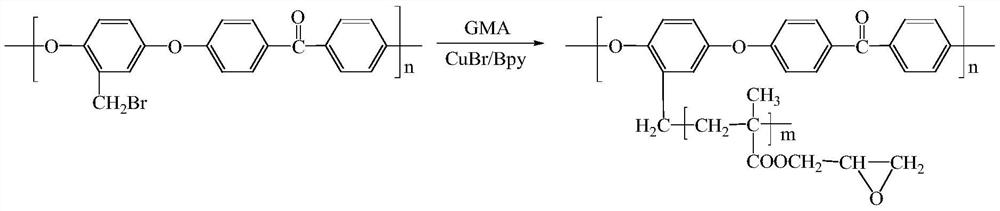

Preparation method of monolithic polyaryletherketone bipolar membrane with porphyrin hydrolytic dissociation catalytic group on side chain

ActiveCN111617644AEliminate film forming processLower resistanceSemi-permeable membranesComplex ion-exchangersSide chainBis epoxide

The invention relates to a preparation method of a monolithic polyaryletherketone bipolar membrane with a porphyrin hydrolysis catalytic group on a side chain. The preparation method comprises the following steps: respectively synthesizing polysulfone base membrane mixed solutions containing porphyrin and epoxy group side groups by taking bromomethylated polysulfone and a bromomethylated polysulfone polymer as starting raw materials, mixing the polysulfone base membrane mixed solutions, performing casting on a clean glass plate, and performing drying to obtain a polysulfone base membrane containing porphyrin and epoxy group side groups; and sulfonating, aminating and quaternizing the base membrane, and washing the base membrane with deionized water to obtain the monolithic polyaryletherketone bipolar membrane containing a phthalocyanine side group. According to the bipolar membrane prepared by the invention, through nucleophilic substitution reaction, an epoxy group is introduced intoa polysulfone side group, and anion and cation exchange membranes are introduced into a polysulfone molecular chain, so that a membrane forming process is omitted, and the use of carcinogen chloromethyl ether is avoided. The prepared bipolar membrane has a self-catalysis effect, and is low in resistance and low in transmembrane voltage. After long-term use, the problems of bubbling, cracking and the like of a middle interface layer, which are easily caused in the use process of a composite bipolar membrane, can be avoided.

Owner:FUJIAN NORMAL UNIV

Composite nano antibacterial fiber gauze fabric and preparation process thereof

InactiveCN112522832AHigh mechanical strengthImprove waterproof performanceBiochemical fibre treatmentFibre typesCotton fibrePolyester

The invention relates to a composite nano antibacterial fiber gauze fabric and a preparation process thereof. The gauze fabric is formed by weaving warp yarns and weft yarns, the warp yarns are formedby blending antibacterial fibers and cotton fibers, the weft yarns are formed by blending bamboo fibers and polyurethane fibers, and the antibacterial fibers are obtained by modifying polyester fibers with a composite nano material. The problems that in the research field of antibacterial textiles, a fabric after-finishing method is mainly adopted in a preparation method of the antibacterial textiles, so that an antibacterial layer is formed on the surface of a textile material, but an antibacterial fabric in the prior art is not long in service life and not ideal in antibacterial effect aresolved. The prepared antibacterial fibers and the cotton fibers with high air permeability are blended to form the warp yarns, the waterproof and anti-aging bamboo fibers and the polyurethane fibers with high elasticity are blended to form the weft yarns, and then the warp yarns and the weft yarns are woven to form the gauze fabric. The prepared gauze fabric has the advantages of being high in antibacterial property and lasting in antibacterial property.

Owner:ANHUI HEBANG TEXTILE TECH CO LTD

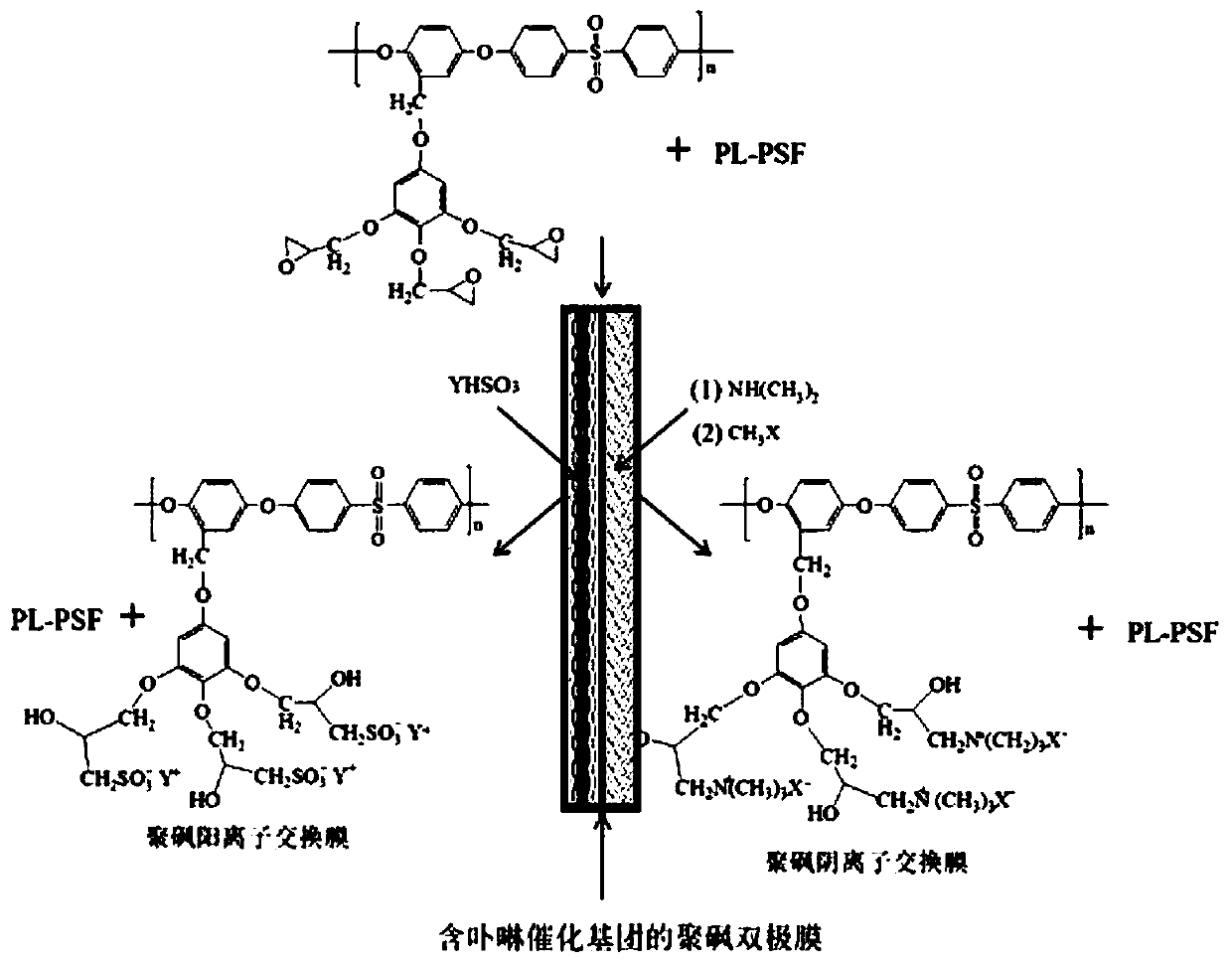

Preparation method of monolithic polysulfone bipolar membrane with side group bonded with porphyrin group

ActiveCN111530312AImprove stabilityExtended service lifeSemi-permeable membranesComplex ion-exchangersEpoxyPolymer science

The invention relates to a preparation method of a monolithic polysulfone bipolar membrane with a side group bonded with a porphyrin group. The preparation method comprises the following steps: respectively synthesizing a polysulfone-based membrane mixed solution containing porphyrin and epoxy group side groups by taking bromo-methylated polysulfone and a bromo-methylated polysulfone polymer as starting raw materials, mixing, casting on a clean glass plate, and drying to prepare a polysulfone-based membrane containing porphyrin and epoxy group side groups; and sulfonating, aminating and quaternizing the base membrane, and washing with deionized water to obtain the monolithic polyaryletherketone bipolar membrane containing the phthalocyanine side group. According to the bipolar membrane prepared by the method, an epoxy group is introduced into a polysulfone side group through nucleophilic substitution reaction, and anion and cation exchange membranes are introduced into a polysulfone molecular chain so that a membrane forming process is omitted, and the use of carcinogen chloromethyl ether is avoided. The prepared bipolar membrane has a self-catalysis effect, and is low in resistance and low in transmembrane voltage. And after long-term use, the problems of bubbling, cracking and the like of the middle interface layer, which are easily caused in the use process of the compositebipolar membrane, can be avoided.

Owner:FUJIAN NORMAL UNIV

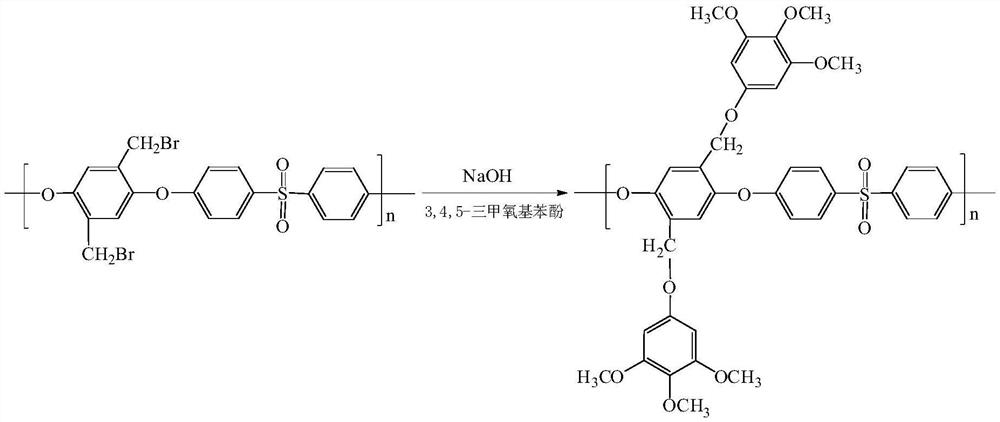

Preparation method of monolithic polysulfone bipolar membrane with side group bonded with phthalocyanine catalytic group

ActiveCN111530313AIncreased stability and longevityEasy to produceSemi-permeable membranesComplex ion-exchangersComposite materialPendant group

The invention relates to a preparation method of a monolithic polysulfone bipolar membrane with a side group bonded with a phthalocyanine catalytic group. The preparation method comprises the following steps: taking a bromomethylated polysulfone polymer as a starting raw material, respectively synthesizing an epoxy group-containing substituent polysulfone polymer and a polysulfone side group bonded phthalocyanine polymer, mixing the epoxy group-containing substituent polysulfone polymer and the polysulfone side group bonded phthalocyanine polymer, casting on a clean glass plate, and drying toprepare a polysulfone-based membrane containing a phthalocyanine group side group and an epoxy group side group; and sulfonating, aminating and quaternizing the base membrane, and washing with deionized water to obtain the monolithic phthalocyanine group-containing polysulfone bipolar membrane. According to the bipolar membrane prepared by the method, an epoxy group is introduced into a polysulfone side group through nucleophilic substitution reaction, and anion and cation exchange membranes are introduced into a polysulfone molecular chain so that a membrane forming process is omitted, and the use of carcinogen chloromethyl ether is avoided. The prepared bipolar membrane has a self-catalysis effect, and is low in resistance and low in transmembrane voltage. And after long-term use, the problems of bubbling, cracking and the like of the middle interface layer, which are easily caused in the use process of the composite bipolar membrane, can be avoided.

Owner:FUJIAN NORMAL UNIV

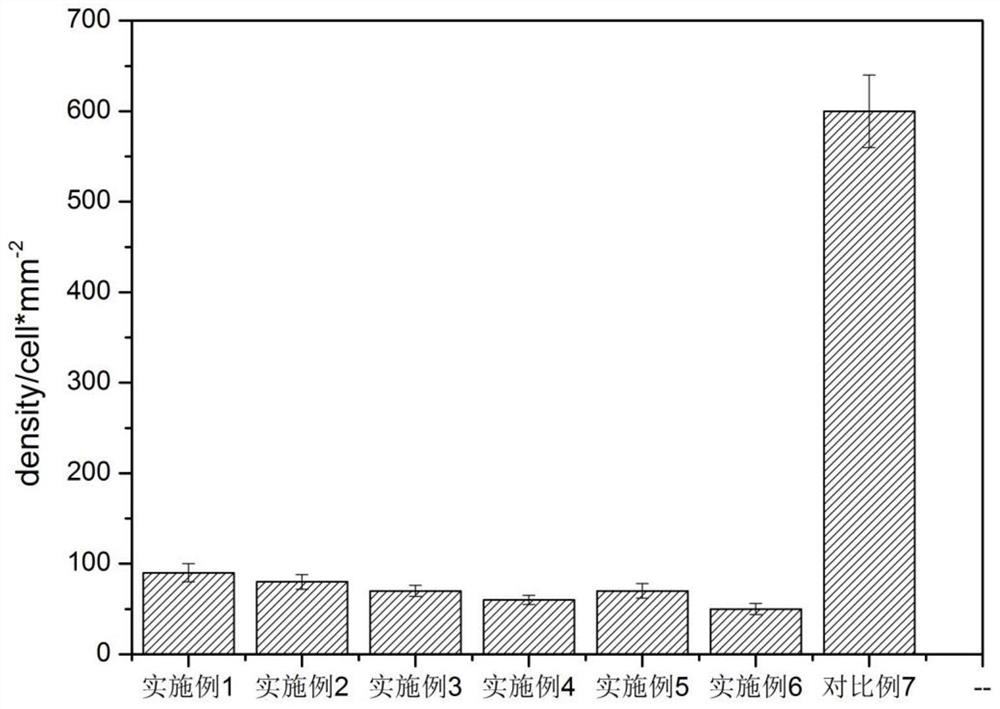

A kind of preparation method of surface modified ZTA ceramic particles reinforced steel matrix composite material

ActiveCN109706438BEnhanced interface bindingHigh yield strengthLiquid/solution decomposition chemical coatingAl powderGraphite

The invention discloses a preparation method of a surface-modified ZTA ceramic particle reinforced steel based composite material. The preparation method comprises the steps that sensitization and activation treatment is conducted on ZTA particles, surface plating is conducted, the ZTA particles are plated with nickel and chromium to achieve surface metallization by controlling the components andthe proportion of a plating solution, the ZTA particles plated with Cr-Ni layers, Ni-Cr alloy powder and Al powder are put into a graphite mold to be made into a preform which is of a honeycomb structure through vacuum sintering, molten metal is poured by adopting a casting infiltration method, and after cooling is conducted, the reinforced steel based composite material is obtained. According tothe preparation method of the surface-modified ZTA ceramic particle reinforced steel based composite material, the ZTA particles are plated with nickel and chromium to achieve surface metallization bycontrolling the components and the proportion of the plating solution, the wet problem with a metal matrix is solved, and then the mechanical property of the composite material is improved; and meanwhile, the technology is easy to operate, the cost is reduced to a large extent, no toxicity or pollution is generated, the great potential on increasing the economic benefit and the social benefit isachieved, and the good prospect of being applied to the harsh abrasive wear condition is achieved.

Owner:XI AN JIAOTONG UNIV +1

Autocatalytic alkyd resin and preparation method thereof

ActiveCN109880068AShorten drying timeThere is no problem of uneven gloss and affecting transparencyPolyester coatingsBenzoic acidReflux

The invention discloses an autocatalytic alkyd resin and a preparation method thereof. The preparation method comprises the following steps: putting glycerol, benzoic acid, soya-bean oil acid, phthalic anhydride, a color reducer, xylene and a self-made drier into a four-necked flask; conducting heating to a reflux state by using a heating jacket, conducting reacting at 180-200 DEG C for 3 hours, separating out water, then conducting heating to 200-210 DEG C, conducting reacting for 5 hours, conducting cooling to 100 DEG C when the acid value is 10-20 mgKOH / g, adding xylene, and conducting stirring to obtain the self-catalytic alkyd resin. According to the alkyd resin, a group with a drying effect is introduced, self-catalysis is realized, the drying time of PU paint can be shortened without adding a drier when the paint is prepared, compared with an additional drier, the catalytic effect is more stable, the problem that the glossiness of a paint film is not uniform due to non-uniform precipitation and dispersion of an additional drier is avoided, the polishing property and yellowing resistance of the primer are improved, and the later paint preparation cost of a client is reduced.

Owner:鹤山市肇能新材料有限公司

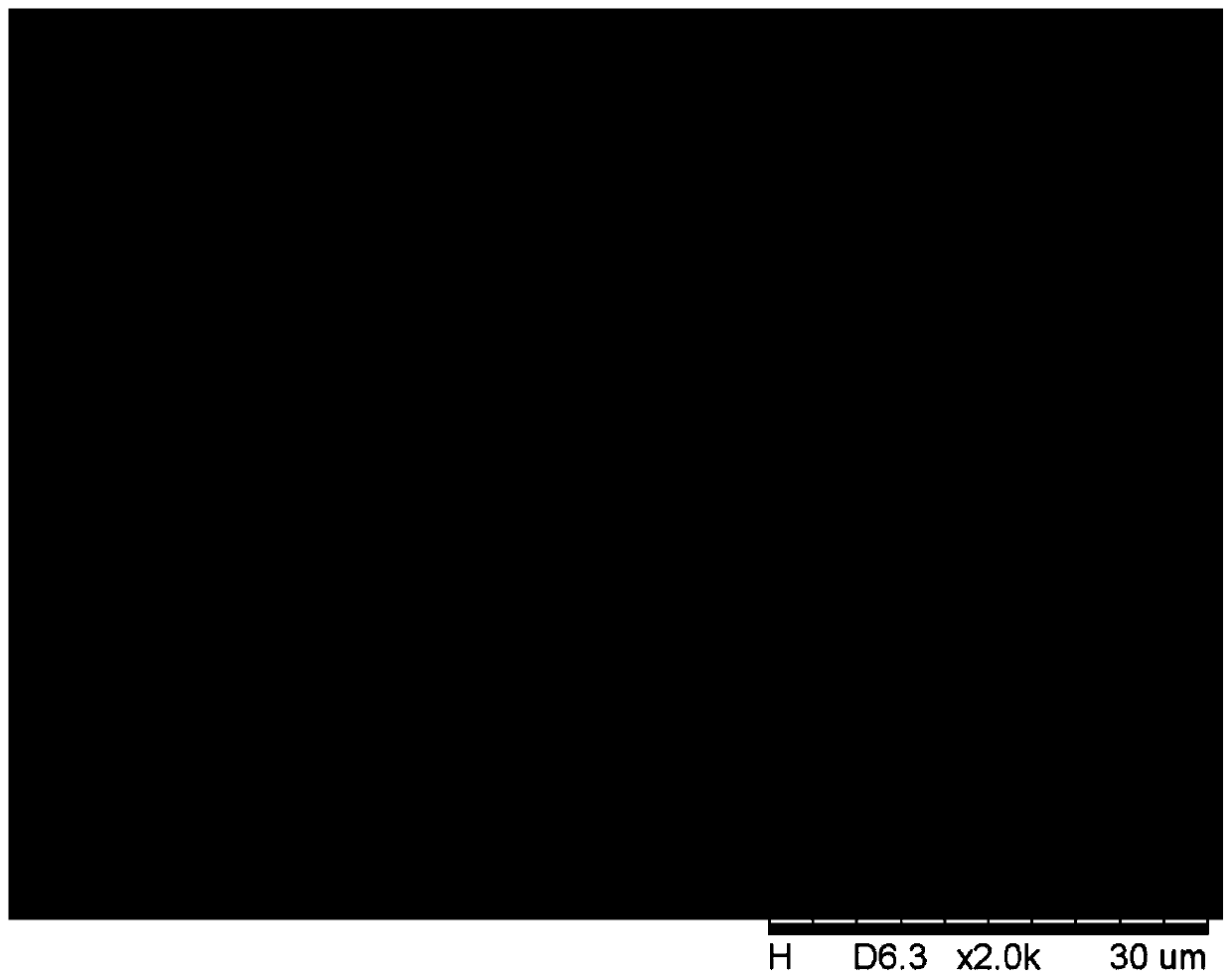

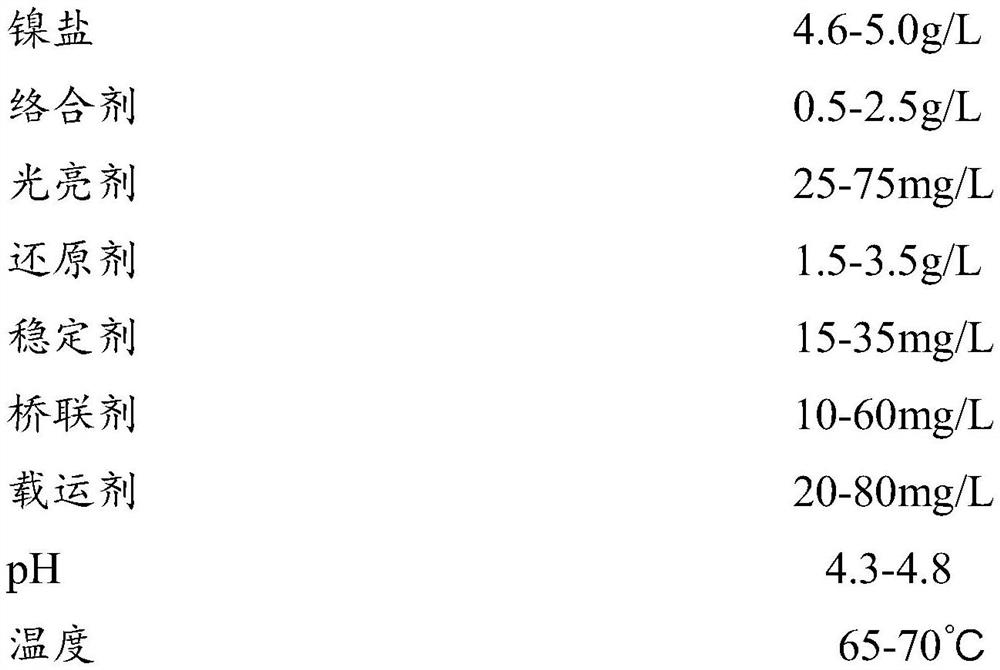

Chemical nickel-gold process applied to wafer aluminum-copper base material in field of IGBT (Insulated Gate Bipolar Translator) power devices

ActiveCN114481106ASolve the real problemImprove adsorption capacityLiquid/solution decomposition chemical coatingSuperimposed coating processNickel saltChemical plating

The invention discloses a chemical nickel-gold process of a wafer aluminum-copper base material applied to the field of IGBT power devices. The chemical nickel-gold process comprises a process flow, an activating solution formula, a chemical nickel formula, a chemical gold formula and the like. The technological process comprises the steps of oil removal, water washing, micro-etching, water washing, presoaking, activation, water washing, vacuum water washing, dry ice spray washing, thin copper electroplating, water washing, chemical nickel plating, water washing and chemical gold plating. The formula of the activating solution comprises ruthenium salt, platinum salt, concentrated sulfuric acid, a surfactant, a stabilizer, a complexing agent and a dispersing agent. The nickel plating formula comprises nickel salt, a complexing agent, a brightening agent, a reducing agent, a stabilizing agent, a bridging agent and a carrying agent. The gold plating formula comprises gold salt, a complexing agent, a stabilizing agent, an underpotential agent, a reducing agent and a nucleating agent. The excellent chemical nickel-gold plating process of the wafer aluminum-copper base material in the field of IGBT power devices can be realized, and the chemical nickel-gold plating process has the characteristics of being excellent in stability, bright and smooth, free of skip plating and diffusion plating, good in oxidation resistance, good in weldability and the like.

Owner:珠海市创智芯科技有限公司

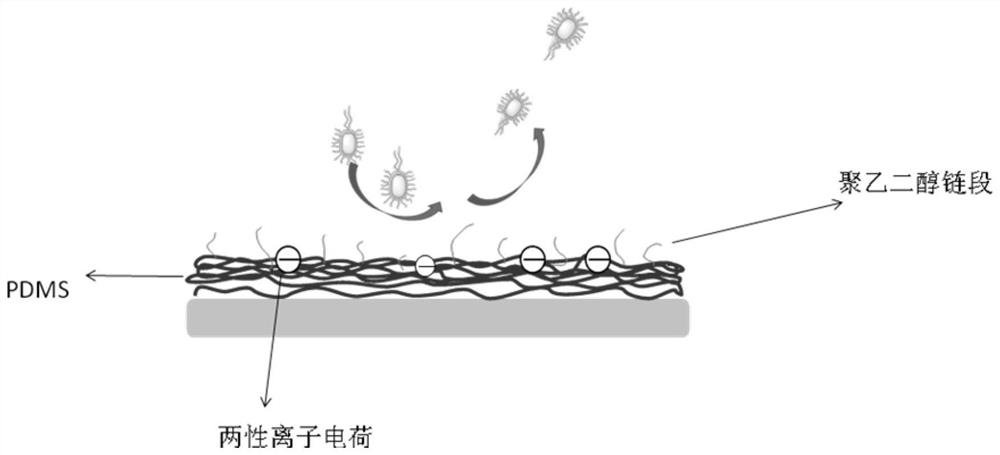

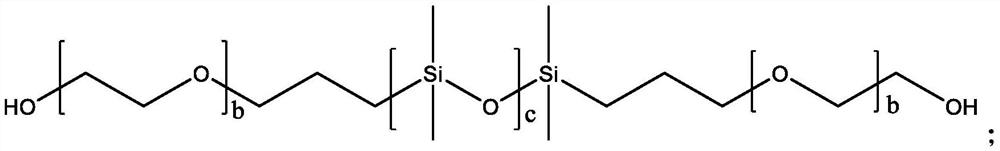

Ionic silicone gel antifouling coating and preparation method thereof

InactiveCN113056532APrevent adhesionSelf-catalyzedAntifouling/underwater paintsPaints with biocidesSilicone GelsPolymer science

An ionic silicone gel antifouling coating, comprises an A component and a B component: The A component includes di-polyethylene glycol-terminated polydimethylsiloxane, hydroxyl-terminated polydimethylsiloxane, a pigment and a solvent. The B component includes bis[3-(triethoxysilyl)propyl]amine, zwitterionic acrylic monomer and solvent. A preparation method of the antifouling coating includes the preparation method of the A component and the B component. The preparation method of the A component is: stir and disperse the polydimethylsiloxane, the solvent and the pigment that are capped with two polyethylene glycol: The preparation method of the B component is: under the conditions of anhydrous, nitrogen atmosphere and 35 DEG C, bis[3-(triethoxysilyl)propyl]amine, zwitterionic acrylic monomer and solvent are ultrasonically dispersed.

Owner:XIAMEN SUNRUI SHIP COATING

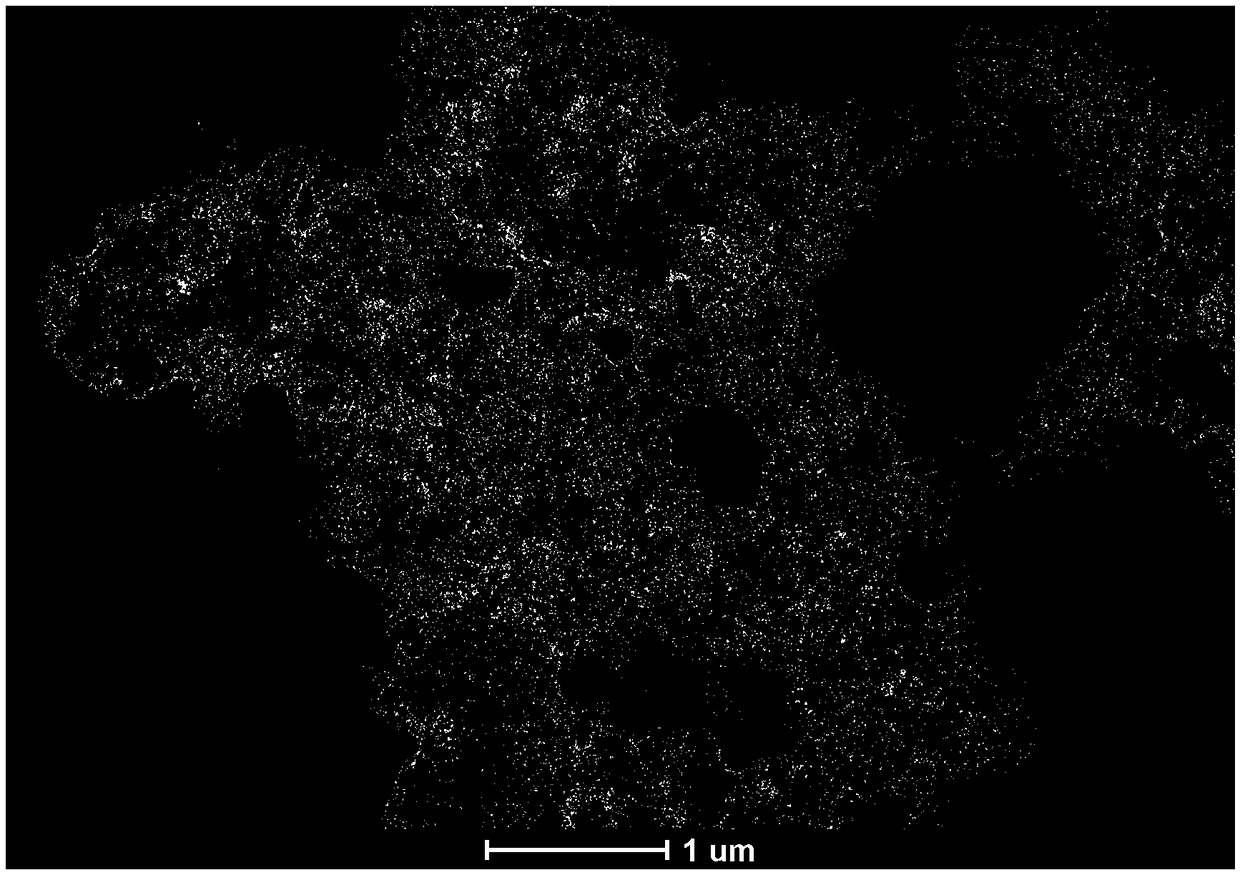

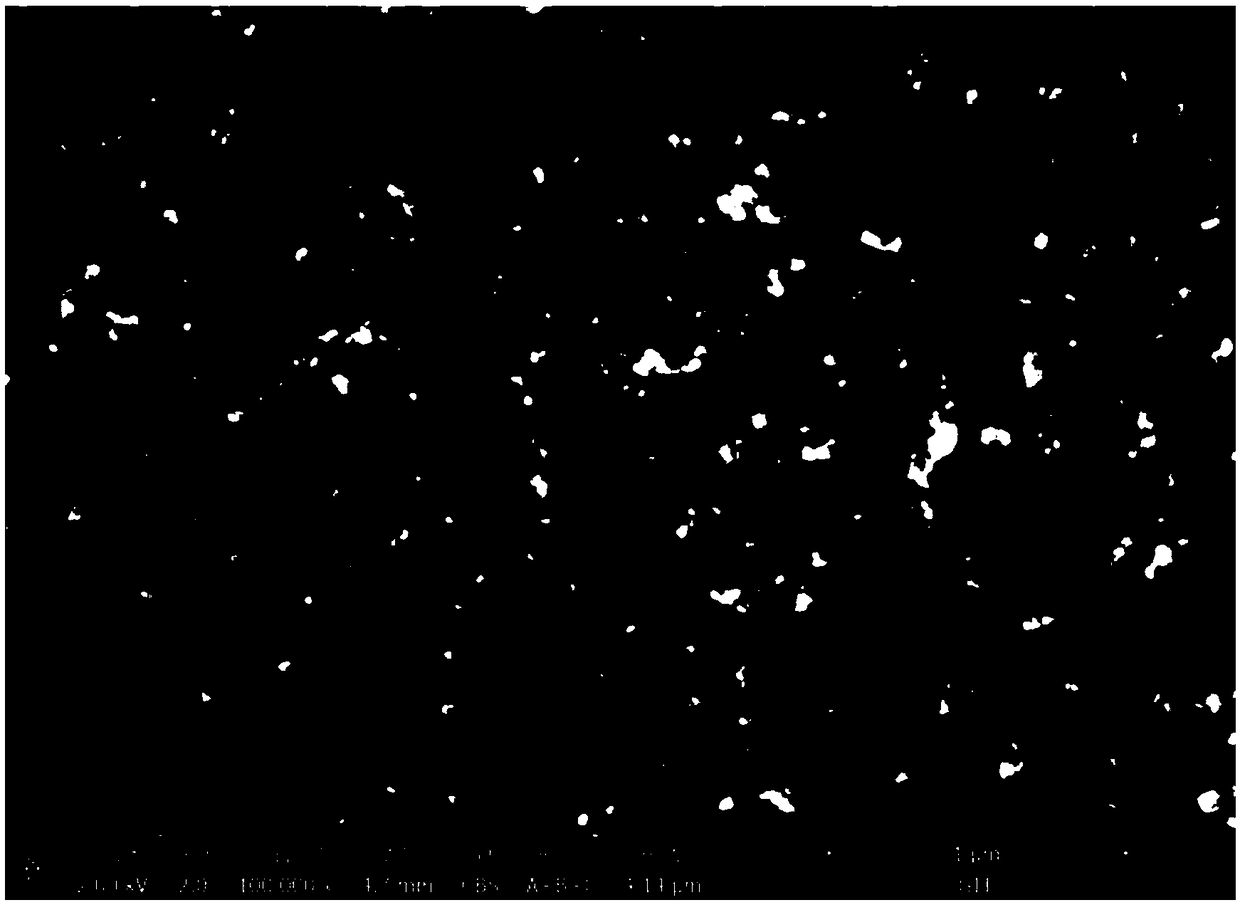

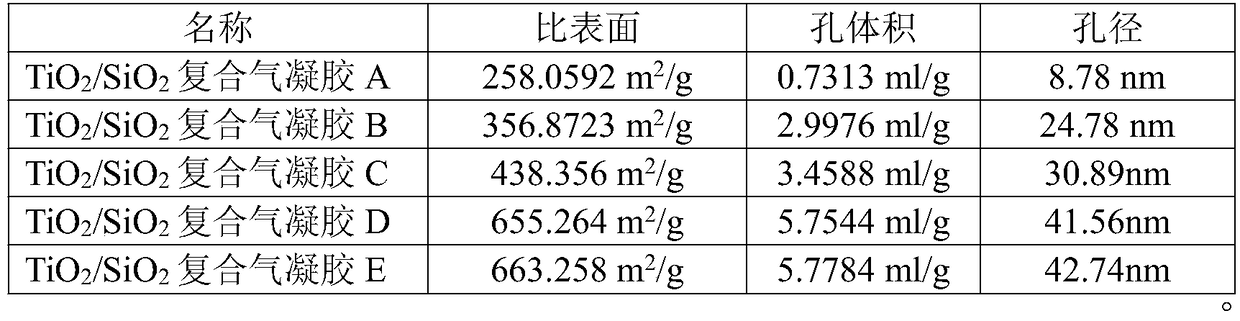

Method for fast preparing TiO2/SiO2 composite aerogel through autocatalysis alcoholysis

InactiveCN108905911AFast preparationRapid responseAerogel preparationColloidal chemistry detailsSupercritical dryingGel preparation

The invention discloses a method for fast preparing TiO2 / SiO2 composite aerogel through autocatalysis alcoholysis. The method is characterized by comprising the following steps of (1) TiO2 / SiO2 composite sol preparation: taking absolute ethyl alcohol; dropwise adding titanium tetrachloride in a continuous stirring way to form a solution A; then, dropwise adding silicon tetrachloride into the solution A; finally, dropwise adding ammonia water with the concentration being 0.1 to 0.5 mol / L; performing hydrolysis at room temperature to prepare TiO2 / SiO2 composite sol; (2) TiO2 / SiO2 composite gel preparation: performing stirring for 20 to 30min in a water bath being 60 to 80 DEG C; performing still standing at room temperature for 0.5 to 1h until gelatination is realized; obtaining TiO2 / SiO2 composite gel; (3) TiO2 / SiO2 composite gel aging and solvent replacement: putting the TiO2 / SiO2 composite gel into a water bath pot being 40 to 60 DEG C; performing solvent replacement by an analytically pure absolute ethyl alcohol solution; changing the absolute ethyl alcohol once every 2 to 4h; performing replacement for 24h; (4) TiO2 / SiO2 composite gel drying: performing supercritical drying on the TiO2 / SiO2 composite gel subjected to solvent replacement by the absolute ethyl alcohol; obtaining the TiO2 / SiO2 composite aerogel.

Owner:GUIZHOU INST OF TECH

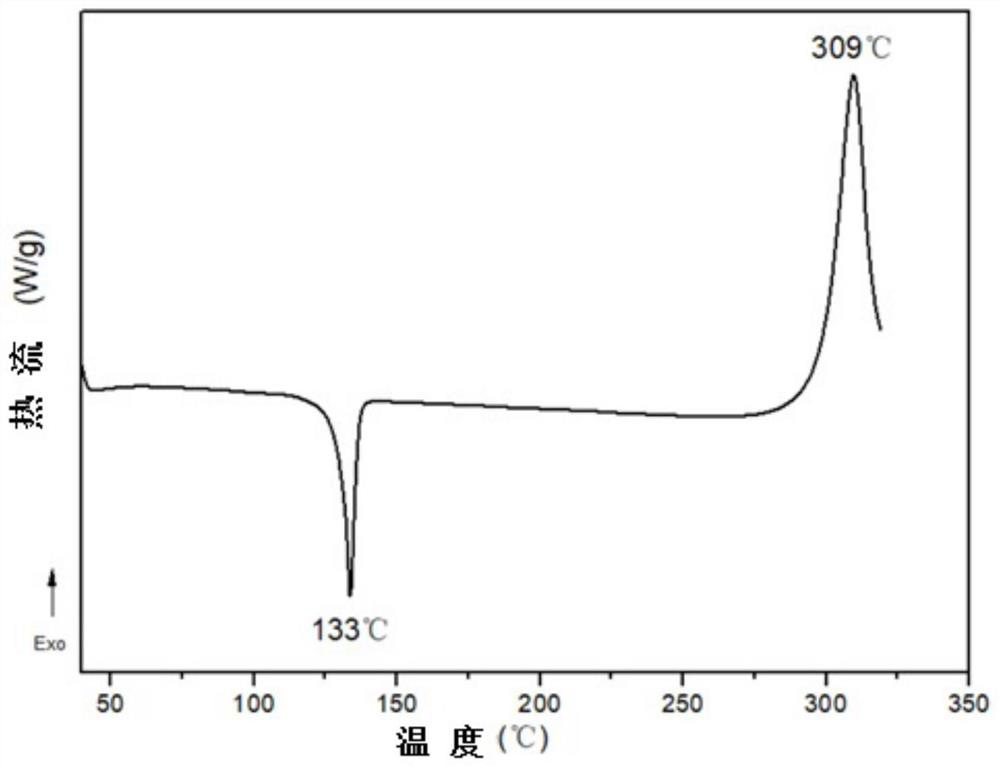

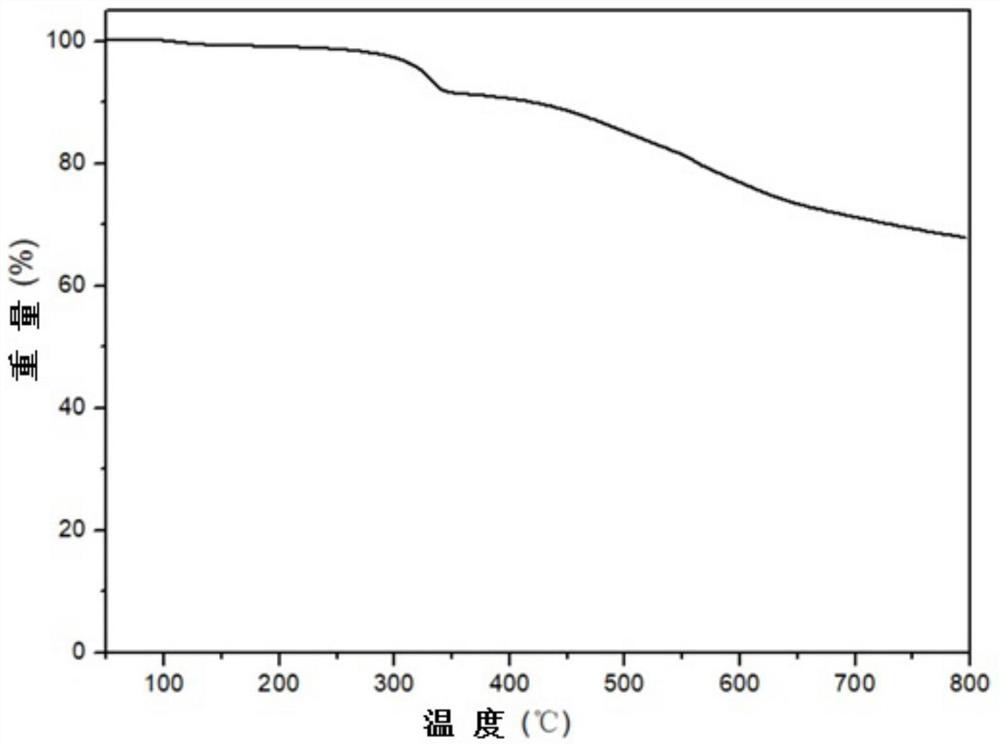

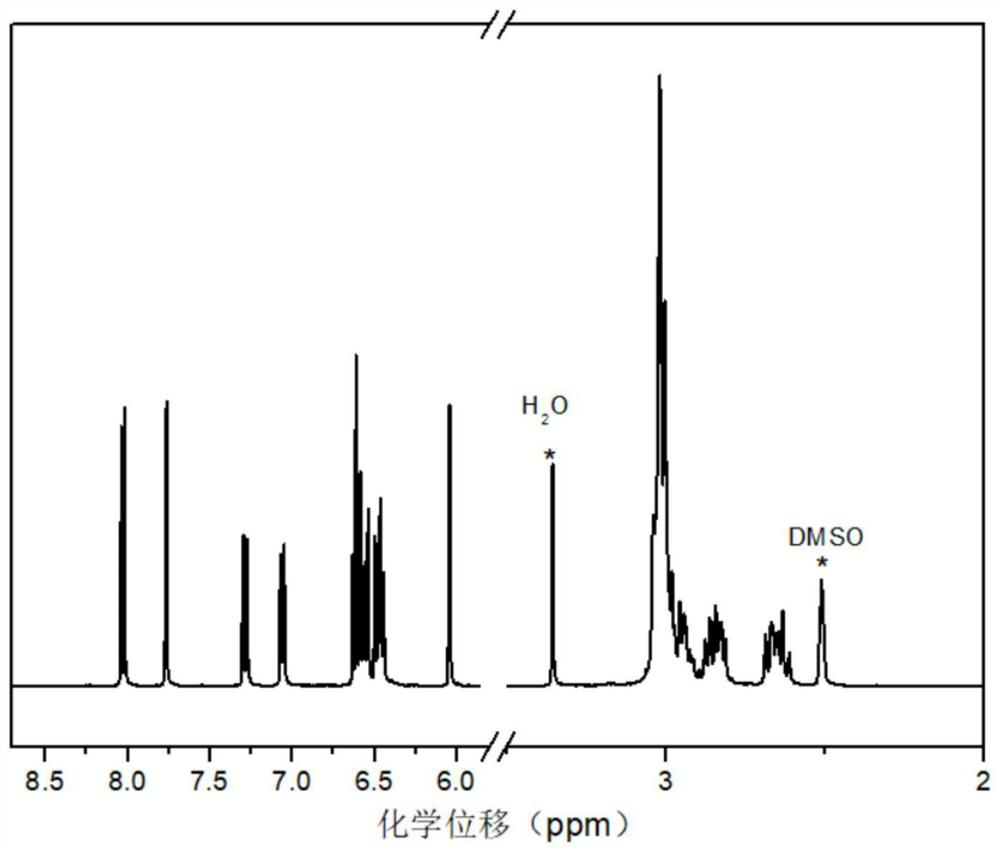

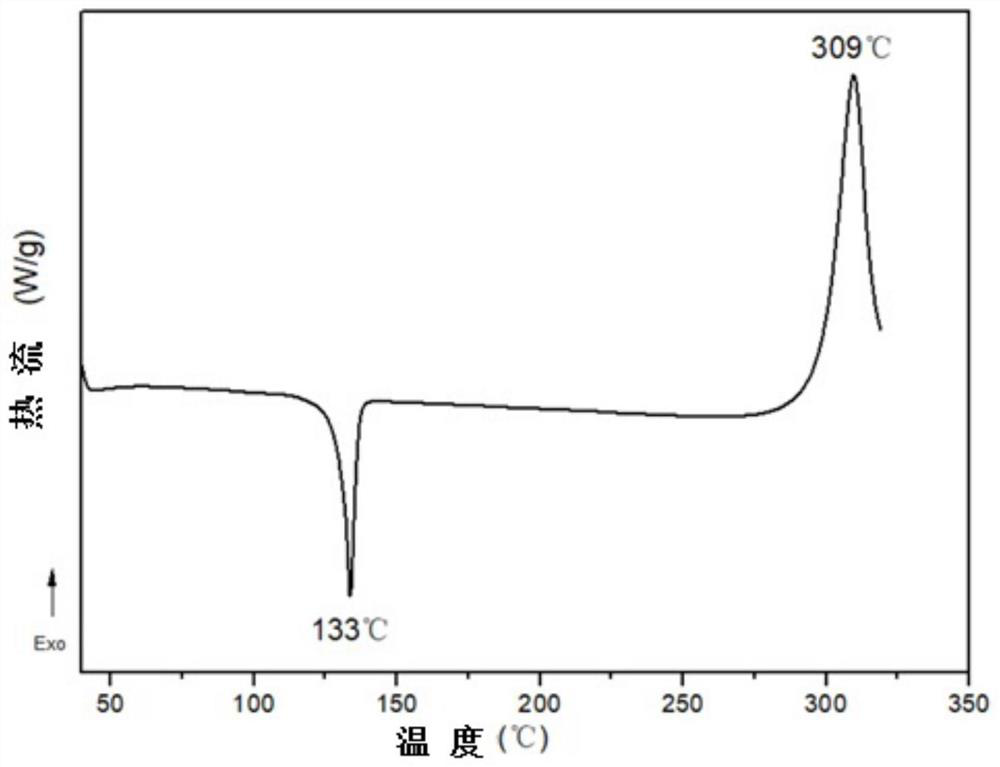

A kind of prepreg based on high temperature resistant composite material resin and preparation method thereof

The invention provides a prepreg based on a high-temperature-resistant composite material resin and a preparation method thereof. The preparation method comprises the following steps: preparing an epoxy resin and benzoxazine in a ratio of 100:(20-40), and mixing in an 80-DEG C environment at the rate of 500 rpm for 20-50 minutes; impregnating carbon fibers in the resin at 80-90 DEG C for 7-10 minutes, and baking in a 140-150-DEG C environment for 10-15 minutes to obtain the prepreg for the high-temperature-resistant composite material. The epoxy resin is prepared from a phenol formaldehyde epoxy resin F51 and one of a glycidyl amine epoxy resin (AG-80), an ester ring epoxy resin (TDE-85) and a hydantoin epoxy resin, and the benzoxazine is 3-pyridyl-3,4-dihydro-1,3-benzoxazine. The resin for the high-temperature-resistant composite material has high heat resistance, and satisfies the application demands of the product in the fields with higher requirements for heat resistance.

Owner:成都鲁晨新材料科技有限公司

A preparation method of monolithic polysulfone bipolar membrane with porphyrin groups bonded to side groups

ActiveCN111530312BReduce usageEliminate film forming processSemi-permeable membranesComplex ion-exchangersEpoxyPolymer science

The invention relates to a method for preparing a monolithic polysulfone bipolar membrane with side groups bonded to porphyrin groups. The present invention uses bromomethylated polysulfone and bromomethylated polysulfone polymers as starting materials to synthesize polysulfone-based membrane mixed solutions containing porphyrin and epoxy group side groups respectively, and cast them on a clean A polysulfone-based membrane containing porphyrin and epoxy side groups was prepared by drying on a glass plate; after the base membrane was sulfonated, ammonized and quaternized, it was washed with deionized water to obtain a monolithic phthalocyanine-containing Poly(aryletherketone) bipolar membranes with side groups. The bipolar membrane prepared by the present invention adopts a nucleophilic substitution reaction, introduces an epoxy group on the polysulfone side group, introduces an anion and a cation exchange membrane method into the polysulfone molecular chain, and saves the film-forming process and avoids the carcinogen chlorine Use of methyl ether. The prepared bipolar membrane has self-catalysis, low bipolar membrane resistance and low transmembrane voltage. Long-term use, there will be no problems such as bubbling and cracking in the middle interface layer that are prone to occur during the use of composite bipolar membranes.

Owner:河北森斯环保科技有限公司

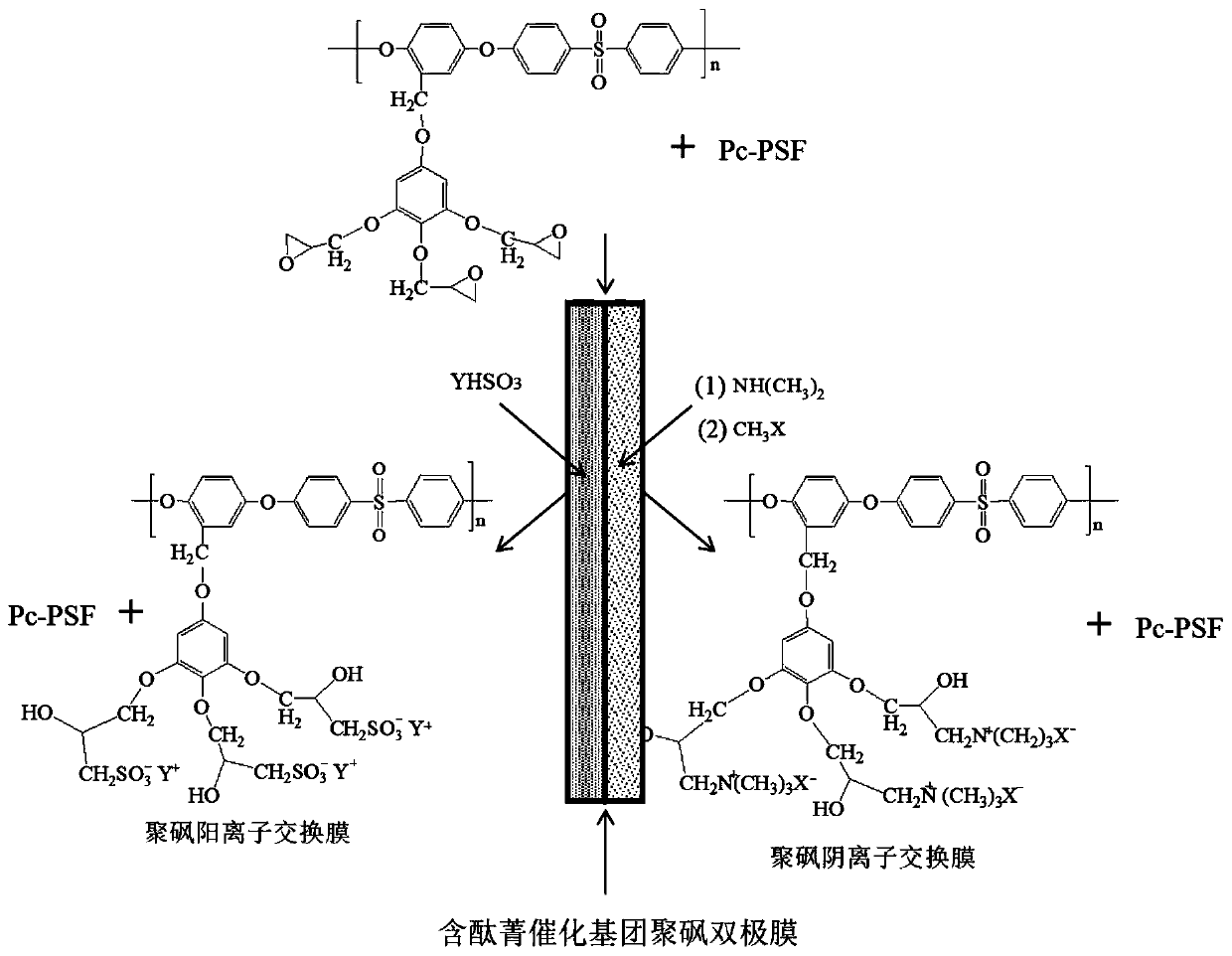

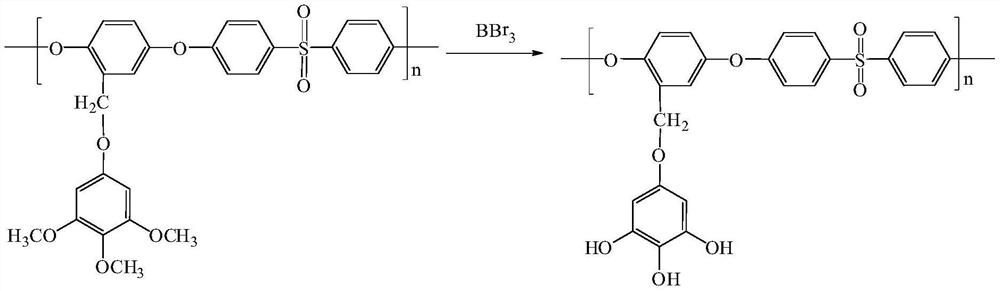

Preparation method of monolithic polyaryletherketone bipolar membrane containing phthalocyanine group in side group

ActiveCN111499916BReduce usageEliminate film forming processSemi-permeable membranesEpoxyPolymer science

The invention relates to a method for preparing a monolithic polyaryletherketone bipolar membrane containing a phthalocyanine catalytic group in a side group. The present invention uses bromomethylated polyaryletherketones and phthalocyanines as starting materials to synthesize polyaryletherketone polymers containing epoxy groups and polymers with phthalocyanines bonded to the side groups of polyaryletherketones. After casting on a clean glass plate, the polyarylether ketone base film containing phthalocyanine and epoxy group side groups was prepared; after the base film was sulfonated, ammonized and quaternized, it was washed with deionized water to obtain a monolithic Type polyaryletherketone bipolar membranes containing phthalocyanine side groups. The present invention utilizes epoxy groups to react with sulfonating agents and aminating agents to introduce anion and cation exchange membranes into polyaryletherketone molecular chains, thereby eliminating the film-forming process and avoiding carcinogen chlorine in the traditional bipolar membrane preparation process. Use of methyl ether. The prepared bipolar membrane has self-catalysis, low bipolar membrane resistance, low transmembrane voltage, long-term use, and no problems such as bubbling and cracking of the intermediate interface layer that are prone to occur during use of the composite bipolar membrane.

Owner:FUJIAN NORMAL UNIV

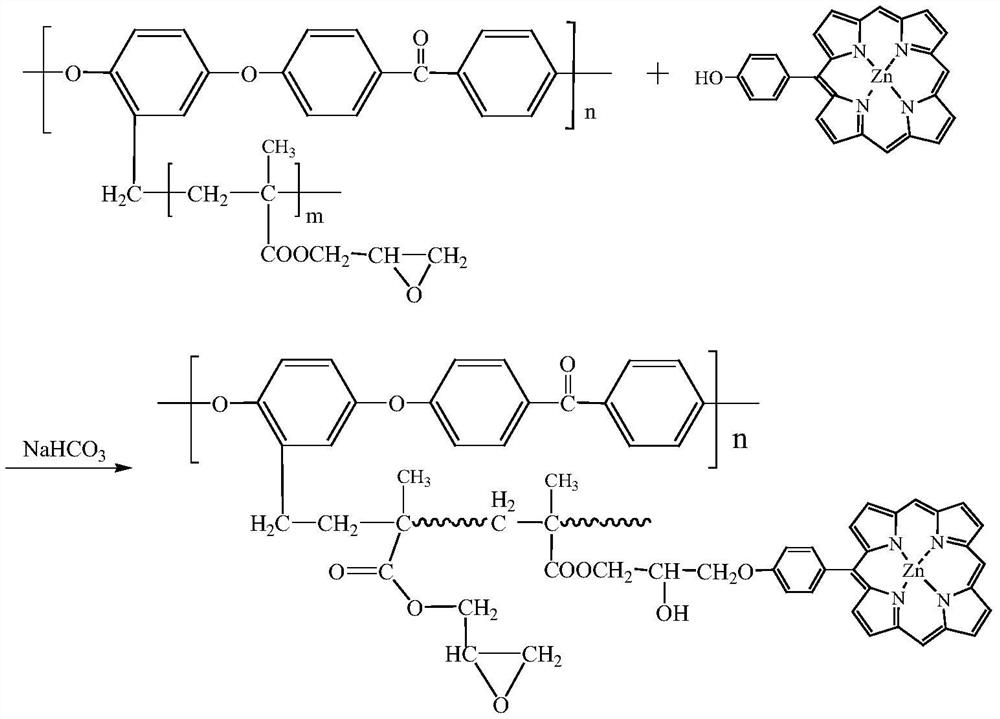

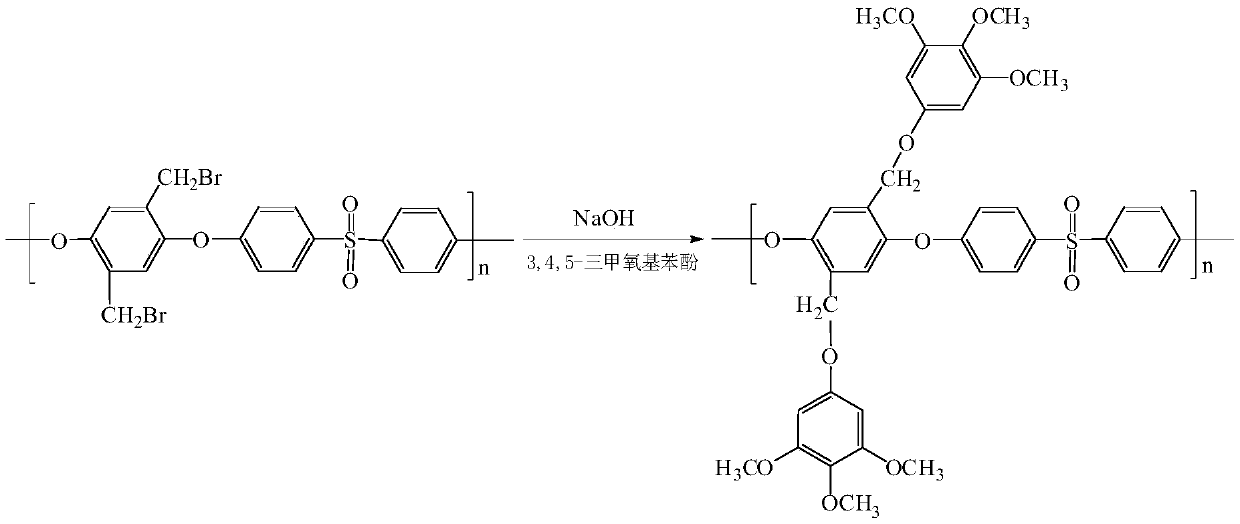

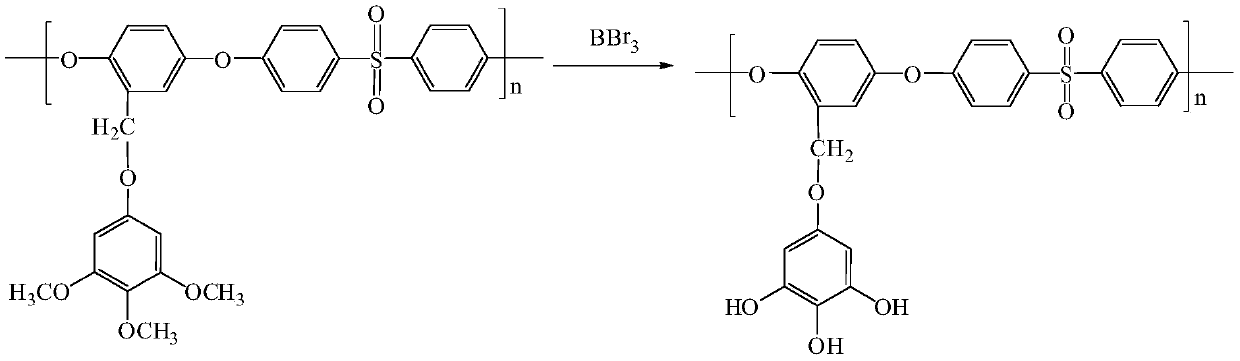

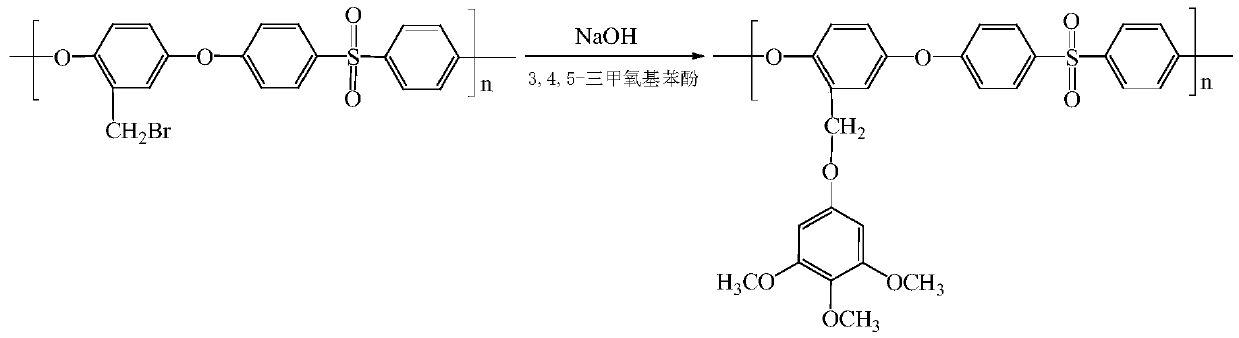

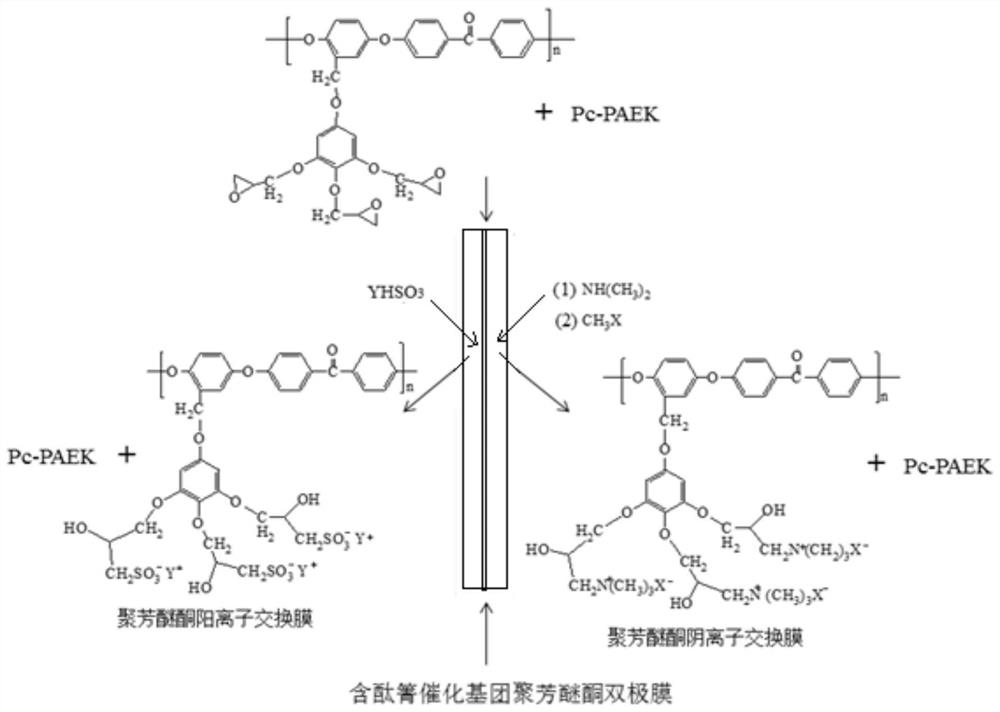

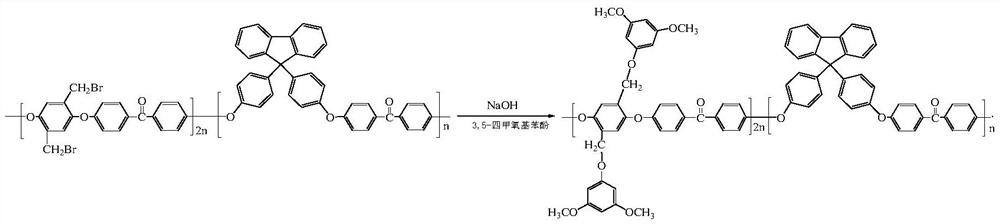

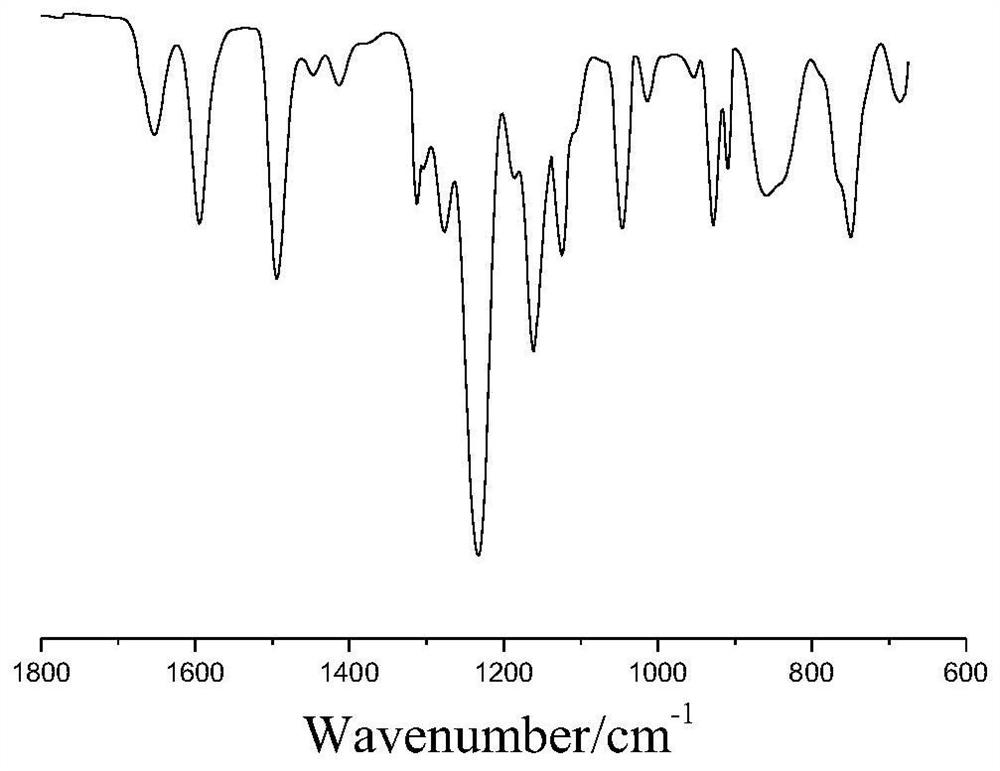

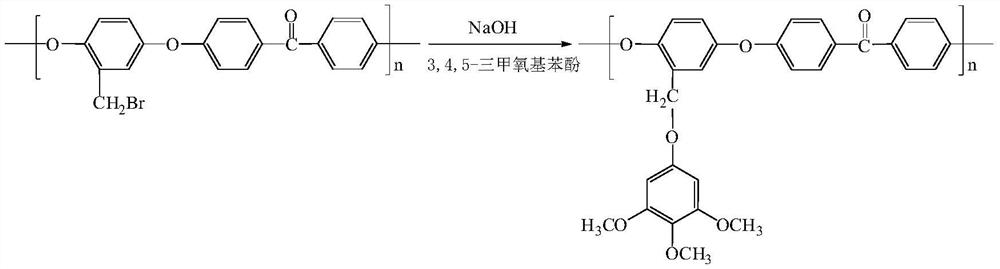

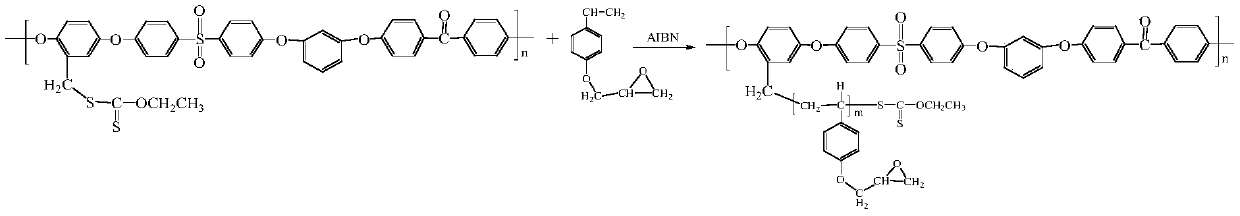

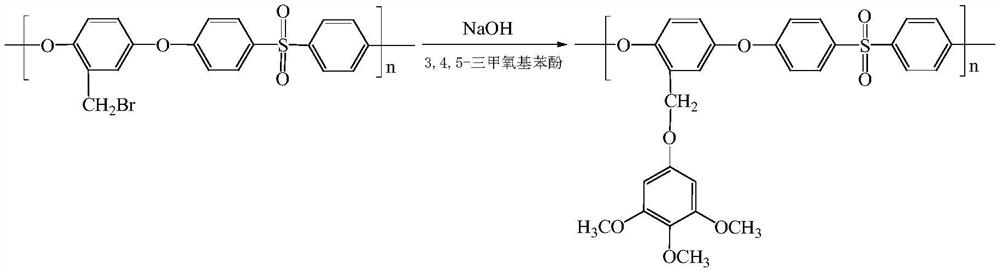

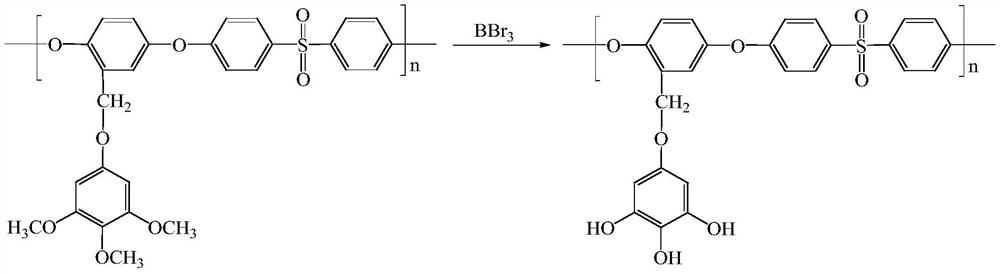

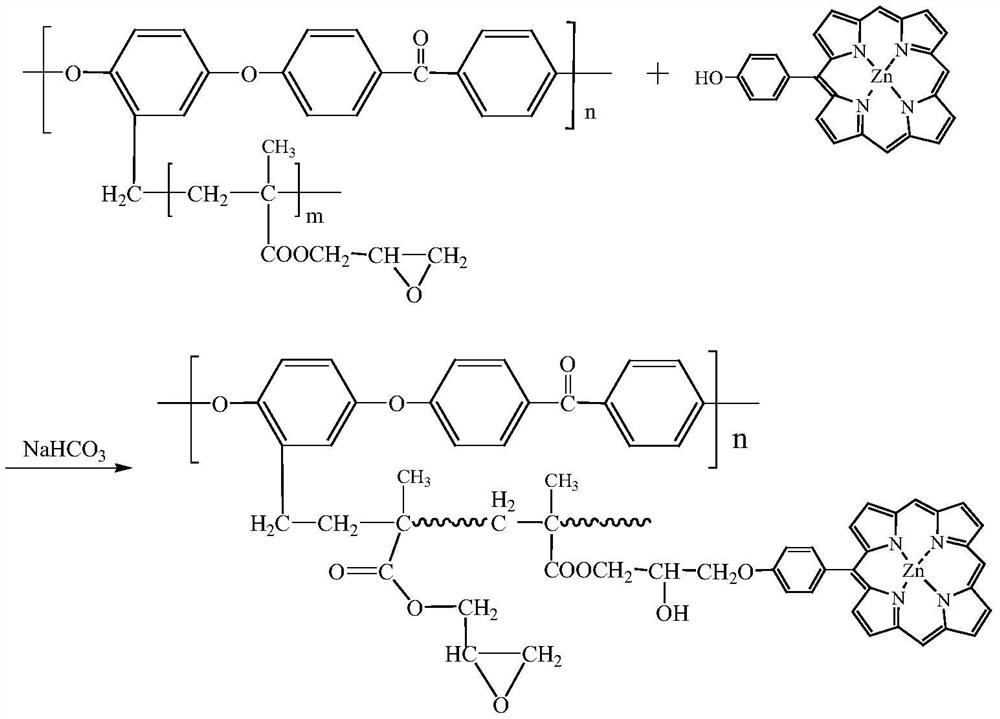

Preparation method of monolithic polyaryletherketone bipolar membrane containing porphyrin catalytic group in side group

ActiveCN111530308BReduce usageEliminate film forming processSemi-permeable membranesComplex ion-exchangersEpoxyAryl

The invention relates to a preparation method of a monolithic polyaryletherketone bipolar membrane containing a porphyrin group in a side group. Its scheme: bromomethylated polyaryl ether ketone and methoxy-containing phenol are reacted to obtain methoxy-phenol-containing poly-aryl-ether-ketone polymer; methoxy-phenol-containing polyaryl ether ketone polymer and boron tribromide solution Reaction to obtain hydroxyl-containing polyaryletherketone polymer; hydroxyl-containing polyaryletherketone polymer adding epichlorohydrin to react to obtain epoxy group-substituted polyaryletherketone polymer; bromomethylated polyaryletherketone polymer Compounds with hydroxyl-substituted porphyrins, NaHCO 3 The reaction is to obtain a polymer in which porphyrins are bonded to the side groups of poly(aryl ether ketone); PAEK-EG and Pc-PAEK are mixed and then cast and dried, and then the poly(aryl ether ketone-based membrane) is subjected to sulfonation reaction and amination reaction, The monolithic polyaryletherketone bipolar membrane containing porphyrin catalytic group was obtained by quaternary amination reaction. The monolithic bipolar membrane of the present invention does not produce a "bubbling" phenomenon during use, which is beneficial to improving stability and service life.

Owner:FUJIAN NORMAL UNIV

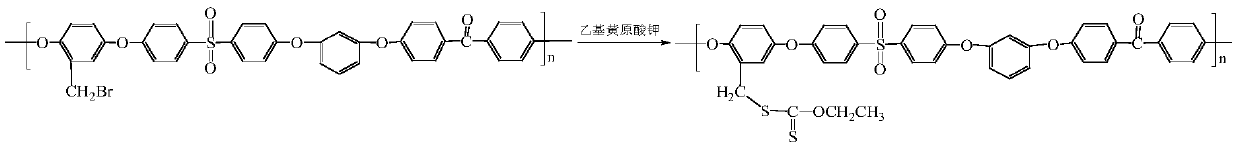

Preparation method of monolithic poly(aryl ether sulfone ketone) bipolar membrane with side chain containing phthalocyanine water dissociation catalytic group

InactiveCN111495215AReduce usageEliminate film forming processMembranesSemi-permeable membranesEpoxyPolymer science

The invention relates to a preparation method of a monolithic polyether sulfone ketone bipolar membrane with a side chain containing a phthalocyanine water dissociation catalytic group. The preparation method comprises the steps: respectively synthesizing a poly(aryl ether sulfone ketone) copolymer and a poly(aryl ether sulfone ketone) polymer by taking bromo-methylated poly(aryl ether sulfone ketone), an epoxy group-containing substituent monomer and bipyridine as starting raw materials, mixing, casting on a glass plate, and drying to prepare a poly(aryl ether sulfone ketone) base membrane containing phthalocyanine side chains; and sulfonating, aminating and quaternizing the base membrane, and washing with deionized water to obtain the monolithic phthalocyanine-containing poly(aryl ethersulfone ketone) bipolar membrane. According to the bipolar membrane prepared by the method, a monomer side chain with an epoxy group is introduced and grafted on a poly(aryl ether sulfone ketone) sidegroup through reversible addition-fragmentation chain transfer polymerization, and the molecular weight of the side chain with the epoxy group is controllable. The prepared bipolar membrane has a self-catalysis effect, and is low in resistance and low in transmembrane voltage. After long-term use, the problems of bubbling, cracking and the like of a middle interface layer of a compound bipolar film, which are easily caused in the use process of the composite bipolar membrane, can be avoided.

Owner:FUJIAN NORMAL UNIV

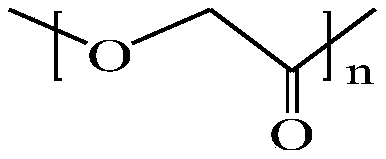

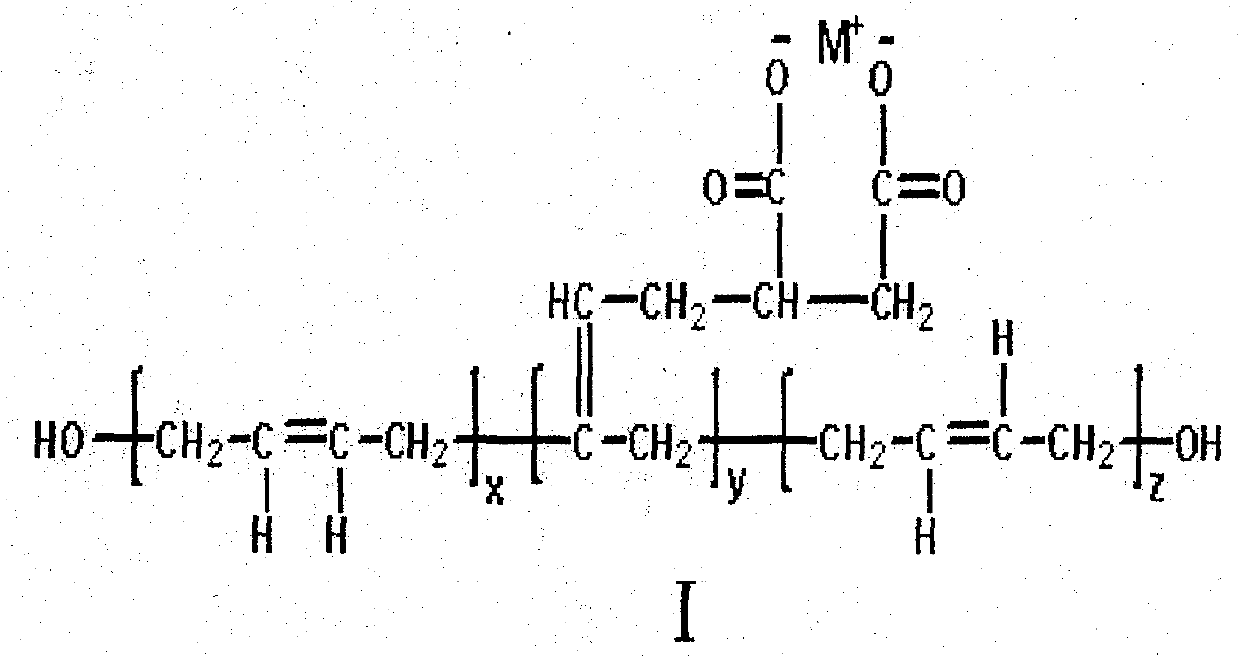

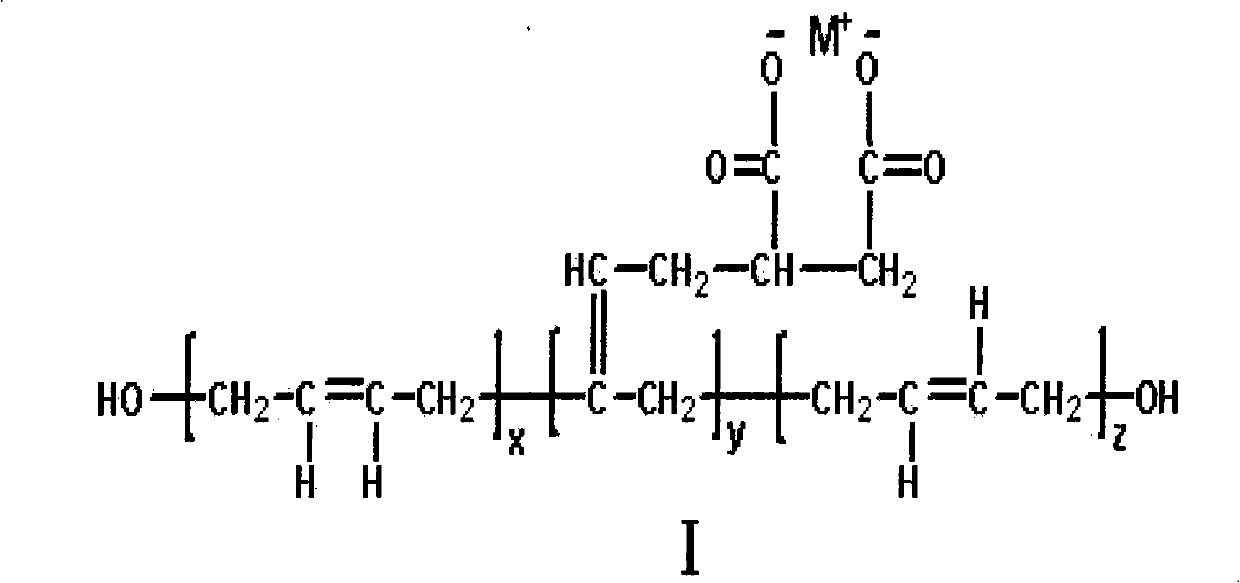

Oxygen uptake polyester composite material for packaging with isolation performance and method for producing the same

The present invention relates to an oxygen-absorption polyester composite used for barrier package. The oxygen-absorption polyester composite is characterized by comprising bottle grade polyester and autocatalytic deoxidant; the content of the bottle grade accounts for 90-99.9 weight percent in the whole composite; the content of the autocatalytic deoxidant accounts for 0.1-10 weight percent in the whole composite; a general structural formula of the autocatalytic deoxidant is formula I; in the formula, x, y and z are 5 to 40; and M<+> is Cu<2+>, Co<2+>, Ni<2+>, Mn<2+>, Fe<2+>, Cr<3+> or Zn<2+>. The present invention also relates to a method for preparing the oxygen-absorption polyester composite used for the barrier package. The invention has the advantages of high oxygen absorbability, low using quantity of transition metal ion in polyester package material, the more uniform distribution and better stability of a catalyst in the polyester package material, and difficulty in transferring.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

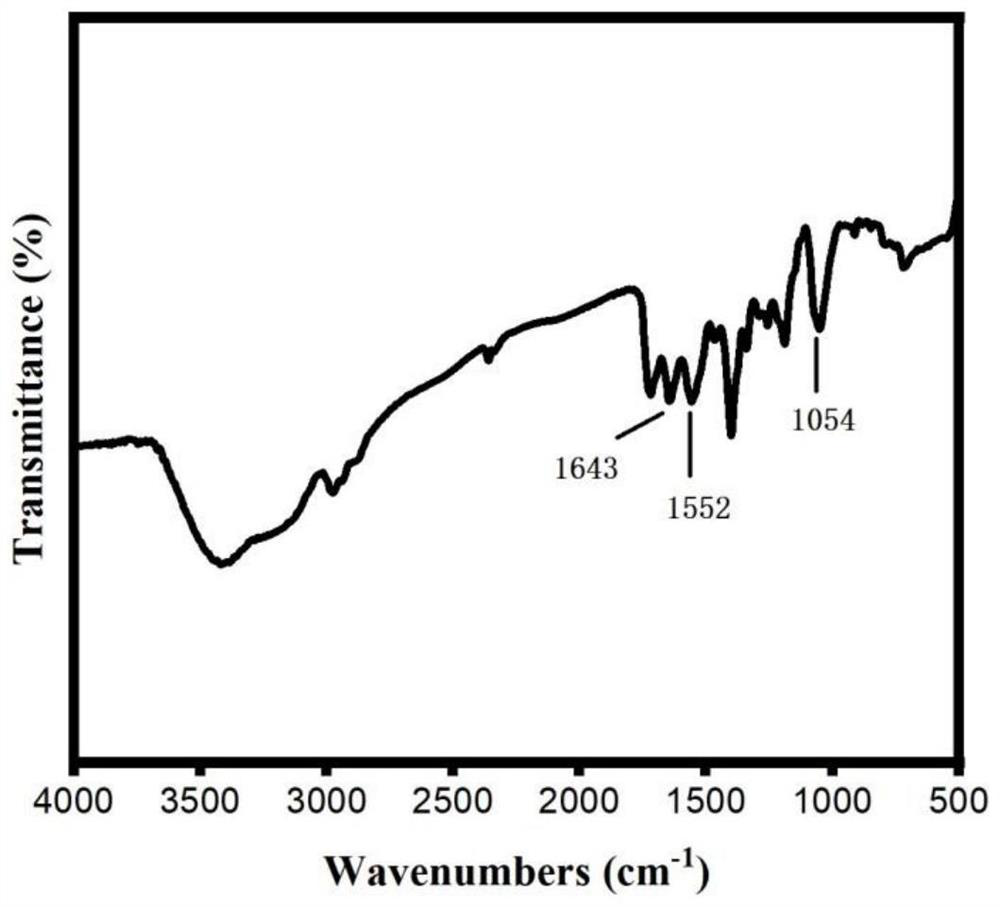

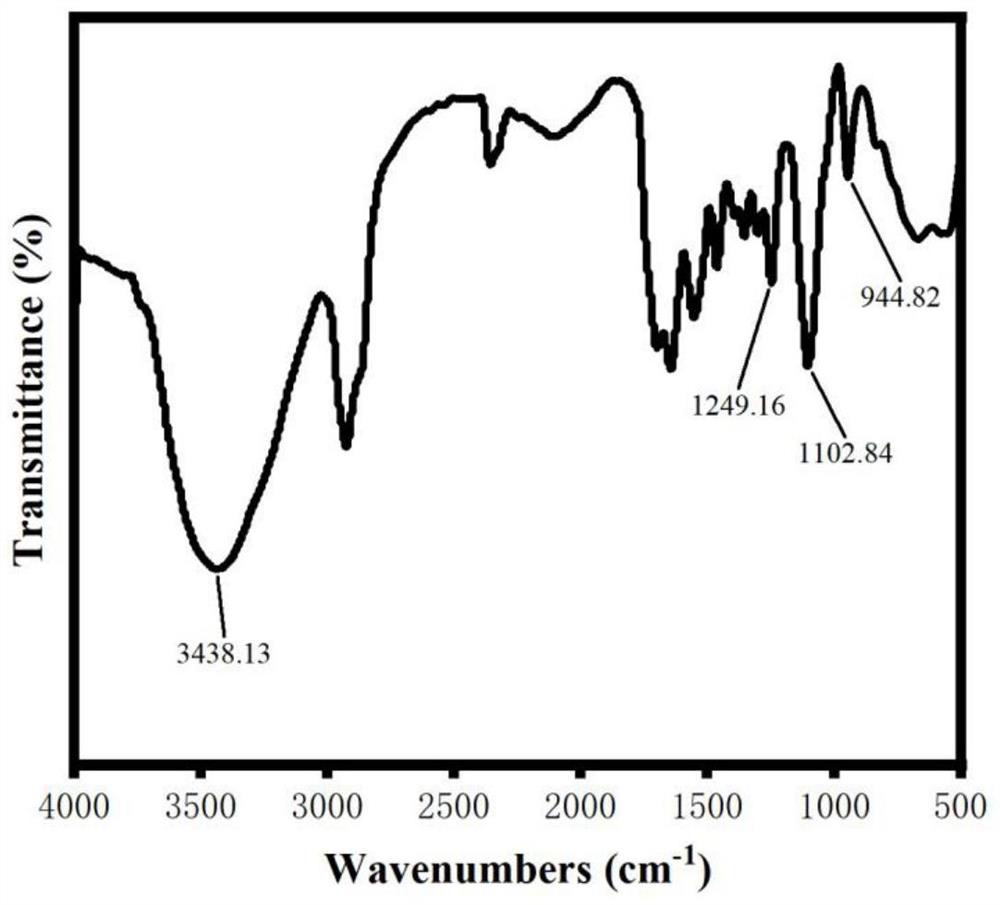

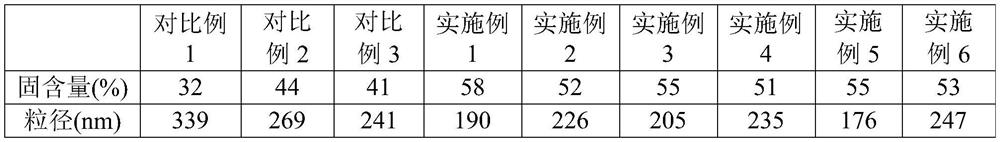

Waterborne polyurethane dispersoid with high solid content as well as preparation method and application of waterborne polyurethane dispersoid

The invention relates to the technical field of waterborne polyurethane, and discloses a high-solid-content waterborne polyurethane dispersoid as well as a preparation method and application thereof.The high-solid-content waterborne polyurethane dispersoid is prepared from the following raw materials: 40-55% of bio-based hyperbranched polyurethane, 0.5-5% of a neutralizing agent, 0.5-5% of a sulfonate chain extender and the balance of water; the preparation method comprises the following steps: reacting organic acid anhydride with tris (hydroxymethyl) aminomethane in a solvent to prepare a hyperbranched chain extender; vegetable oil, diisocyanate and high polymer dihydric alcohol are subjected to a reaction to prepare a bio-based branched polyurethane prepolymer, a hyperbranched chain extender is added into the system for a reaction, and the bio-based hyperbranched polyurethane is obtained. The solid content of the dispersion can reach 50%-65%, the particle size of the dispersion is smaller than 250 nm, the dispersion can be stably stored for a long time, meanwhile, the dispersion has the characteristics of high solid content, bio-based raw materials, no solvent and autocatalysis, and the dispersion has important significance on industry development.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV

A kind of self-catalyzed alkyd resin and preparation method thereof

The invention discloses a self-catalyzed alkyd resin and a preparation method thereof. During the preparation, glycerin, benzoic acid, soy oil acid, phthalic anhydride, color reducing agent, xylene and self-made drier are put into a four-necked flask, and the Raise the temperature to reflux, react at 180-200°C for 3 hours, then divide the water and raise the temperature to 200-210°C, react for 5 hours, when the acid value is 10-20mgKOH / g, cool down to 100°C, add xylene and stir to obtain autocatalytic Alkyd resin. The alkyd resin achieves self-catalysis by introducing a group with drying effect, and can shorten the drying time of PU paint without adding a drier when making paint. Compared with an external drier, the catalytic effect It is more stable, and there is no problem of uneven gloss of the paint film caused by uneven precipitation and dispersion of the external drier, which improves the sandability and yellowing resistance of the primer, and reduces the cost of the customer's later paint production.

Owner:鹤山市肇能新材料有限公司

Epoxy resin curing agent, synthesis method and curing method

ActiveCN105646846BLow viscosityHigh activityCarboxylic acid nitrile preparationOrganic compound preparationEpoxyEthylenediamine

The invention provides an epoxy resin curing agent, a synthesis method and a curing method and belongs to the field of curing agent products. The epoxy resin curing agent is N,N'-bis(3-aminopropyl) ethanediamine and is synthesized from raw materials including ethanediamine, ketone, acrylonitrile and the like through multi-step reactions. The epoxy resin curing agent has high curing strength, wear resistance and scratch resistance and has a higher curing speed at a low temperature, a surface after curing is bright, is not prone to oxidation and has excellent yellowing resistance. The synthesis method of the epoxy resin curing agent is simple in process and convenient to control.

Owner:雅安市弘利展化工有限公司

A preparation method of side group-bonded phthalocyanine catalytic group monolithic polysulfone bipolar membrane

ActiveCN111530313BReduce usageEliminate film forming processSemi-permeable membranesComplex ion-exchangersPolymer scienceAutocatalysis

The invention relates to a method for preparing a side group-bonded phthalocyanine catalytic group monolithic polysulfone bipolar membrane. The present invention uses bromomethylated polysulfone polymers as starting materials, respectively synthesizes polysulfone polymers containing epoxy group substituents and polysulfone side groups bonded with phthalocyanine polymers, mixes them and casts them on a clean A glass plate was dried to prepare a polysulfone-based membrane containing phthalocyanine group side groups and epoxy group side groups; after the base membrane was sulfonated, ammonized and quaternized, it was washed with deionized water to obtain a monolithic Polysulfone bipolar membranes containing phthalocyanine groups. The bipolar membrane prepared by the present invention adopts a nucleophilic substitution reaction, introduces an epoxy group on the polysulfone side group, introduces an anion and a cation exchange membrane method into the polysulfone molecular chain, and saves the film-forming process and avoids the carcinogen chlorine Use of methyl ether. The prepared bipolar membrane has self-catalysis, low bipolar membrane resistance and low transmembrane voltage. Long-term use, there will be no problems such as bubbling and cracking in the middle interface layer that are prone to occur during the use of composite bipolar membranes.

Owner:FUJIAN NORMAL UNIV

an epoxy curing agent

ActiveCN109912781BLow temperature and quick dryingFast curingThiol preparationPolymer scienceFirming agent

The invention relates to a water-based epoxy curing agent for water-based epoxy resin, its preparation method and its use method. The water-based epoxy curing agent uses mercapto and amino groups as curing reaction groups. The structure of the curing agent contains a tertiary amine structure, which can be dispersed or dissolved in water. Compared with the polyamine curing agent, the quick-drying curing agent prepared by the present invention has a shorter curing time. Faster, can achieve low-temperature curing, better impact resistance, and the quick-drying curing agent prepared by the present invention has a faster curing time than the mercaptan curing agent, and at the same time, the hardness, bending and impact resistance of the film are significantly improved.

Owner:SUZUKA INTERNATIONAL (SHANGHAI) CO LTD

Preparation method of monolithic polyaryletherketone bipolar membrane containing porphyrin water dissociation catalytic group in side chain

ActiveCN111617644BReduce usageEliminate film forming processSemi-permeable membranesComplex ion-exchangersEpoxyPolymer science

The invention relates to a method for preparing a monolithic polyaryl ether ketone bipolar membrane containing a porphyrin water dissociation catalytic group in the side chain, using bromomethylated polysulfone and bromomethylated polysulfone polymer as starting materials to synthesize The polysulfone-based membrane mixture containing porphyrin and epoxy group side groups is mixed and cast on a clean glass plate, and dried to prepare the polysulfone-based membrane containing porphyrin and epoxy group side groups; After the base membrane is sulfonated, ammonized and quaternized, it is washed with deionized water to obtain a monolithic polyaryletherketone bipolar membrane containing phthalocyanine side groups. The bipolar membrane prepared by the present invention adopts a nucleophilic substitution reaction, introduces an epoxy group on the polysulfone side group, introduces an anion and a cation exchange membrane method into the polysulfone molecular chain, and saves the film-forming process and avoids the carcinogen chlorine Use of methyl ether. The prepared bipolar membrane has self-catalysis, low bipolar membrane resistance and low transmembrane voltage. Long-term use, there will be no problems such as bubbling and cracking in the middle interface layer that are prone to occur during the use of composite bipolar membranes.

Owner:FUJIAN NORMAL UNIV

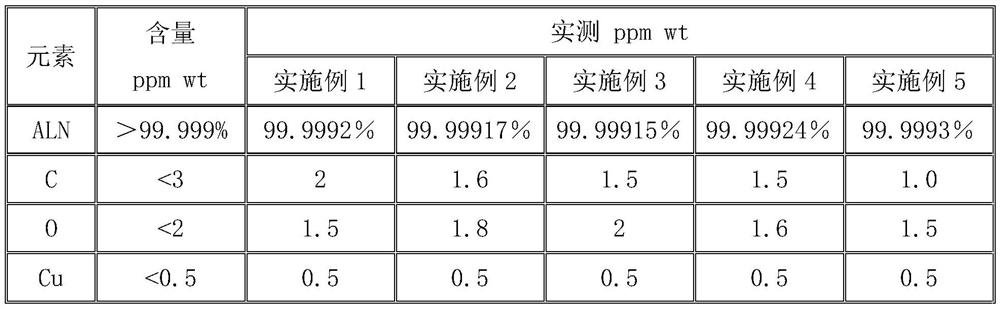

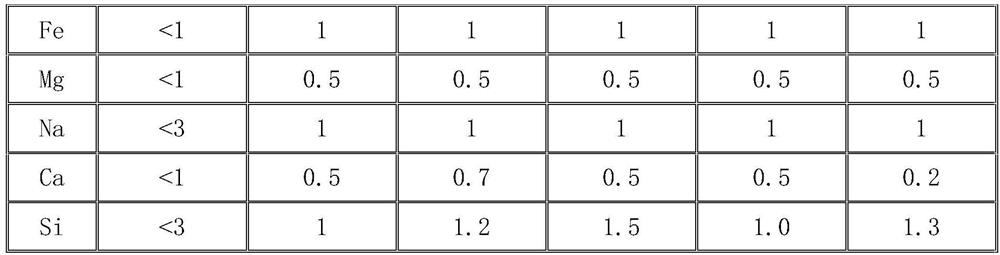

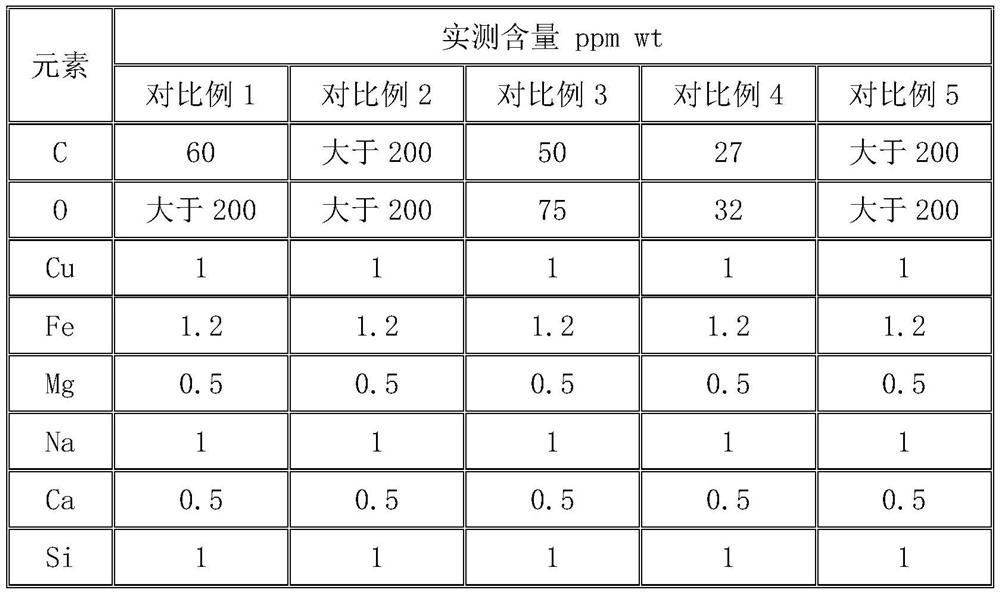

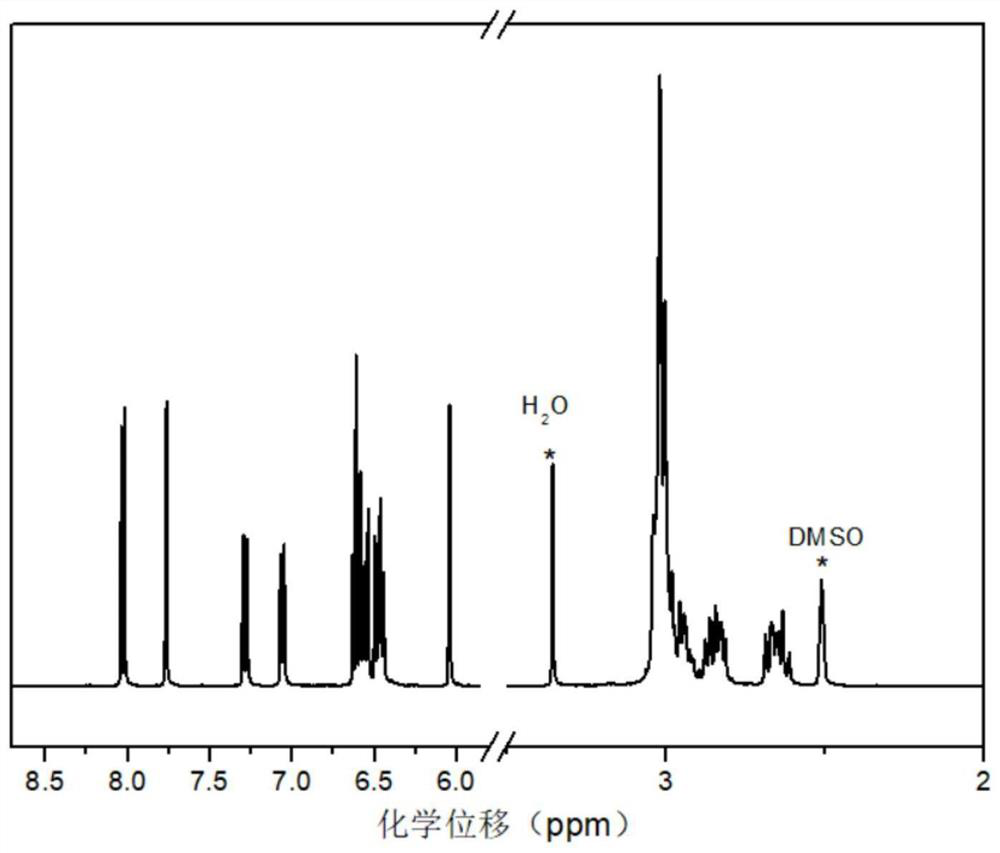

A kind of preparation method of self-catalyzed high-purity aluminum nitride

ActiveCN111825066BGuaranteed puritySpeed up thermal motionNitrogen compoundsPhysical chemistryAluminium powder

The invention discloses a method for preparing self-catalyzed high-purity aluminum nitride, which belongs to the technical field of aluminum nitride synthesis, and comprises the following steps: (1) mixing materials: aluminum hydroxide powder, carbon powder, and aluminum nitride powder are used as the The raw materials are uniformly mixed according to a certain weight ratio to obtain a mixed material; (2) high-temperature synthesis: the mixed material is placed in a mixed gas flow of nitrogen and propane at a certain pressure at 1350-1420 ° C, and reacted for 1.5-3 hours to obtain a reaction product ; (3) Decarburization: remove the carbon in the reaction product to obtain aluminum nitride powder. In the preparation method of self-catalyzed high-purity aluminum nitride disclosed by the present invention, aluminum nitride is selected as a seed crystal, and the reaction is carried out in a mixed gas flow of nitrogen and propane at a certain pressure, the thermal motion of reaction molecules is enhanced, and the diffusion and penetration rate is increased. It has a self-catalytic effect, shortens the reaction synthesis time, and reduces the reaction synthesis temperature by 200-400°C; and avoids the pollution of impurity elements brought in by adding other additives, and ensures the purity of the prepared aluminum nitride.

Owner:SHANDONG HENGJING NEW MATERIAL CO LTD

Phthalonitrile monomer containing parylene structure, phthalonitrile resin and preparation method thereof

ActiveCN113402423BSelf-catalyzedAvoid defectsOrganic compound preparationCarboxylic acid nitrile purification/separationPolymer scienceParylene

The invention discloses a parylene structure-containing phthalonitrile monomer, a phthalonitrile resin and a preparation method thereof. The parylene structure-containing phthalonitrile monomer is a parylene structure-containing phenol. The compound, nitrophthalonitrile is used as raw material, and it is obtained by reaction under the action of basic catalyst. The phthalonitrile monomer containing parylene structure is subjected to step heating and curing reaction to obtain parylene-containing phthalonitrile resin. In the present invention, the parylene structure is introduced into the phthalonitrile structure for the first time, and the prepared phthalonitrile monomer containing the parylene structure has a lower melting point, has an autocatalytic effect, and can be used as a traditional phthalonitrile monomer. The solidified curing agent is also a derivative monomer of parylene structure, which can be formed by thermal processing, which greatly reduces the processing difficulty and processing cost.

Owner:SICHUAN UNIV

Phthalonitrile monomer containing parylene structure, phthalonitrile resin and preparation method thereof

ActiveCN113402423ASelf-catalyzedAvoid defectsOrganic compound preparationCarboxylic acid nitrile purification/separationPolymer scienceParylene

The invention discloses a phthalonitrile monomer containing a parylene structure, a phthalonitrile resin and a preparation method thereof, and the phthalonitrile monomer containing a parylene structure is obtained by taking a parylene structure-containing phenolic compound and nitrophthalonitrile as raw materials and reacting under the action of a basic catalyst. The phthalonitrile resin containing parylene is obtained through stepped heating curing reaction on the phthalonitrile monomer containing the parylene structure. According to the invention, the parylene structure is introduced into the phthalonitrile structure for the first time, and the prepared phthalonitrile monomer containing the parylene structure is reduced in melting point, has an autocatalysis effect, can be used as a curing agent for curing a traditional phthalonitrile monomer, is also a derivative monomer of the parylene structure, and can be subjected to hot processing molding; and the processing difficulty and the processing cost are greatly reduced.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com