A kind of preparation method of self-catalyzed high-purity aluminum nitride

An aluminum nitride, autocatalytic technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of poor fluidity, long reaction time, high cost, and ensure stability and consistency, diffusion and penetration rate. The effect of increasing and bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

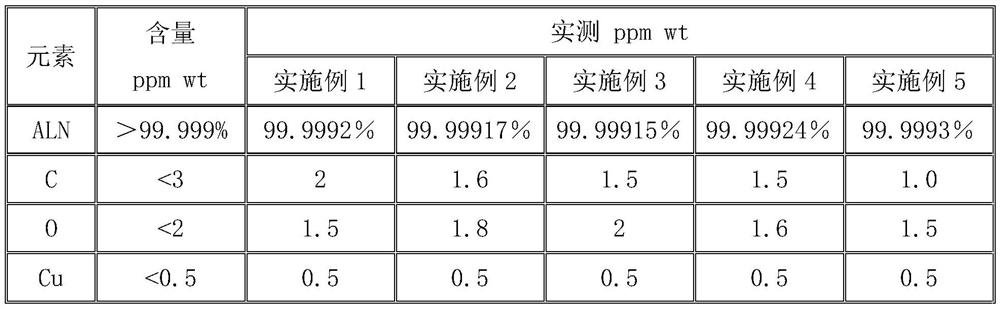

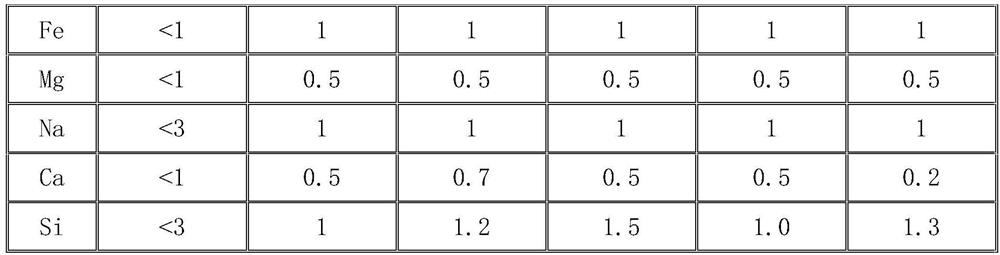

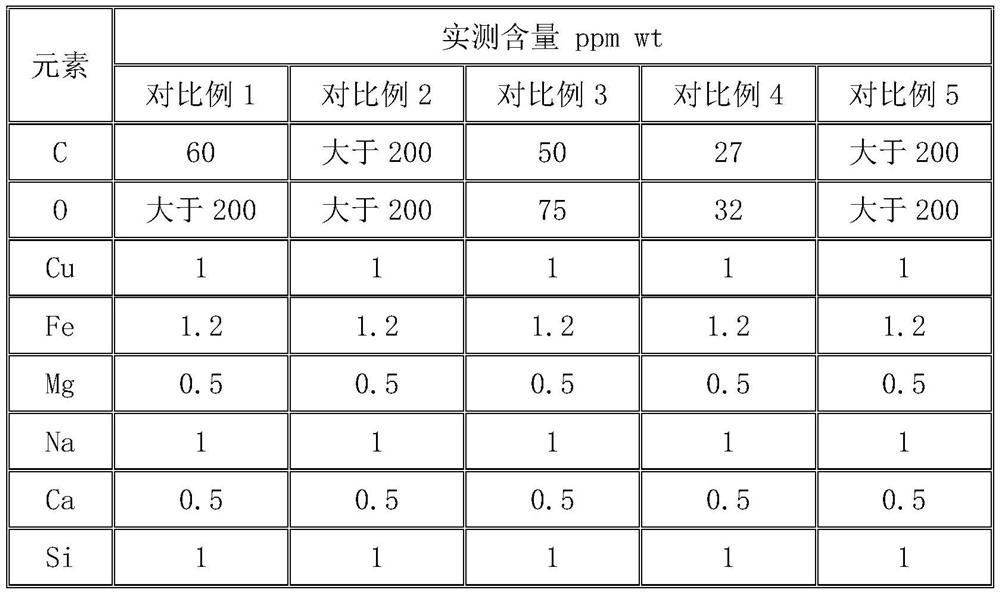

Examples

Embodiment 1

[0048] Embodiment 1: The preparation method of self-catalyzed high-purity aluminum nitride in this embodiment is as follows:

[0049] (1) Mixture:

[0050] (1.1) Feeding: Use a clean towel to wipe off the dust and foreign matter on the surface of the aluminum hydroxide powder, carbon powder, aluminum nitride powder raw material bag, add 72 kg of aluminum hydroxide powder, 39 kg of carbon powder, and 2.0 kg of aluminum nitride powder to mix In the mixing tank on the machine, tighten the screw on the mixing tank to fix the lid, start the mixer, control the speed at 15 rpm, and mix for 12 hours to obtain the mixed material;

[0051] (1.2) Unloading: After mixing according to the specified time, control the switch of the mixer so that the outlet of the mixer is vertically downward, wipe off the dust on the outer surface of the mixing tank and the outlet with a clean towel, and put the pre-prepared The good raw material barrel is placed under the discharge port, and the valve is o...

Embodiment 2

[0062] Embodiment 2: the difference between this embodiment and embodiment 1 is:

[0063] The weight of aluminum hydroxide powder is 70 kg, the weight of carbon powder is 36 kg, and the weight of aluminum nitride powder is 2.2 kg;

[0064] During mixing, the rotating speed of the mixer was 12 revs / min, and the mixing time was 18 hours;

[0065] In the reaction furnace, the flow rate of the mixed gas flow is controlled at 0.4L / min, the pressure of the mixed gas flow is controlled at 0.2MPa, the feed rate of propane accounts for 1.0% of the nitrogen, the temperature in the reaction furnace is 1350°C, and the crucible is placed on the push plate Automatically advance a board every 12 minutes;

[0066] The decarburization temperature in the oxidation furnace is 600°C, and the time is 2 hours;

[0067] Other operations are the same.

Embodiment 3

[0068] Embodiment 3: the difference between this embodiment and embodiment 1 is:

[0069] The weight of aluminum hydroxide powder is 60 kg, the weight of carbon powder is 30 kg, and the weight of aluminum nitride powder is 1.6 kg;

[0070] During mixing, the rotating speed of the mixer was 20 rpm, and the mixing was done for 12 hours;

[0071] In the reaction furnace, the flow rate of the mixed gas flow is controlled at 0.5L / min, the pressure of the mixed gas flow is controlled at 0.3MPa, the feed rate of propane accounts for 1.2% of the nitrogen, the temperature in the reaction furnace is 1400°C, and the crucible is placed on the push plate Automatically advance a board every 14 minutes;

[0072] The decarburization temperature in the oxidation furnace is 700°C, and the time is 1.7 hours;

[0073] Other operations are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com