Preparation method of surface-modified ZTA ceramic particle reinforced steel based composite material

A technology of ceramic particles and composite materials, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of peeling off of the composite layer along the bonding surface, high brittleness, early fracture or peeling, etc., and achieve economical improvement. Benefits and social benefits, simple process operation, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

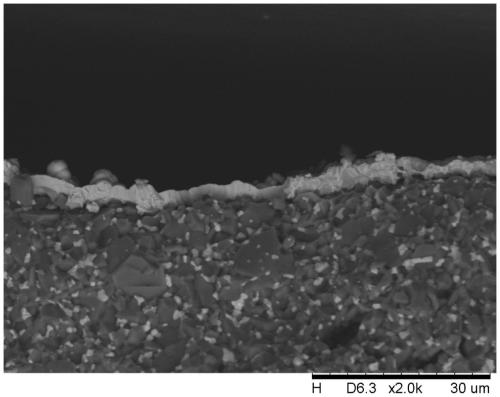

Image

Examples

preparation example Construction

[0027] A method for preparing a surface-modified ZTA ceramic particle reinforced iron-based composite material of the present invention comprises the following steps:

[0028] S1. Soak ZTA ceramic particles in acetone for 10 to 30 minutes, followed by ultrasonic cleaning for 5 to 15 minutes, followed by deionized water cleaning and alcohol rinsing, and drying in an electric constant temperature blast drying oven at a temperature of 105°C , the time is 6h, standby;

[0029] S2. Use a stannous chloride solution with a concentration of 5 to 15g / L to sensitize the ZTA ceramic particles for 10 to 30 minutes, and perform an activation treatment with a palladium chloride solution with a concentration of 0.3 to 0.6g / L for 10 to 30 minutes, and then adsorb on the surface Pd 2+ The reducing agent H in the sodium hypophosphite solution with a concentration of 5-15g / L 2 PO 2 - In situ reduction to metallic Pd;

[0030] S3. Prepare a stabilizer with methanol, sodium sulfite and ferrou...

Embodiment 1

[0041] 1) First, soak the ZTA particles in acetone for 10 minutes, ultrasonically clean them for 5 minutes, then wash them with deionized water, rinse them with alcohol, and dry them;

[0042] 2) Next, sensitize the ZTA ceramic particles with 5g / L stannous chloride solution for 10min, activate with 0.3g / L palladium chloride solution for 10min, and the Pd adsorbed on the surface 2+ Reducing agent H in 5g / L sodium hypophosphite solution 2 PO 2 - In situ reduction to metallic Pd;

[0043] 3) Prepare a stabilizer with methanol, sodium sulfite and ferrous sulfate in proportion, then dissolve 70g / L chromium sulfate, dissolve 35g / L boric acid in deionized water at 50°C, and magnetically stir until completely dissolved, then mix the chromium sulfate solution with boric acid Stir the solution for 1.5h; introduce complexing agent - oxalic acid 0.2mol / L, continue to stir for 1h to make it completely complexed, add 0.1mol / L of citric acid, continue stirring for 1h, add deionized water ...

Embodiment 2

[0048] 1) First, soak ZTA particles in acetone for 20 minutes, ultrasonically clean for 10 minutes, wash with deionized water, rinse with alcohol, and dry;

[0049] 2) Next, carry out sensitization treatment 20min to ZTA ceramic particle with the stannous chloride solution of 10g / L, 0.4g / L palladium chloride solution activation treatment 20min, the H in the sodium hypophosphite solution of 10g / L 2 PO 2 - In situ reduction of Pd 2+ ;

[0050] 3) Prepare a stabilizer with methanol, sodium sulfite and ferrous sulfate in proportion, then dissolve 95g / L chromium sulfate, dissolve 50g / L boric acid in deionized water at 65°C, stir until completely dissolved, and mix the chromium sulfate solution with boric acid Stir the solution for 1.5h; introduce complexing agent - oxalic acid 0.6mol / L, continue stirring for 2h to make it complex completely, add 0.5mol / L citric acid, continue stirring for 1.5h, add deionized water to 1L, adjust the pH value To 2.5, ZTA ceramic particles are pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com