Preparation method and preparation system for ultralight composite traction belt

A composite material and traction belt technology, used in belts, auxiliary devices for rope making, applications, etc., can solve the problems of poor impregnation of fiber fabrics and affect the performance of traction belts, achieve good impregnation, improve load transfer and resistance. Fatigue performance, effect of improving tensile properties and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

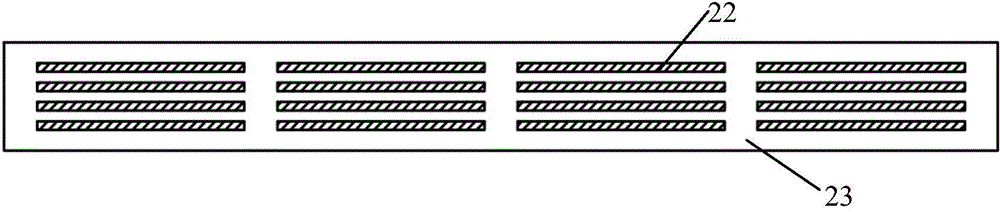

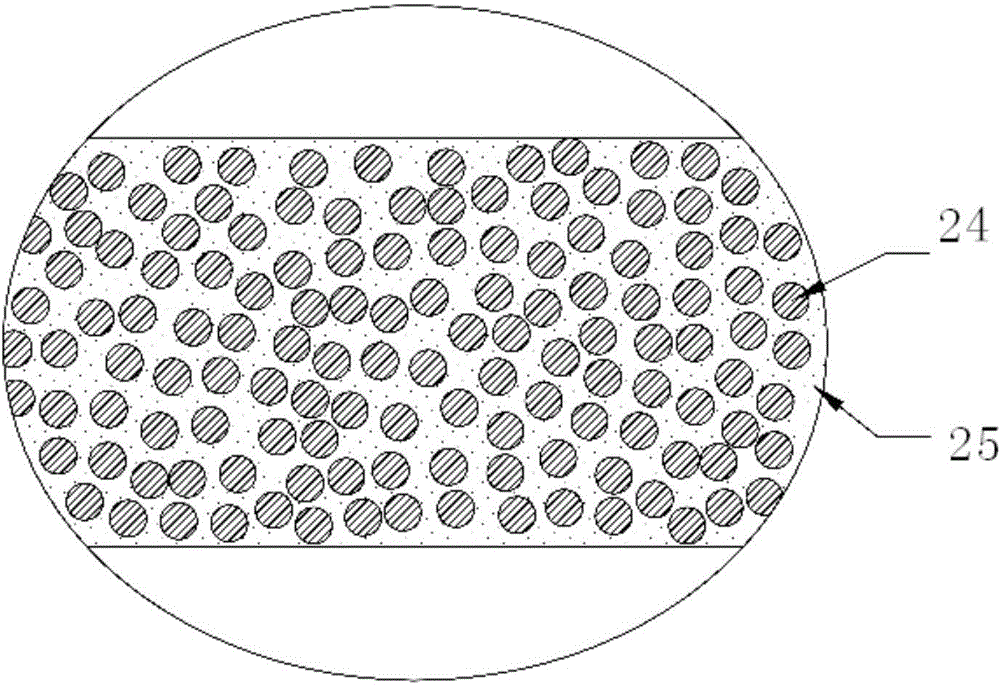

[0038] by figure 1 The traction belt composed of 4 layers and 4 columns (4×4 structure) composite material reinforcement sheet is shown as an example. The untwisted continuous fiber in the composite material reinforcement sheet is selected from carbon fiber, and the thermosetting resin in the composite material reinforcement sheet is epoxy resin. , The thermoplastic resin constituting the matrix is polyurethane resin.

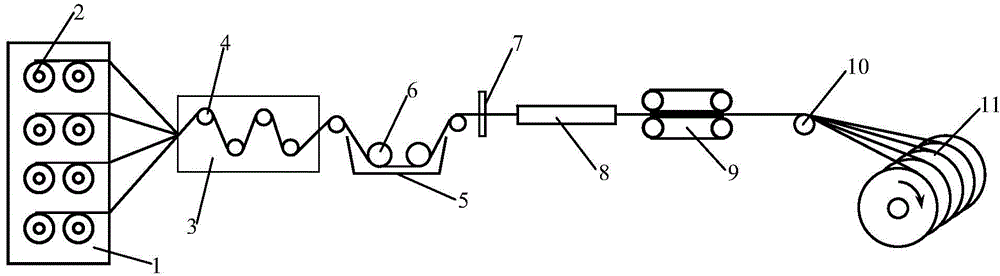

[0039] Select 24 T300 continuous carbon fiber clusters treated with sizing agent, and place them on the fiber reel 2 on the creel 1 respectively. Set the temperature of the pultrusion mold 8 to 150-180° C., and start to preheat the pultrusion mold 8 . Mix the selected epoxy resin and its curing agent evenly, and add it into the dipping tank 3.

[0040] Start the forming device for the composite material reinforcing sheet, adjust the continuous fiber yarn cluster and the spreading roller 4, so that the carbon fiber is evenly spread out, and the tension force...

Embodiment 2

[0046] Figure 5 Shown is a 6×4 structural carbon fiber reinforced epoxy resin and thermoplastic polyurethane resin hybrid composite ultra-lightweight traction belt

[0047] The preparation process of the continuous fiber reinforced thermosetting composite material sheet is similar to the preparation process of Example 1, the main difference is that the number of continuous fiber yarn clusters in the embodiment is adjusted from 24 to 16, and 4 relatively thin continuous composite material sheets are obtained material, and repeated 5 times to obtain 24 continuous sheets of continuous carbon fiber reinforced thermosetting epoxy resin composites.

[0048] The preparation process of the continuous carbon fiber-reinforced hybrid composite traction belt is similar to the preparation process in Example 1, the main difference is that the 4×4 die in Example 1 is replaced with a 6×4 extrusion die to prepare Figure 5 Continuous carbon fiber reinforced epoxy resin and thermoplastic poly...

Embodiment 3

[0051] preparation figure 1 The shown 4×4 carbon fiber reinforced vinyl resin and thermoplastic polyurethane resin hybrid composite ultra-light traction belt, its implementation process is similar to that of Example 1, only the epoxy resin in Example 1 is replaced with vinyl resin , and reset the temperature of the pultrusion mold to 140-190° C., and the rest of the process and parameters and equipment are the same as in Example 1. The composite traction belt of Example 3 can be prepared.

[0052] Compared with the existing steel wire reinforced traction belt with the same size, the tensile performance of the prepared composite material traction belt is more than 1.6 times, and the weight is only 1 / 5 of the steel wire reinforced traction belt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com