Chemical nickel-gold process applied to wafer aluminum-copper base material in field of IGBT (Insulated Gate Bipolar Translator) power devices

A technology of chemical nickel gold and power devices, applied in the field of chemical nickel gold plating, can solve the problems of slow nickel plating, affecting product yield, disconnection of chloride lines, etc., and achieve the effect of promoting rapid formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

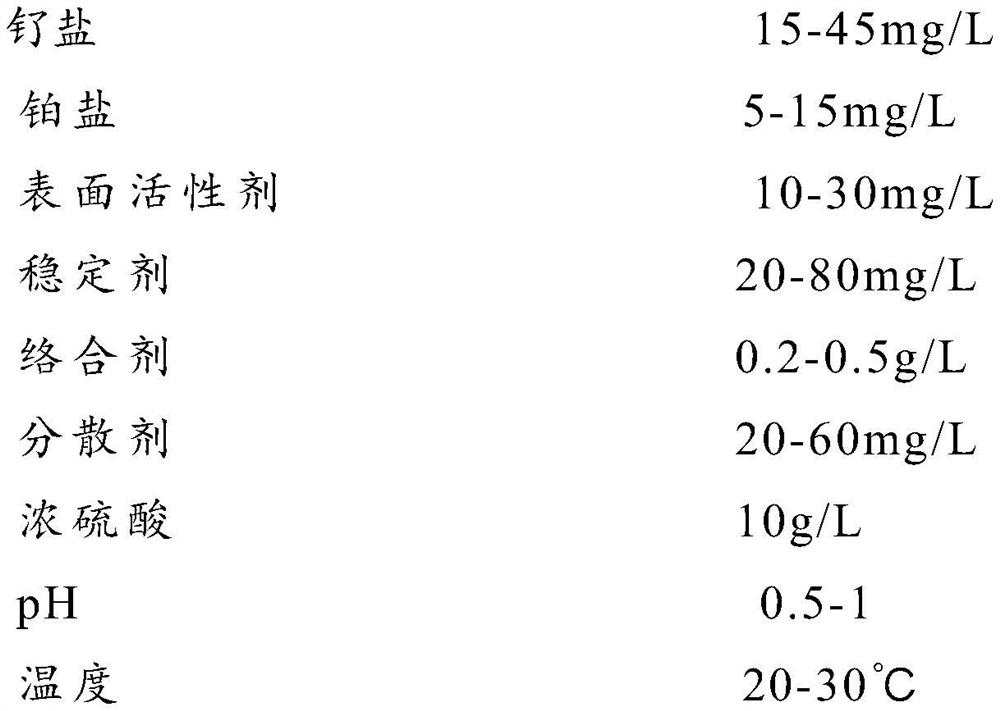

[0064] An activation solution applied to the chemical nickel-gold pretreatment of wafer aluminum-copper substrates in the field of IGBT power devices, comprising components with the following mass concentrations, calculated per liter of bath solution:

[0065]

[0066]

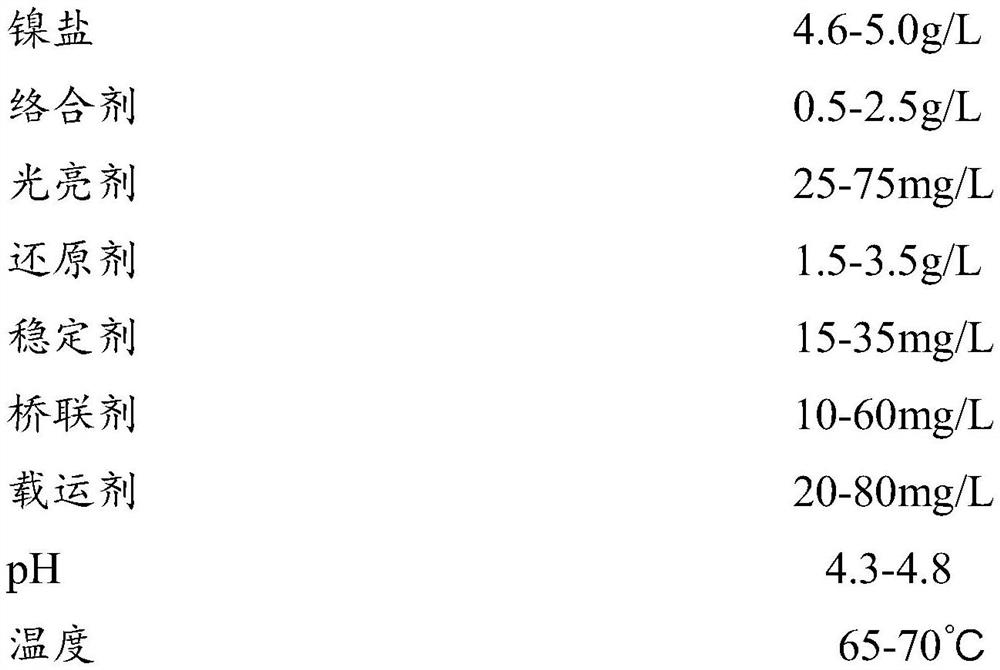

[0067] An electroless nickel plating solution applied to wafer aluminum-copper substrates in the field of IGBT power devices, comprising the following mass concentration components, calculated per liter of bath solution:

[0068]

[0069] An electroless gold plating solution applied to wafer aluminum-copper substrates in the field of IGBT power devices, comprising the following mass concentration components, calculated per liter of bath solution:

[0070]

[0071] The product test result obtained by embodiment 1 is: 1, the stability of the activation solution is excellent, the stability of the chemical nickel solution is excellent, and the stability of the electroless gold plating solution is excell...

Embodiment 2

[0073] An activation solution applied to the chemical nickel-gold pretreatment of wafer aluminum-copper substrates in the field of IGBT power devices, comprising components with the following mass concentrations, calculated per liter of bath solution:

[0074]

[0075] An electroless nickel plating solution applied to wafer aluminum-copper substrates in the field of IGBT power devices, comprising the following mass concentration components, calculated per liter of bath solution:

[0076]

[0077] An electroless gold plating solution applied to wafer aluminum-copper substrates in the field of IGBT power devices, comprising the following mass concentration components, calculated per liter of bath solution:

[0078]

[0079] The product test result obtained by embodiment 2 is: 1, the stability of the activation solution is excellent, the stability of the chemical nickel solution is excellent, and the stability of the electroless gold plating solution is excellent; Nickel...

Embodiment 3

[0081] An activation solution applied to the chemical nickel-gold pretreatment of wafer aluminum-copper substrates in the field of IGBT power devices, comprising components with the following mass concentrations, calculated per liter of bath solution:

[0082]

[0083] An electroless nickel plating solution applied to wafer aluminum-copper substrates in the field of IGBT power devices, comprising the following mass concentration components, calculated per liter of bath solution:

[0084]

[0085]

[0086] An electroless gold plating solution applied to wafer aluminum-copper substrates in the field of IGBT power devices, comprising the following mass concentration components, calculated per liter of bath solution:

[0087]

[0088] The product test result obtained by embodiment 3 is: 1, the stability of the activation solution is excellent, the stability of the chemical nickel solution is excellent, and the stability of the electroless gold plating solution is excell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com