Waterborne polyurethane dispersoid with high solid content as well as preparation method and application of waterborne polyurethane dispersoid

A water-based polyurethane, high solid content technology, applied in the field of water-based polyurethane, can solve the problems of aggravating global warming, reducing system viscosity, environmental pollution, etc., and achieving the effects of reducing transportation costs, low prices, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

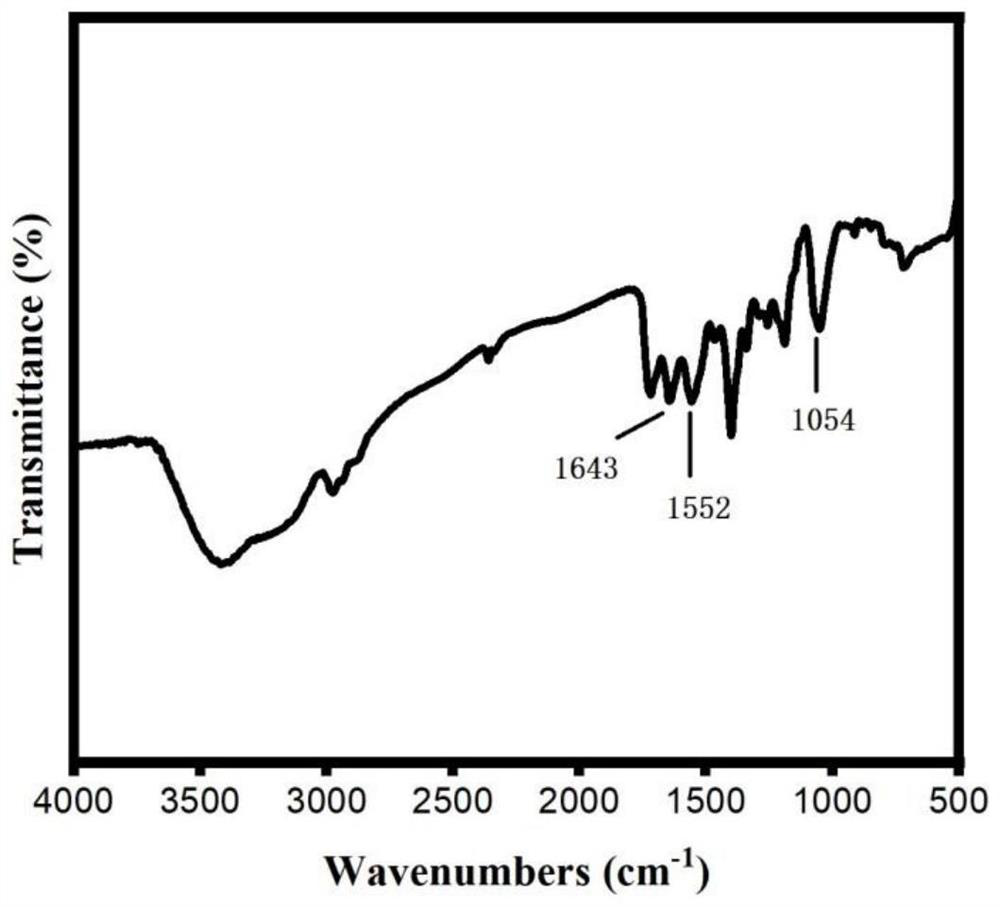

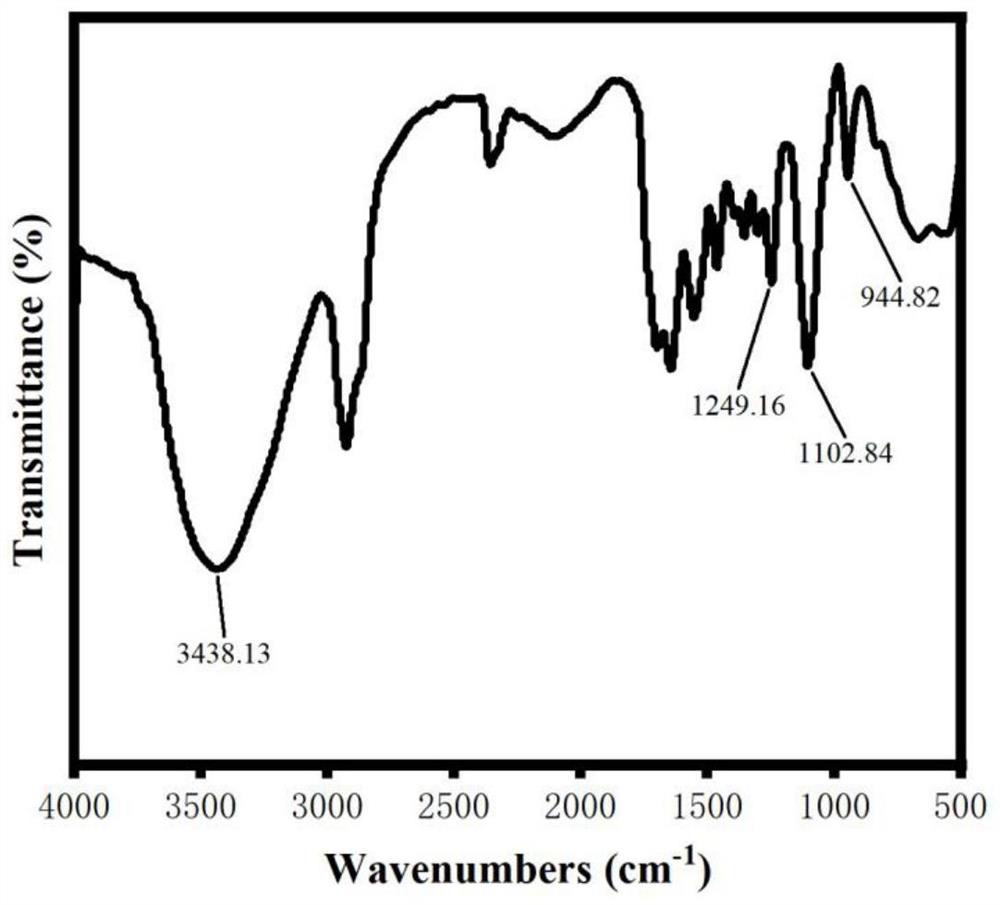

Image

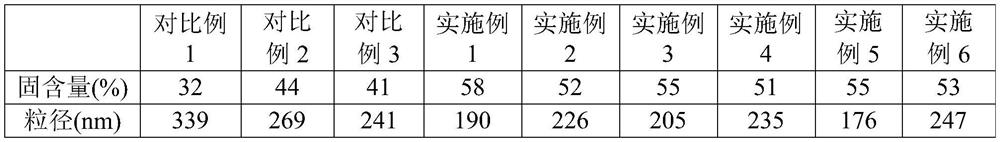

Examples

Embodiment 1

[0052] (1) Weigh 8.2g of norbornene dianhydride and 6.1g of tris(hydroxymethyl)aminomethane according to the ratio of the acid anhydride functional group of norbornene dianhydride to tris(hydroxymethyl)aminomethane amino functional group at 1:1.2 and dissolve in 200mL In methanol, the temperature was raised to 50 °C with magnetic stirring, reacted for 1 hour under nitrogen protection, and after rotary evaporation at 45 °C, a chain extender A with catalytic and hyperbranched properties was obtained.

[0053] (2) get 0.01mol castor oil 9.3g, add 0.04mol isophorone diisocyanate 8.9g, pass nitrogen, be warming up to 80 ℃ and react for 4 hours, then add 0.03mol polyethylene glycol 18g and react for 1.5 hours to obtain bio-based To the hyperbranched polyurethane prepolymer, add 2.85 g of chain extender A (0.01 mol) with catalytic hyperbranching properties obtained in step (1), react for 2 hours, and dry to obtain bio-based hyperbranched polyurethane.

[0054] (3) Take 18 g of bio-ba...

Embodiment 2

[0057] The preparation method of high solid content aqueous polyurethane dispersion comprises the following steps:

[0058] (1) According to the functional group ratio of the acid anhydride functional group of methyl nadic anhydride to the amino functional group of tris(hydroxymethyl) aminomethane, 1:1.2, take 9 g of methyl nadic anhydride and 7.2 g of tris(hydroxymethyl) aminomethane to dissolve In 350 mL of methanol, the temperature was raised to 50 °C with magnetic stirring, reacted for 1 hour under nitrogen protection, and after rotary evaporation at 45 °C, a chain extender with catalytic and hyperbranched properties was obtained.

[0059] (2) get 0.03mol castor oil 27.9g, add 0.09mol isophorone diisocyanate 20g, pass nitrogen, be warming up to 80 DEG C and react for 4 hours, then add 0.08mol polyethylene glycol 48g and react for 2 hours to obtain bio-based hyperbranching The polyurethane prepolymer was synthesized, and 5.7 g of the chain extender (0.02 mol) with catalytic...

Embodiment 3

[0063] The preparation method of high solid content aqueous polyurethane dispersion comprises the following steps:

[0064] (1) According to the functional group ratio of the acid anhydride functional group of norbornene dioic anhydride to the functional group of tris(hydroxymethyl)aminomethane amino group of 1:1.4, take 9g of norbornene dianhydride and 9.6g of tris(hydroxymethyl)aminomethane dissolved in In 350 mL of methanol, the temperature was raised to 30 °C with magnetic stirring, reacted under nitrogen protection for 2 hours, and after rotary evaporation at 45 °C, a chain extender with catalytic and hyperbranched properties was obtained.

[0065] (2) get 0.04mol castor oil 37.3g, add 0.1mol isophorone diisocyanate 22.3g, pass nitrogen, be warming up to 80 DEG C and react for 4 hours, then add 0.13mol polytetrahydrofuran 80g and react for 2 hours to obtain bio-based hyperbranched To the polyurethane prepolymer, add 8.5 g of the chain extender (0.03 mol) with catalytic hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com