an epoxy curing agent

An epoxy curing agent, epoxy technology, applied in the direction of organic chemistry, mercaptan preparation, etc., can solve the problem of paint film performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

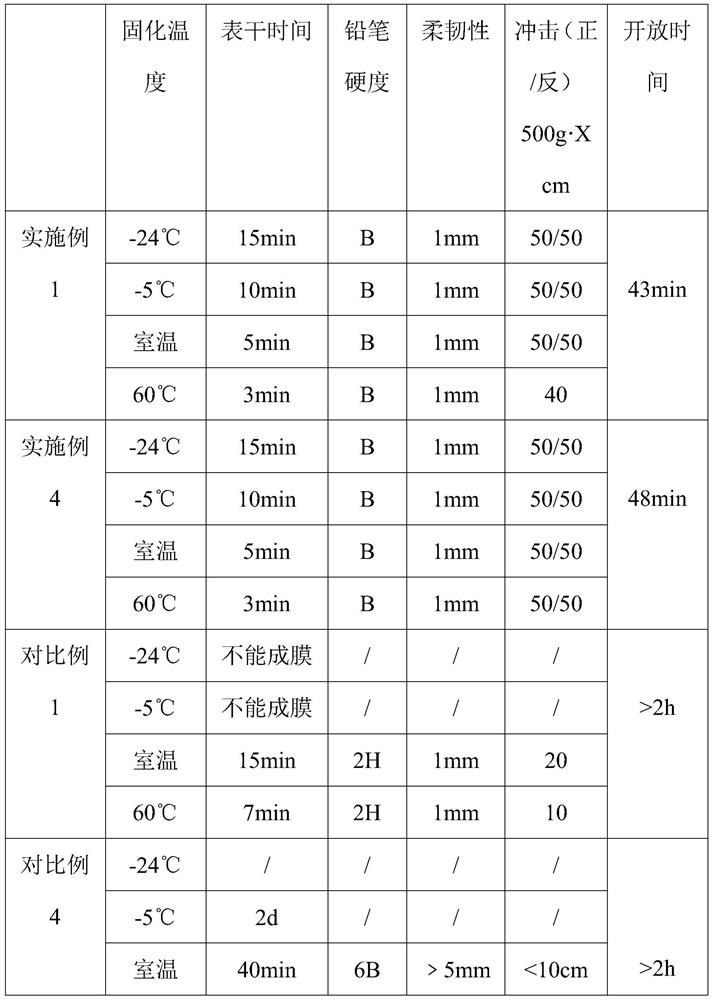

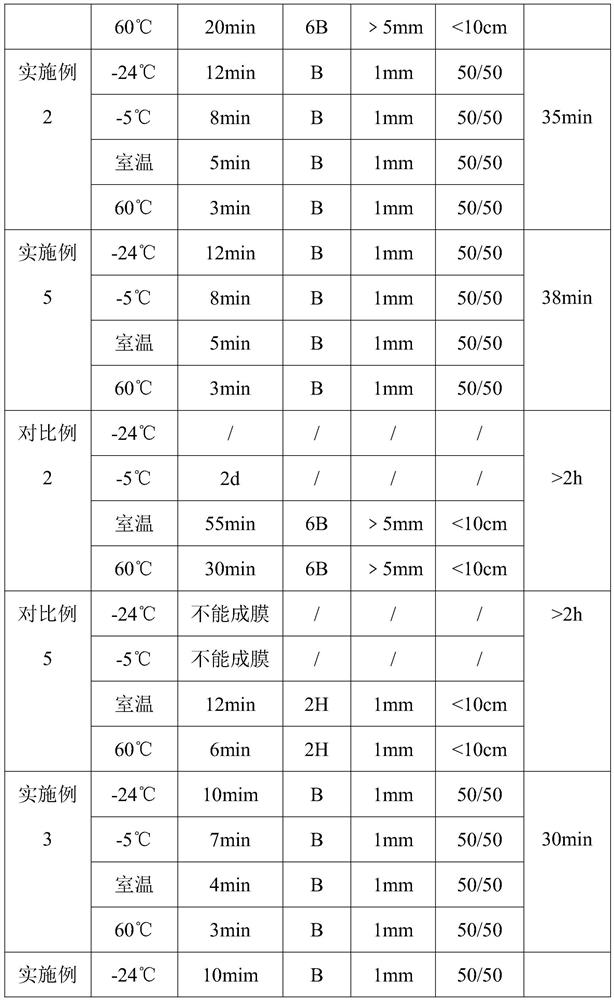

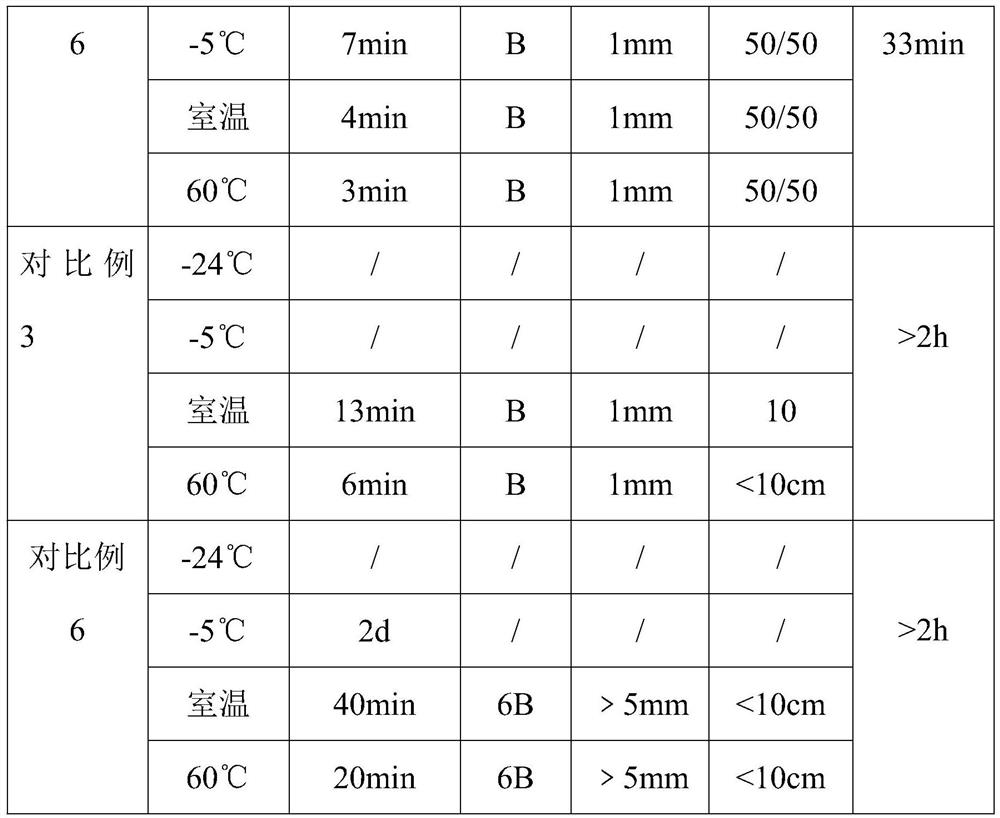

Examples

Embodiment 1

[0028] Preparation of mercapto-containing cyclic carbonate: Add 59 parts of glycerol carbonate, 78.8 parts of 3-mercaptopropionic acid, 6.9 parts of p-toluenesulfonic acid, and 30 parts of anhydrous magnesium sulfate into the reaction flask. React at 80°C for 8 hours, wash and dry to obtain mercapto-containing cyclocarbonate.

[0029] Take 4.9 parts of mercapto-containing cyclocarbonate, 1.2 parts of diethylenetriamine, and 3 parts of propylene glycol methyl ether, mix them and heat them in a water bath at 70°C for 8 hours to obtain a diethylenetriamine-based dihydric thiol compound containing a carbamate bond. .

[0030] 6.2 parts of diethylenetriamine-based dihydric mercaptan compound, 3.0 parts of formaldehyde, wait until the temperature in the reaction kettle is no longer changed, and the reaction is completed to obtain a diethylenetriamine-based quick-drying epoxy curing agent.

[0031] Take 0.56 parts of curing agent and 10.23 parts of EPKI 6520-W-53 epoxy emulsion and ...

Embodiment 2

[0033] Take 4.9 parts of mercapto-containing cyclocarbonate in Example 1, 3.5 parts of triethylenetetramine, and 3.5 parts of propylene glycol methyl ether, mix them, and then heat and react in a water bath at 70° C. for 8 hours to obtain a triethylenetetramine-based dihydric mercaptan compound.

[0034] Get 10.48 parts of triethylenetetramine-based dihydric mercaptan compound, 0.9 part of formaldehyde, and react at normal temperature. After the temperature in the reactor is no longer changed, the reaction is completed, and a triethylenetetramine-based quick-drying compound containing a carbamate bond is obtained. type epoxy curing agent.

[0035] Take 1.09 parts of curing agent and 10.23 parts of EPKI 6520-W-53 epoxy emulsion and mix evenly, scrape the film on the tin plate, place it at -24°C, -5°C, room temperature and 60°C to test the curing time and mechanical properties , pour the remaining material on the polytetrafluoroethylene plate to test the opening time

Embodiment 3

[0037] Take 4.9 parts of mercapto-containing cyclocarbonate in Example 1, 2.2 parts of tetraethylenepentamine, and 5 parts of propylene glycol methyl ether, mix them, heat and react in a water bath at 70° C. for 8 hours, and obtain a tetraethylenepentamine-based dihydric mercaptan compound.

[0038]Get 9.1 parts of tetraethylenepentamine-based dihydric mercaptan compound, 1.1 parts of formaldehyde, and react at normal temperature. After the temperature in the reactor is no longer changed, the reaction is completed, and the tetraethylenepentamine-based quick-drying compound containing carbamate bonds is obtained. type epoxy curing agent.

[0039] Take 0.52 parts of curing agent and 10.23 parts of EPKI 6520-W-53 epoxy emulsion and mix evenly, scrape the film on the tin plate, place it at -24°C, -5°C, room temperature and 60°C to test the curing time and mechanical properties , and the remaining material was poured on a polytetrafluoroethylene plate to test the opening time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com