Low temperature quick-setting moistureproof leveling mortar

A technology of leveling mortar and low temperature, applied in the field of leveling mortar, can solve the problems of single function of leveling mortar, easy freezing and cracking, time-consuming and laborious construction of leveling mortar, etc., and achieve the effect of smooth and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

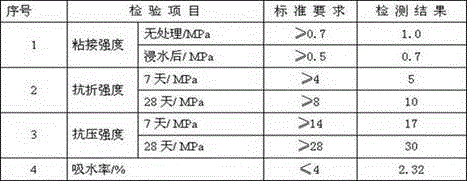

Examples

Embodiment 1

[0029] It is composed of powder material and liquid material, and the proportion of powder material and liquid material is mixed according to the ratio of mass to number of 1:0.18.

[0030] The powder is prepared from the following components by mass ratio: 350 parts of Portland cement, 4 parts of rapid hardening early strength agent, 3 parts of thixotropic lubricant, 1.5 parts of thickening and water-retaining agent, 40-100 mesh quartz sand 250 parts, 250 parts of 100-140 mesh quartz sand, 141 parts of calcium powder, 0.5 part of environmental-friendly water reducer; among them, the strength grade of Portland cement is 42.5 or 52.5, choose one of the two; rapid hardening and early strength Aluminum oxide is used as the agent; hectorite clay is used as the thixotropic lubricant; starch ether is used as the thickening and water-retaining agent;

[0031] The liquid material is prepared from the following components in the mass-to-number ratio: 830 parts of cationic acrylic emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com