Epoxy curing agent

An epoxy curing agent, epoxy technology, used in organic chemistry, mercaptan preparation and other directions, can solve problems such as the decline of paint film performance, achieve the effects of low VOC, easy dispersion and dissolution, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

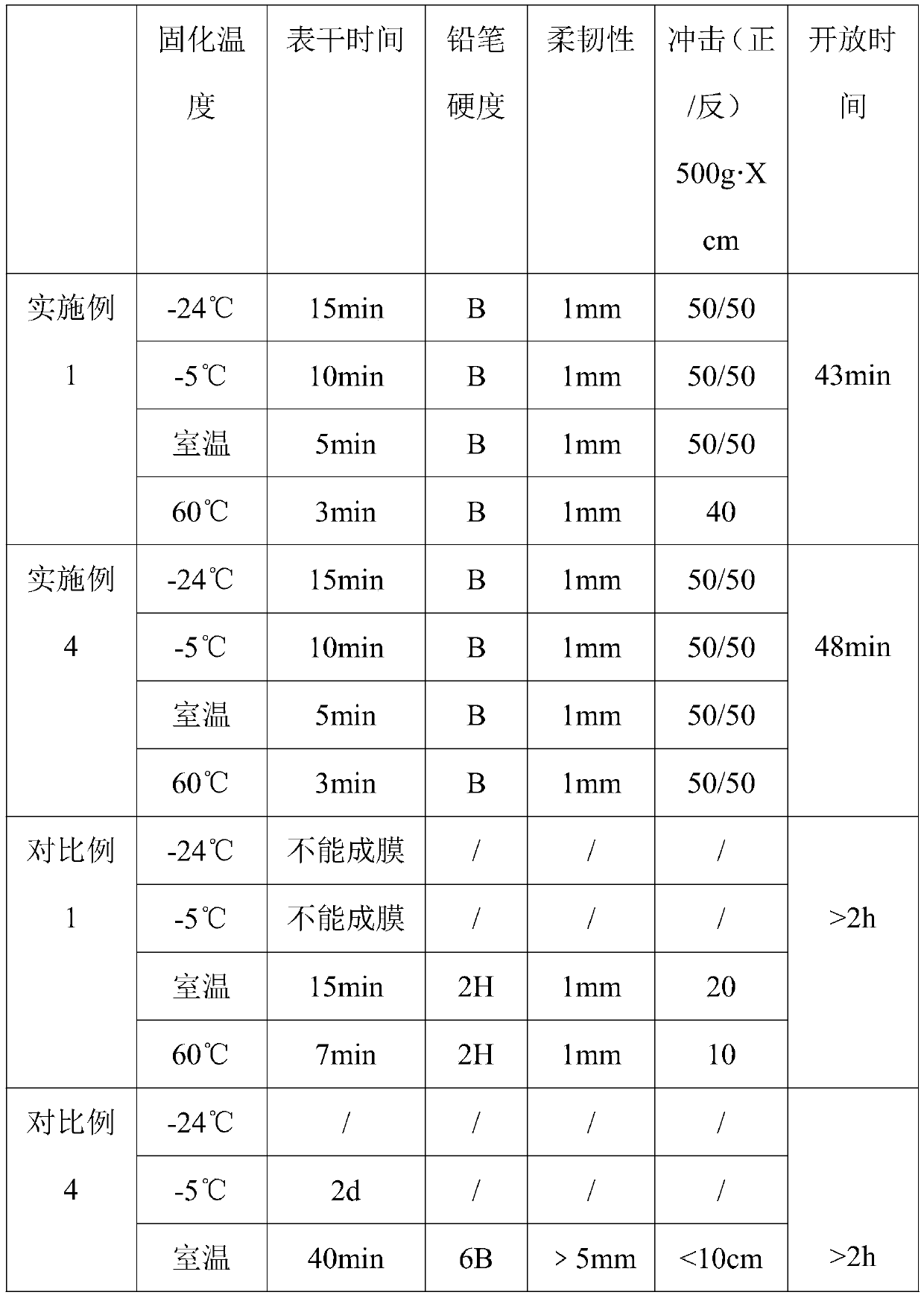

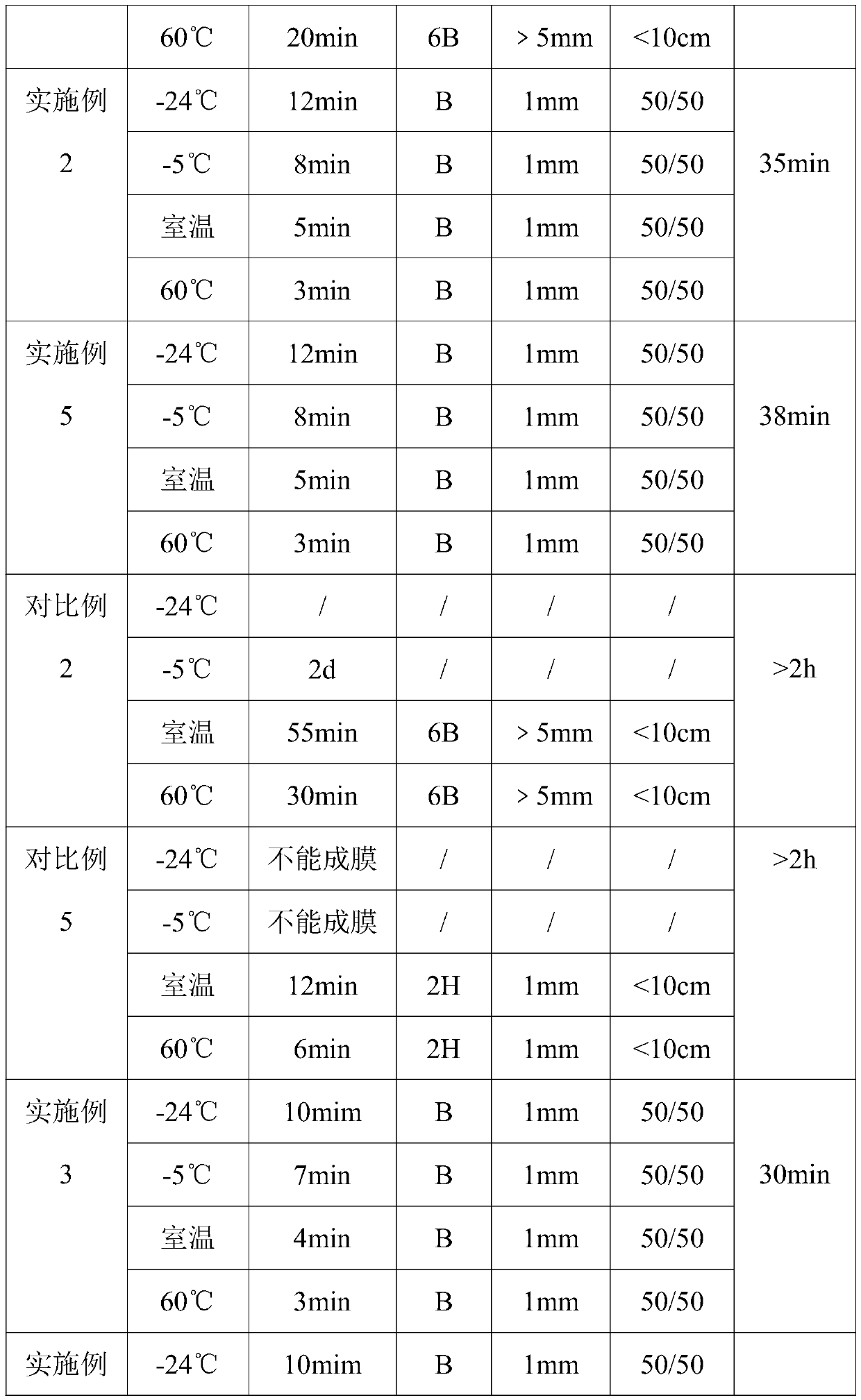

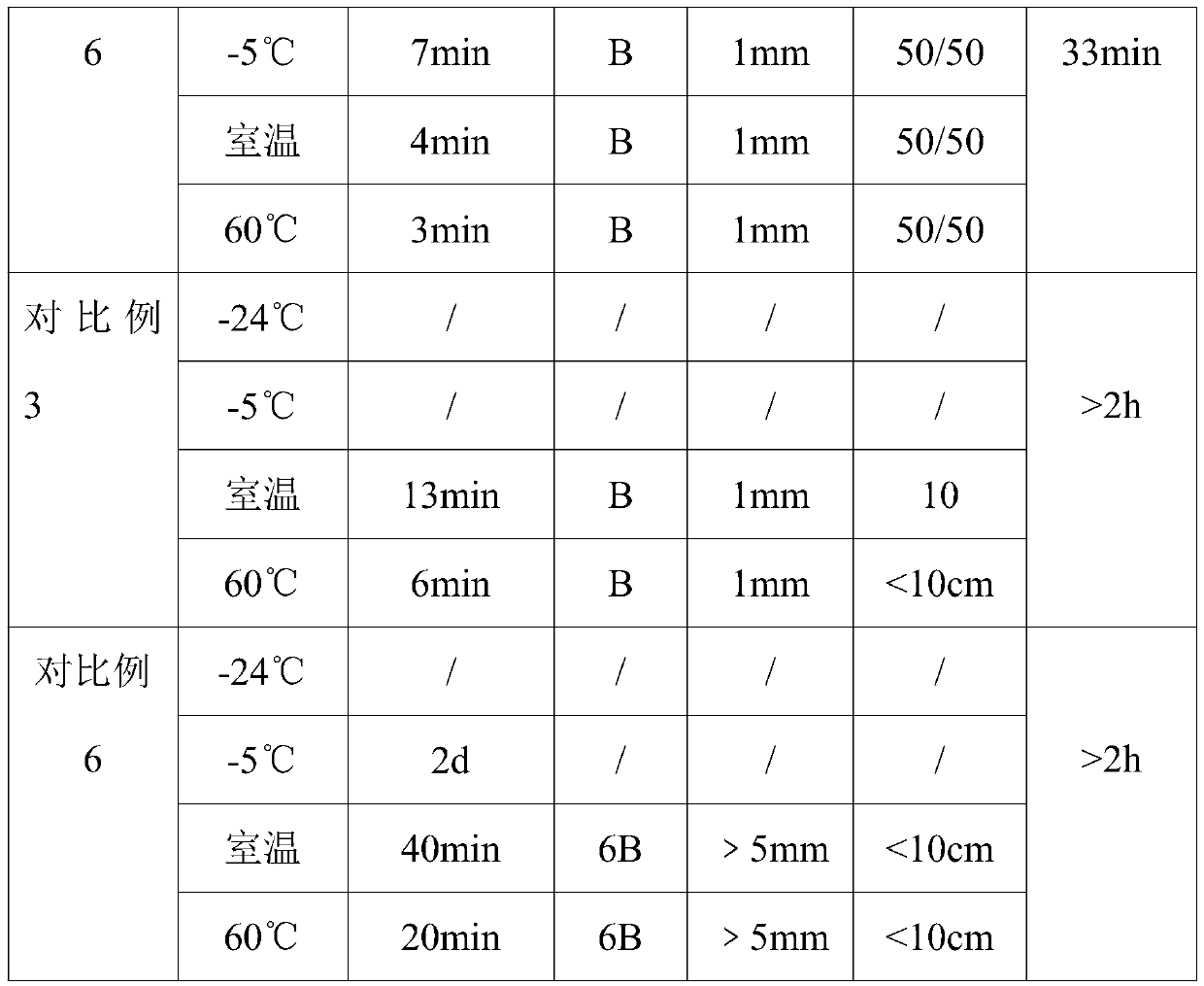

Examples

Embodiment 1

[0028] Preparation of sulfhydryl-containing cyclic carbonate: 59 parts of glycerol carbonate, 78.8 parts of 3-mercaptopropionic acid, 6.9 parts of p-toluenesulfonic acid, and 30 parts of anhydrous magnesium sulfate were added to the reaction flask. Reaction at 80°C for 8 hours, washing and drying to obtain cyclic carbonate containing mercapto group.

[0029] Take 4.9 parts of cyclic carbonate containing mercapto group, 1.2 parts of diethylenetriamine, and 3 parts of propylene glycol methyl ether. After mixing, heat in a water bath at 70°C for 8 hours to obtain a diethylenetriamine-based dibasic mercaptan compound containing urethane bonds. .

[0030] 6.2 parts of diethylenetriamine-based dibasic mercaptan compound and 3.0 parts of formaldehyde, after the temperature in the reactor does not change, the reaction ends, and the diethylenetriamine-based quick-drying epoxy curing agent is obtained.

[0031] Take 0.56 parts of curing agent and 10.23 parts of EPKI 6520-W-53 epoxy emulsion a...

Embodiment 2

[0033] Take 4.9 parts of mercapto group-containing cyclic carbonate, 3.5 parts of triethylenetetramine, and 3.5 parts of propylene glycol methyl ether in Example 1 and mix them and react by heating in a water bath at 70°C for 8 hours to obtain a triethylenetetraamine-based dibasic mercaptan compound.

[0034] Take 10.48 parts of triethylenetetraamine-based dibasic mercaptan compound and 0.9 parts of formaldehyde, and react at room temperature. After the temperature in the reactor does not change, the reaction is completed, and a triethylenetetramine-based quick-drying containing carbamate bond is obtained. Type epoxy curing agent.

[0035] Take 1.09 parts of curing agent and 10.23 parts of EPKI 6520-W-53 epoxy emulsion and mix evenly, scrape the film on a tinplate, and test the curing time at -24℃, -5℃, room temperature and 60℃, and test the mechanical properties , The remaining material is poured on the Teflon board to test the opening time

Embodiment 3

[0037] Take 4.9 parts of mercapto group-containing cyclic carbonate in Example 1, 2.2 parts of tetraethylenepentamine, and 5 parts of propylene glycol methyl ether. After mixing, the mixture is heated in a water bath at 70°C for 8 hours to obtain a tetraethylenepentamine dibasic mercaptan compound.

[0038] Take 9.1 parts of tetraethylenepentamine-based dibasic mercaptan compound and 1.1 parts of formaldehyde, and react at room temperature. After the temperature in the reactor does not change, the reaction is completed, and the tetraethylenepentamine-based quick-drying containing carbamate bond is obtained. Type epoxy curing agent.

[0039] Take 0.52 parts of curing agent and 10.23 parts of EPKI 6520-W-53 epoxy emulsion and mix evenly, scrape the film on a tinplate, and test the curing time at -24℃, -5℃, room temperature and 60℃, and test the mechanical properties , The remaining material is poured on the PTFE board to test the opening time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com