Abrasion-resistant single-component polyurethane coating and preparation method thereof

A polyurethane coating, a single-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor resistance to heavy pressure, slow drying speed, etc., and achieve the effect of high hardness and bright and beautiful paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In a second aspect, the present invention provides a method for preparing a wear-resistant one-component polyurethane coating, comprising the following steps:

[0031] (1) Add polyester polyol into the reaction kettle, heat to 100-120°C, vacuum dehydrate for 1-2h, cool to room temperature and fill with nitrogen to store for later use;

[0032] (2) adding isocyanate into the reaction kettle, stirring and heating, raising the temperature to 60-90°C, and reacting for 2-5h;

[0033] (3) Add end-capped amino resin, stir and keep at 60-90°C for 1-2h, then add fillers, additives and solvents under stirring, stir and disperse for 0.2-1h, discharge and seal for storage, and obtain the wear-resistant single Component polyurethane coatings;

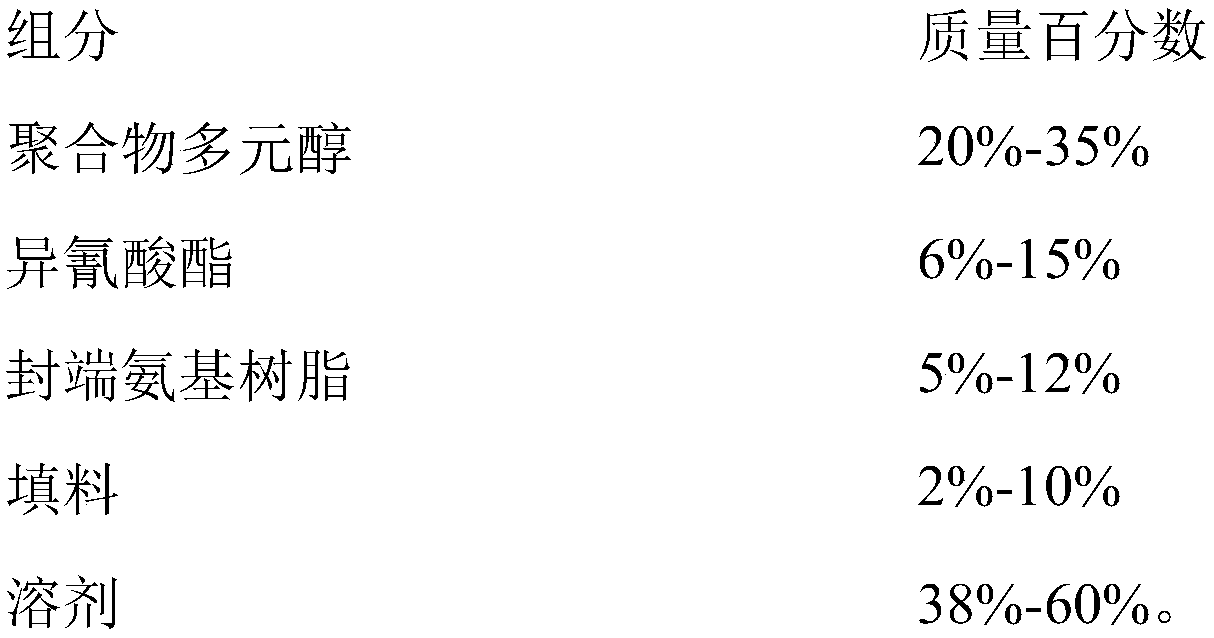

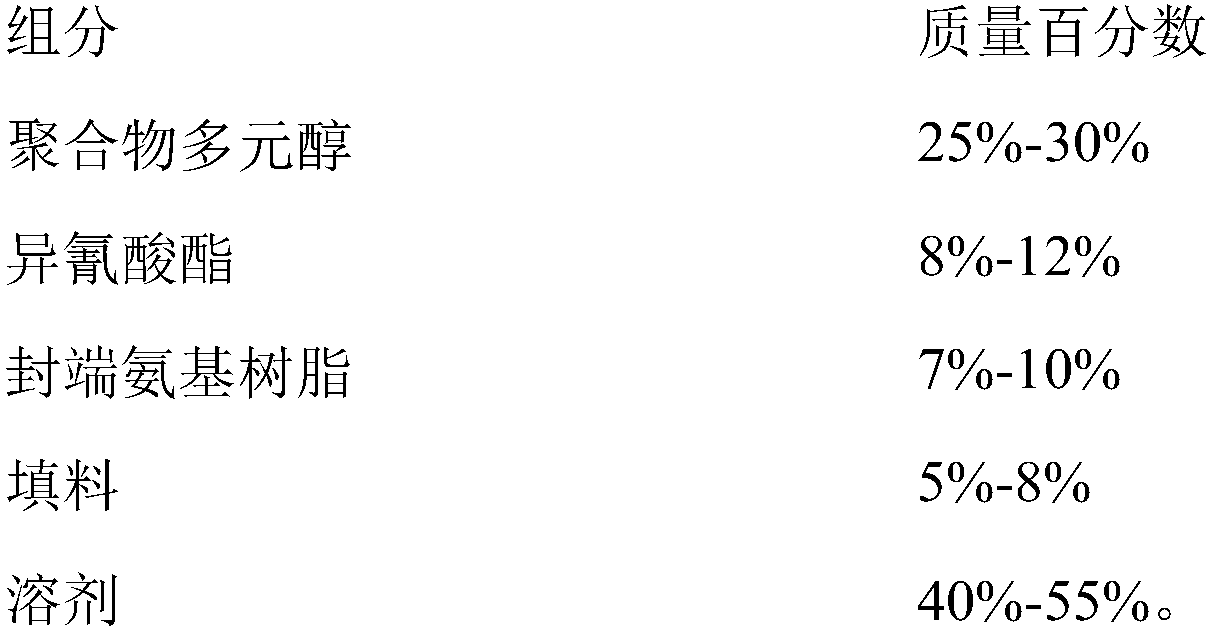

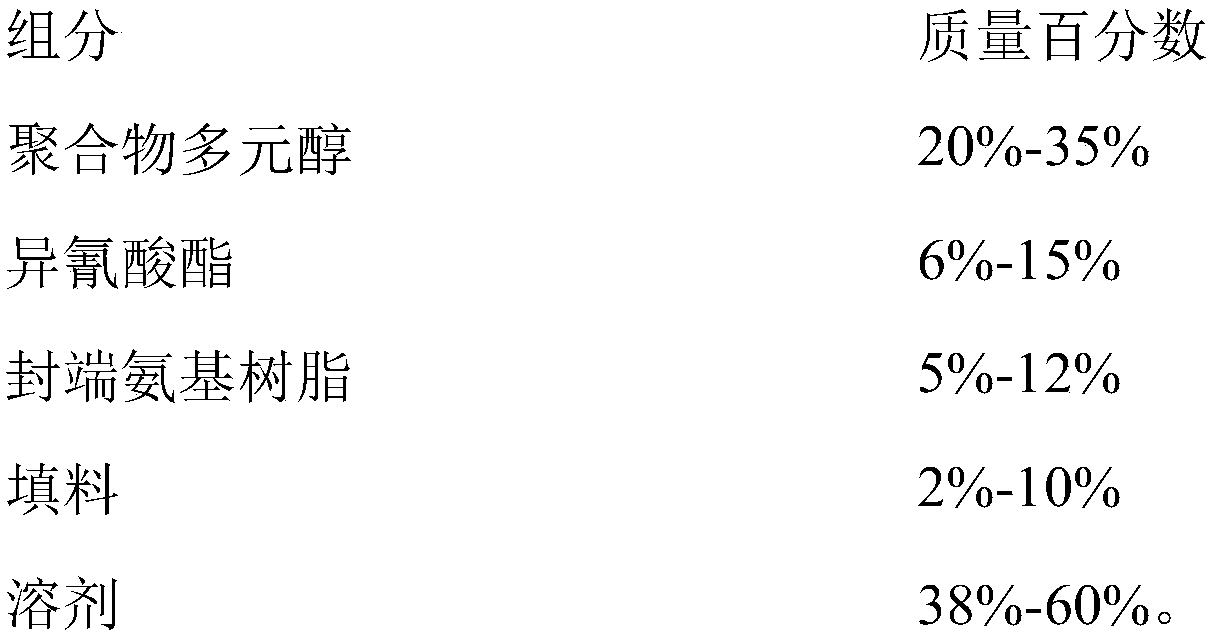

[0034] The mass percent of above-mentioned each component is:

[0035]

[0036] In the present invention, 4,4'-diphenylmethane diisocyanate, polymethylene polyphenyl polyisocyanate, diphenylmethane diisocyanate, toluene diisocyanate, hex...

Embodiment 1

[0039] Add 28 parts by mass of polyethylene adipate into the reaction kettle, heat to 110° C., vacuum dehydrate for 1 hour, cool to room temperature and fill with nitrogen for storage.

[0040] (2) Add 9.5 parts by mass of toluene diisocyanate into the reaction kettle, heat with stirring, raise the temperature to 75° C., and react for 3.5 hours.

[0041] (3) Add 7.5 parts by mass of salicylaldimine, stir and keep warm for 1.5h, then add 6.5 parts by mass of aluminum oxide and 50 parts by mass of xylene under stirring, stir and disperse for 0.5h, then discharge and seal for preservation, to obtain a polyurethane coating .

Embodiment 2

[0043] (1) Add 10 parts by mass of polyethylene adipate and 15 parts by mass of polyethylene adipate-propylene glycol into the reaction kettle, heat to 105°C, vacuum dehydrate for 1.5h, cool to room temperature and Store in nitrogen gas for later use.

[0044] (2) Add 3 parts by mass of 4,4'-diphenylmethane diisocyanate and 5 parts by mass of hexamethylene diisocyanate into the reaction kettle, stir and heat, raise the temperature to 70°C, and react for 4 hours.

[0045] (3) Add 7 parts by mass of N, N'-(methyl-butylmethylene)-diethylenetriamine, stir and insulate for 1.5h, then add 5 parts by mass of chopped glass fiber and 25 parts by mass under stirring Parts by mass of acetone and 30 parts by mass of ethyl acetate were stirred and dispersed for 0.3 h, and then discharged and sealed for storage to obtain a polyurethane coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com