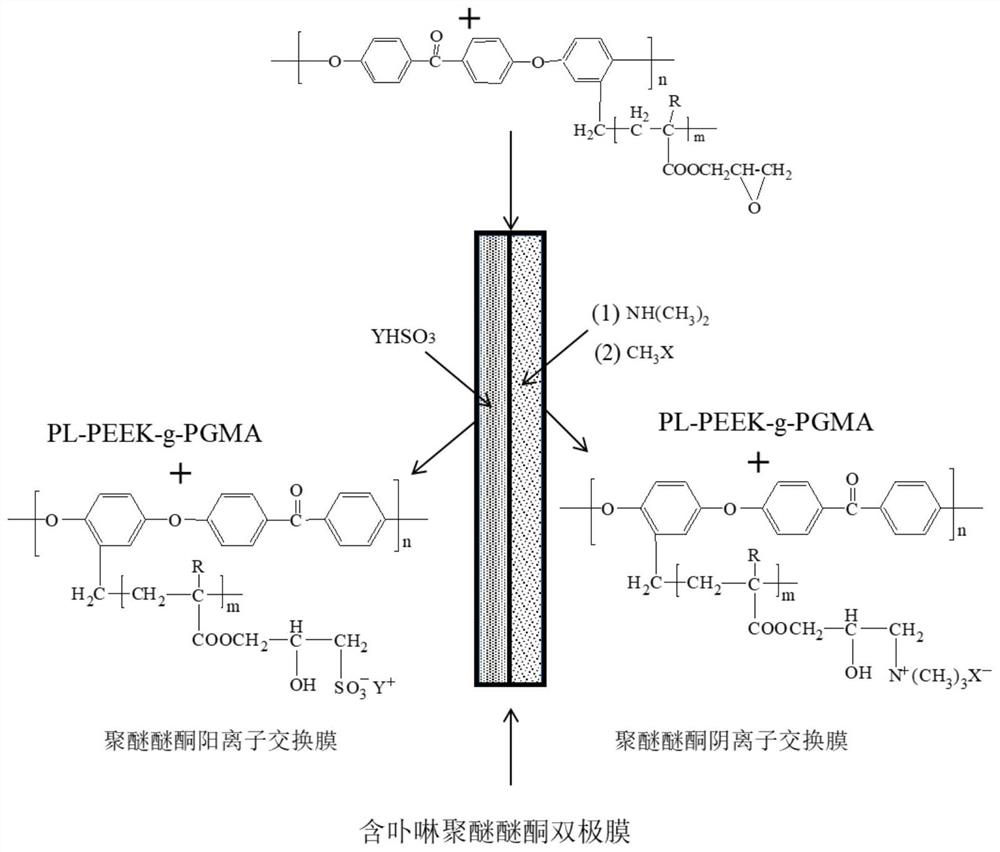

Preparation method of monolithic polyaryletherketone bipolar membrane containing porphyrin water dissociation catalytic group in side chain

A polyaryletherketone, bipolar membrane technology, applied in chemical instruments and methods, membrane technology, ion exchange and other directions, can solve the problems of poor graft uniformity, limited use range, increased synthesis steps, etc., and achieves low transmembrane voltage. , The effect of eliminating the film forming process and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

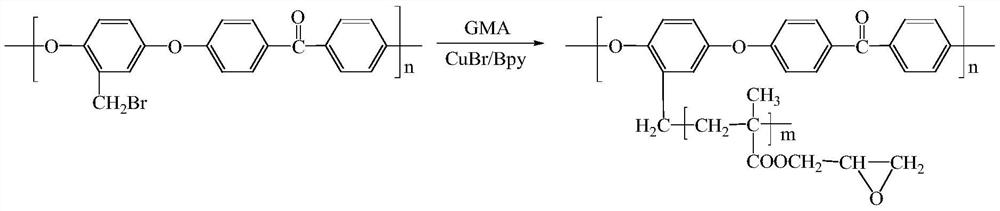

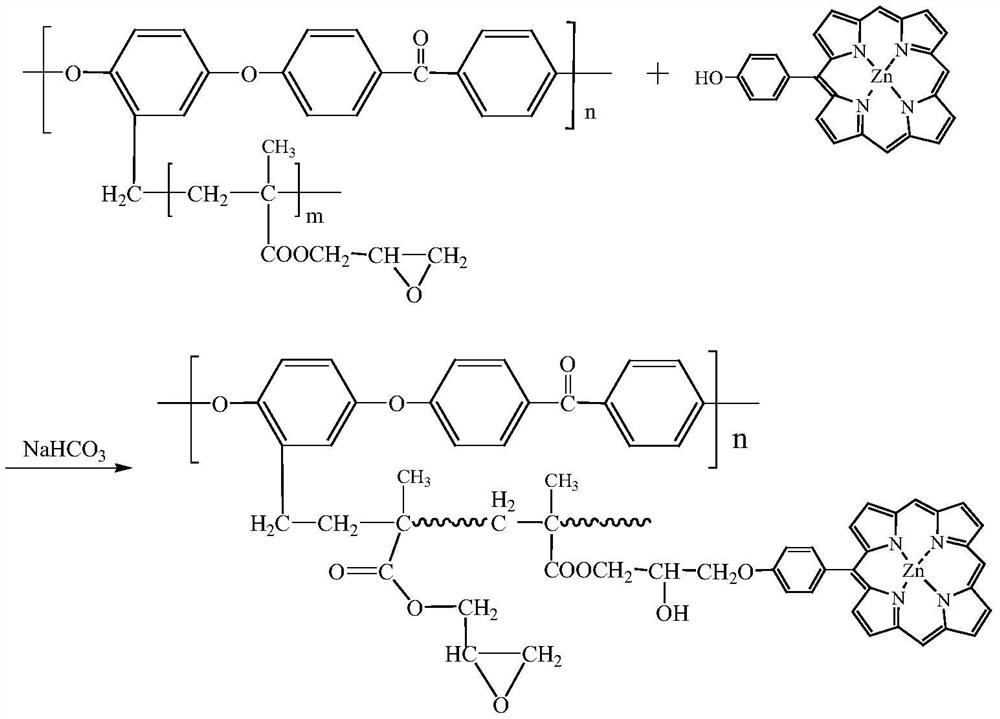

Embodiment 1

[0040] (1) Take 2.0g of bromomethylated polyaryletherketone (BPEEK) into a three-necked flask, dissolve it with 60mL of N-methylpyrrolidone, pass nitrogen gas to remove oxygen, and use methylated polyaryletherketone (based on bromomethyl Based on moles): glycidyl methacrylate (GMA): CuBr: N, N, N', N", N'" pentamethyldiethylenetriamine (PMDETA) molar ratio is 1:40: 1:2 Add glycidyl methacrylate and CuBr in turn, stir well and then add PMDETA. CuBr and PMDETA were used as the catalyst system, and the reaction was carried out at constant temperature for 12 hours at 70°C under the protection of nitrogen. The reaction solution was precipitated with ethanol, and the precipitate was soaked in running water for 24 hours to remove CuBr and CuBr in the precipitate. 2 , PMDETA and unreacted glycidyl methacrylate, filtered, and dried to obtain a solid. The dried graft polymer was dissolved in tetrahydrofuran and cast on a glass plate to form a film, and dried in a constant temperature ...

Embodiment 2

[0051] (1) PEEK-g-PGMA graft copolymer

[0052] Take 2g of bromomethylated polyaryletherketone (BPEEK) and add it into a three-neck flask, dissolve it with 60mL of N-methylpyrrolidone, and pass nitrogen to remove oxygen. ): glycidyl acrylate (GMA): CuBr: N, N, N', N", N'" pentamethyldiethylenetriamine (PMDETA) with a molar ratio of 1:40:1:2 followed by adding formaldehyde Glycidyl acrylate and CuBr, stir well and then add PMDETA. CuBr and PMDETA were used as the catalyst system, and the reaction was carried out at constant temperature for 16 hours at 70°C under nitrogen protection. The reaction solution was precipitated with ethanol, and the precipitate was soaked in running water for 24 hours to remove CuBr and CuBr in the precipitate. 2 , PMDETA and unreacted glycidyl methacrylate, filtered, and dried to obtain a solid. The dried graft polymer was dissolved in tetrahydrofuran and cast on a glass plate to form a film, and dried in a constant temperature oven at 80°C for 24...

Embodiment 3

[0062] (1) Take 2g of bromomethylated polyaryletherketone (BPEEK) and add it to a three-neck flask, dissolve it with 60mL of N-methylpyrrolidone, pass nitrogen to remove oxygen, and press methylated polyaryletherketone (with bromomethyl In terms of moles): vinyl phenyl glycidyl ether (GST): CuBr: N, N, N', N", N'" pentamethyldiethylenetriamine (PMDETA) molar ratio is 1:40: 1:2 Add vinyl phenyl glycidyl ether and CuBr in turn, stir well and then add PMDETA. CuBr and PMDETA were used as the catalytic system, and the reaction was carried out at constant temperature for 20 h at 70 °C under nitrogen protection. The reaction solution was precipitated with ethanol, and the precipitate was soaked in running water for 24 hours to remove CuBr and CuBr in the precipitate. 2 , PMDETA and unreacted glycidyl methacrylate, filtered, and dried to obtain a solid. The dried graft polymer was dissolved in tetrahydrofuran and cast on a glass plate to form a film, and dried in a constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com