Autocatalytic and dealcoholized room-temperature vulcanized silicone rubber and preparation method thereof

A room temperature vulcanization, silicone rubber technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of limited application of silicone rubber and long curing time, and achieve good curing cross-linking performance and curing time. Short, low-energy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

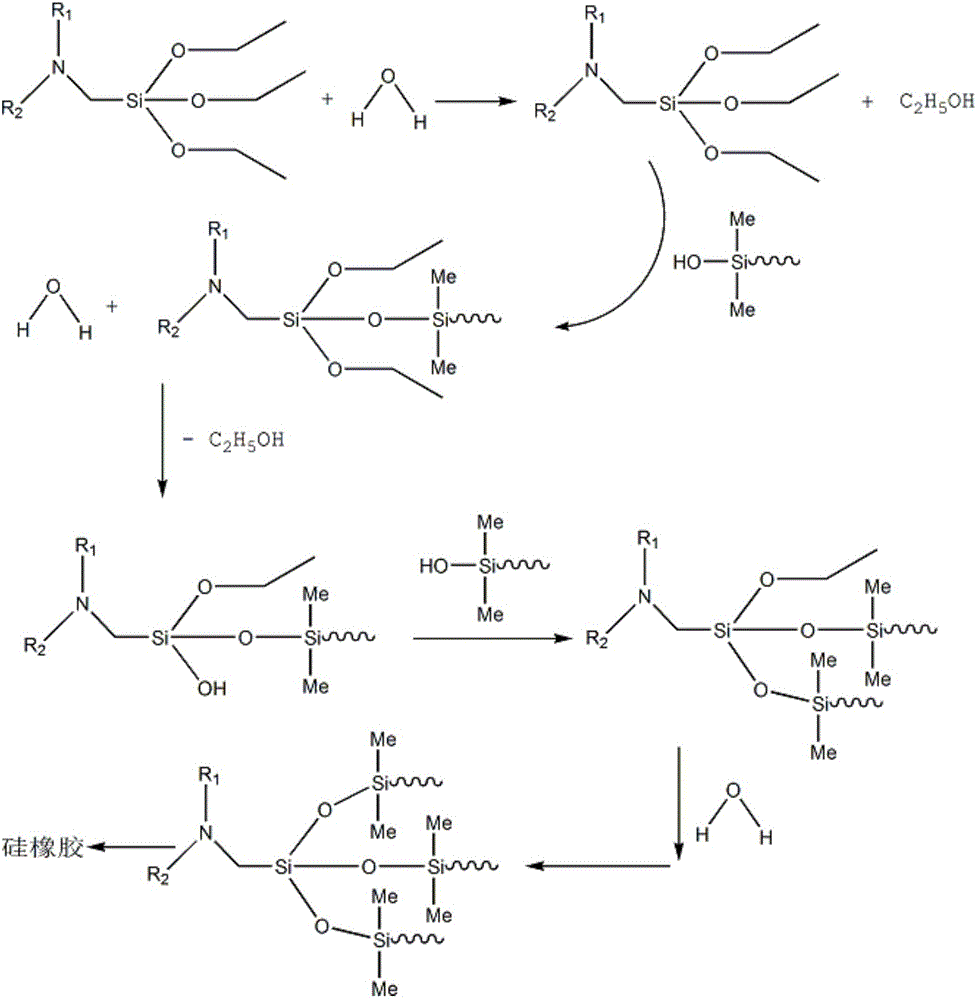

Method used

Image

Examples

Embodiment 1

[0045] At a temperature of 27°C and a humidity of 43%, 100 parts of α, ω-dihydroxypolydimethylsiloxane (relative molecular weight 39000g / mol) with a viscosity of 3000cSt and 15 parts of precipitated silica Add it into the planetary stirring tank, raise the temperature to 150°C, mix for 30min under the vacuum condition of -0.09~-0.1MPa, and cool down to below 40°C. If it is viscous (poor fluidity), add an appropriate amount of cyclohexane to dilute, and then add 2.25 parts of α-(N-n-butyl)aminomethyltriethoxysilane as a crosslinking agent at -0.09~-0.1 Stir under MPa vacuum until uniform without bubbles. Curing, that is, from catalyzed deketoxime type room temperature vulcanizing silicone rubber.

[0046] Put it on a horizontal surface, and use the finger touch method to measure the surface dry time of 2'45" using GB / T13477.5-2002 Building Sealing Materials Test Method Five Part Five Surface Dry Time Determination.

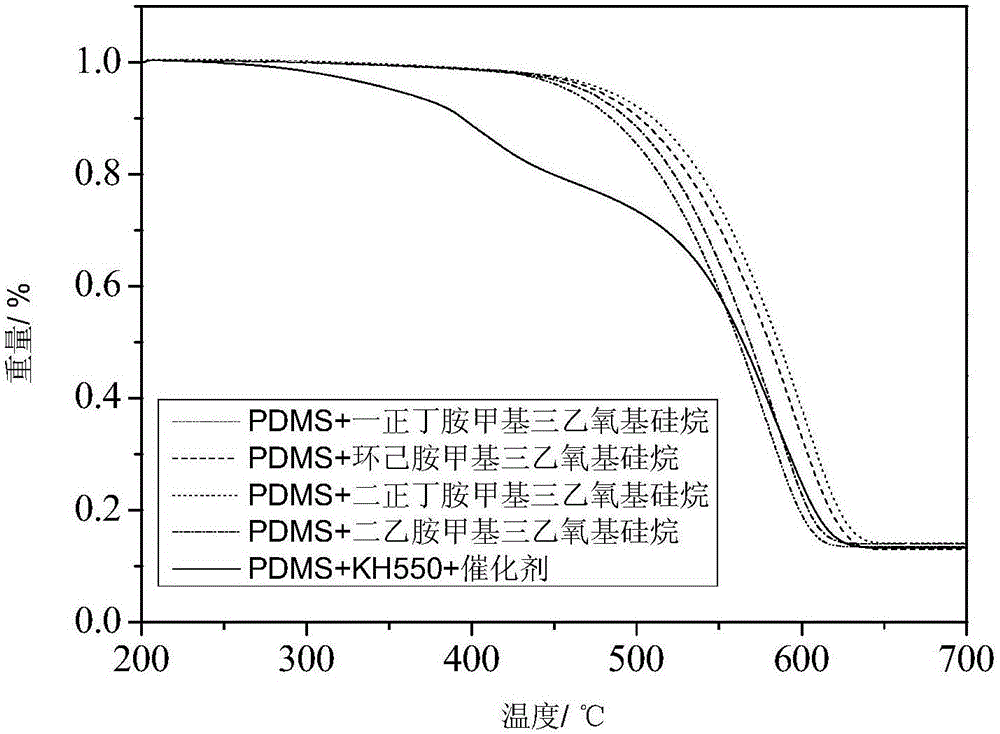

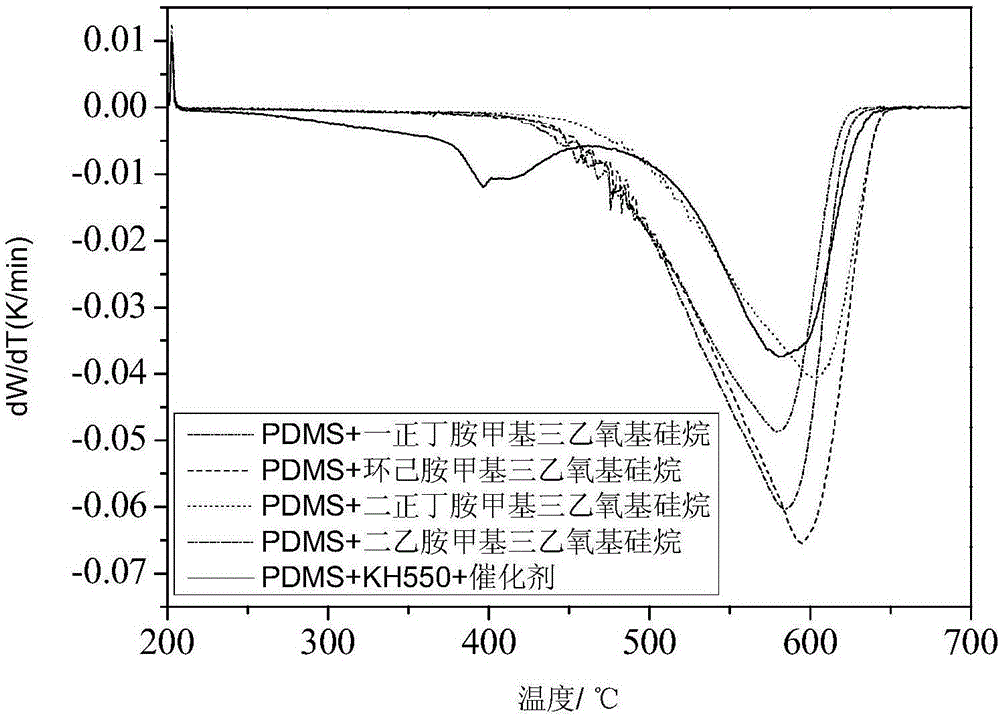

[0047] The resulting self-catalyzed dealcoholized room temp...

Embodiment 2

[0050] According to the steps of Example 1, the difference is that the crosslinking agent is replaced by 2.25 parts of α-(N-cyclohexyl)aminomethyltriethoxysilane, and the performance test results are shown in Table 1.

Embodiment 3

[0052] According to the steps of Example 1, the difference is that the crosslinking agent is replaced by α-(N,N-diethyl)aminomethyltriethoxysilane, and the performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com