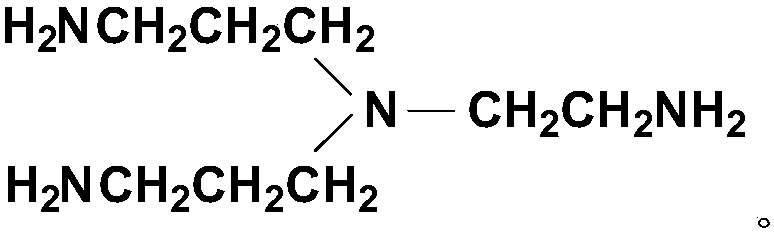

Epoxy resin curing agent, synthesis method and curing method

A technology of epoxy resin curing and synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of imino compounds, etc. It can solve the problem of stickiness on the surface of cured products, lack of color and yellowing resistance, and curing failure of the system surface etc. to achieve excellent yellowing resistance, bright surface and excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Step 1. To prepare ketimine, put 1.2kg of ethylenediamine into a 5L three-necked bottle equipped with a dripping reflux device, raise the temperature to 40°C, then slowly add 1.16kg of acetone dropwise, keep the temperature at 40-45°C and wait for 1 hour The acetone was added dropwise and closed, and after the dropwise addition was completed, the temperature was kept at 40-45° C. for 3 hours. After the reaction is completed, turn on the vacuum pump, keep the temperature at 80-90° C., and the vacuum at -0.08 MPa, and remove 360 g of water by distillation under reduced pressure.

[0068] Step 2. To prepare the cyanoethylated adduct, lower the temperature in the three-neck flask to 70°C, slowly add 2.12kg of acrylonitrile dropwise, and keep the temperature at 70-80°C, and complete the dropwise addition of acrylonitrile within 2 hours , continue to maintain the temperature at 70-80 ° C for 1 hour, cool and discharge the material for later use.

[0069] Step 3. Prepare cy...

Embodiment 2

[0073] Step 1. To prepare ketimine, put 1.2kg of ethylenediamine into a 5L three-necked bottle equipped with a dripping reflux device, raise the temperature to 45°C, slowly add 1.44kg of methyl ethyl ketone dropwise, keep the temperature at 40-45°C and dissolve within 1 hour Stop the dropwise addition of methyl ethyl ketone, and keep the temperature at 50-60°C for 2 hours after the dropwise addition is completed. After the reaction is completed, turn on the vacuum pump, keep the temperature at 100-110° C., vacuum degree -0.08 MPa, and remove 360 g of water by distillation under reduced pressure.

[0074] Step 2. To prepare the cyanoethylation adduct, cool down the temperature in the three-necked flask to 70°C, slowly add 2.12kg of acrylonitrile dropwise, and keep the temperature at 80-85°C, complete the dropwise addition of acrylonitrile within 2 hours, continue The temperature was maintained for 0.5 hours. Cool and discharge for later use.

[0075] Step 3. Prepare cyano h...

Embodiment 3

[0079] Step 1. To prepare ketimine, put 1.2kg of ethylenediamine into a 5L three-neck bottle equipped with a dripping reflux device, raise the temperature to 30°C, slowly add 1.5kg of methyl ethyl ketone dropwise, keep the temperature at 50±3°C and dissolve within 1.5 hours Stop the dropwise addition of methyl ethyl ketone, and keep the temperature at 60° C. for 2 hours after the dropwise addition is completed. After the reaction is completed, raise the temperature to 80°C, turn on the vacuum pump, keep the temperature at 100-110°C, and vacuum degree -0.08MPa, and distill off the water under reduced pressure.

[0080] Step 2. To prepare the cyanoethylated adduct, lower the temperature in the three-necked flask to 50°C, slowly add 2.3kg of acrylonitrile dropwise, and keep the temperature at 56±3°C, complete the dropwise addition of acrylonitrile within 2 hours, continue The temperature was maintained for 2 hours. Cool and discharge for later use.

[0081] Step 3. Prepare cyan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com