Method for fast preparing TiO2/SiO2 composite aerogel through autocatalysis alcoholysis

A technology of composite aerogel and autocatalytic alcohol, applied in aerogel preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of long production cycle, high cost, complicated preparation method, etc., and achieve reliable source , light weight, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

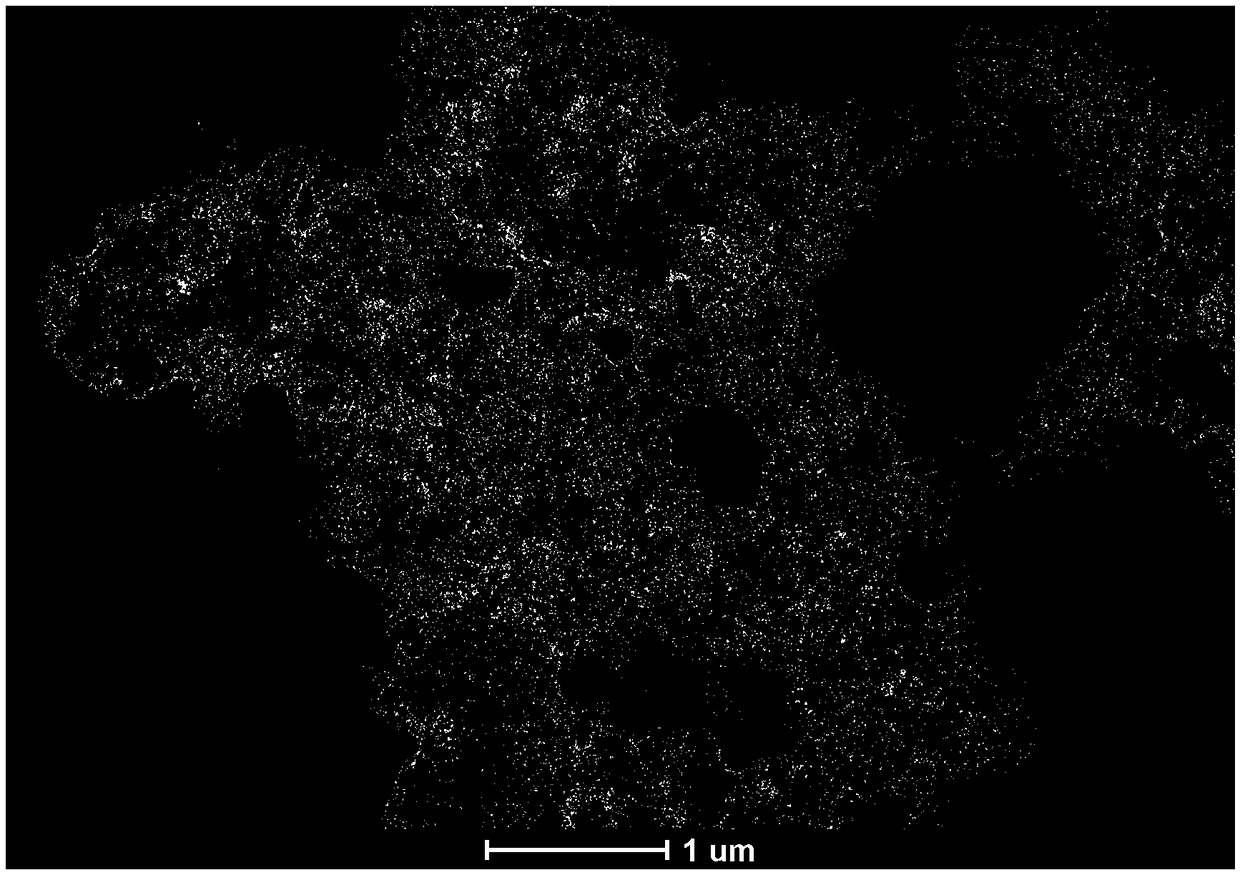

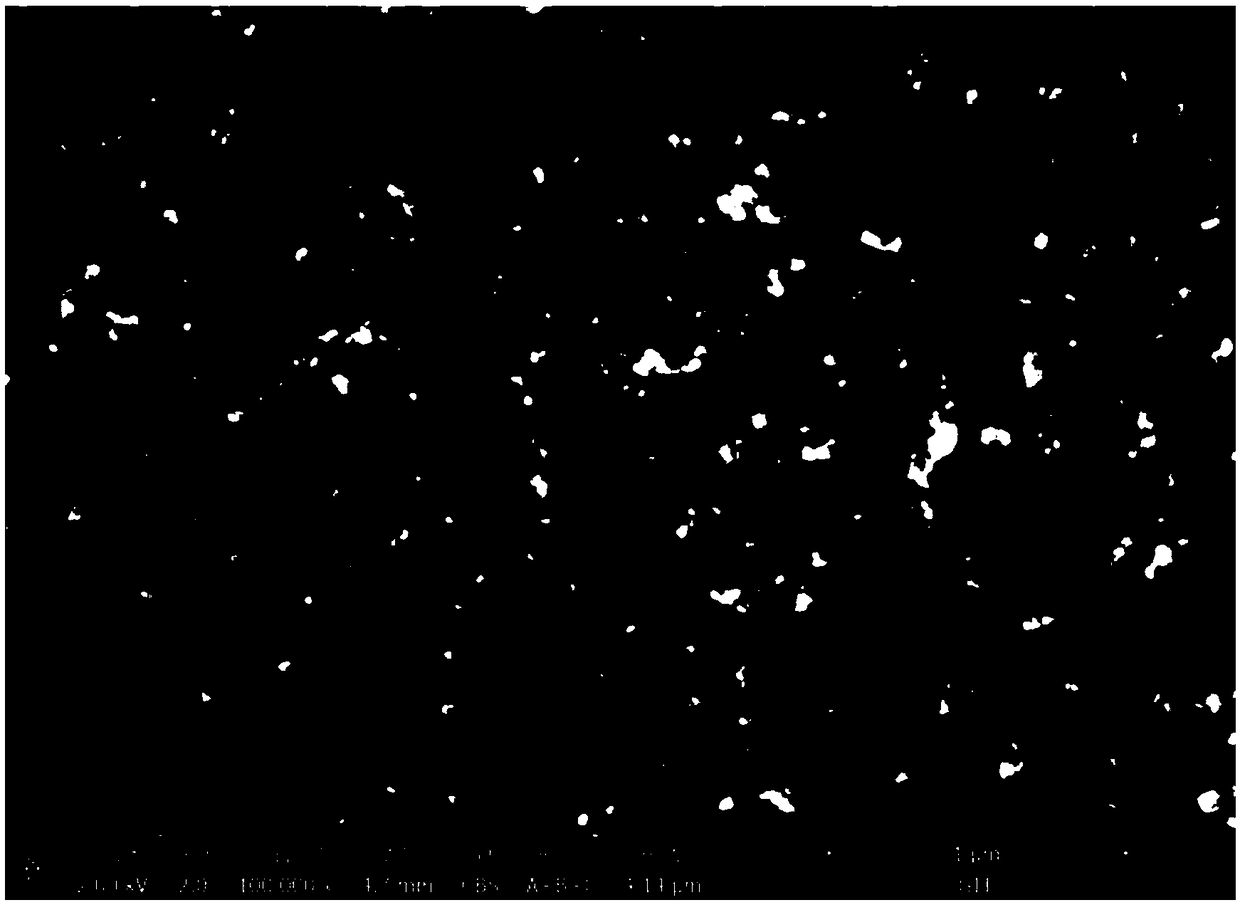

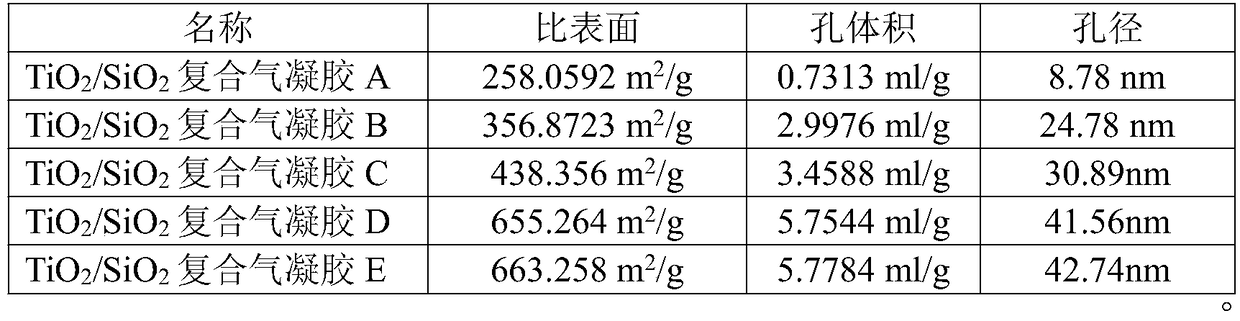

[0015] TiO 2 / SiO 2 Composite airgel A: Take 20ml of absolute ethanol, add 5ml of TiCl dropwise to absolute ethanol under constant stirring 4 , and then continue to drop 5mlSiCl 4 , and then slowly drop 0.1mol / L ammonia water into this solution to obtain TiO 2 / SiO 2 Composite solution A. Put the solution in a water bath and stir in a water bath at 60°C to 80°C for 20 to 30 minutes, stop stirring, and let it stand at room temperature for 0.5 to 1 hour until it gels to obtain TiO 2 / SiO 2 Composite Gel A. The obtained gel A was placed in a water bath at 40°C-60°C, and the solvent was replaced with analytically pure absolute ethanol solution, and the absolute ethanol was replaced every 2-4h for 24h. Finally, supercritical drying is carried out to obtain TiO 2 / SiO 2 Composite airgel A.

Embodiment 2

[0017] TiO 2 / SiO 2 Composite airgel B: Take 24ml of absolute ethanol, add 4ml of TiCl dropwise to absolute ethanol under constant stirring 4 , and then continue to drop 8mlSiCl 4 , and then slowly drop 0.3mol / L ammonia water into this solution to obtain TiO 2 / SiO 2 Composite solution B. Put the solution in a water bath and stir in a water bath at 60°C to 80°C for 20 to 30 minutes, stop stirring, and let it stand at room temperature for 0.5 to 1 hour until it gels to obtain TiO 2 / SiO 2Composite Gel B. The obtained gel B was placed in a water bath at 40°C-60°C, and the solvent was replaced with analytically pure absolute ethanol solution, and the absolute ethanol was replaced every 2-4h for 24h. Finally, supercritical drying is carried out to obtain TiO 2 / SiO 2 Composite airgel B.

Embodiment 3

[0019] TiO 2 / SiO 2 Composite airgel C: take 40ml of absolute ethanol, add 10ml of TiCl dropwise to absolute ethanol under constant stirring 4 , and then continue to drop 5mlSiCl 4 , and then slowly drop 0.5mol / L ammonia water into this solution to obtain TiO 2 / SiO 2 Composite solution C. Put the solution in a water bath and stir in a water bath at 60°C to 80°C for 20 to 30 minutes, stop stirring, and let it stand at room temperature for 0.5 to 1 hour until it gels to obtain TiO 2 / SiO 2 Composite gel C. The obtained gel C was placed in a water bath at 40°C-60°C, and the solvent was replaced with analytically pure absolute ethanol solution, and the absolute ethanol was replaced every 2-4h for 24h. Finally, supercritical drying is carried out to obtain TiO 2 / SiO 2 Composite airgel C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com