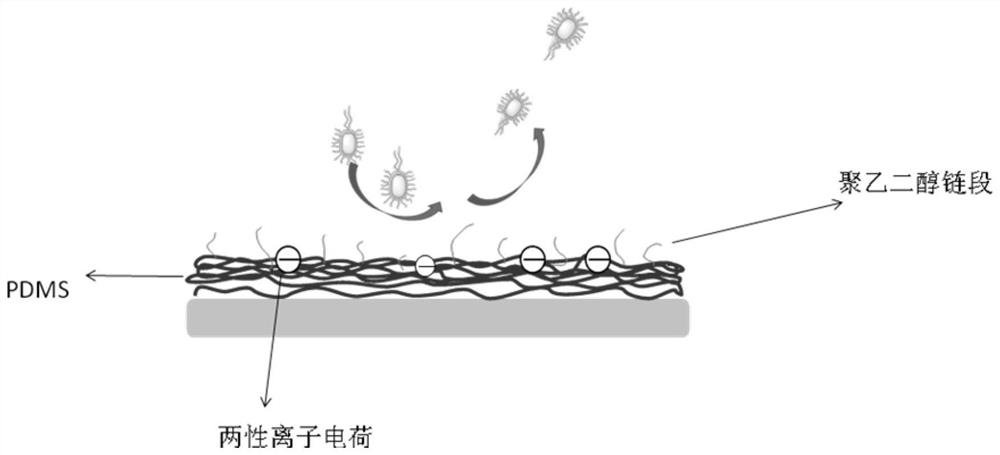

Ionic silicone gel antifouling coating and preparation method thereof

A technology of antifouling coatings and silicone gel, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of inability to effectively prevent marine organisms from adhering, and the environment of antifouling coatings is not friendly enough. To achieve the effect of preventing marine organisms from adhering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

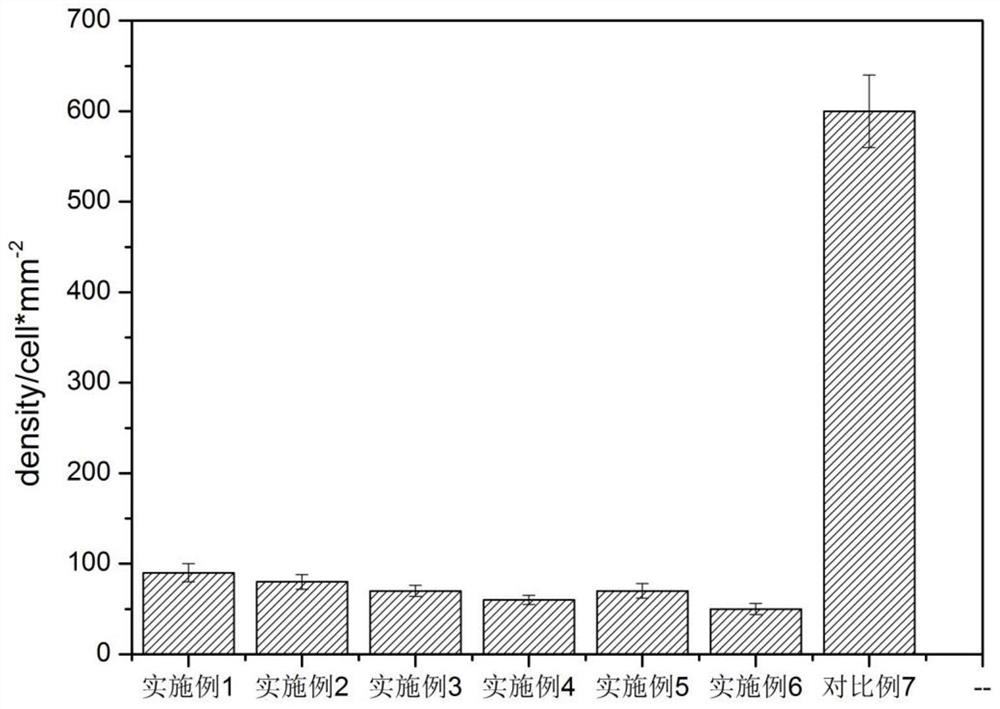

Examples

Embodiment 1

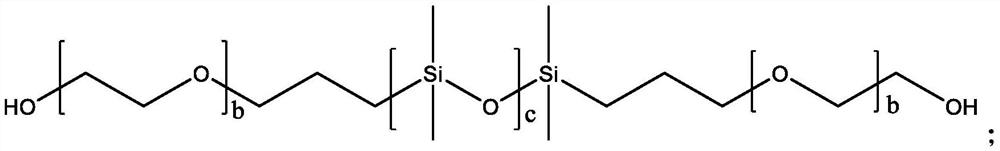

[0048] The b of the BPEG-PDMS is 15, and the c is 15; the a of PDMS is 150; the solvent in the first component is toluene; the pigment is titanium white; the zwitterionic acrylic acid monomer is SBA; Toluene;

[0049] And prepare as follows:

[0050] The preparation method of component A is: disperse BPEG-PDMS, PDMS, toluene and titanium dioxide at 2000rpm for 40 minutes, and stir evenly;

[0051] The preparation method of component B is as follows: ultrasonically disperse BTSA, SBA and xylene in anhydrous, nitrogen atmosphere and 35° C. for 1 hour.

Embodiment 2

[0053]The b of the BPEG-PDMS is 20, and the c is 18; the a of PDMS is 200; the solvent in the first component is toluene; the pigment is iron yellow; the zwitterionic acrylic monomer is CBA; Toluene;

[0054] And prepare as follows:

[0055] The preparation method of component A is: disperse BPEG-PDMS, PDMS, toluene and iron yellow at 2000rpm for 40 minutes, and stir evenly;

[0056] The preparation method of component B is as follows: BTSA, CBA and xylene are ultrasonically dispersed for 1 hour under the conditions of anhydrous, nitrogen atmosphere and 35°C.

Embodiment 3

[0058] The b of the BPEG-PDMS is 22, and the c is 18; the a of PDMS is 225; the solvent in the first component is toluene; the pigment is iron red; the zwitterionic acrylic acid monomer is SBA; Toluene;

[0059] And prepare as follows:

[0060] The preparation method of component A is: disperse BPEG-PDMS, PDMS, toluene and iron red at 2000rpm for 40 minutes, and stir evenly;

[0061] The preparation method of component B is as follows: ultrasonically disperse BTSA, SBA and xylene in anhydrous, nitrogen atmosphere and 35° C. for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com