Oxygen uptake polyester composite material for packaging with isolation performance and method for producing the same

A technology for polyester composite materials and packaging, applied in the field of polyester composite materials, can solve the problems of low catalytic efficiency, uneven distribution, low solubility, etc., achieve excellent gas barrier performance, improve catalytic efficiency, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

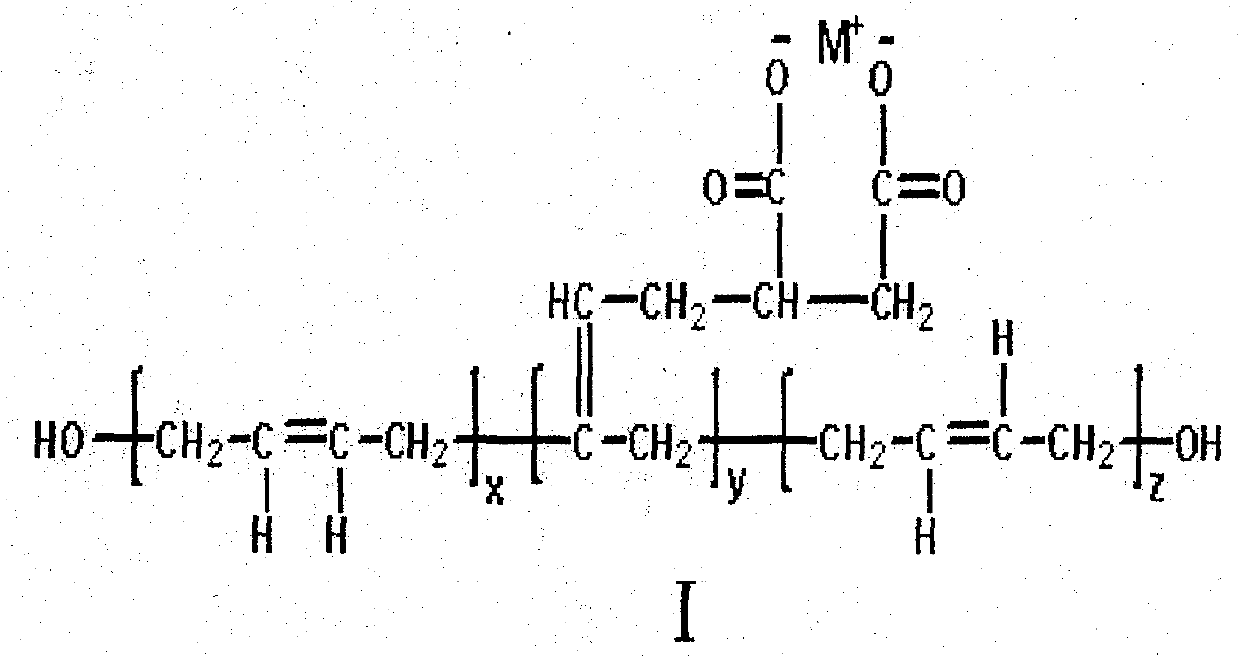

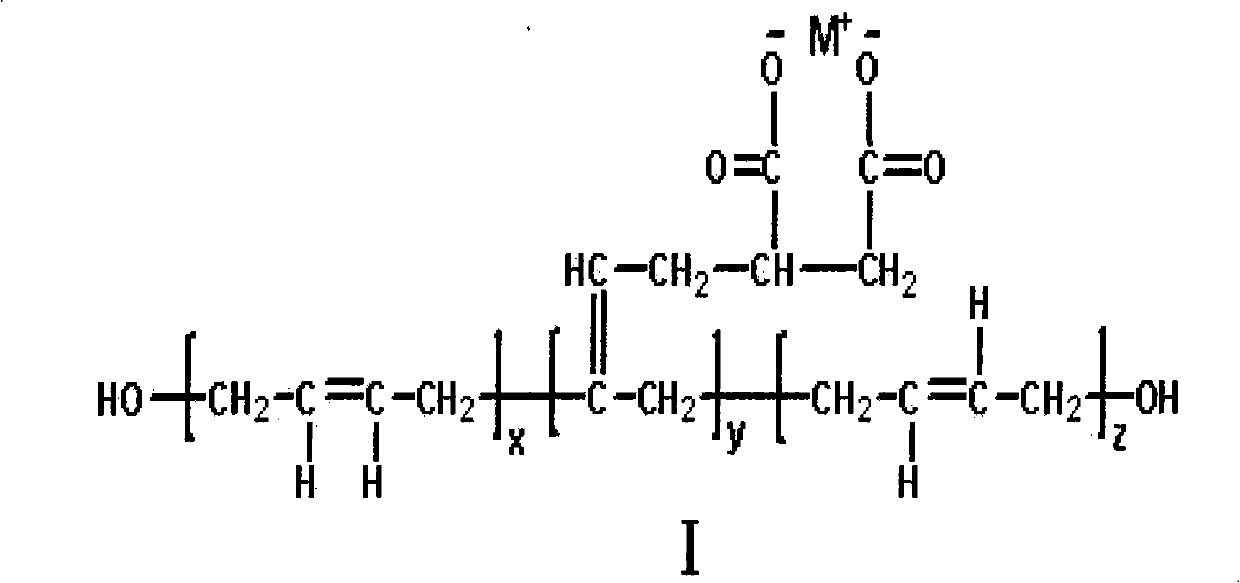

[0027] Example 1, the preparation method of self-catalyzed oxygen scavenger, its steps are as follows:

[0028] (1) Add 500g of butadiene monomer to neutralize 5g of dibenzoyl peroxide in a 1-liter three-neck flask, stir mechanically, slowly rise to 80°C over 30 minutes and keep it warm to allow it to undergo polymerization for 60 minutes; After the reaction finishes, the unreacted butadiene is separated and recovered through flash evaporation and compression, and the polymer-containing feed liquid is left to stand at 40° C. for 10 hours, then washed 3 times with an aqueous solution of sodium hydroxide with a concentration of 15% by weight, and then Wash 2 times with deionized water; then dry the feed liquid in a fluidized bed drier to obtain 450g of polybutadiene liquid polymer, the temperature is 120°C, and the drying time is 10 hours; the yield reaches 90%, 1, 2 The polymerized structural units account for about 10% of the total polymerized units, and the relative molecular...

example 2

[0033] On the technical PET production line of Italy NOY engineering company, increase the liquid metering pump; The main body PET is the bottle-grade polyester product produced by the national standard of bottle-grade polyester, and the self-catalyzed oxygen scavenger and 2,6-naphthalene obtained in example 1 Diformic acid is added to the mixing tank, mixed evenly under the protection of nitrogen, and fully mixed with the main PET melt in the static mixer after passing through the filter, metering pump and three-way valve; the mixed melt is then filtered through the melt After being filtered by a granulator, the oxygen-absorbing polyester composite material for barrier packaging is obtained by cooling and granulating by a granulator; the metering pump measures so that the content of the self-catalyzed oxygen scavenger added in the entire material is 1.1% by weight, 2,6-naphthalene The content of the added amount of diformic acid in the whole material was 0.5% by weight.

example 3

[0035] On the PET production line, add liquid metering pumps. The main body PET is a bottle-grade polyester product produced according to the national standard of bottle-grade polyester. Add the self-catalyzed oxygen scavenger and 2,6-naphthalene dicarboxylic acid prepared in Example 1 into the mixing tank, mix evenly under nitrogen protection, After passing through a filter, a metering pump, and a three-way valve, it is fully mixed with the main PET melt in a static mixer. The mixed melt is filtered through a melt filter, and then cooled and pelletized by a pelletizer to obtain an oxygen-absorbing polyester composite material for barrier packaging; the metering pump is used to measure the content of the self-catalyzed oxygen scavenger in the entire material. The amount of 2,6-naphthalene dicarboxylic acid added was 3% by weight, so that the content of the entire material was 1.0% by weight.

[0036] The oxygen-absorbing polyester composite material for barrier packaging obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com