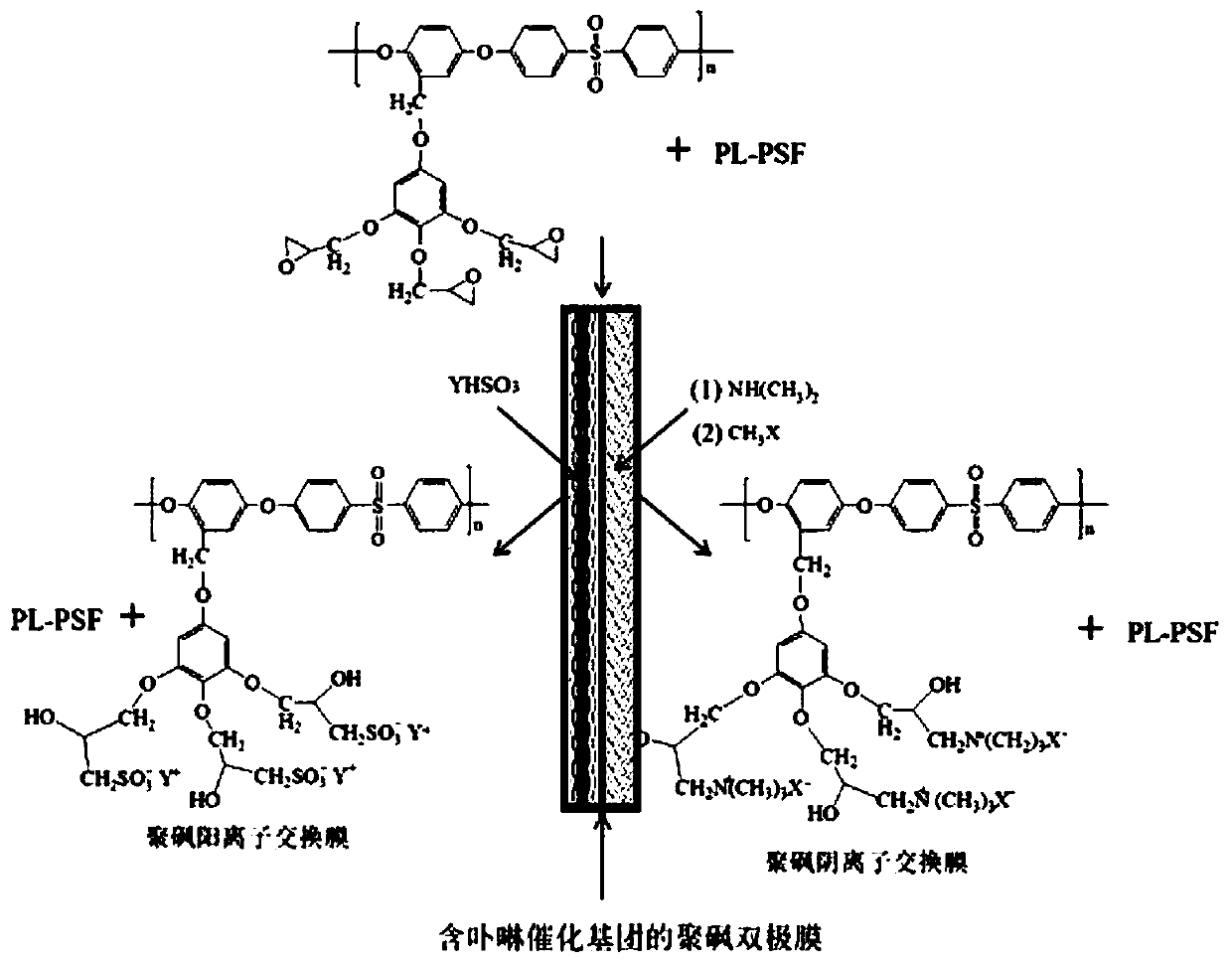

Preparation method of monolithic polysulfone bipolar membrane with side group bonded with porphyrin group

A porphyrin group, bipolar membrane technology, applied in chemical instruments and methods, chelate ion exchange, membrane technology, etc., can solve the problem of low chemical stability and thermal stability of functional groups, and limited scope of use , low utilization rate of monomers, etc., to achieve good economic benefits and promotion value, improve stability and service life, and save the effect of film forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

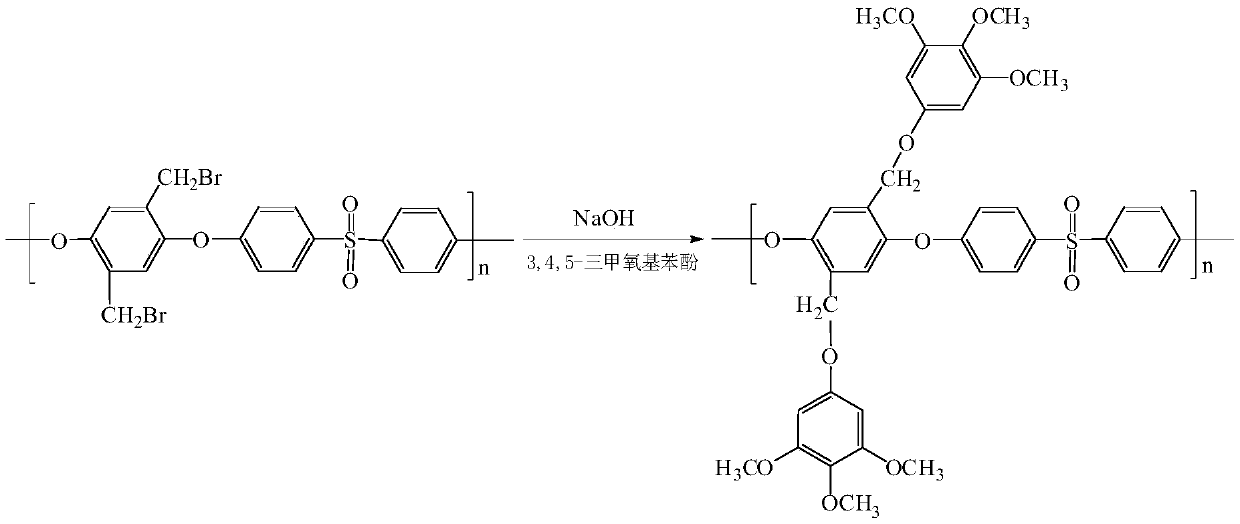

[0042] (1) Take 50.0g of bromomethylated polysulfone into a three-necked flask, dissolve it with 60mL of N-methylpyrrolidone, and set aside. Weigh again 38.9g 3,4,5-trimethoxyphenol and 7.85g NaOH, dissolve with 30mL N-methylpyrrolidone, stir at room temperature for 0.5h, add dropwise to bromomethylated polysulfone solution, stir at room temperature 10h, after the reaction is over, use a mixed solvent precipitant with a volume ratio of water and ethanol of 1:1 to precipitate the product. After filtering, the precipitate is rinsed with ethanol several times, and the precipitate is soaked in deionized water. After 24 hours, filter and precipitate The product was vacuum-dried at 70°C to prepare a methoxy-containing polysulfone polymer.

[0043]

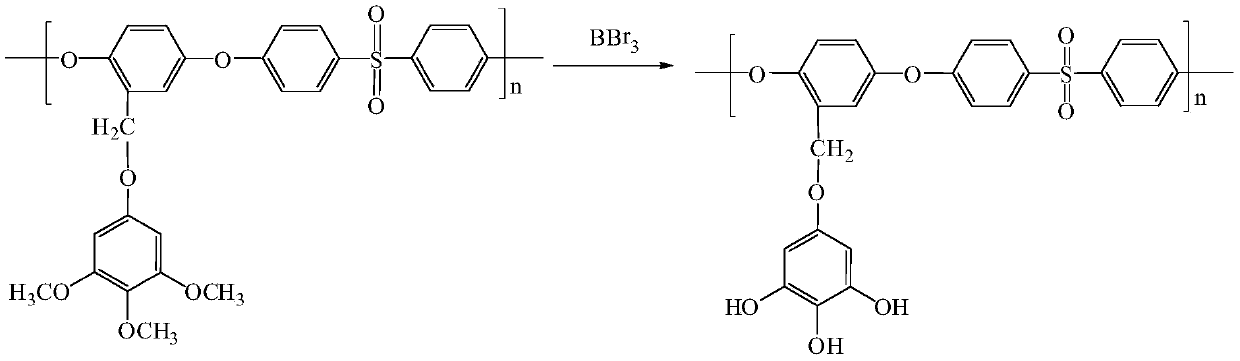

[0044] (2) Weigh 50.0 g of methoxy-containing polysulfone polymer into a 500 mL three-neck flask, install a constant pressure dropping funnel, and protect it with a nitrogen balloon after vacuuming. Add 240mL of pre-dried dichloromet...

Embodiment 2

[0055] (1) Synthesis of water catalyst in the middle layer of bipolar membrane-side chain bonded porphyrin substituent PL-PSF polymer: In a 1000mL three-necked flask, add 50.0g of bromomethylated polysulfone polymer and 500mL of DMAc to be copolymerized After the substance is fully dissolved, the 200mL DMAc solution and 11.2g NaHCO 3 , put them into a three-necked flask, raise the temperature to 50°C under the protection of nitrogen, and react at a constant temperature for 5 hours. After the reaction, immediately cool the system to room temperature with an ice-water bath, and use a mixture of distilled water and methanol as a precipitant to precipitate the product polymerization The material was washed with the mixed solution several times, and dried in vacuum to obtain a polymer (PL-PSF) with porphyrin (PL) bonded to the side chain.

[0056]

[0057] (2) Take 50.0g of bromomethylated polysulfone into a three-necked flask, dissolve it with 500mL of N-methylpyrrolidone, and ...

Embodiment 3

[0068] (1) Synthesis of water catalyst in the middle layer of bipolar membrane-side chain bonded porphyrin substituent PL-PSF polymer: In a 100mL three-necked flask, add 10.0g of bromomethylated polysulfone polymer and 100mL of DMAc to be copolymerized After the substance is fully dissolved, 50mL DMAc solution and 2.4g NaHCO 3 , put them into a three-necked flask, raise the temperature to 50°C under the protection of nitrogen, and react at a constant temperature for 5 hours. After the reaction, immediately cool the system to room temperature with an ice-water bath, and use a mixture of distilled water and methanol as a precipitant to precipitate the product polymerization The material was washed with the mixed solution several times, and dried in vacuum to obtain a polymer (PL-PSF) with porphyrin (PL) bonded to the side chain.

[0069]

[0070] (2) Take 50.0g of bromomethylated polysulfone into a three-necked flask, dissolve it with 500mL of N-methylpyrrolidone, and set asi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com