Antibacterial wet tissue for human body and preparation method of antibacterial wet tissue

A technology of wet wipes and human body, which is applied in cosmetic preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of hindering bacterial metabolism, low degree of automation, and low work efficiency, and achieve high degree of automation, Improve work efficiency and good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

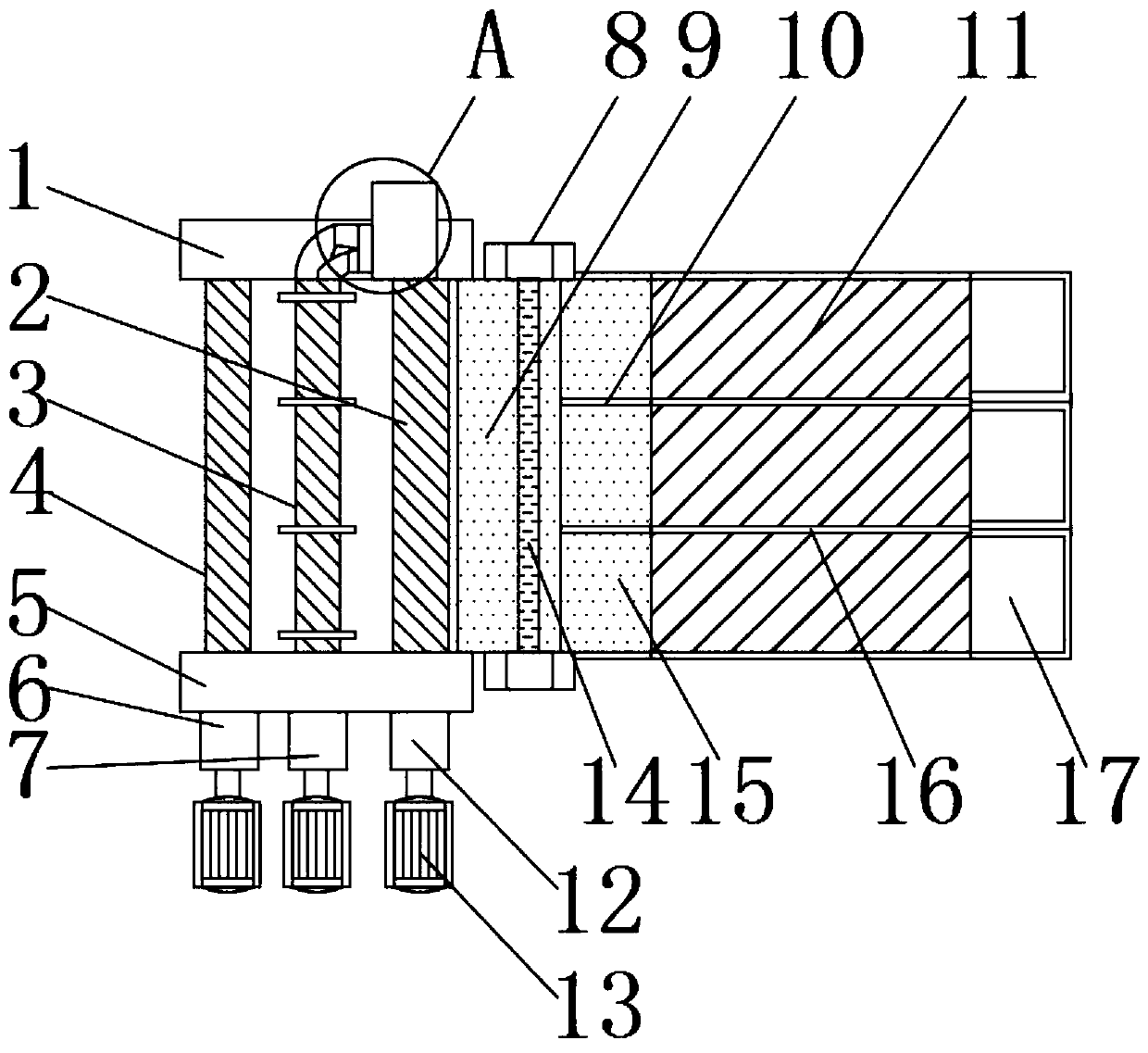

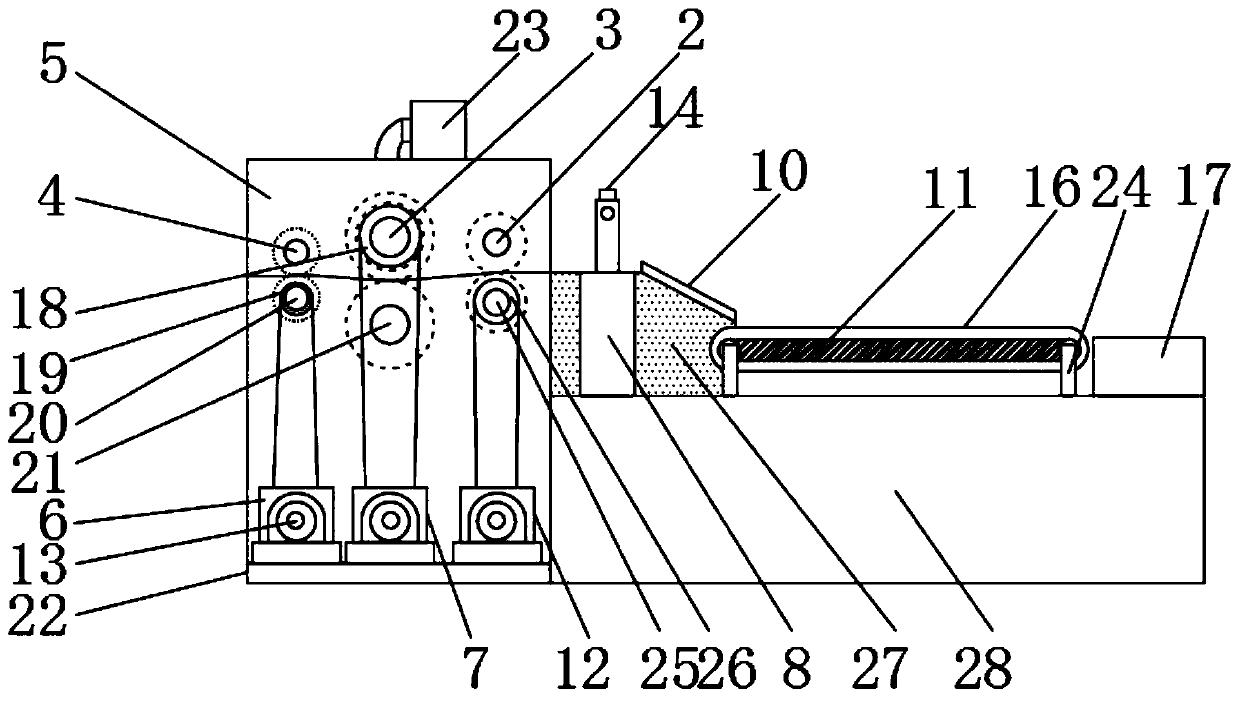

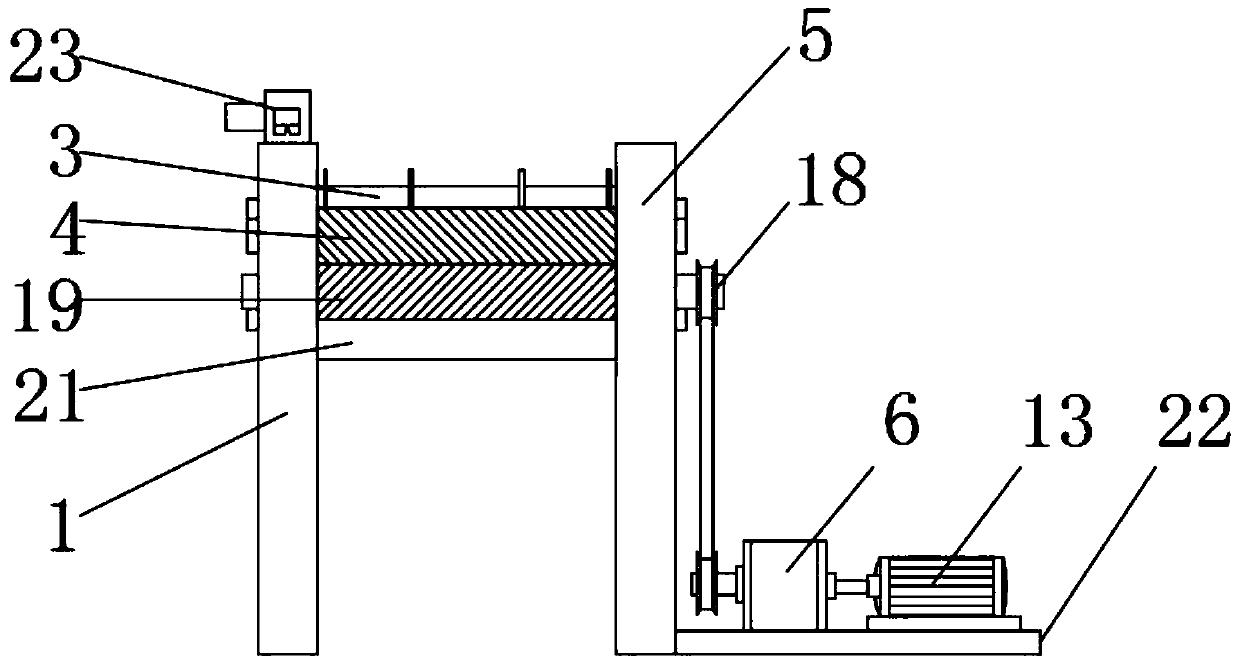

[0056] see Figure 1-7 As shown, this embodiment is an antibacterial wet wipe for human body, which is obtained by soaking block-shaped non-woven fabric in antibacterial liquid;

[0057] The non-woven fabric comprises the following component raw materials in parts by weight: 40 parts of viscose, 40 parts of polyester;

[0058] The antibacterial liquid comprises the following component raw materials in parts by weight: 0.02 part of bactericide, 0.1 part of preservative, 0.1 part of glycerin, 0.05 part of antibacterial agent, 0.06 part of natural preservative, 0.07 part of olive oil, 0.01 part of citric acid, 95 parts of deionized water share;

[0059] This antibacterial wet tissue is prepared by following steps:

[0060] Step 1: taking raw materials according to parts by weight;

[0061] Step 2: Prepare non-woven fabrics, and use a non-woven fabric cutting device to cut the formed non-woven fabrics according to a predetermined size to obtain block-shaped non-woven fabrics fo...

Embodiment 2

[0087] see Figure 1-7 As shown, this embodiment is an antibacterial wet wipe for human body, which is obtained by soaking block-shaped non-woven fabric in antibacterial liquid;

[0088] The non-woven fabric comprises the following component raw materials in parts by weight: 50 parts of viscose, 50 parts of polyester;

[0089] The antibacterial liquid comprises the following component raw materials in parts by weight: 0.04 parts of bactericide, 0.3 part of preservative, 0.3 part of glycerin, 0.10 part of antibacterial agent, 0.09 part of natural preservative, 0.11 part of olive oil, 0.02 part of citric acid, 100 parts of deionized water share;

[0090] This antibacterial wet tissue is prepared by following steps:

[0091] Step 1: taking raw materials according to parts by weight;

[0092] Step 2: Prepare non-woven fabrics, and use a non-woven fabric cutting device to cut the formed non-woven fabrics according to a predetermined size to obtain block-shaped non-woven fabrics fo...

Embodiment 3

[0105] see Figure 1-7 As shown, this embodiment is an antibacterial wet wipe for human body, which is obtained by soaking block-shaped non-woven fabric in antibacterial liquid;

[0106] The non-woven fabric comprises the following component raw materials in parts by weight: 60 parts of viscose, 60 parts of polyester;

[0107] The antibacterial liquid comprises the following component raw materials in parts by weight: 0.07 part of bactericide, 0.5 part of preservative, 0.5 part of glycerin, 0.15 part of antibacterial agent, 0.13 part of natural preservative, 0.14 part of olive oil, 0.03 part of citric acid, 105 parts of deionized water share;

[0108] This antibacterial wet tissue is prepared by following steps:

[0109] Step 1: taking raw materials according to parts by weight;

[0110] Step 2: Prepare non-woven fabrics, and use a non-woven fabric cutting device to cut the formed non-woven fabrics according to a predetermined size to obtain block-shaped non-woven fabrics f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com