Preparation method of anti-wrinkle glossy cotton and linen fabric

A glossy and fabric technology, used in textiles, biochemical fiber treatment, fabrics, etc., can solve the problems of dull and non-smooth fabrics, dull fabric colors, and poor wrinkle resistance of cotton and linen fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

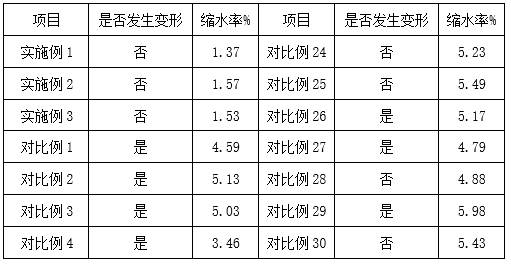

Embodiment 1

[0044] The invention discloses a preparation method of an anti-wrinkle glossy cotton and linen fabric.

[0045] Cotton and linen fabrics are interwoven with modified hemp yarns and modified cotton yarns. The specific preparation process of the fabrics is as follows:

[0046]1) Take the modified hemp yarn as the warp and the modified cotton yarn as the weft, separate the warp and weft into 20g / L sodium hydroxide solution and soak for 30min, take it out, and put it into clear water with a hardness of 4 Repeat the cleaning several times, and put the washed warp and weft in a cool place to dry;

[0047] 2) The warp and weft are interwoven according to the ratio of 100 / 100, and the plain weave method is used to obtain the fabric; the fabric is baked in an oven to set the shape, the oven temperature is 75°C, and the baking time is 15 minutes;

[0048] 3) Immerse the fabric in step 3) in 5mmol / L sodium hydroxide solution to remove impurities on the surface of the fabric for 1 hour; ...

Embodiment 2

[0074] The invention discloses a preparation method of an anti-wrinkle glossy cotton and linen fabric.

[0075] Cotton and linen fabrics are interwoven with modified hemp yarns and modified cotton yarns. The specific preparation process of the fabrics is as follows:

[0076] 1) Take the modified hemp yarn as the warp and the modified cotton yarn as the weft, separate the warp and weft into 20g / L sodium hydroxide solution and soak for 30min, take it out, and put it into clear water with a hardness of 4 Repeat the cleaning several times, and put the washed warp and weft in a cool place to dry;

[0077] 2) The warp and weft are interwoven according to the ratio of 100 / 100, and the plain weave method is used to obtain the fabric; the fabric is baked in an oven to set the shape, the oven temperature is 75°C, and the baking time is 15 minutes;

[0078] 3) Immerse the fabric in step 3) in 5mmol / L sodium hydroxide solution to remove impurities on the surface of the fabric for 1 hour;...

Embodiment 3

[0104] The invention discloses a preparation method of an anti-wrinkle glossy cotton and linen fabric.

[0105] Cotton and linen fabrics are interwoven with modified hemp yarns and modified cotton yarns. The specific preparation process of the fabrics is as follows:

[0106] 1) Take the modified hemp yarn as the warp and the modified cotton yarn as the weft, separate the warp and weft into 20g / L sodium hydroxide solution and soak for 30min, take it out, and put it into clear water with a hardness of 4 Repeat the cleaning several times, and put the washed warp and weft in a cool place to dry;

[0107] 2) The warp and weft are interwoven according to the ratio of 100 / 100, and the plain weave method is used to obtain the fabric; the fabric is baked in an oven to set the shape, the oven temperature is 75°C, and the baking time is 15 minutes;

[0108] 3) Immerse the fabric in step 3) in 5mmol / L sodium hydroxide solution to remove impurities on the surface of the fabric for 1 hour;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com