Low-temperature resistance and high-compatibility mixed material and preparation method thereof

A mixed material and low-temperature resistant technology, which is applied in the field of low-temperature-resistant and highly compatible mixed materials and their preparation, can solve the problems of low-temperature resistance and limited PE content, and achieve low cost, good compatibility, and material compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

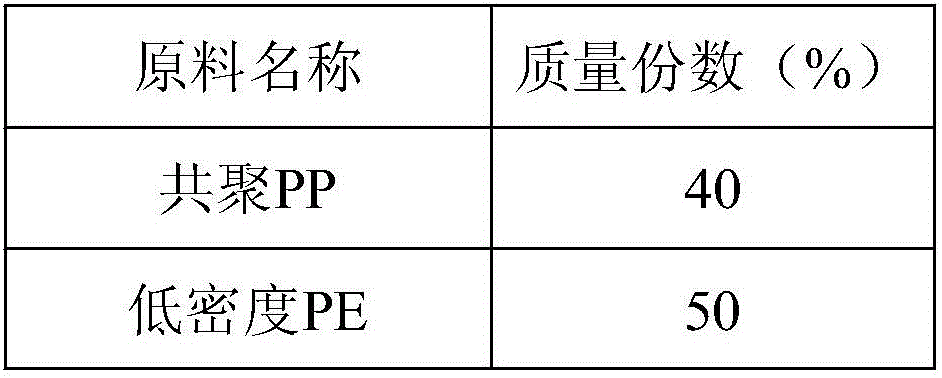

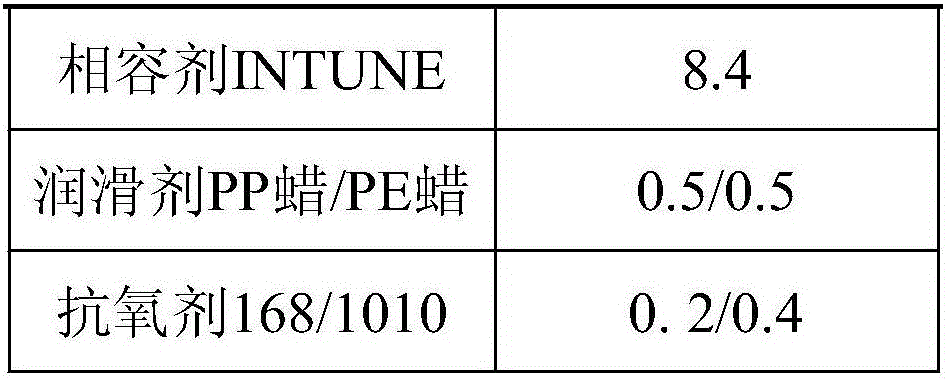

[0029] Prepare the raw materials for each component according to the table below:

[0030] Table 1 Composition list of mixed materials

[0031] raw material name

[0032] The steps to make the mixed material are as follows:

[0033] Weigh a certain amount of copolymerized PP and pour it into a mixing bucket, add white mineral oil (the amount added is 1% of the total weight of each component) and stir for 5 minutes, then add an appropriate amount of lubricant and antioxidant and stir for 5 minutes, add low-density PE Stir with the compatibilizer INTUNE for 10 minutes, and finally the mixture is obtained.

[0034] The compound is extruded, the extruding equipment is parallel extruding granulator in the same direction, the extruding temperature is 185-220°C, the screw speed is 280 rpm, then cooled, and finally pelletized to obtain a low temperature resistant and highly compatible compound Material.

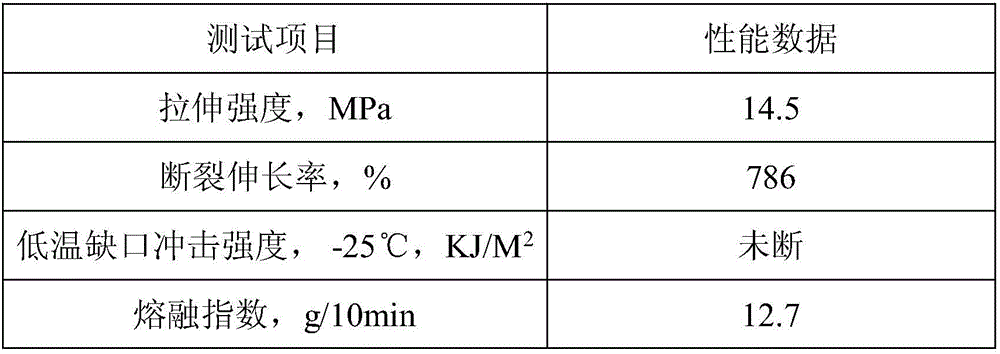

[0035] Use the prepared low-temperature-resistant and high-compatib...

Embodiment 2

[0040] Prepare the raw materials for each component according to the table below:

[0041] Table 3 Composition list of mixed materials

[0042]

[0043]

[0044] The steps to make the mixed material are as follows:

[0045] Weigh a certain amount of copolymerized PP and pour it into a mixing bucket, add white mineral oil (the amount added is 2% of the total weight of each component) and stir for 5 minutes, then add an appropriate amount of lubricant and antioxidant and stir for 5 minutes, add low-density PE Stir with the compatibilizer INTUNE for 10 minutes, and finally the mixture is obtained.

[0046] The compound is extruded, the extruding equipment is parallel extruding granulator in the same direction, the extruding temperature is 185-220°C, the screw speed is 290 rpm, then cooled, and finally pelletized to obtain a low temperature resistant and high compatible compound Material.

[0047] Use the prepared low-temperature-resistant and high-compatible mixed materi...

Embodiment 3

[0052] Prepare the raw materials for each component according to the table below:

[0053]Table 5 Composition list of mixed materials

[0054] raw material name

Parts by mass (%)

Copolymerized PP

43

low density PE

53

Compatibilizer INTUNE

3

0.25 / 0.25

Antioxidant 168 / 1010

0.25 / 0.25

[0055] The steps to make the mixed material are as follows:

[0056] Weigh a certain amount of copolymerized PP and pour it into the mixing tank, add white mineral oil and stir for 5 minutes (the amount of white mineral oil is 1% of the total weight of each component), then add an appropriate amount of lubricant and antioxidant and stir for 5 minutes, add low Density PE and compatibilizer INTUNE were stirred for 10 minutes, and finally the mixture was obtained.

[0057] The compound is extruded, and the extruding equipment is parallel extrusion granulator in the same direction, the extrusion temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com