Fully automatic inner circle chamfering device

A round chamfering and fully automatic technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as large vibration of the workpiece, achieve the effect of eliminating edge knocking, reducing processing costs, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

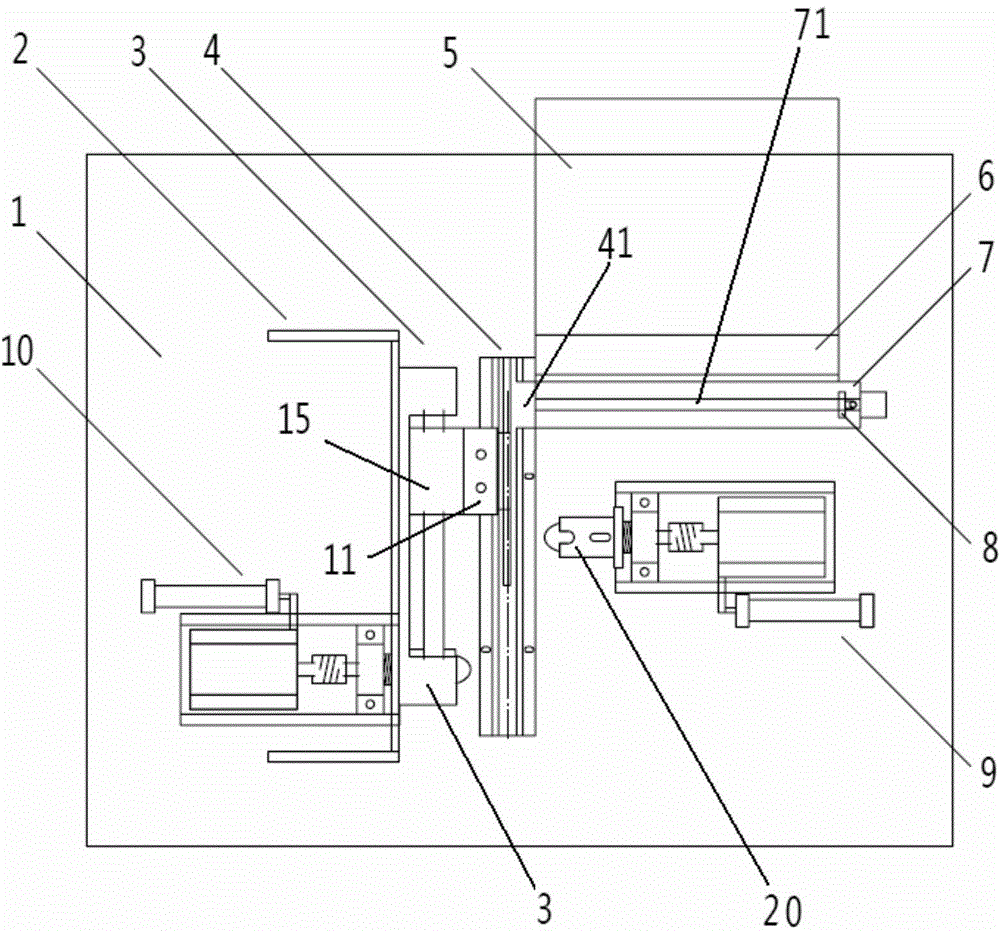

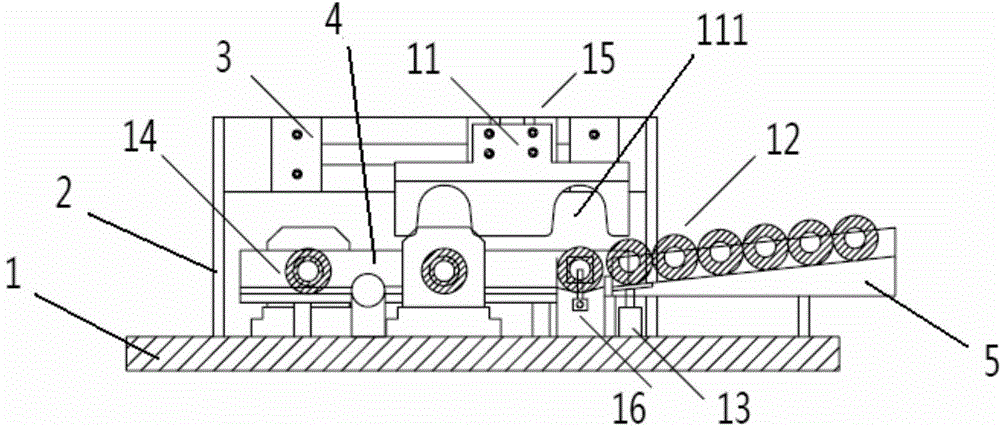

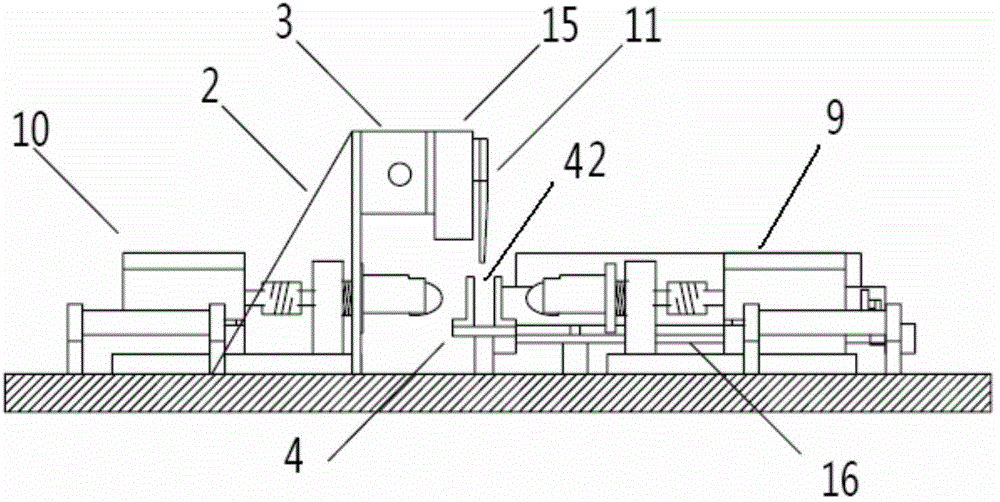

[0032] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention includes a base 1 , a workpiece positioning mechanism, a first grinding head mechanism 9 , and a second grinding head mechanism 10 . Among them, the base 1 is in the shape of a plate, preferably made of stainless steel with a thickness of about 10mm, and the installation and positioning holes of each component on it are threaded blind holes, so as to ensure that the water on the base 1 will not penetrate to the bottom through the positioning holes and affect the base 1. The devices below, for example, the electrical control system that may be arranged in the case below the base 1 .

[0033] The workpiece positioning mechanism is located on the base 1 for positioning the workpiece 12 for grinding. It has the function of gripping and fixing the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com