Charging basket on-line detecting mechanism of multi-chamber vacuum furnace

A detection mechanism and vacuum furnace technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of high energy consumption, low efficiency, easy pollution, etc., to improve work efficiency, accurate transmission, and ensure the quality of vacuum annealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

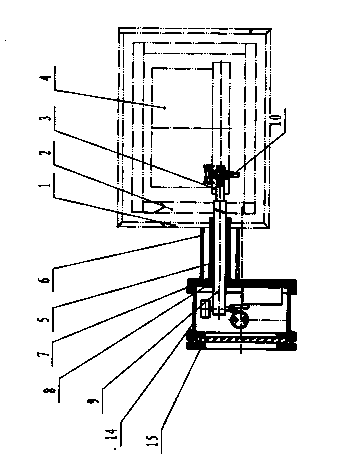

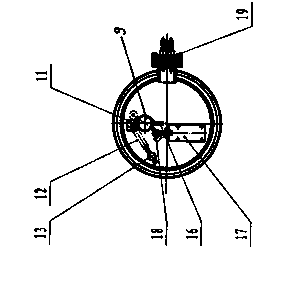

[0011] An online detection mechanism for a material basket in a multi-chamber vacuum furnace, comprising a vacuum heating chamber 1, a vacuum heating chamber furnace 2 is arranged in the vacuum heating chamber 1, and a vacuum heating chamber roller drive is arranged in the vacuum heating chamber 2 Mechanism 3, a material basket 4 is provided on the drum transmission mechanism 3 of the vacuum heating chamber, a sealed detection shaft bearing seat 5 is provided on the side wall of the vacuum heating chamber 1, and a cooling water jacket 6 is sleeve-welded on the detection shaft bearing seat 5 A brass sleeve 7 is arranged in the sealed detection shaft bearing seat 5, and a basket position detection shaft 9 is movable in the brass sleeve 7, and the inner end of the basket position detection shaft 9 passes through the vacuum heating chamber 1 in sequence The side wall of the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com