Method and system for manufacturing cooled slag-making pellets from steel plant dedusting ash or steel plant sludge

A technology for steel mill sludge and slag balls, applied in the field of iron and steel metallurgy, can solve the problems of high equipment investment, low quality, high energy consumption, etc., and achieve the effects of improving quality, reducing costs, and being beneficial to energy conservation and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

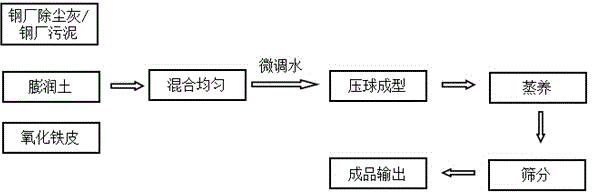

[0032] A method for making cooling slagging pellets with steel mill dust or steel mill sludge, comprising the steps of:

[0033] 1) Prepare steel mill dust or steel mill sludge, use dry collection method to collect steelmaking dust dust through a bag filter, and transport it to the pelletizing workshop; or use wet collection method to collect steelmaking dust through a paper, 2. Gravity dehydrator, elbow dehydrator, and wet spin dehydrator are brought into the sewage tank by the turbid ring water of the converter, and then into the sewage treatment equipment, and the sludge is transported to the pelletizing workshop after sedimentation;

[0034] 2), take the raw materials according to the mass ratio of 75% steel mill dust and / or steel mill sludge, 12% scale, and 13% bentonite and mix them uniformly;

[0035] 3), the above-mentioned mixture is fine-tuned with water and formed into pellets by briquetting; after adding a small amount of water, the moisture content in the mixture ...

Embodiment 2

[0040] A method for making cooling slagging pellets with steel mill dust or steel mill sludge, comprising the steps of:

[0041] 1) Prepare steel mill dust or steel mill sludge, use dry collection method to collect steelmaking dust dust through a bag filter, and transport it to the pelletizing workshop; or use wet collection method to collect steelmaking dust through a paper, 2. Gravity dehydrator, elbow dehydrator, and wet spin dehydrator are brought into the sewage tank by the turbid ring water of the converter, and then into the sewage treatment equipment, and the sludge is transported to the pelletizing workshop after sedimentation;

[0042] 2), take the raw materials according to the mass ratio of 80% steel mill dust and / or steel mill sludge, 17% scale, and 3% bentonite and mix them uniformly;

[0043] 3), the above-mentioned mixture is fine-tuned with water and formed into pellets by briquetting; after adding a small amount of water, the moisture content in the mixture a...

Embodiment 3

[0048] A method for making cooling slagging pellets with steel mill dust or steel mill sludge, comprising the steps of:

[0049] 1) Prepare steel mill dust or steel mill sludge, use dry collection method to collect steelmaking dust dust through a bag filter, and transport it to the pelletizing workshop; or use wet collection method to collect steelmaking dust through a paper, 2. Gravity dehydrator, elbow dehydrator, and wet spin dehydrator are brought into the sewage tank by the turbid ring water of the converter, and then into the sewage treatment equipment, and the sludge is transported to the pelletizing workshop after sedimentation;

[0050] 2), according to the mass ratio of steel mill dust and / or steel mill sludge 84%, scale 10%, bentonite 6% by weighing raw materials and mixing evenly;

[0051] 3), the above-mentioned mixture is fine-tuned with water and then formed into pellets by briquetting; after adding a small amount of water, the moisture content in the mixture ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com