Control method of flocculation washing machine and washing machine

A technology of flocculation washing machine and control method, which is applied in the control device of washing machine, other washing machines, water treatment parameter control and other directions, can solve the problems of small floc particles, inability to achieve effective stratification, inability to achieve stratification, and poor flocculation effect. , to achieve the effect of suitable promotion and use, avoiding inability to stratify, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

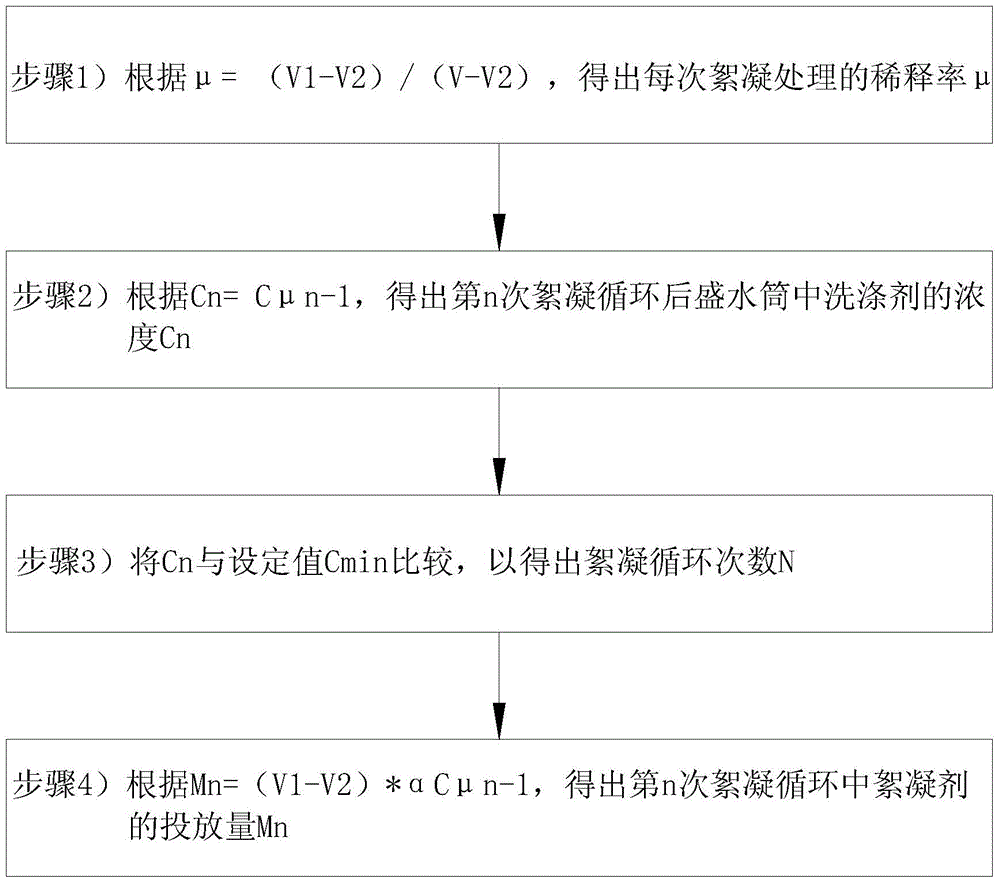

[0051] Such as image 3 As shown, in this example, the number of flocculation cycles N and the amount of flocculant dosage M corresponding to each flocculation cycle n The specific steps of the determination process are as follows:

[0052] 1) The amount of washing water V selected by the user and / or detected by the washing machine is used to call the corresponding amount of water V treated in each flocculation cycle 1 and the residual water volume V of the returned water after treatment 2 ; and use μ=(V 1 -V 2 ) / (V-V 2 ), to obtain the dilution rate μ of each flocculation treatment;

[0053] 2) According to C n =Cμ n (n can be any integer greater than 0), the concentration C of detergent in the outer barrel after the nth flocculation cycle is obtained n ;

[0054] 3) Add C n with set value C min Compare to obtain the number of flocculation cycles N;

[0055] 4) According to M n =(V 1 -V 2 )*αCμ n-1 , to get the amount of flocculant M in the nth flocculation cy...

Embodiment 2

[0067] In this embodiment, after the washing program of the washing machine is finished, the washing water is used to start the rinsing program, and at the same time, the washing water is subjected to N flocculation cycles, and M is added to the flocculation bucket in each flocculation cycle. n flocculant.

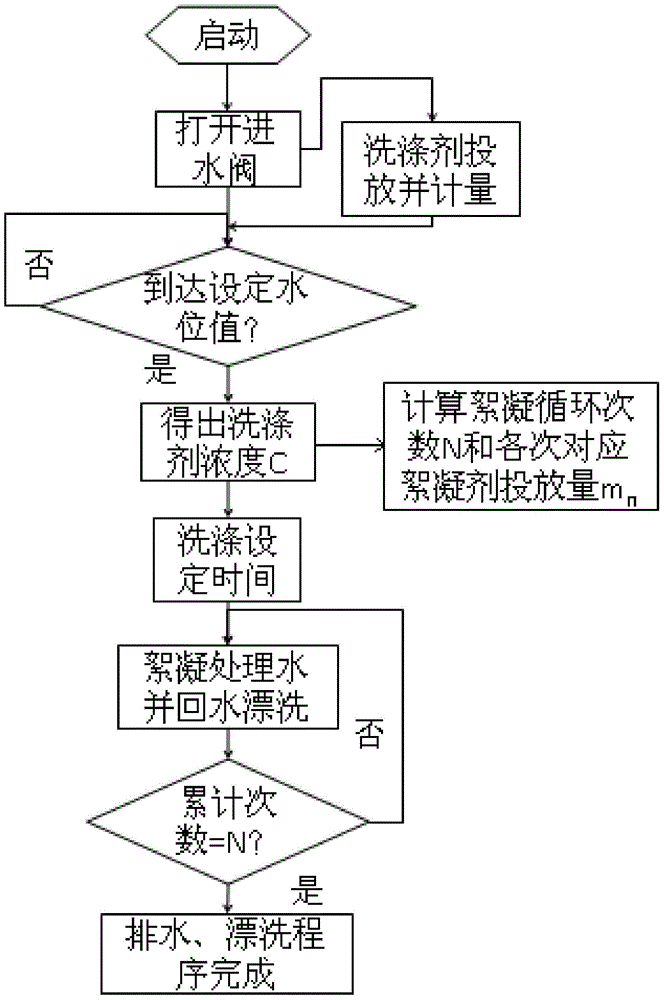

[0068] Such as figure 2 As shown, the specific working process of the washing machine is as follows,

[0069] S1) The washing machine starts to execute the washing program, obtains the washing water volume V and the detergent injection volume m to detect respectively, and obtains the detergent concentration C according to C=m / V;

[0070] S2) According to the detergent concentration C, determine the number of flocculation cycles N of the washing water and the amount of flocculant dosage M corresponding to each flocculation cycle n ;

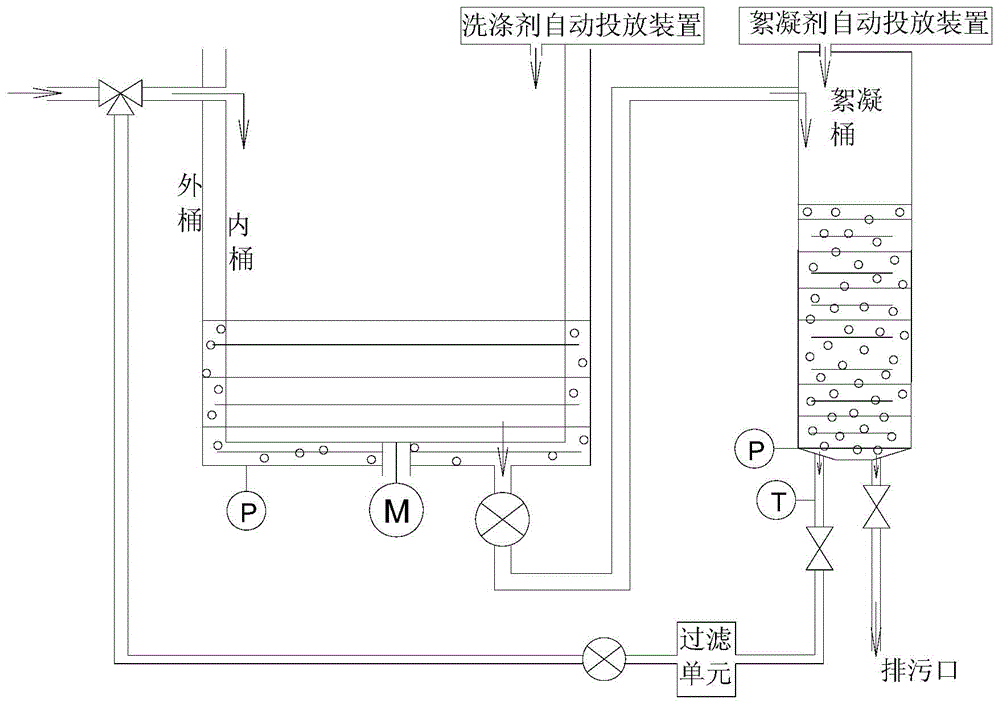

[0071] S3) The washing procedure ends, and the washing water in the outer bucket flows into the flocculation bucket so that the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com