Automatic screwing machine

An automatic locking screw machine and screw technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to achieve full automation, low production efficiency, complexity, etc., to reduce labor intensity and improve locking efficiency. , the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

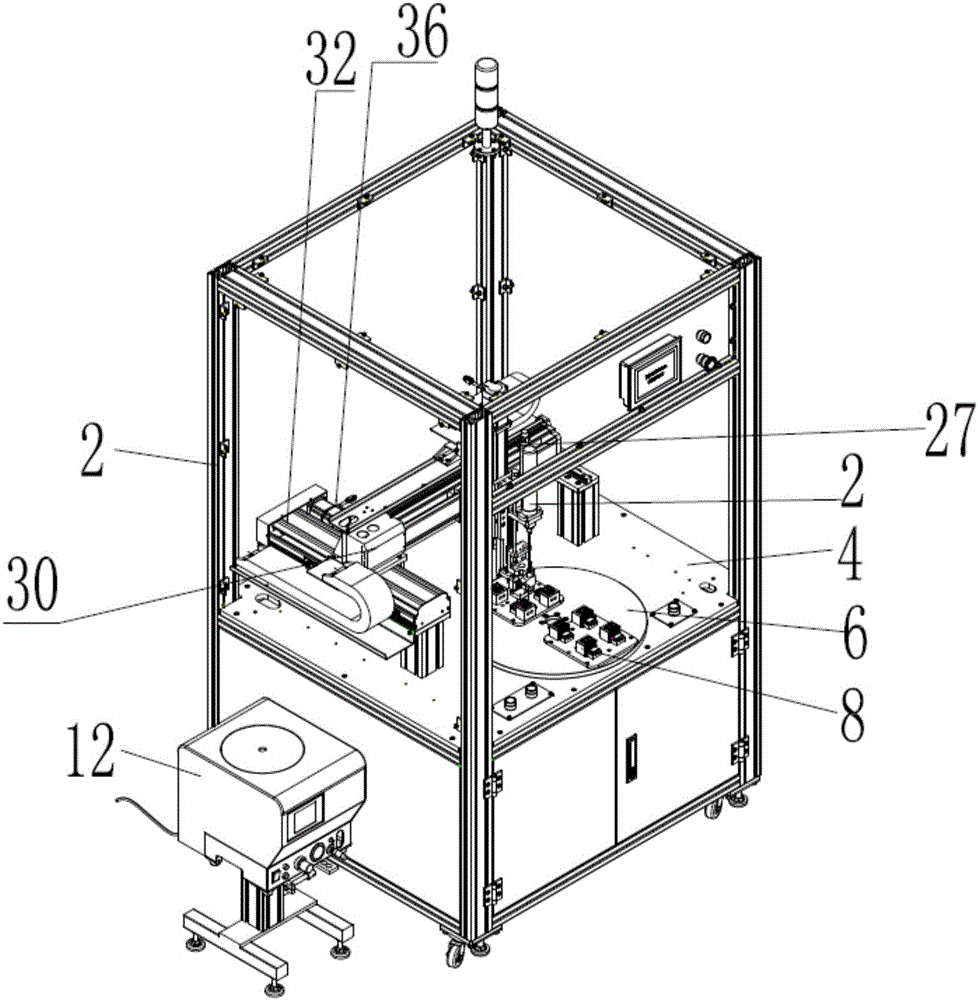

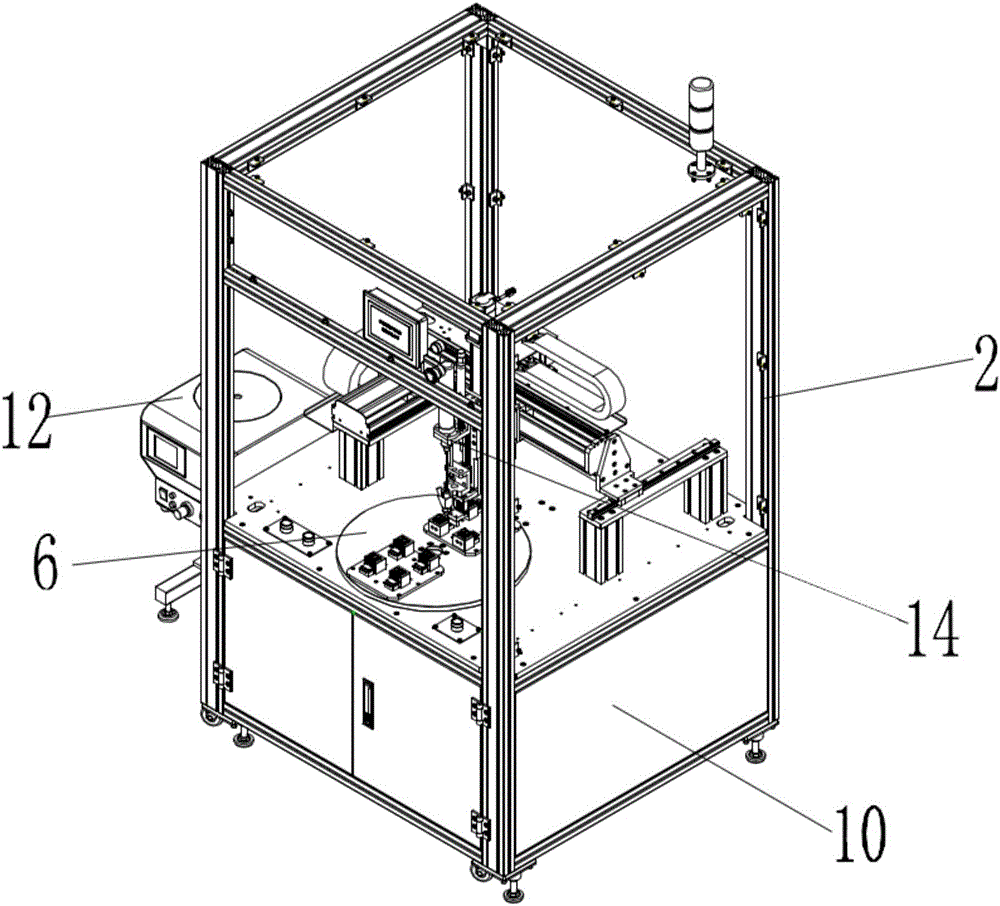

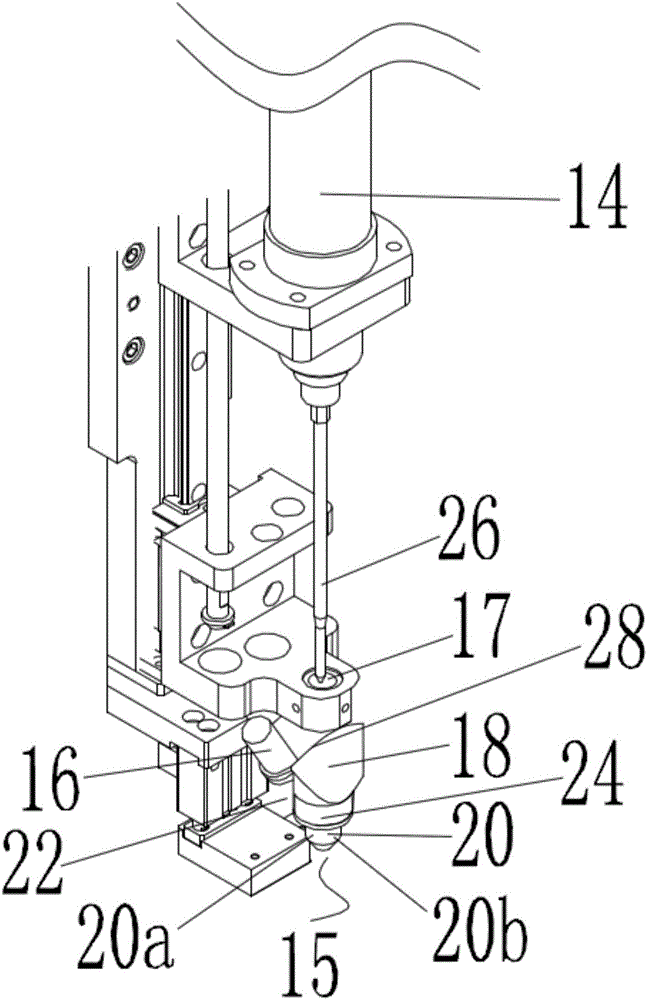

[0027] Such as figure 1 , 2 , 3, this embodiment discloses an automatic screw locking machine, including a frame 2, a base plate 4 is provided on the frame 2, and a clamp mounting seat 6 is detachably provided on the base plate 4, so that The fixture mounting base 6 is provided with a plurality of fixtures 8 for locating screw products to be locked. The screwlock machine also includes a controller 10, a screw feeder 12, a pneumatic screwdriver 14 and a mechanism for driving the screwdriver 14 to move to the target screw hole position. Three-way adjustment workbench, a screw feeder 15 that is arranged on the three-way adjustment workbench and operates synchronously with the screwdriver 14, the screw feeder 15 includes a storage tube 16 for accommodating a plurality of screws, The screw guide cup 18 connected with the storage tube 16 and the feeding nozzle 20 connected with the screw guide cup 18, the discharge port of the screw feeder 12 is connected to the storage tube 16 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com