Patents

Literature

160results about How to "Improve locking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

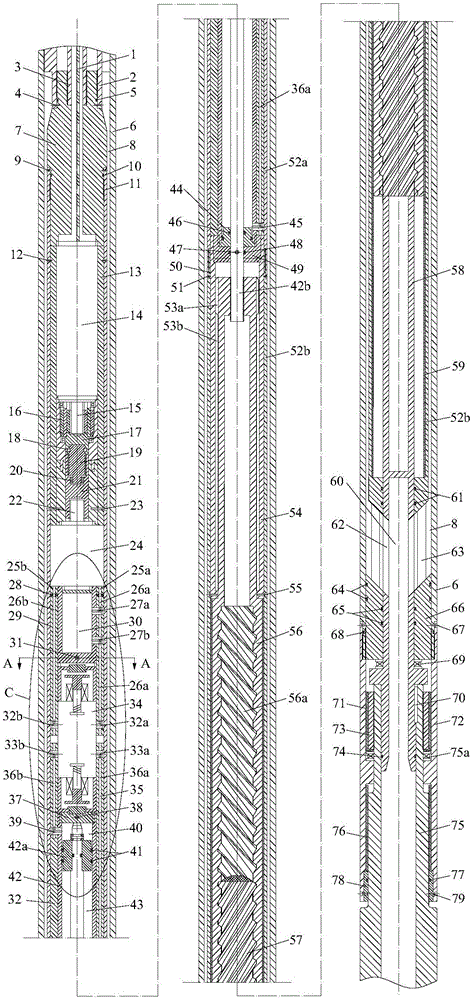

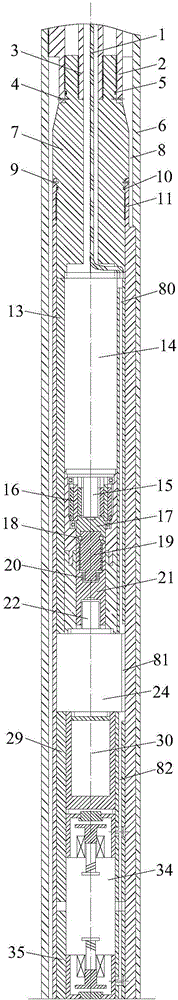

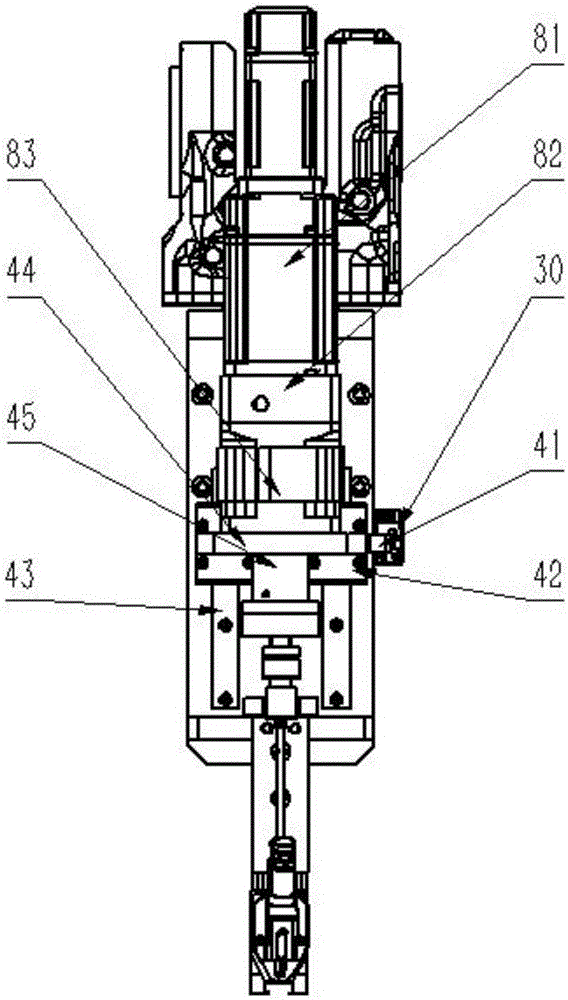

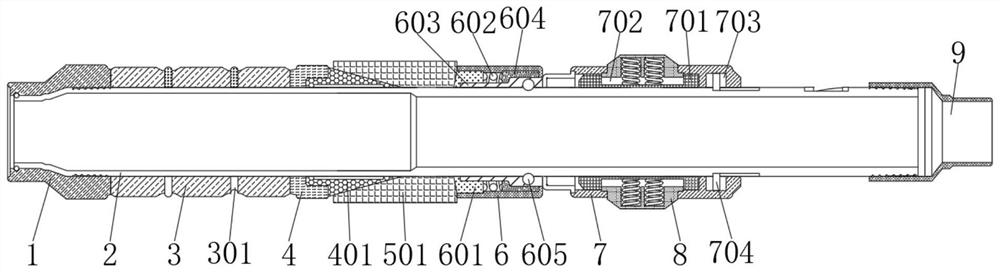

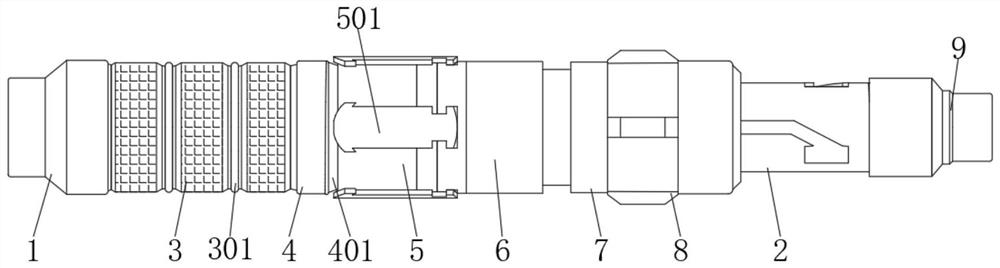

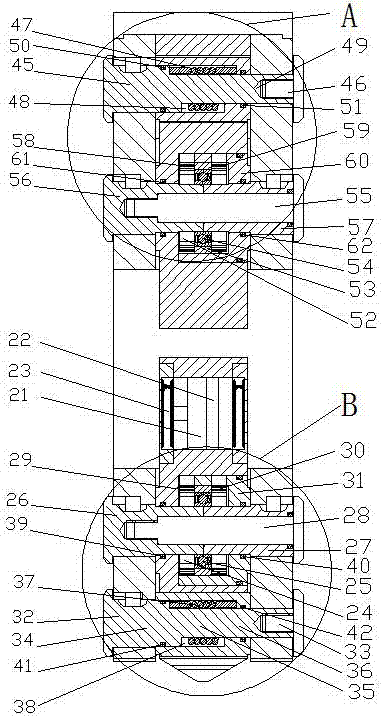

Coiled tubing drilling electric-hydraulic control directional tool

ActiveCN105888550AImprove locking efficiencyGood controllabilityDirectional drillingPistonEngineering

The invention provides a coiled tubing drilling electric-hydraulic control directional tool which comprises a driving part, a hydraulic pump, a reversing valve, a hydraulic cylinder, a drive shaft and a central spindle which are sequentially connected with one another from top to bottom, wherein the hydraulic cylinder comprises a piston, an upper cavity positioned above the piston, and a lower cavity positioned below the piston; the reversing valve is provided with an oil inlet communicated with the hydraulic pump, a first working hole communicated with the upper cavity, and a second working hole communicated with the lower cavity; one end of the drive shaft is connected with the piston; and the other end of the drive shaft can be rotationally connected with the central spindle. According to the invention, flow direction of hydraulic oil is controlled by virtue of the reversing valve, axial reciprocating motion or stop of the piston of the hydraulic cylinder is further controlled, bidirectional rotating or locking of the central spindle is controlled by virtue of the axial reciprocating motion or stop of the drive shaft, and translation is changed into rotation, so that bidirectional continuous control of rotation of a tool face angle can be realized, the tool face is locked by the reversing valve, the hydraulic locking efficiency is improved, and the controllability is high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

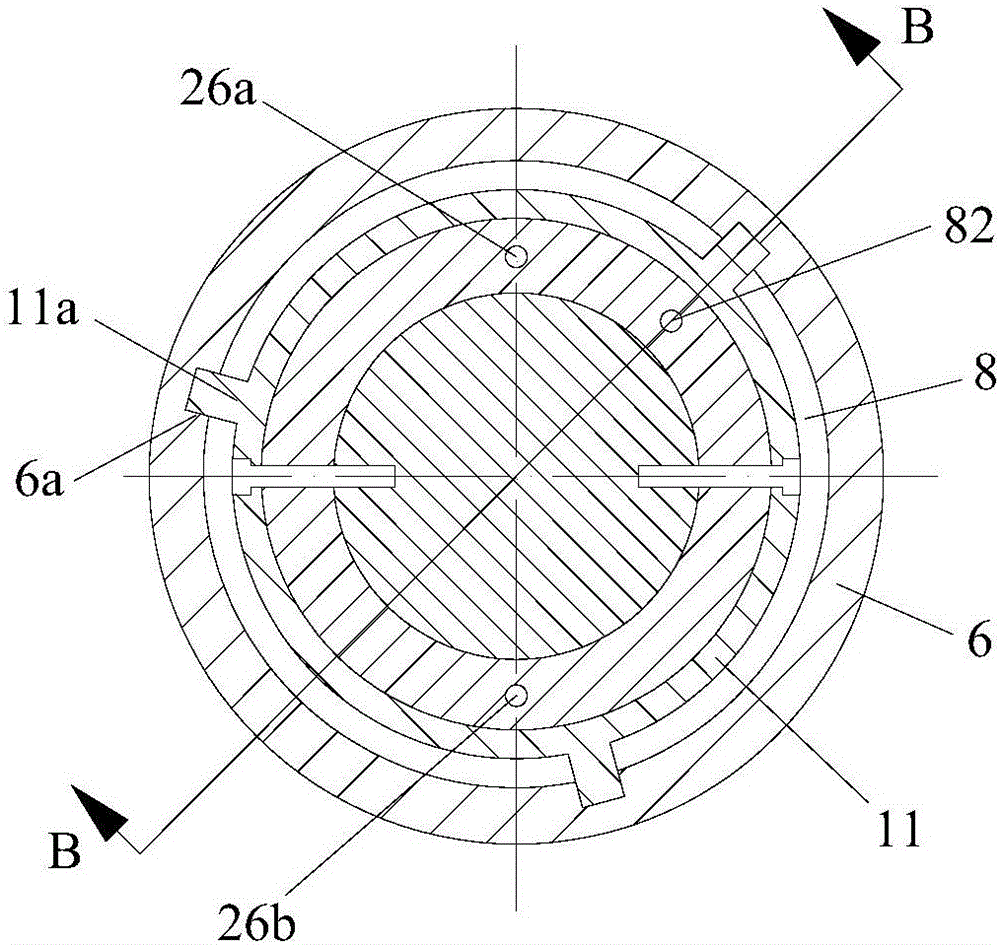

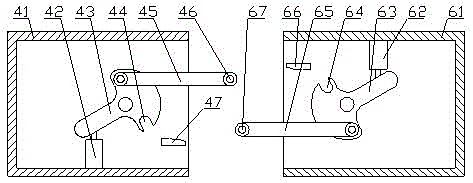

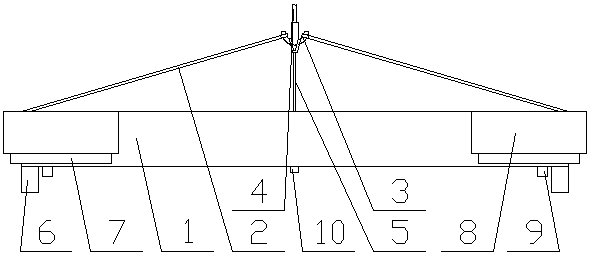

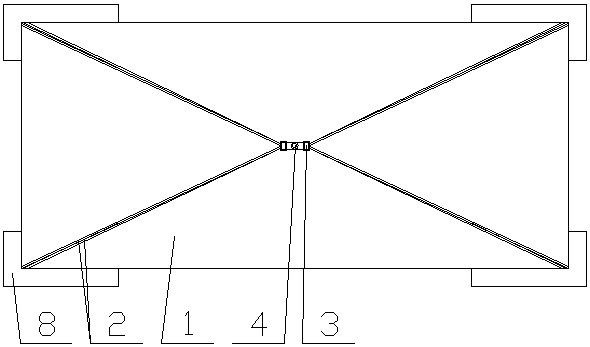

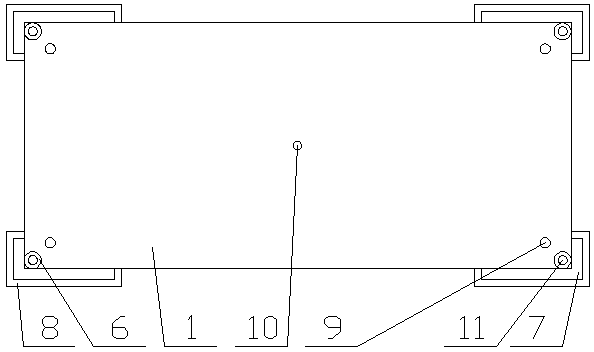

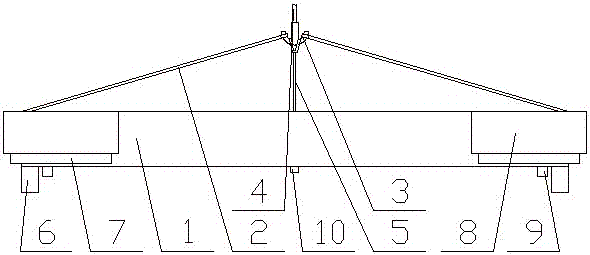

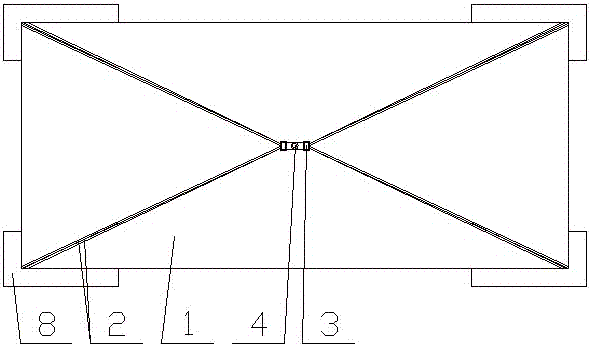

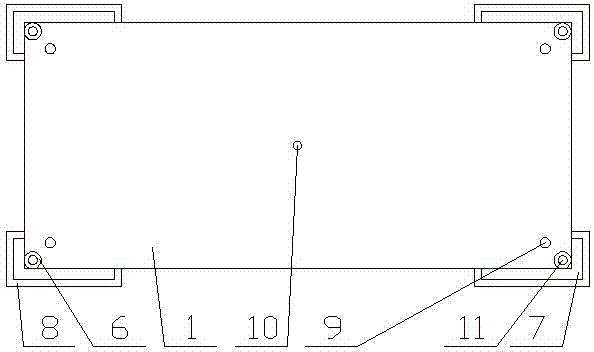

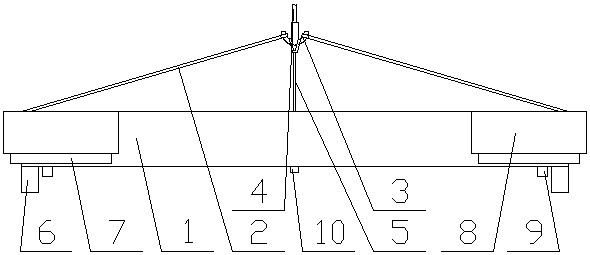

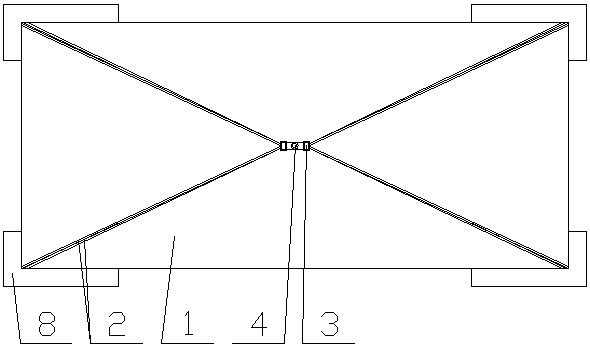

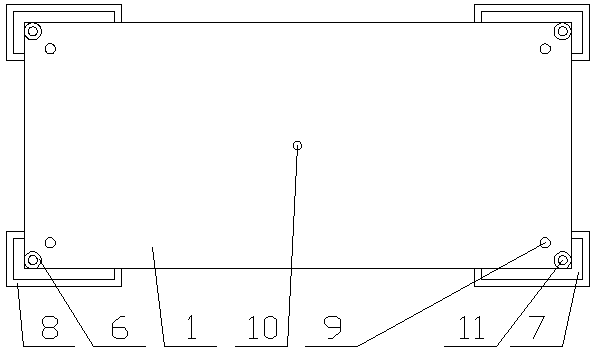

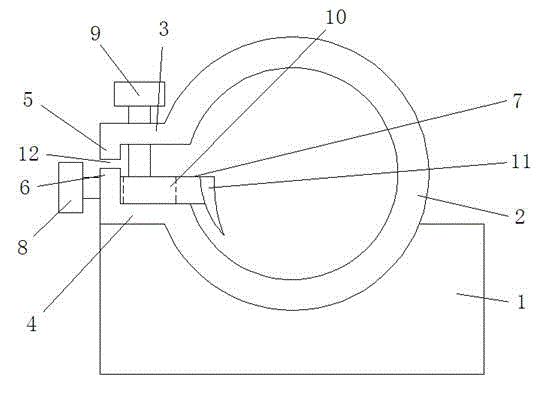

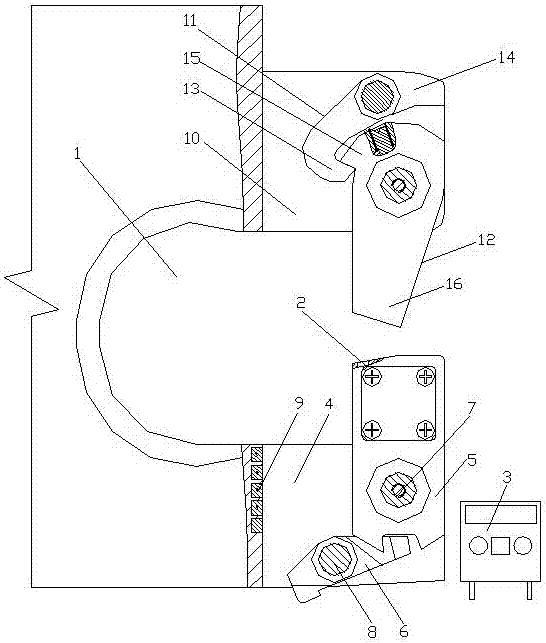

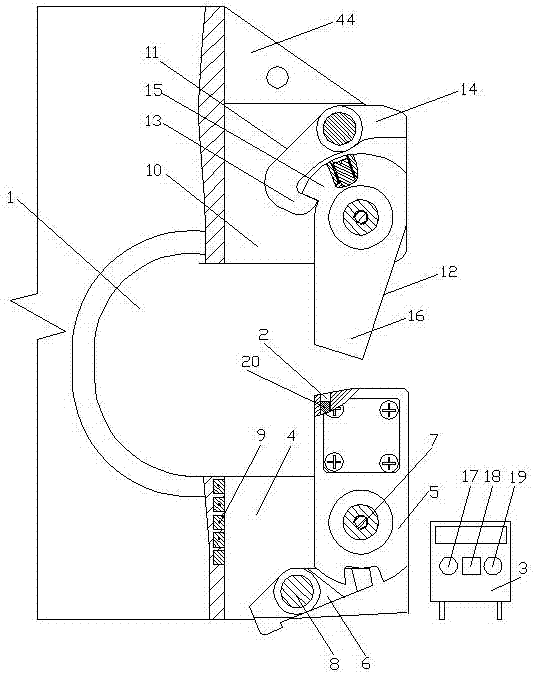

Port hoisting machinery and anchoring wind-preventing mechanism thereof

InactiveCN102311049APrevent rolloverImprove locking efficiencySafety gearEngineeringUltimate tensile strength

The invention discloses an anchoring wind-preventing mechanism of a port hoisting machinery. The anchoring wind-preventing mechanism comprises an anchoring base (1) rigidly connected with the trolley body of the port hoisting machinery, and further comprises an anchoring hook claw (6) disposed on the anchoring base (1) and a driving device capable of driving the anchoring hook claw (6) to hook or loose a positioning pillar (7) in an anchoring pit (9); the anchoring wind-preventing mechanism further comprises a locking member for locking or unlocking the working position of the anchoring hook claw (6). The anchoring wind-preventing mechanism integrates the anchoring function and the wind-preventing function into one, and realizes the anchoring and the wind-preventing functions of the engineering machinery simultaneously, thus the structure is simplified and the working reliability is relatively high; moreover, the mechanism can reduce the labour intensity of the operation staff, realize the quick-locking and improve the efficiency of locking the engineering machinery; and besides, the invention further discloses a port hoisting machinery including said anchoring wind-preventing mechanism.

Owner:SANY GRP

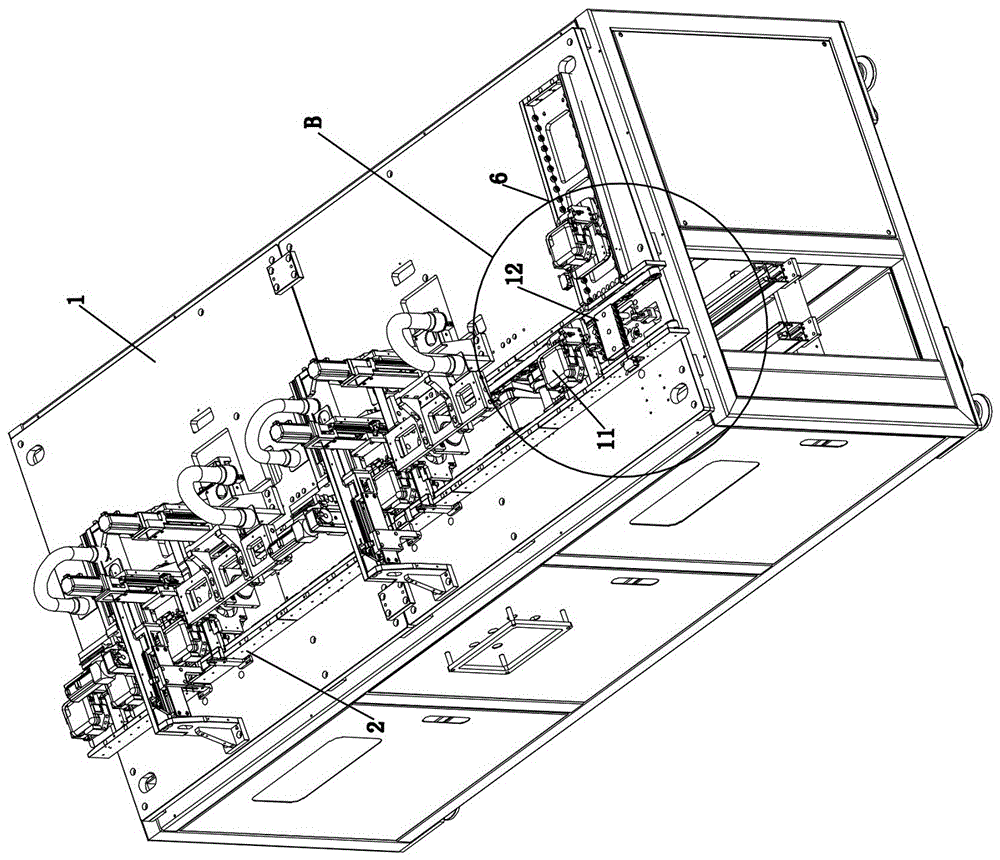

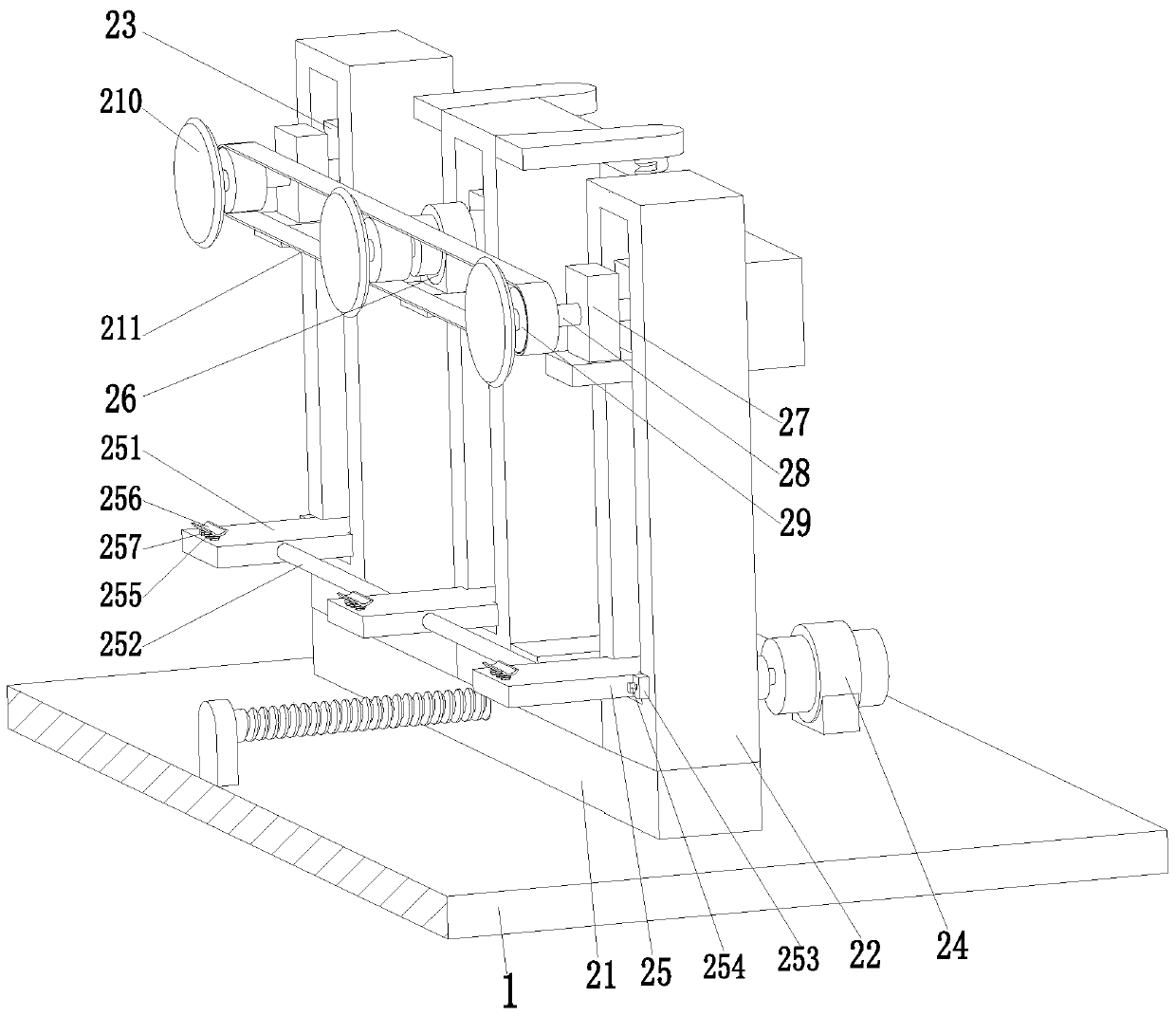

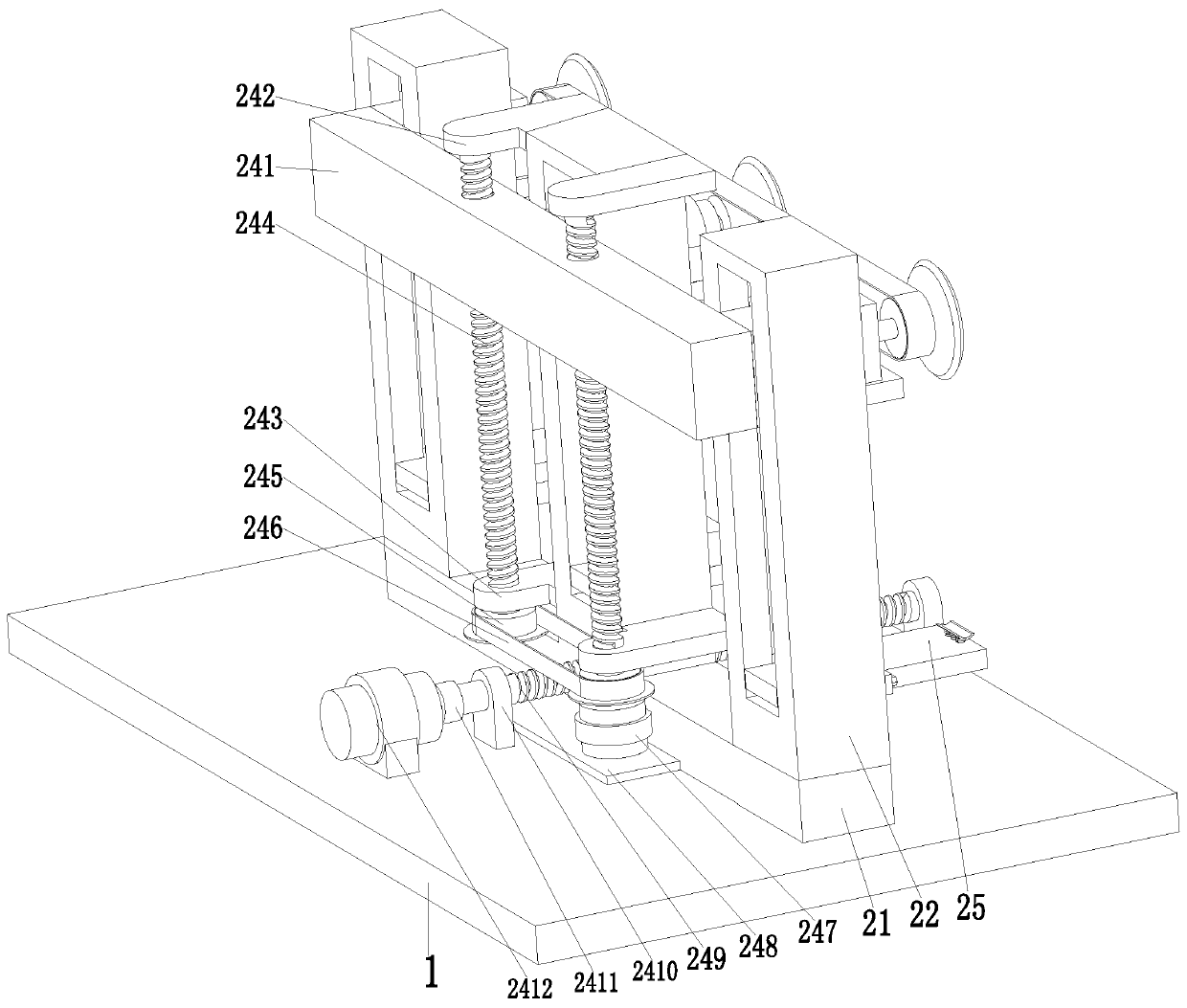

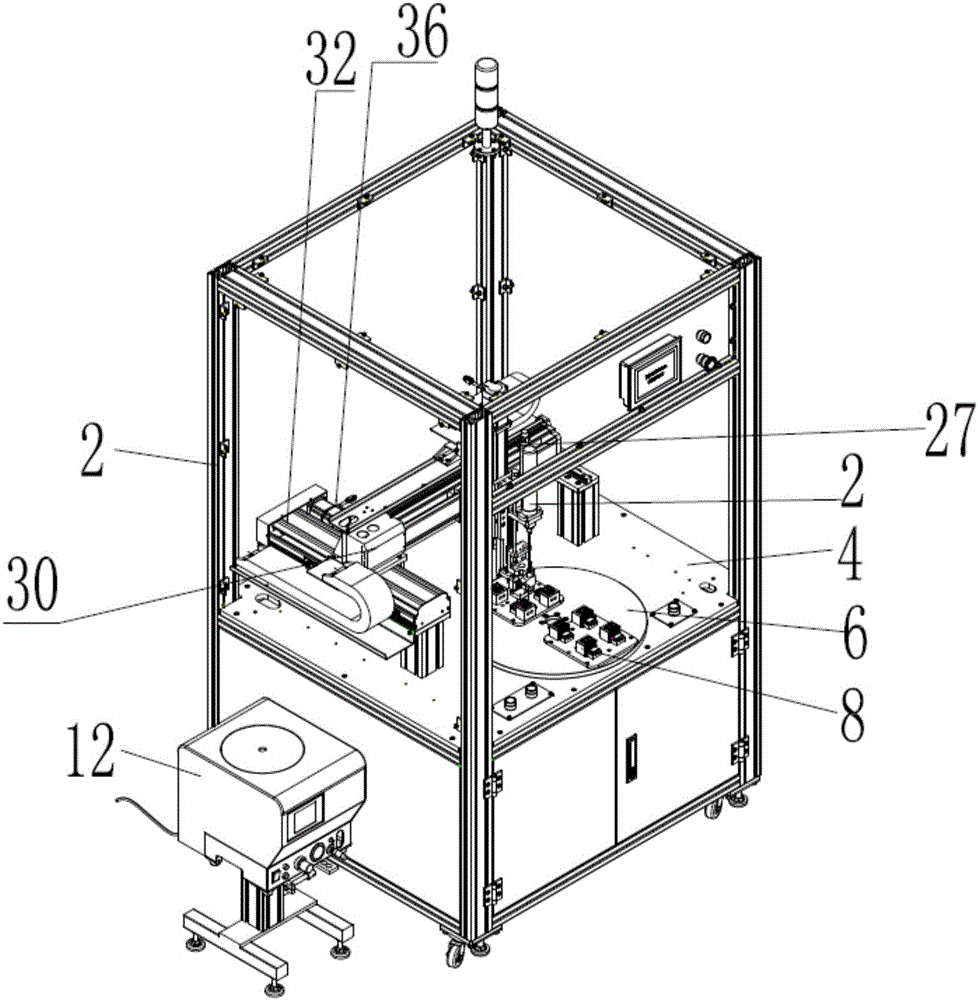

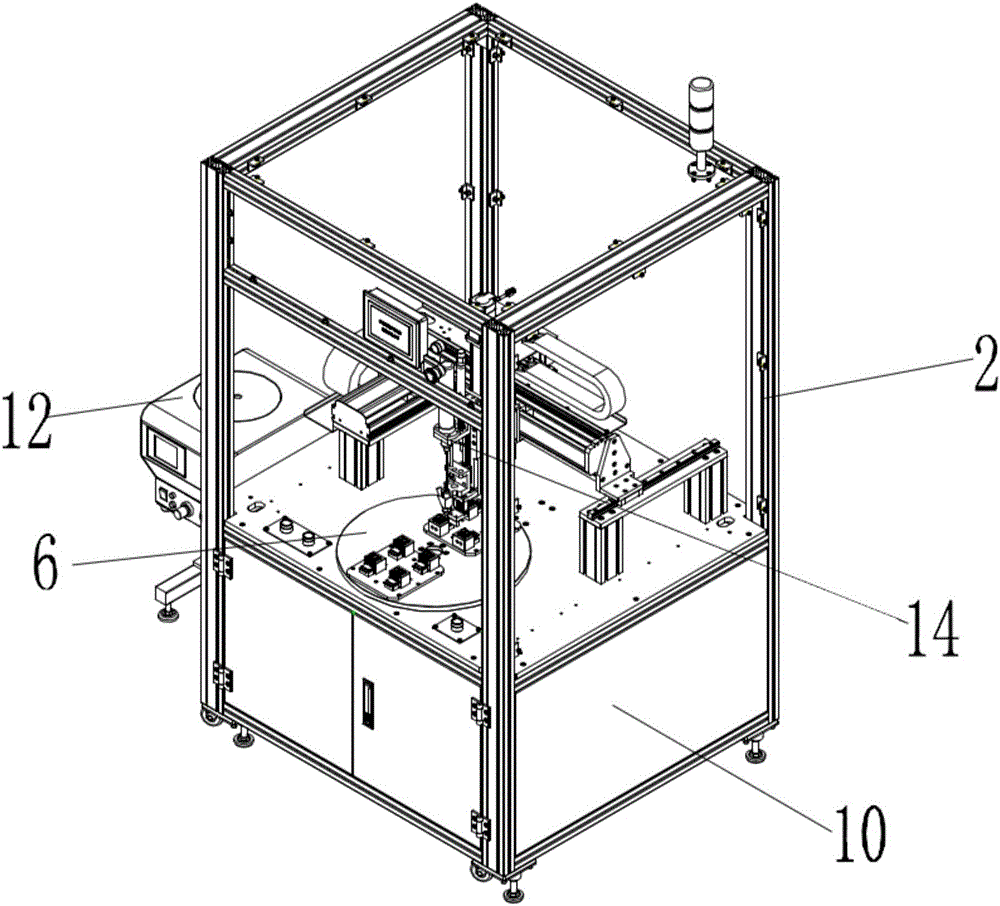

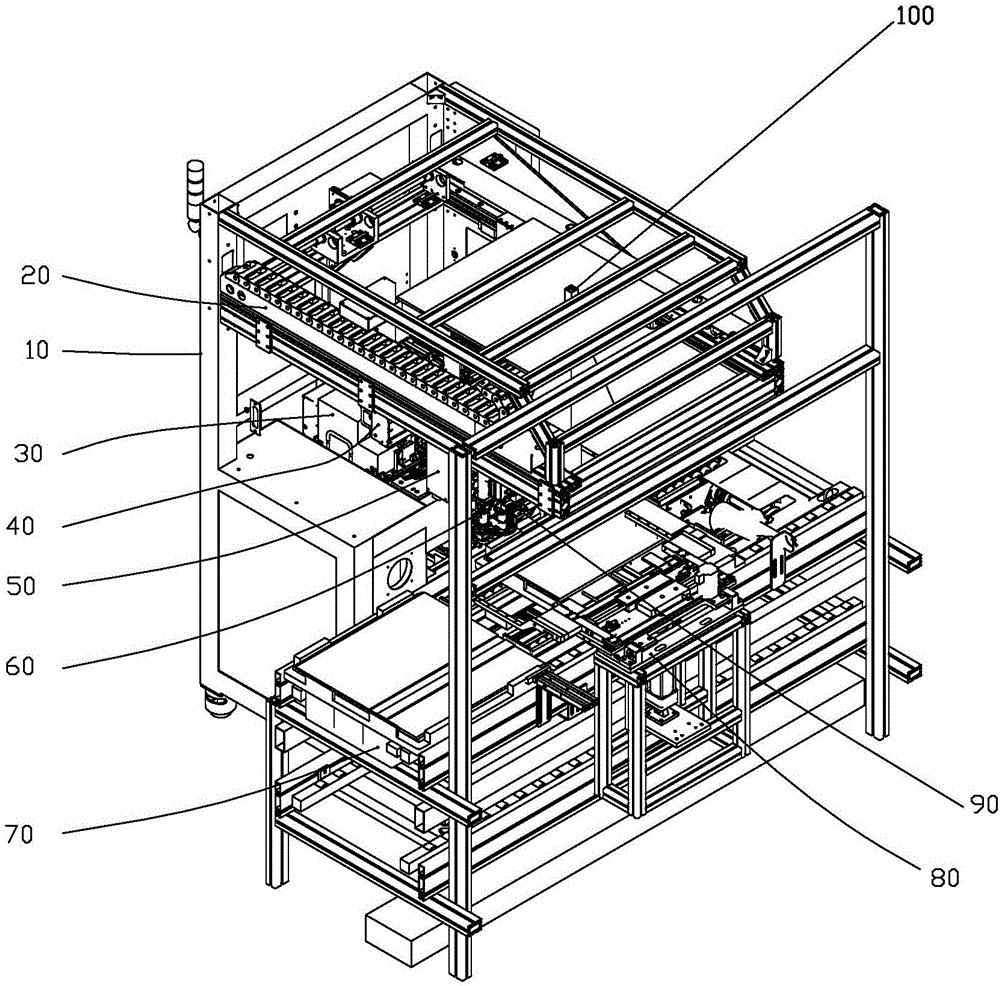

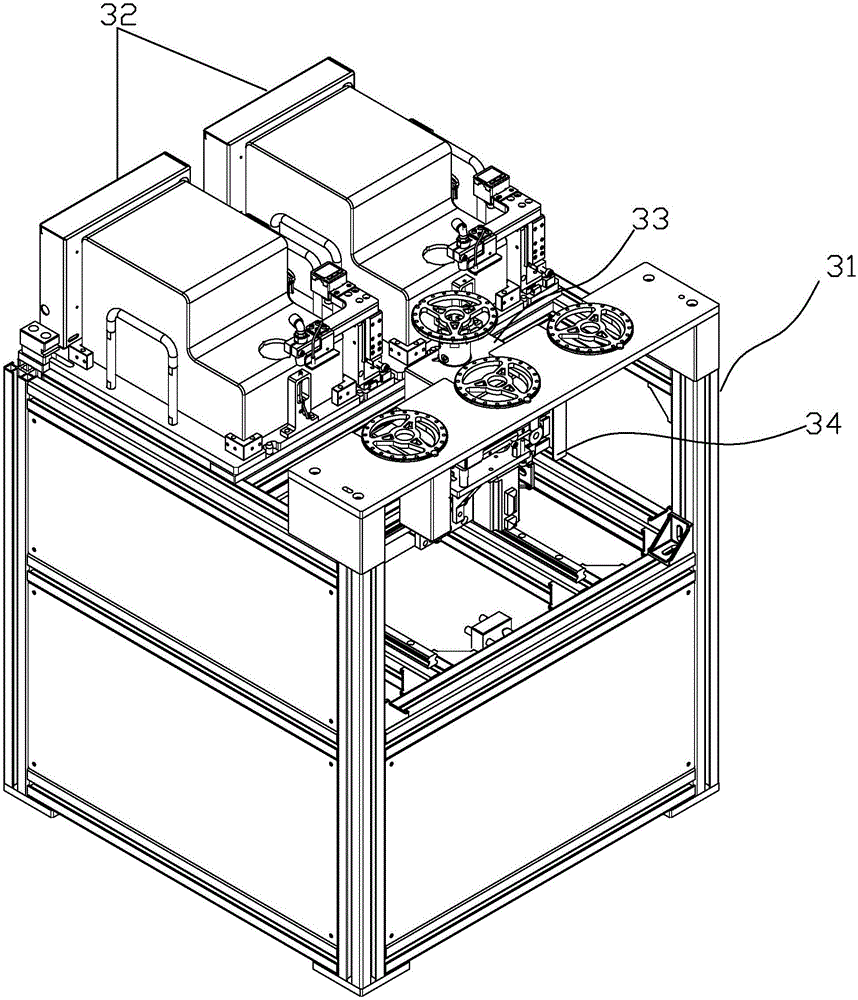

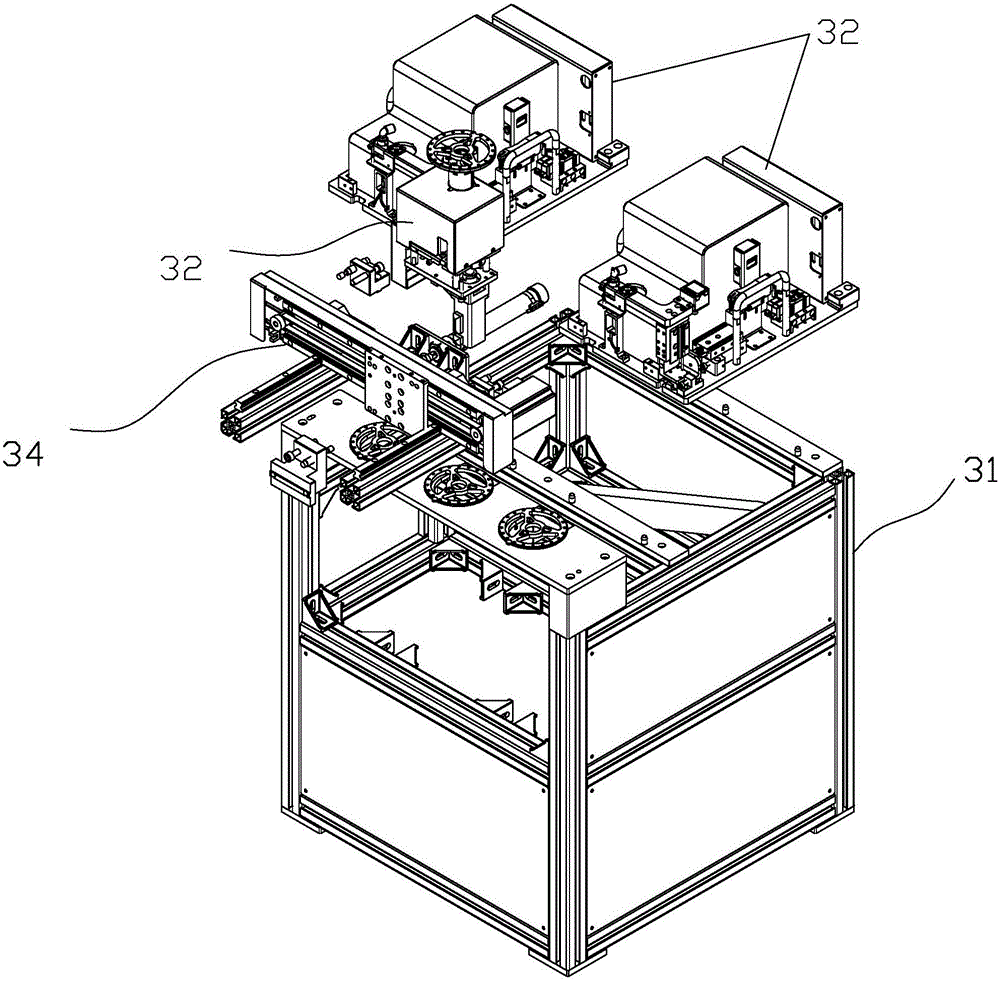

Connecting base self-centering locking production line and connecting base self-centering locking technology

ActiveCN106002207AHomogenization guaranteedImprove quality and efficiencyMaterial gluingMetal working apparatusEngineeringProduction line

The invention discloses a connecting base self-centering locking production line and a connecting base self-centering locking technology. The connecting base self-centering locking production line comprises a working table, a material belt, a positioning mechanism, a first centering mechanism, a second centering mechanism, a product fixing mechanism, a defective product ejecting mechanism and a defective product material belt; the connecting base self-centering locking technology comprises the following processing steps: S1, positioning a product; S2, clamping the position in the Y-axis direction; S3, clamping the position in the Z-axis direction; S4, scanning and shooting a plug and a connecting base center by a CCD; S5, inserting the plug in the connecting base; S6, scanning and shooting the gap between the connecting base and a mounting hole by the CCD; S7, fine tuning the gap; S8, locking a jig; and S9, discharging a non-defective project and ejecting the defective product. The connecting base self-centering locking production line is used for automatically adjusting and locking the mounting clearance of the connecting base, ensures uniform product assembling, improves production quality and production efficiency of the product, and is suitable for modern high-speed automatic production.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

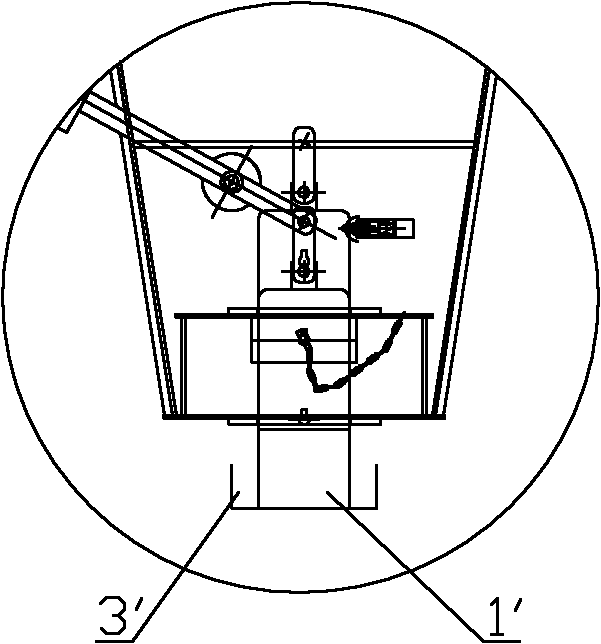

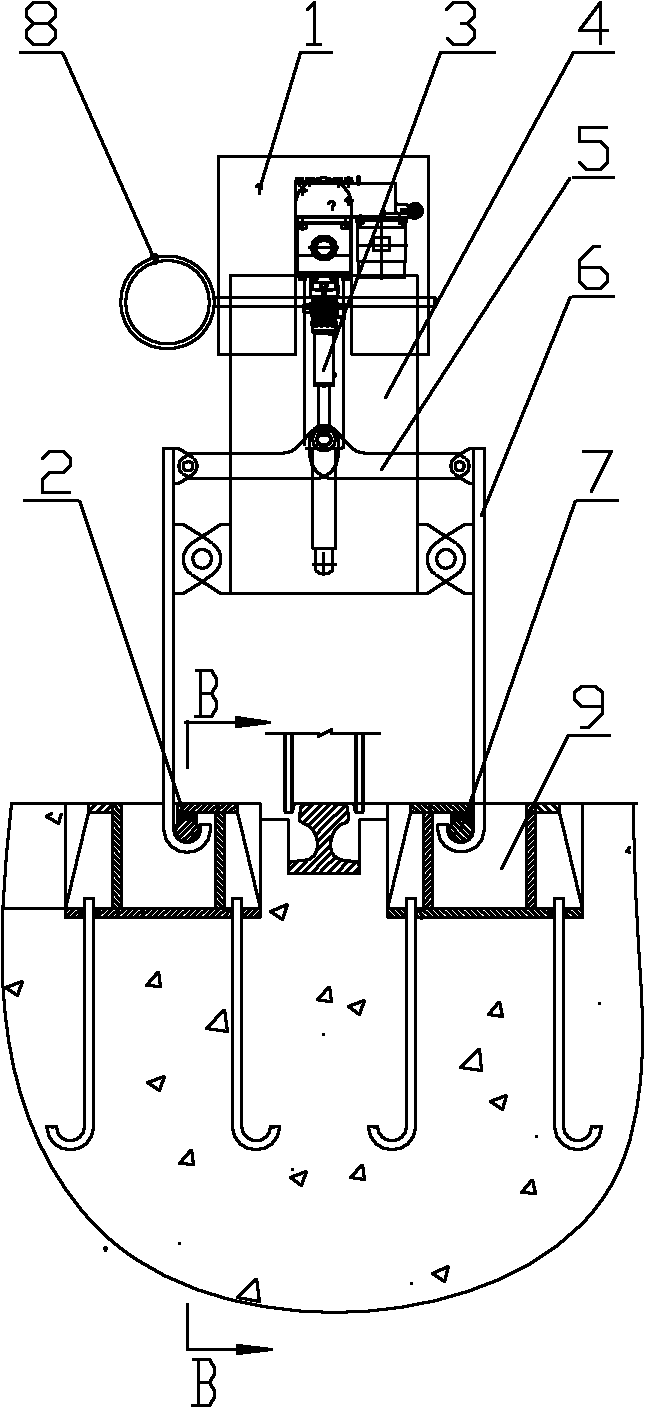

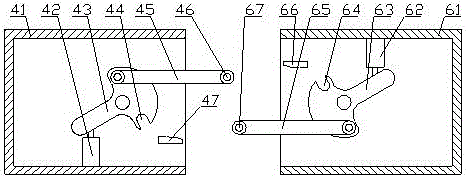

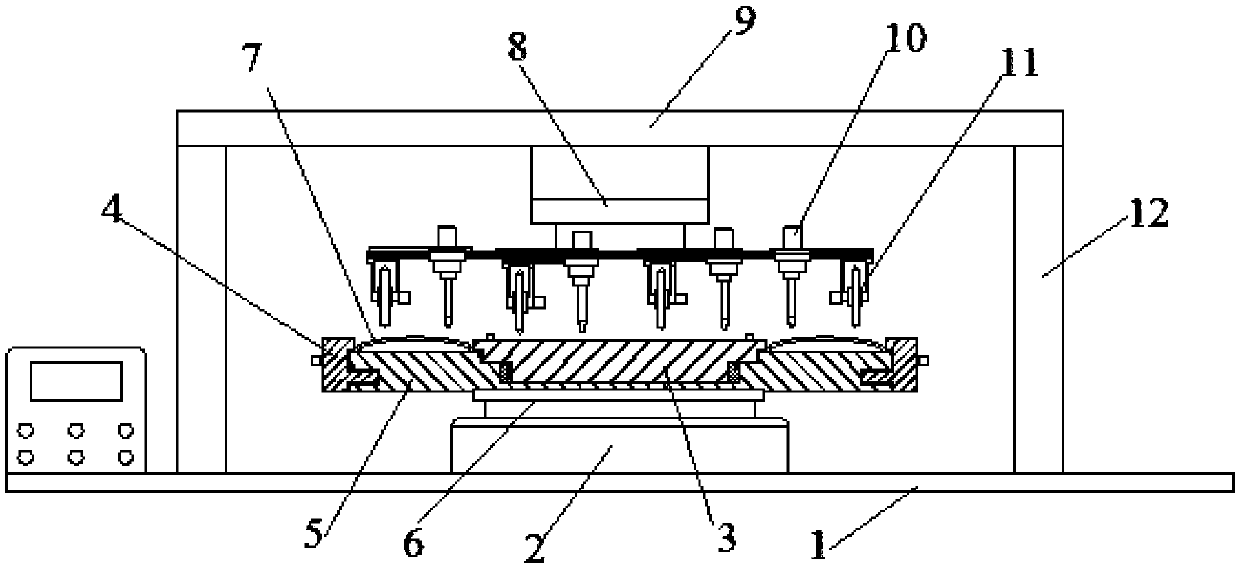

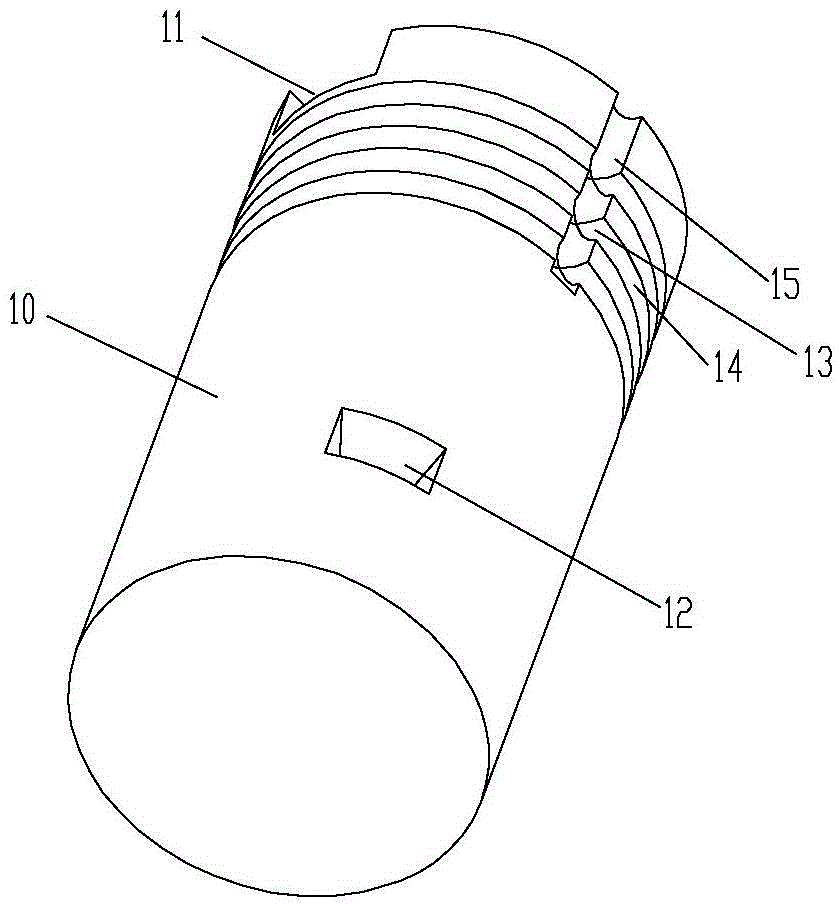

Tubular pile mould closing mechanism

PendingCN108638321AIncrease displacement distanceImprove locking efficiencyMouldsEngineeringMechanical engineering

The invention discloses a tubular pile mould closing mechanism. The mechanism comprises a plurality of linear modules, and a jackhammer assembly and an overturning assembly which are arranged on the linear modules. The jackhammer assembly comprises a jackhammer moving up and down. The overturning assembly comprises an overturning frame moving front, back, up and down. The position of the overturning frame corresponds to that of the jackhammer. A to-be-locked tubular pile mould is arranged between the overturning frame and the jackhammer and comprises an upper half tube and a lower half tube. An upper edge is arranged on the lateral side of the upper half tube, and a lower edge is arranged on the lateral side of the lower half tube. The upper edge and the lower edge are matched in a corresponding mode and enable mould closing to be achieved. A plurality of corresponding grooves aligned with each other are formed in the upper edge and the lower edge correspondingly. Clamping components penetrating through the tails of bolts are formed in the grooves of the lower edge. The bolts are hung upside down in the grooves. The overturning frame enables the bolts to be overturned by 180 degrees, so that the heads of the bolts correspond to the jackhammer. According to the tubular pile mould closing mechanism, the tubular pile mould closing direction adjustment is fast, and the bolts are locked in place.

Owner:苏州睿立汇自动化科技有限公司

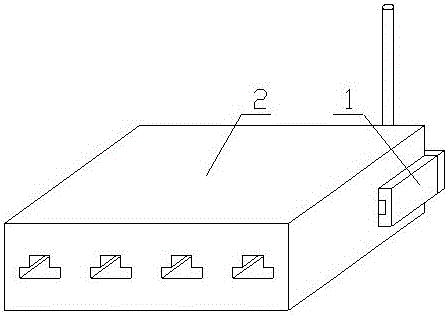

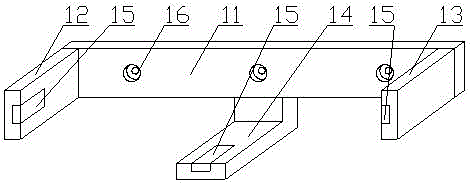

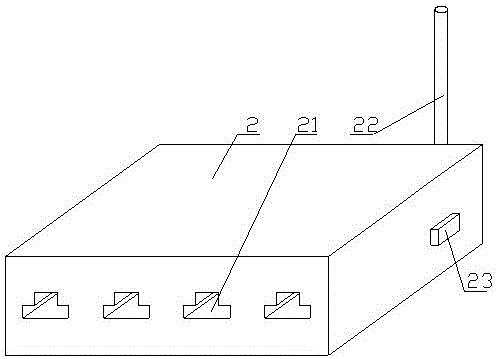

Locking device for router and mounting bracket

InactiveCN105897595AEasy to removeImprove installation stabilityData switching networksEngineeringStructural engineering

The invention discloses a locking device for a router and a mounting bracket, belongs to the router in the technical field of electronic products and aims at providing the locking device for the router and the mounting bracket, which is higher in installation stability and is easily taken from a wall. The technical scheme is as follows: the locking device comprises lock brackets fixedly arranged on the mounting bracket and locking heads fixedly arranged on a router body; each locking head comprises a shell, wherein the interior of the shell is hinged to a swing arm, the free end of the swing arm is connected to a hydraulic driver fixedly connected inside the shell, the connecting end of the swing arm is connected to a locking rod, and the clamping end of the locking rod pierces out of the right wallboard of the shell; each lock bracket comprises a bracket body, wherein the interior of the bracket body is connected to a clamping seat through a fixing plate, a clamping groove is arranged in the clamping seat, and the clamping end of each locking rod can extend into the bracket body through the left side panel of the bracket body and be clamped in the clamping groove. The invention is suitable for the locking device for the router and the mounting bracket.

Owner:CHENGDU ZHIRENSHANYONG INFORMATION TECH CO LTD

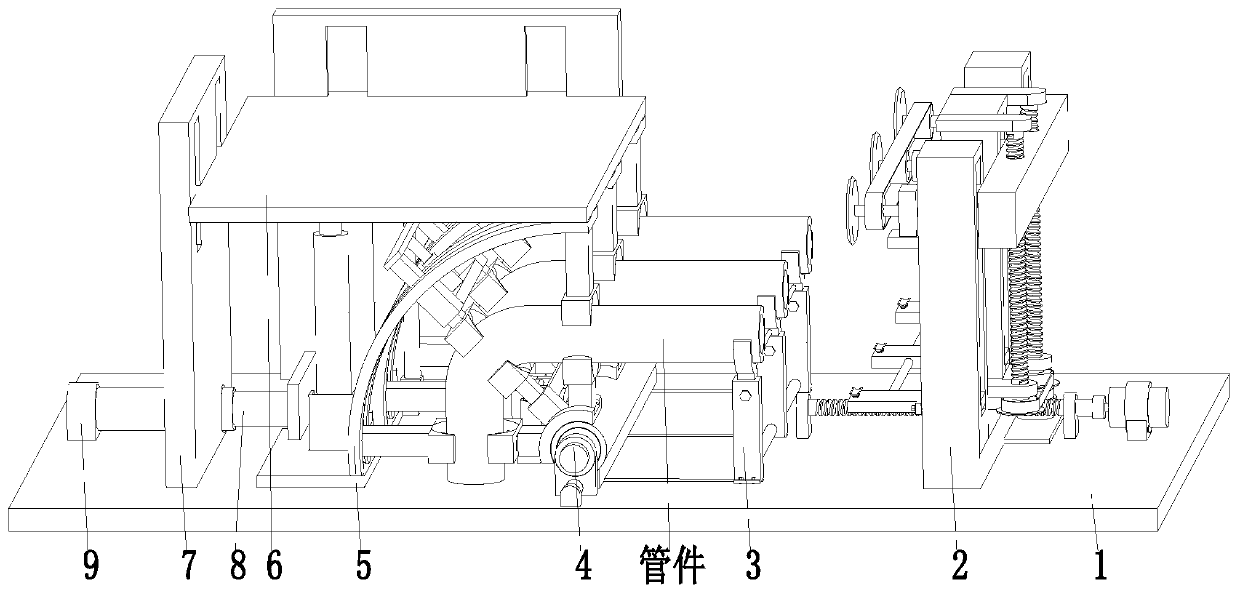

Casting head cutoff and machining treatment equipment for automobile precision part casting

ActiveCN111590145AAccurate and stable cuttingImprove locking efficiencyWork clamping meansFeeding apparatusStructural engineeringMechanical engineering

The invention relates to casting head cutoff and machining treatment equipment for automobile precision part casting. The equipment comprises a base, a cutting mechanism, a bearing mechanism, a lowerclamping mechanism, an upper clamping mechanism, a top plate, supporting plates, a pushing air cylinder and a mounting block. The cutting mechanism is mounted on the right side of the base. The bearing mechanism is mounted on the left side of the cutting mechanism. The lower clamping mechanism is arranged on the left side of the bearing mechanism. The upper clamping mechanism is arranged above thelower clamping mechanism. The top plate is mounted at the top end of the upper clamping mechanism. The supporting plates are mounted on the rear side and the left side of the top plate. The lower ends of the supporting plates are mounted on the base. A hole is formed in the supporting plate on the left side of the top plate. The pushing air cylinder is arranged in the hole. The left end of the pushing air cylinder is mounted on the base through the mounting block, and the right end of the pushing air cylinder is mounted on the left side of the upper clamping mechanism. According to the equipment, the problems that when casting heads of oil way pipe fittings are cut at present, clamps need to be replaced for pipe fittings of different sizes, and only one oil way pipe fitting is cut after being locked at a time can be solved.

Owner:山东丰华汽车零部件有限公司

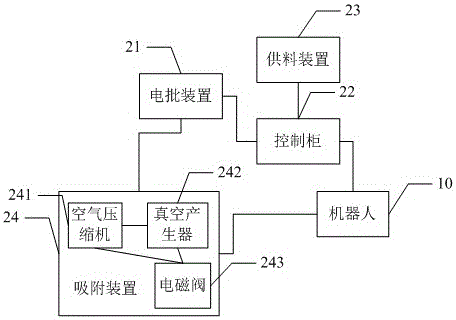

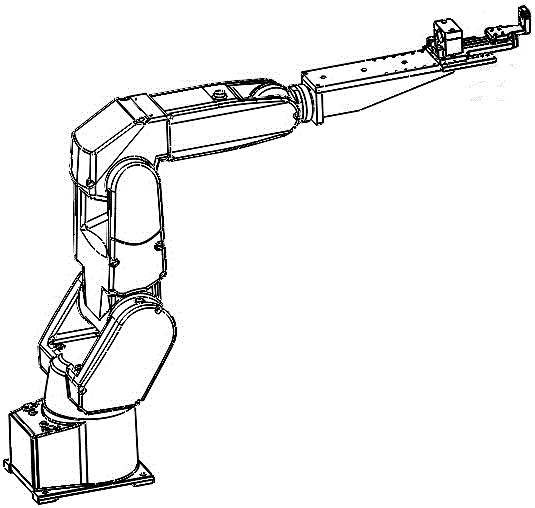

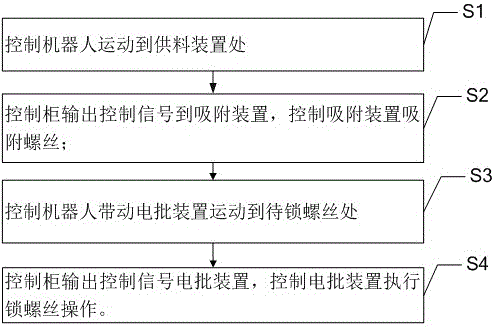

Automatic screw locking system based on robot and implementing method for automatic screw locking system

InactiveCN106736485APrevent deviationHigh precisionMetal working apparatusControl signalScrew system

The invention provides an automatic screw locking system based on a robot and an implementing method for the automatic screw locking system. The implementing method comprises the following steps of: controlling the robot to move to a material supply device; outputting a control signal to an adsorbing device through a control cabinet, and controlling the adsorbing device to adsorb a screw; and controlling the robot to drive an electric screwdriver device to move to a to-be-locked screw, outputting the control signal to the electric screwdriver device through the control cabinet, and controlling the electric screwdriver device to perform screw locking operation. According to the method and the system implemented by the method provided by the invention, the robot is utilized to perform corresponding control operation, so that precise locking and attaching of screws is realized, deviation during locking of screw holes is overcome, high-precision locking and attaching on screws of different models can be realized, scope of application is wide, precision is high, and locking and attaching efficiency is high.

Owner:SHENZHEN UNIV

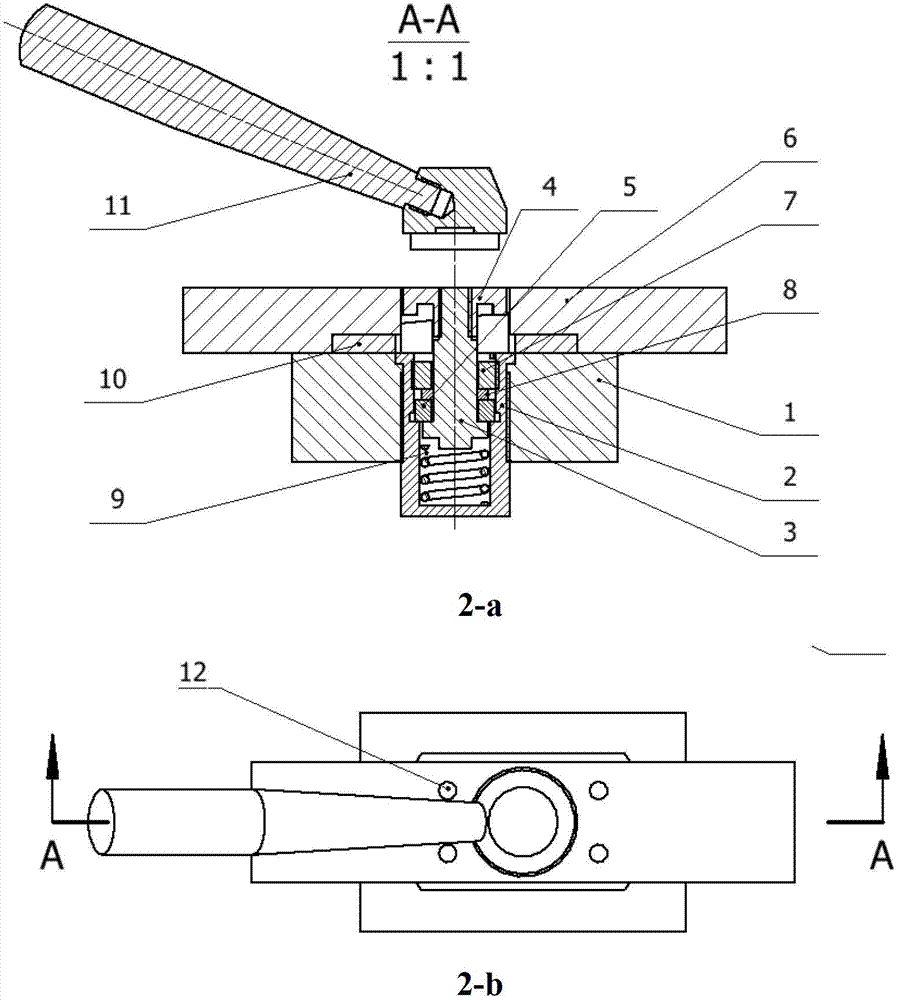

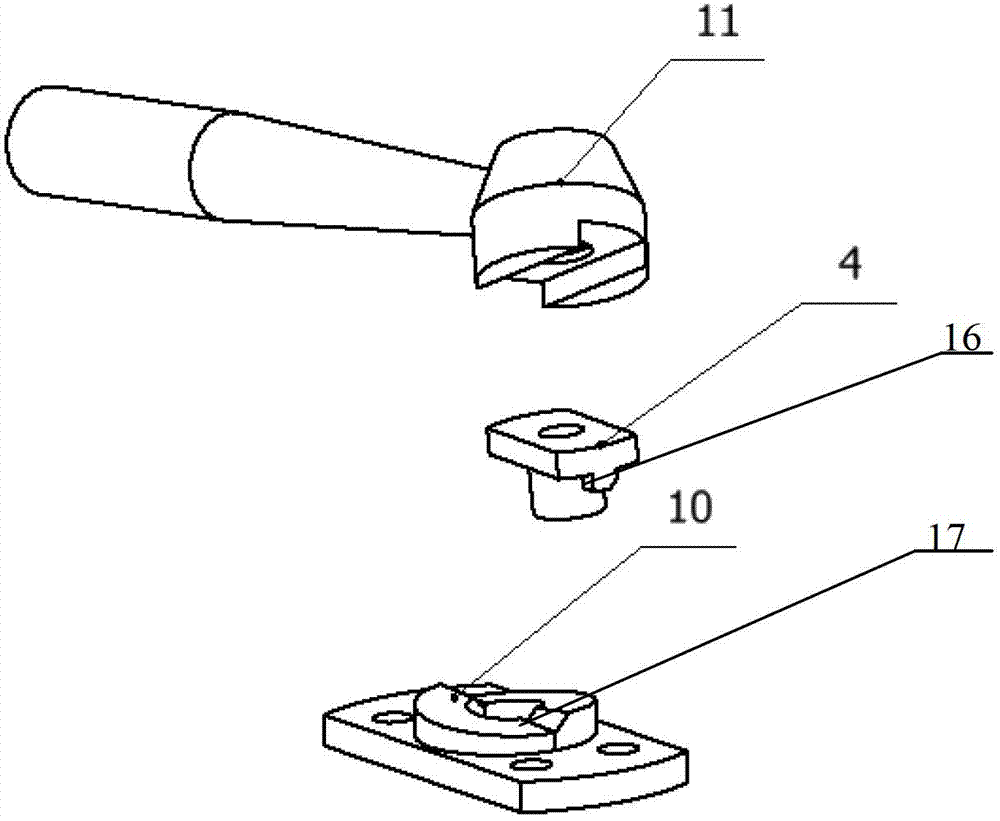

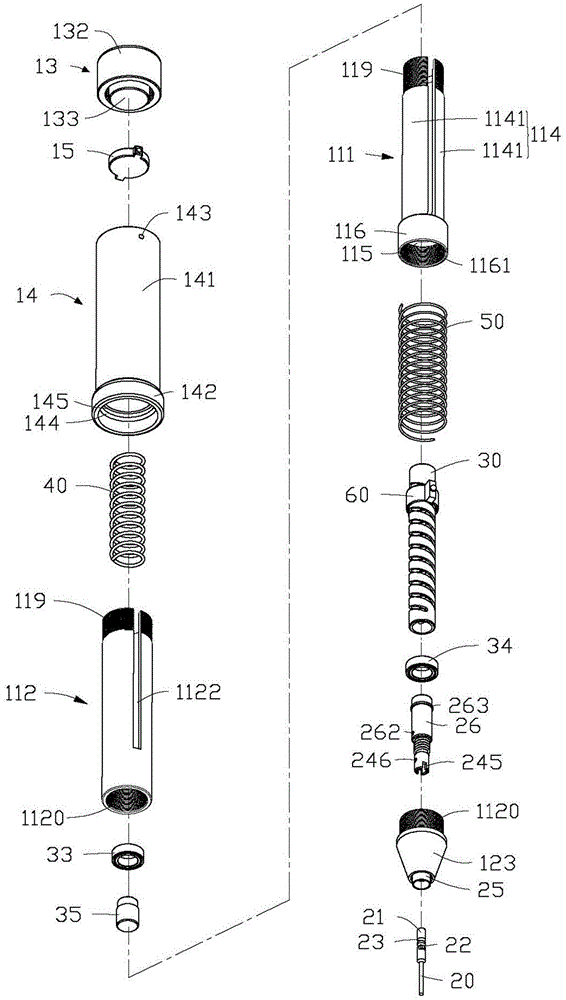

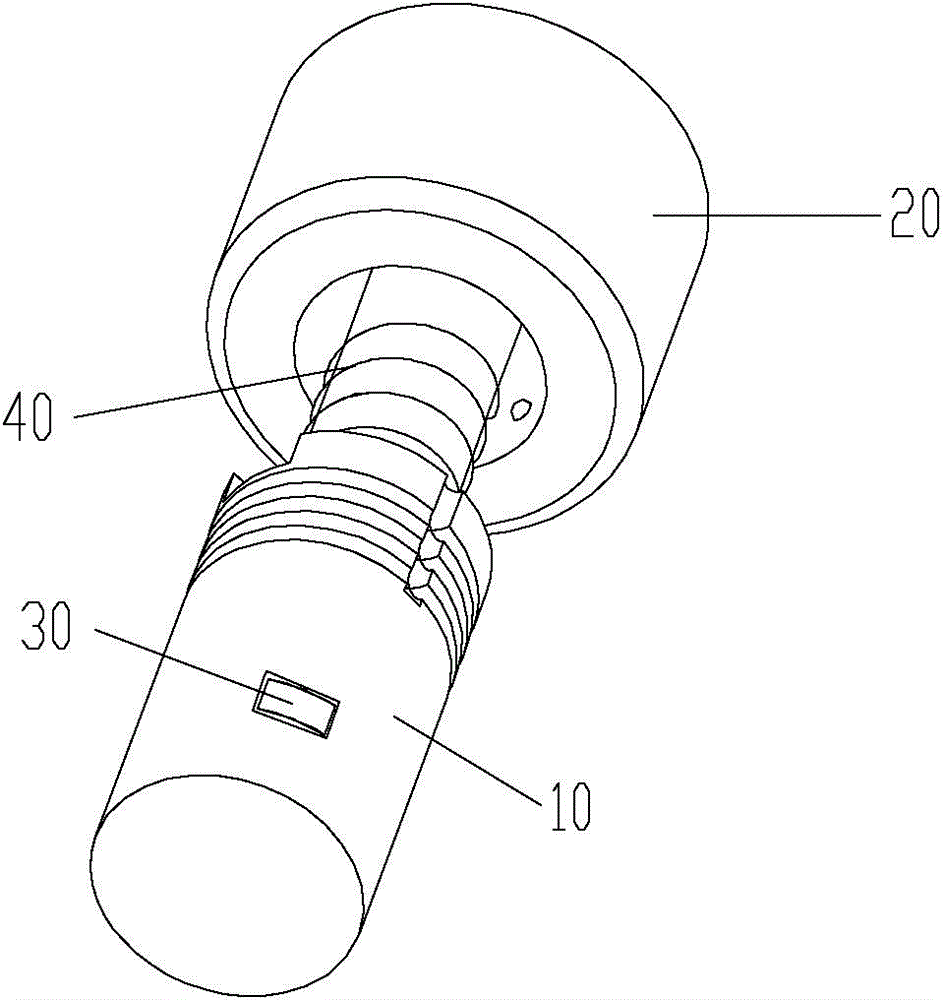

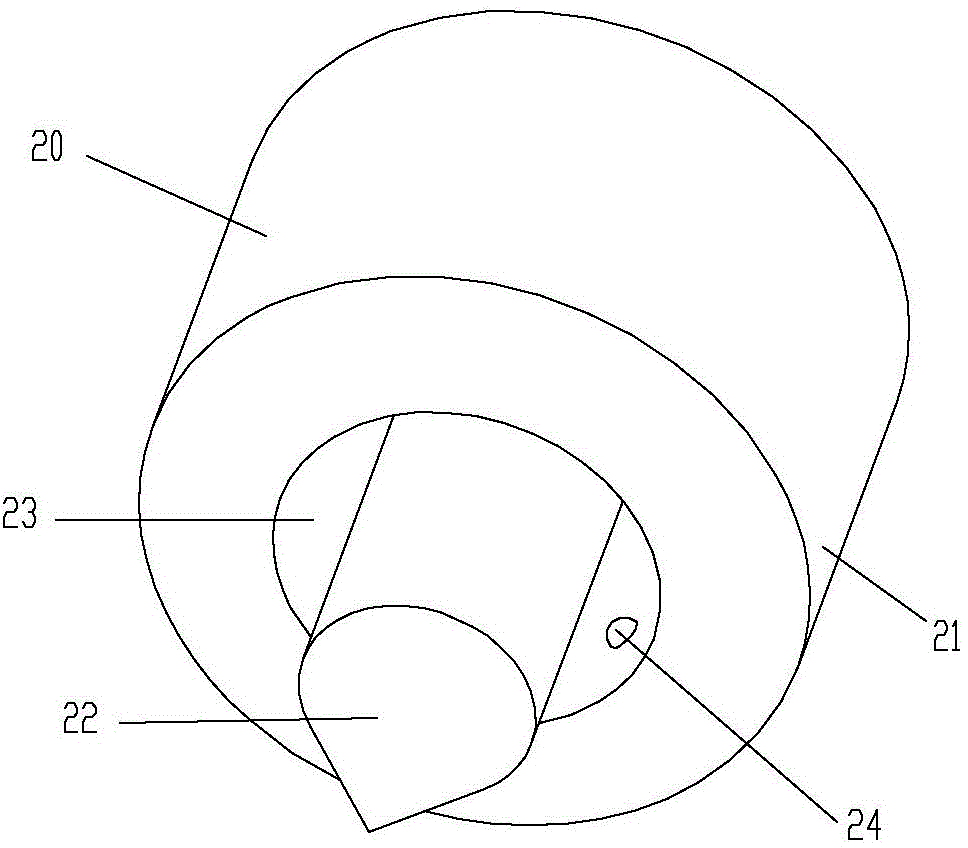

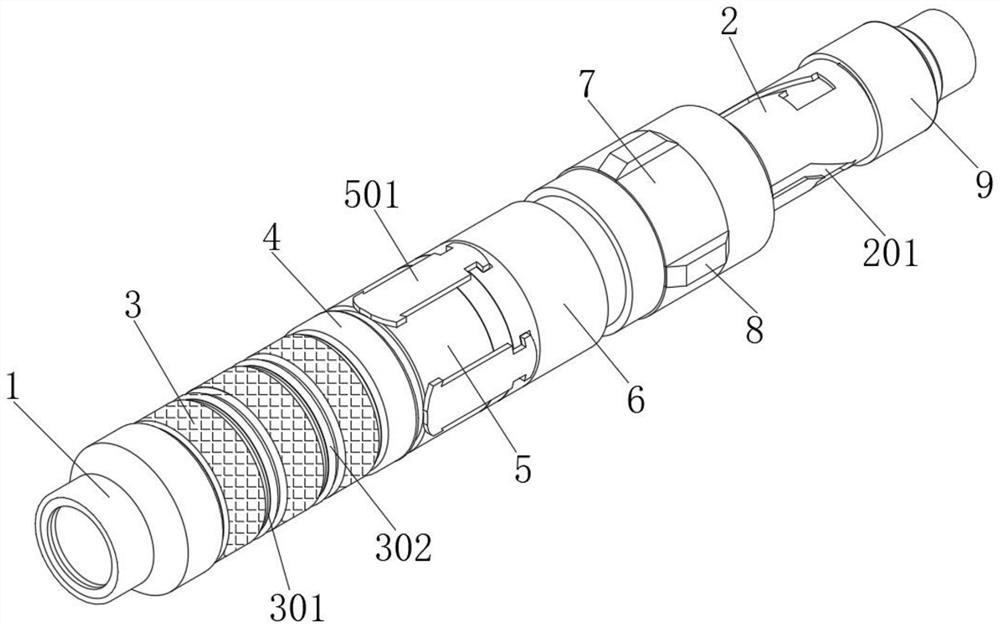

Quick locking mechanism

The invention relates to a connecting structure for quickly locking two parts, in particular to a quick locking mechanism. A locking structure combining an oblique plane and a locking thread is adopted, the quick locking of two workpieces to be locked is realized, and the quick locking mechanism is self-locked and anti-loose after being locked. In the quick locking mechanism, a compression spring is mounted under a locking shaft, the locking shaft rotates in the locking process, when the locking force is excessive due to misuse, the compression spring can play the role of preventing a locking nut from being deadly blocked in the screwing process, and the effect of protecting the thread is realized. The axial displacement of the whole quick locking mechanism in the locking process is the superposition of spiral displacement of the locking shaft and the oblique plane rising displacement of an oblique pressing block, and the locking efficiency is greatly improved; in the locking process, the lower surface of the locking nut presses the upper locking oblique plane of the oblique pressing block, with the effect of a spring gasket, the quick locking mechanism is self-locked and anti-loose after being locked; a special tool in the quick locking mechanism can take the effect of dismantling resistance and prevent the dismantling due to misoperation.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

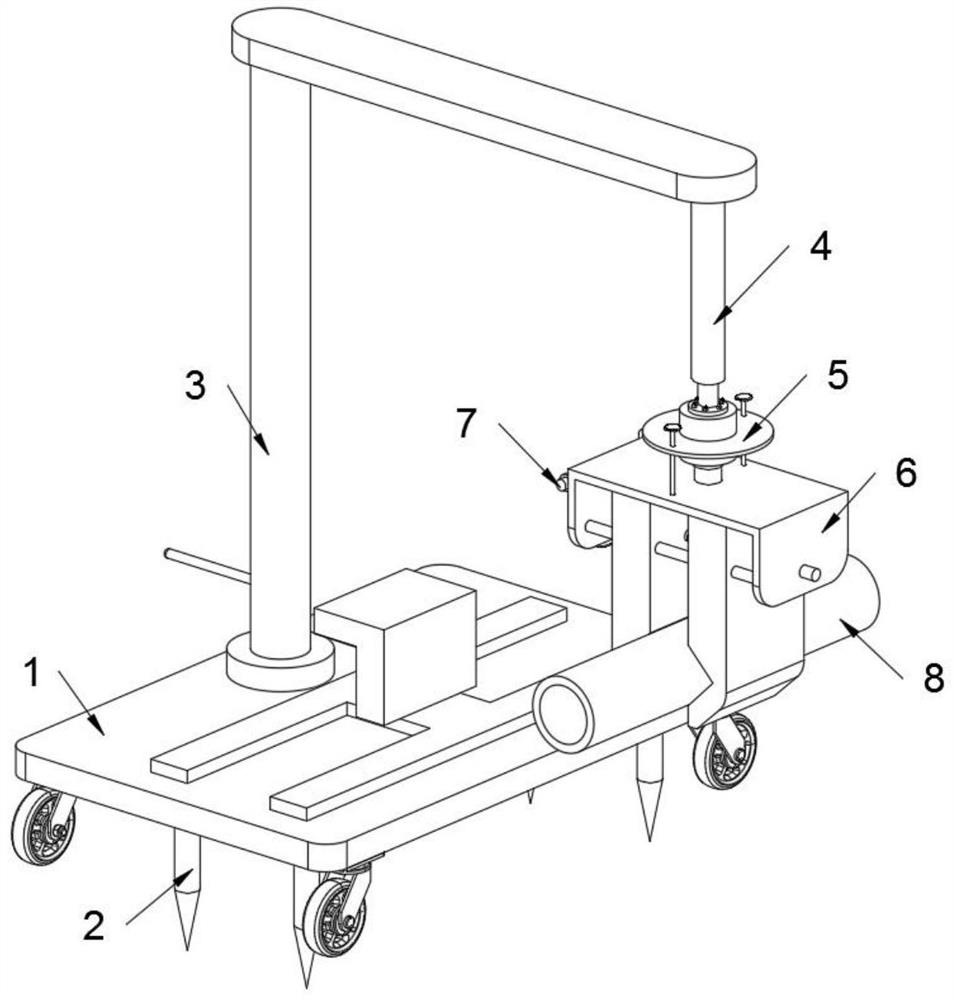

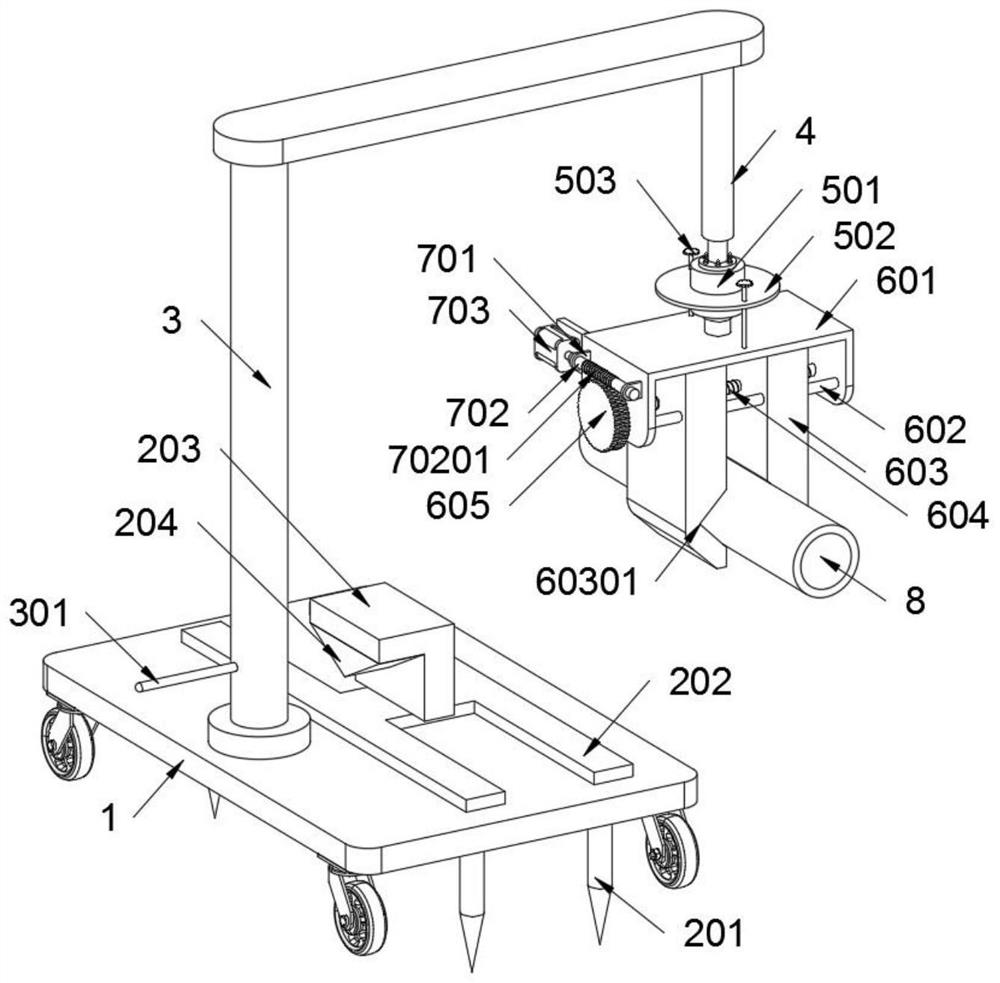

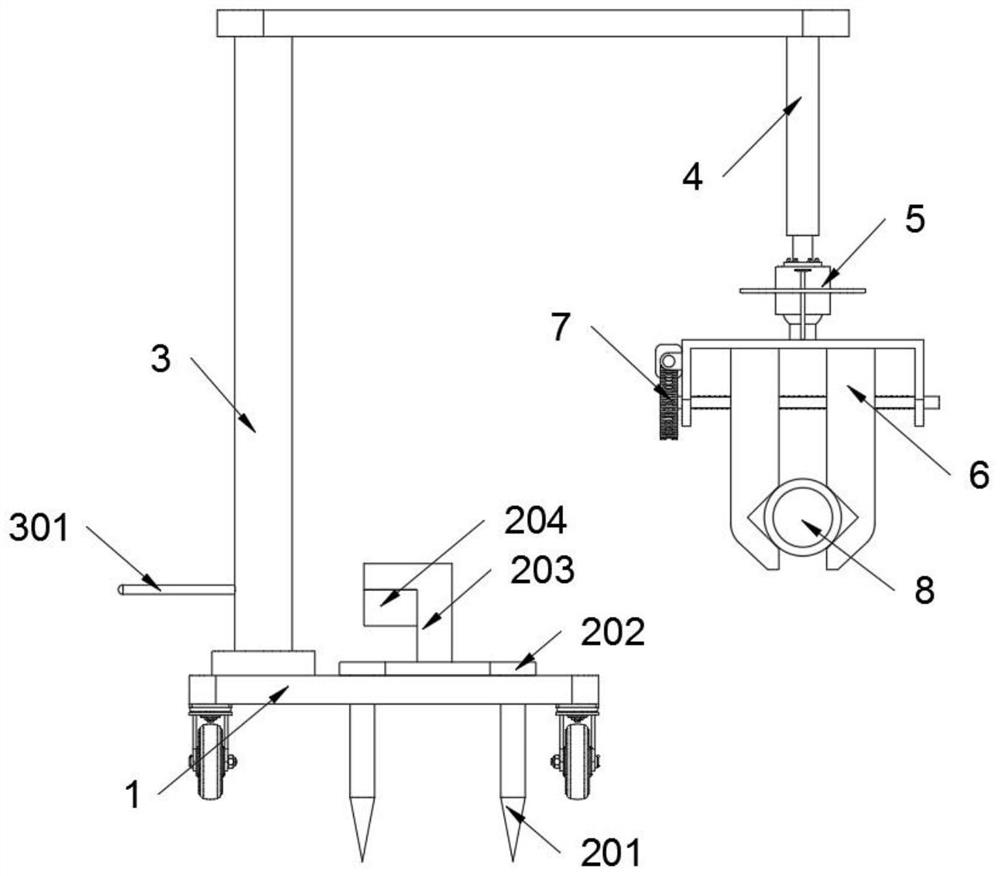

Pipeline burying device for water conservancy projects

PendingCN111824984AImprove fixation efficiencyRealize extractionPipe laying and repairLoad-engaging elementsHydraulic engineeringScrew thread

The invention discloses a pipeline burying device for water conservancy projects, and relates to the technical field of water conservancy projects. The problems are solved that synchronous reverse quick adjustment of two clamp structures cannot be achieved, and two clamps cannot be locked again in a thread transmission adjustment process; and a plurality of ground nails cannot be synchronously fixed during fixing, and mutual combination of the angular rotation of a boom main body and the disassembly of a fixed structure can not be achieved through the structural improvement. The pipeline burying device for the water conservancy projects comprises a base, wherein a fixing structure is inserted and fixed on the base, a boom main body is rotatably connected to the base, and a hydraulic telescopic rod is fixedly connected to the boom main body through bolts. The outer wall of the boom main body is welded with a toggle lever, when the toggle lever rotates along with the boom main body, thetoggle lever is in contact with a force receiving block, and at this time, the force receiving block, a mounting seat, a connecting seat and ground nails are all in a rising state, thereby realizing the extraction of the ground nails from the soil.

Owner:余洋 +4

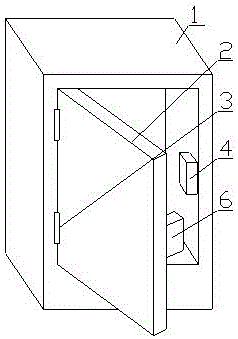

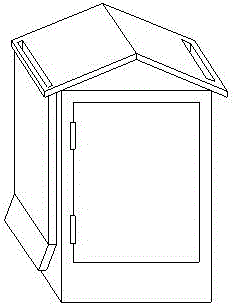

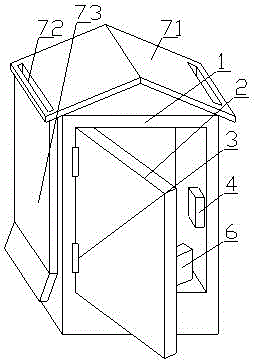

Normally-closed power distribution cabinet

InactiveCN105914595AAchieve lockingReduce manufacturing costNon-mechanical controlsSubstation/switching arrangement casingsControl theoryMechanical engineering

Owner:新都区大丰鹏宇机械厂

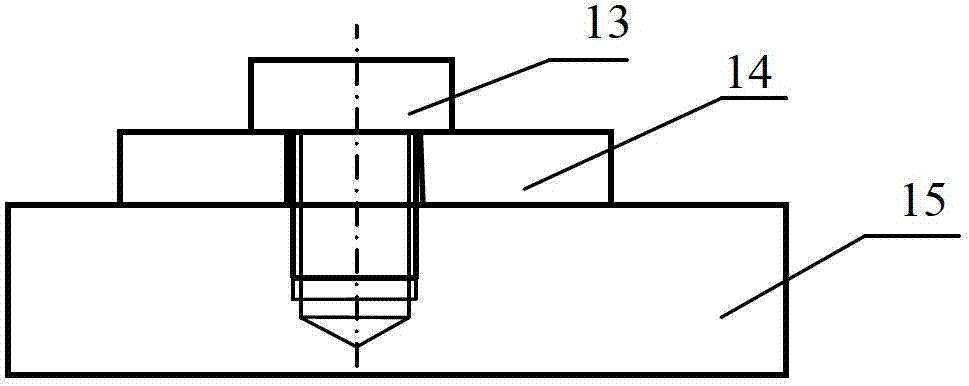

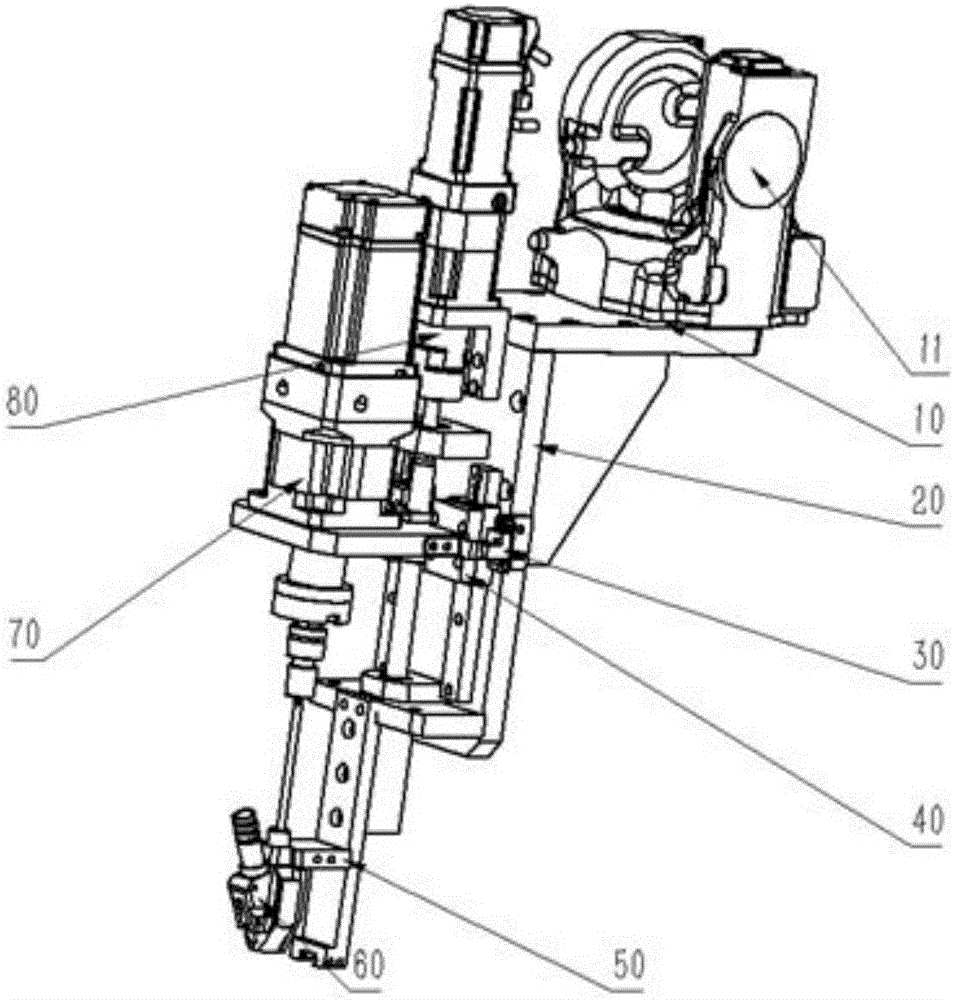

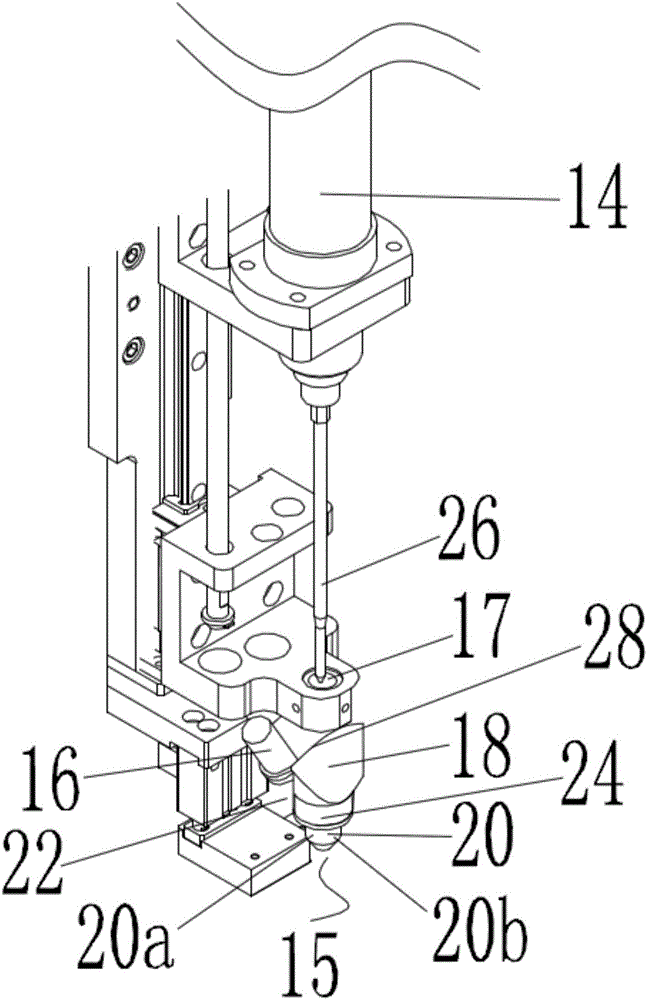

Intelligent end effector device for assembling screw

ActiveCN105935866AEnsure consistencyWarranty requirementsMetal working apparatusActuatorControl theory

The invention discloses an intelligent end effector device for assembling a screw. The device comprises a robot joint connecting plate, a guide rail slide block mechanism, a photoelectric sensor, a servo motor system A, a servo motor system B and a screw storing bin, wherein the robot joint connecting plate is L-shaped and comprises a tail end and a head end; two lead screw mounting plates are correspondingly horizontally arranged at the top and bottom of the head end, and the photoelectric sensor is mounted on the side surface of the head end; the guide rail slide block mechanism is mounted on the head end and is positioned between the two lead screw mounting plates; a servo motor mounting plate is horizontally arranged on the guide rail slide block mechanism; the servo motor system A is arranged at the upper part of the head end; the servo motor system B for controlling a screwdriver to rotate is arranged on the servo motor mounting plate; the screw storing bin for storing the screw is mounted at the lower part of the head end and is arranged below the servo motor system B. the device is used in match with a robot and has the advantages of being high in assembling efficiency, high in success rate and low in labor intensity.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Automatic screwing machine

InactiveCN105855857AOvercome the defect that the action cannot share the deviceNovel structureMetal working apparatusEngineeringAutomation

The invention provides an automatic screwing machine which comprises a clamping installation base, a controller, a screw feeder, a screwdriver and a three-directional adjusting workbench. The screw feeder comprises a storage pipe, a screw guide cup and a feeding nozzle, wherein the feeding nozzle is provided with a first nozzle body and a second nozzle body which are arranged in a split mode and further provided with a nozzle air cylinder for driving the first nozzle body and the second nozzle body to be coupled face to face or separated backwards; and a containing cavity matched with screws in shape is formed inside the first nozzle body and the second nozzle body when the first nozzle body and the second nozzle body are coupled. The spiral feeder of the optimized structure can complete screw feeding and screwing actions under the effect of driving force, two functions are combined into one device really, and the defect that screw feeding and screwing actions cannot share the device of a screwing machine traditionally is overcome; and meanwhile, in cooperation with the three-directional adjusting workbench uniformly controlled by the controller, the feeding and locking positions of the screwdriver can be adjusted freely, screw feeding is accurate, the screw feeding place is accurate, and full automation is achieved.

Owner:SUZHOU MENGCHUAN AUTOMATION TECH

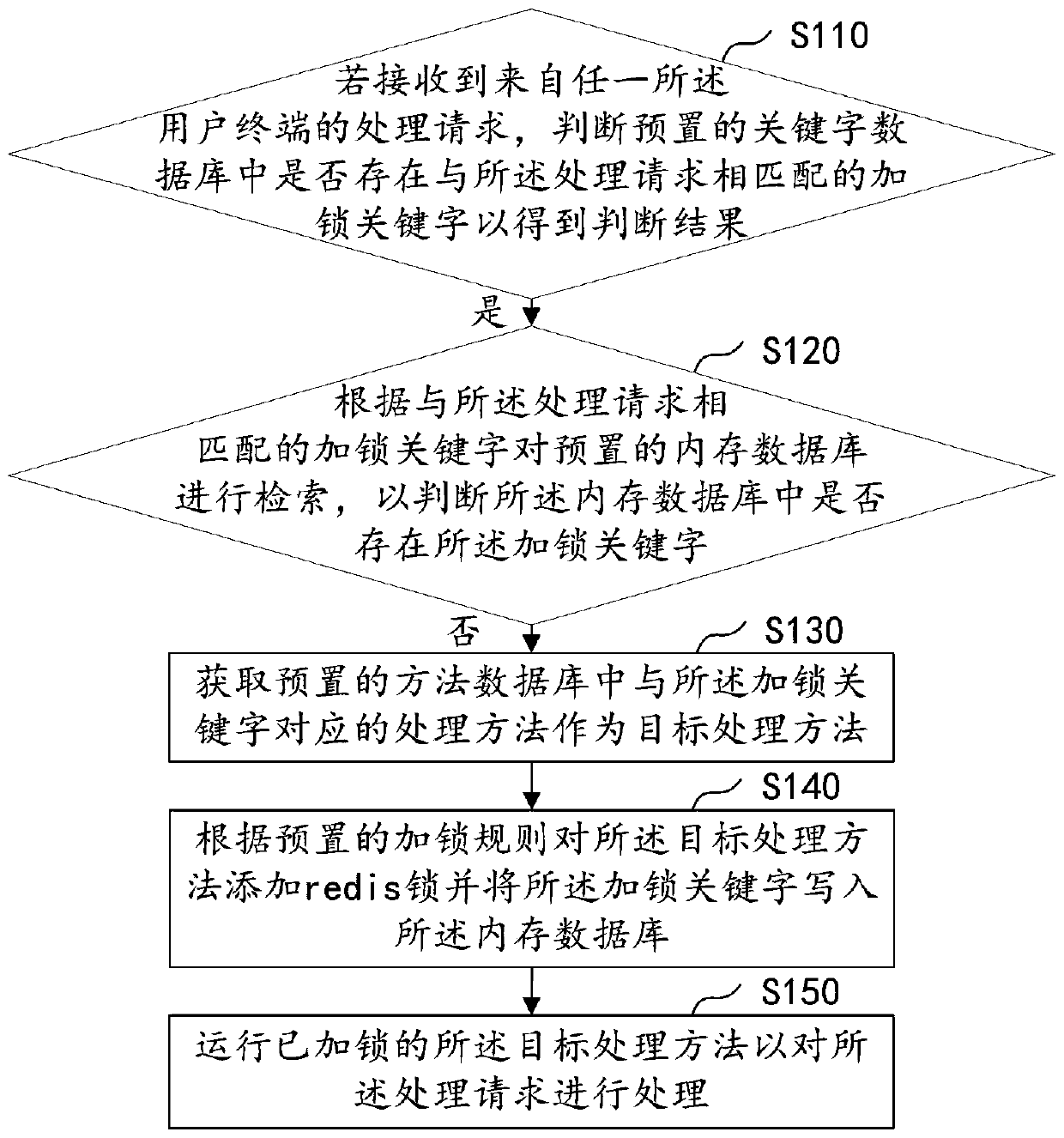

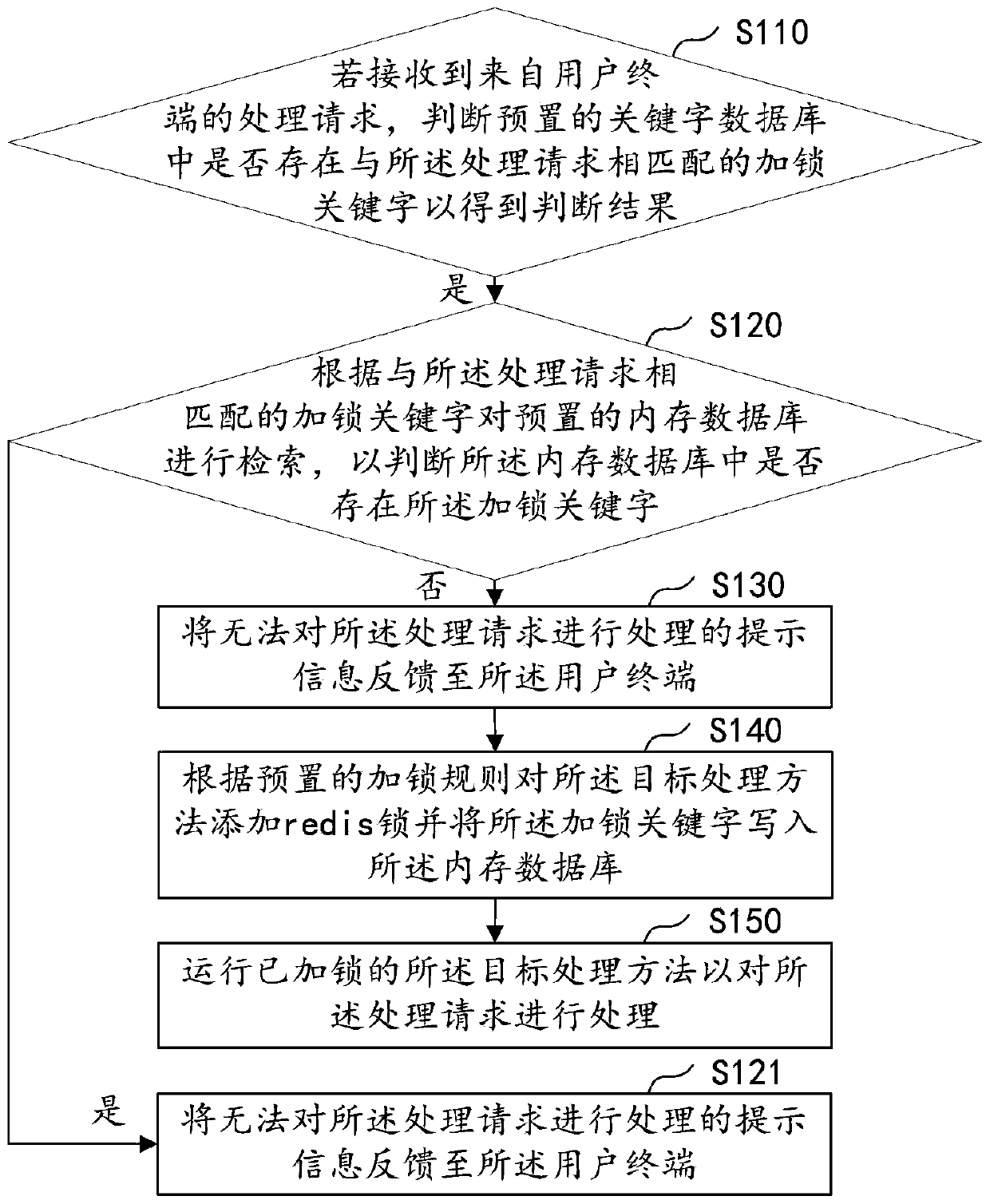

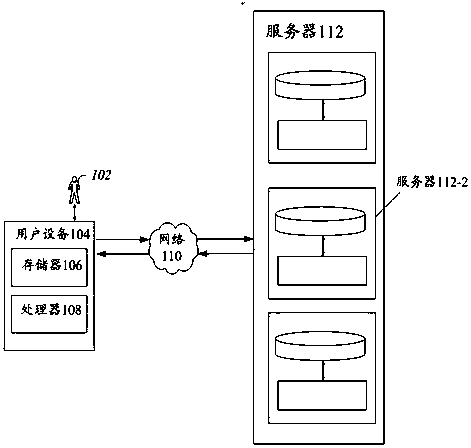

Lock processing method and device for processing request, computer equipment and storage medium

ActiveCN110737681AReduce locking timeImprove locking efficiencyDatabase updatingSpecial data processing applicationsComputer hardwareIn-memory database

The invention discloses a processing request locking processing method and a device, computer equipment and a storage medium, and the method comprises the steps: judging whether a locking keyword matched with a processing request exists in a keyword database if the processing request from any user terminal is received, so as to obtain a judgment result; if the judging result is yes, retrieving thememory database according to a locking keyword matched with the processing request so as to judge whether the locking keyword exists in the memory database; if the locking keyword does not exist in the memory database, obtaining a processing method corresponding to the locking keyword in a preset method database as a target processing method; adding a redis lock to the target processing method according to a preset locking rule, and writing the locking keyword into a memory database; and running the locked target processing method to process the processing request. By means of the method, thelocking time consumption is reduced, the locking efficiency is improved, and the processing efficiency of the processing request is greatly improved.

Owner:SHENZHEN QIANHAI HUANRONG LIANYI INFORMATION TECH SERVICES CO LTD

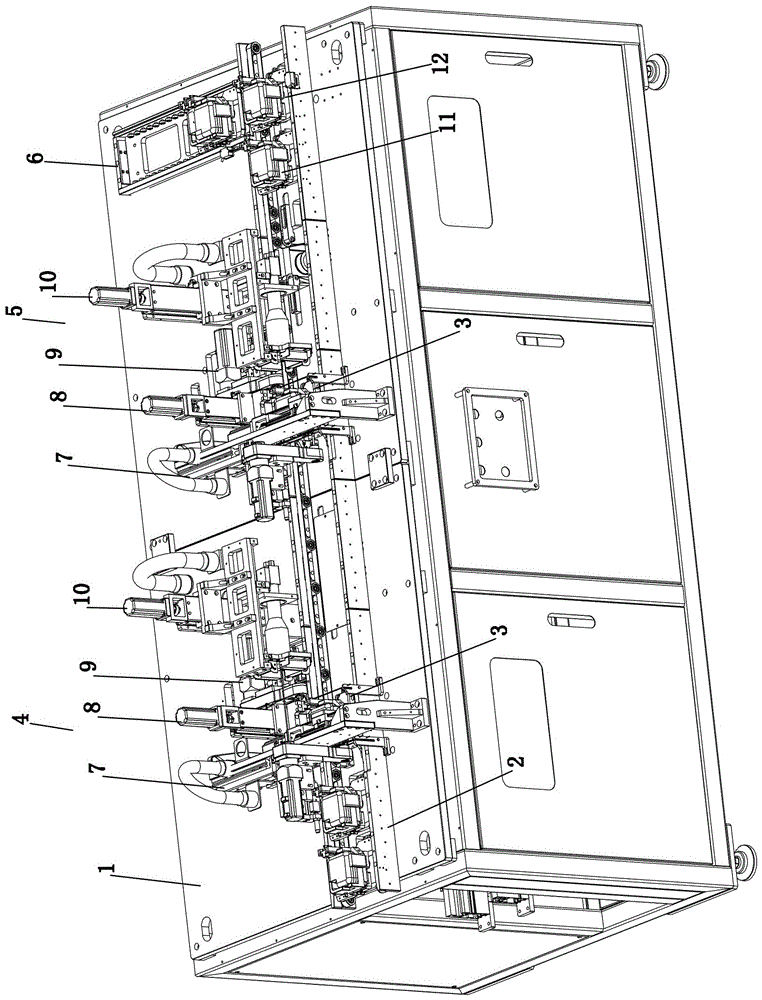

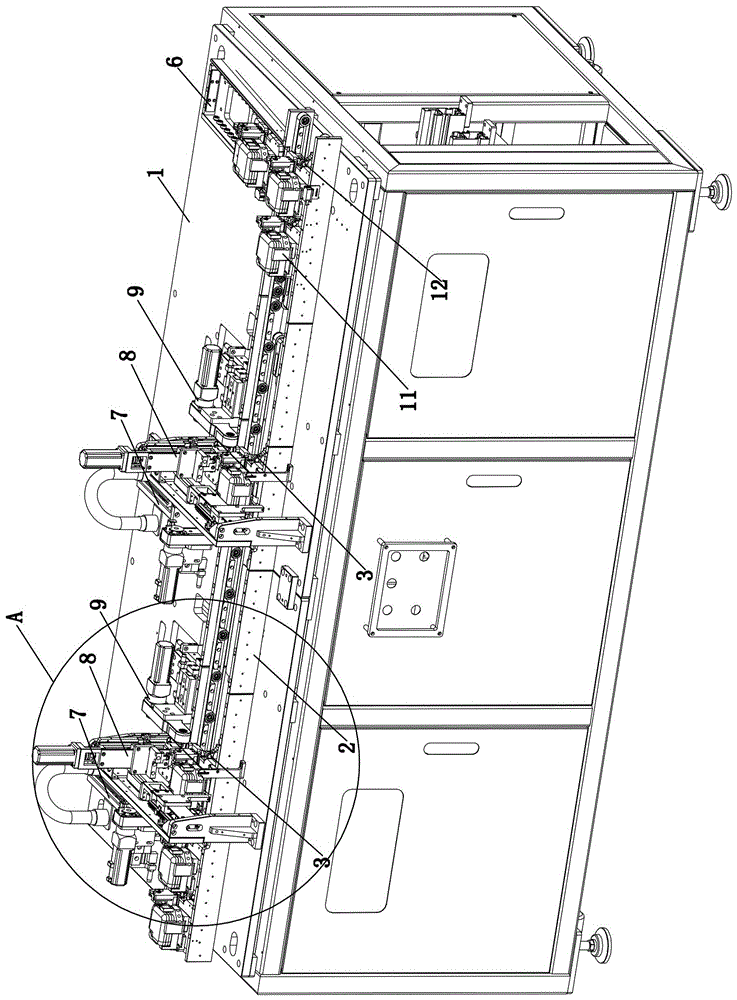

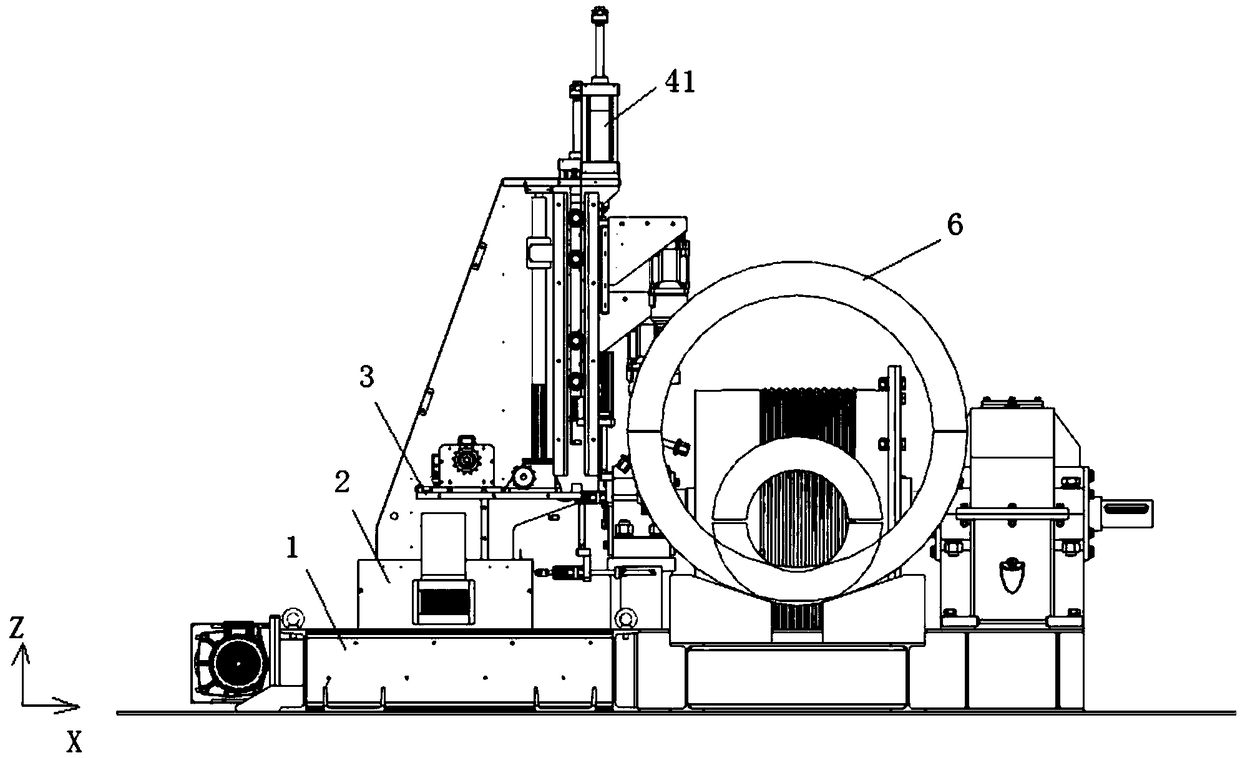

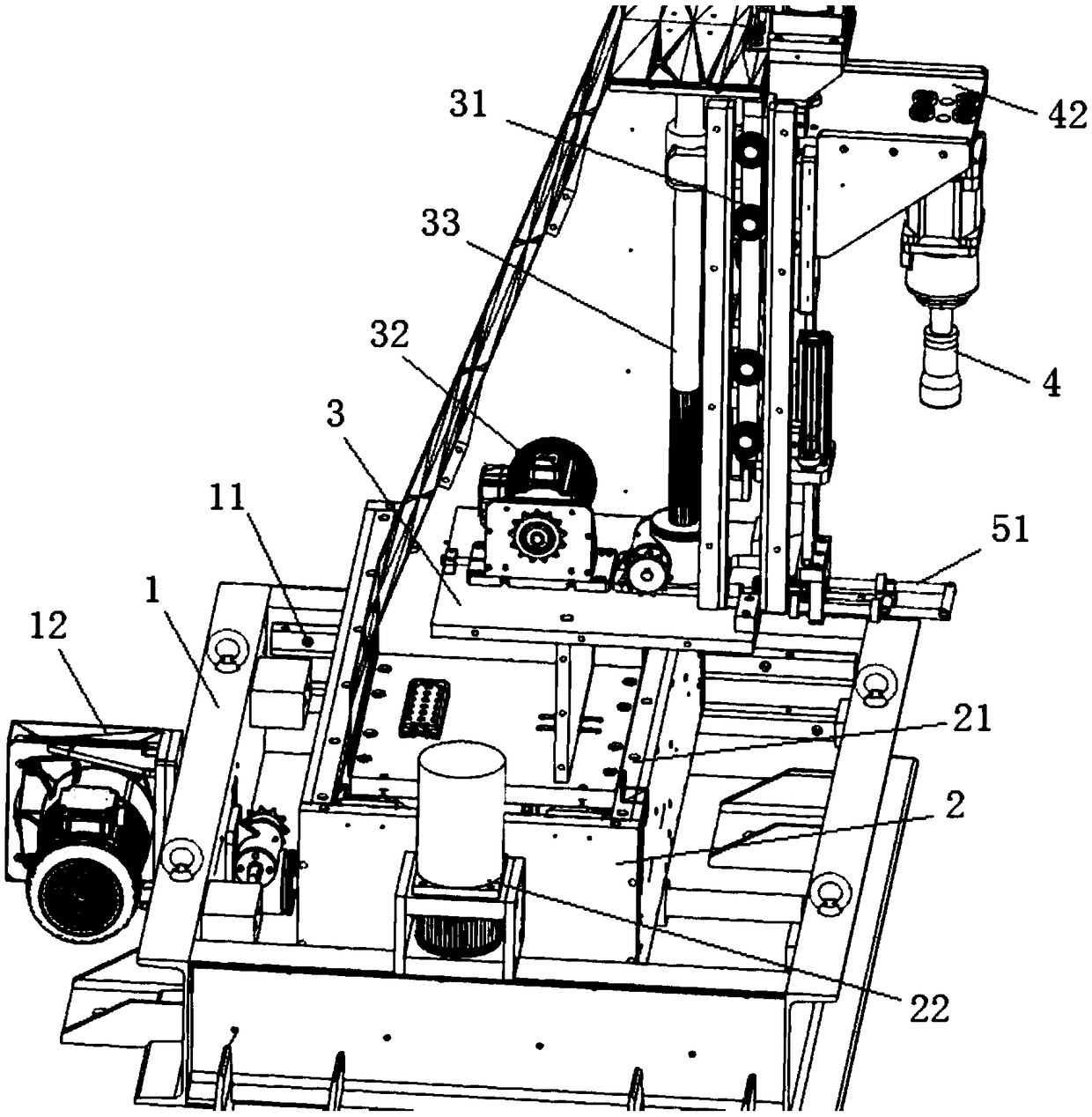

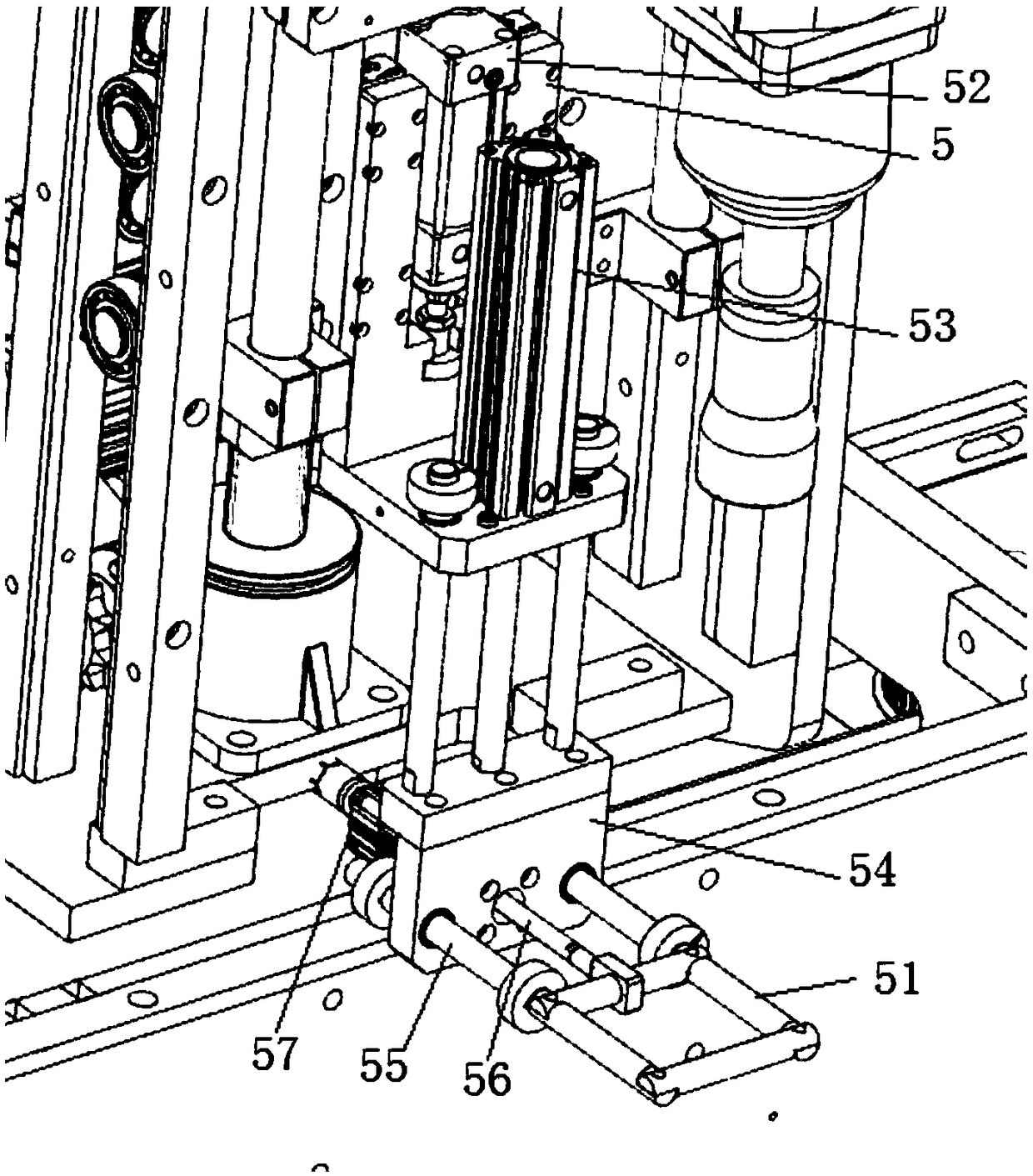

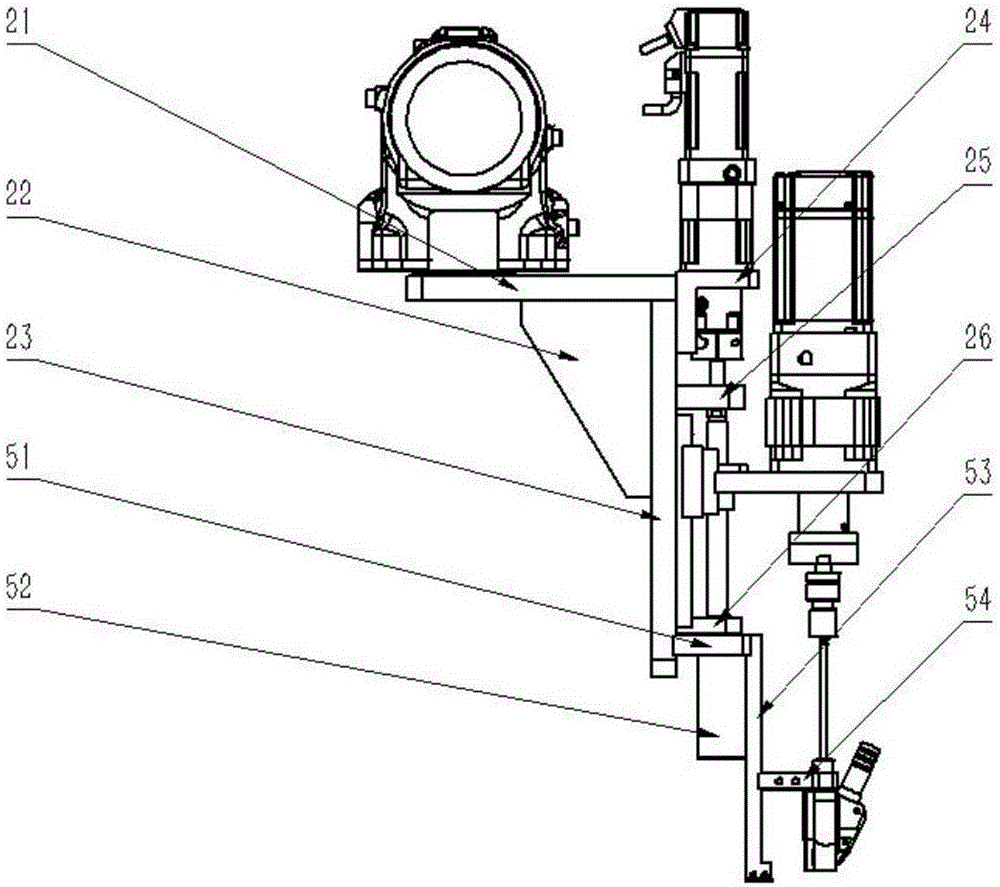

Material storing and material taking integrated automatic screw driving machine

ActiveCN106695311AImprove locking efficiencyPrecise positioningMetal working apparatusProduction lineEngineering

The invention relates to a material storing and material taking integrated automatic screw driving machine which comprises a cabinet main body bracket, a Y-axis assembly, an X-axis assembly and a Z-axis assembly as well as workpiece tray screw supply systems, a left and right lifting rotary locking device, a CCD auxiliary assistant positioning system, a front end clamp, an overturning clamp and a product line body mechanism; the Z-axis assembly is mounted on the X-axis assembly, the X-axis assembly is mounted on the Y-axis assembly, the Y-axis assembly is mounted on the cabinet main body bracket, the workpiece tray screw supply systems are mounted in the cabinet main body, the left and right lifting rotary locking device is mounted on the Z-axis assembly, the CCD auxiliary assistant positioning system is mounted on the top of the cabinet main body, and the front end clamp is mounted at the front end of the cabinet main body bracket to form the automatic screw driving machine. By adopting the plurality of workpiece tray screw supply systems, two electric screwdrivers are matched to realize locking for at least twenty times to reduce the reciprocative material-taking time and material-taking stroke, so that a purpose of improving the locking efficiency is achieved. The product locking stability and production efficiency are extremely improved.

Owner:SHENZHEN MIGHT TECH

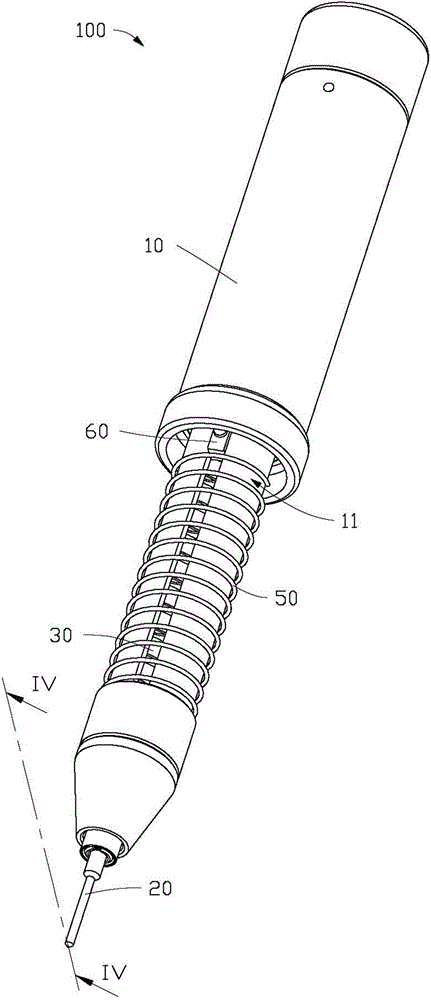

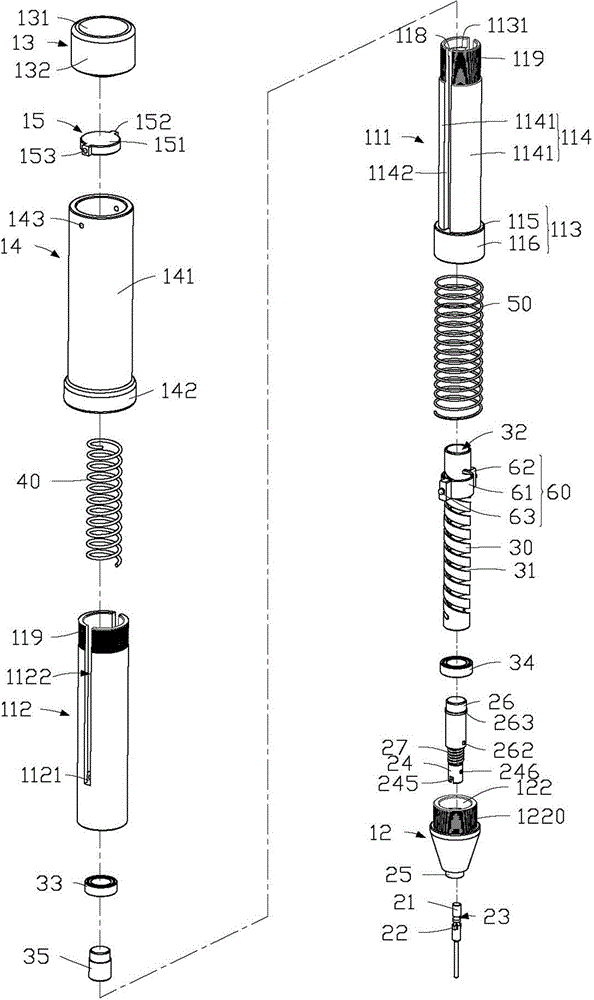

Screwdriver

InactiveCN105773503AImprove locking efficiencySave time and effortScrewdriversLinear motionEngineering

The invention discloses a screwdriver. The screwdriver comprises a shank and a tool bit arranged at the front end of the shank; the shank forms a cavity; at least one chute is axially formed in the side wall of the shank; a spiral rod is positioned in the cavity, and is fixed corresponding to the tool bit; a spiral groove is formed in the outer wall of the spiral rod; an operation part coats the spiral rod, and includes at least one limiting block and thimbles penetrating through the limiting blocks; the limiting blocks are embedded in the chutes, and can slide in the axial direction of the shank; the thimbles are inwards shrunk and inserted in a spiral groove of the spiral rod when being suffered from an external force effect; and the limiting blocks axially slide in the chutes through elastic elements to drive rotation of the spiral rod and the tool bit. Compared with the prior art, the screwdriver skillfully uses the spiral principle for converting a linear motion of the operation part to a rotating motion of the spiral rod to drive the tool bit to realize screw locking along with rotation of the spiral rod, saves more time and labors in use, and is high in efficiency.

Owner:FU TAI HUA IND SHENZHEN +1

Normally-closed moisture-proof power distribution cabinet

InactiveCN105896324ASimple structureReduce manufacturing costSubstation/switching arrangement casingsEngineeringElectrical and Electronics engineering

The invention discloses a normally-closed moisture-proof power distribution cabinet, belongs to the technical field of power distribution cabinets, and aims to provide a normally-closed moisture-proof power distribution cabinet with high locking performance. The normally-closed moisture-proof power distribution cabinet comprises a cabinet body and a cabinet door, wherein the cabinet body is in a pivoting connection with the cabinet door through a pivoting device; an inner wall of the cabinet door is connected with a first locking component; an inner wall of the cabinet body is connected with a second locking component which is matched with the first locking component; the pivoting device comprises a left blade which is fixedly connected to the cabinet body, and a right blade which is fixedly connected to the cabinet door; the left blade is provided with a pivoting ring; the right blade is connected with the pivoting device; the pivoting ring sleeves the pivoting device; a reset mechanism for driving the cabinet door to be closed normally is further arranged between the pivoting ring and the pivoting device; a flashing board is arranged above a top surface of the cabinet body; a cross section of the flashing board is triangular; both sides of the flashing board are provided with rectangular draining holes along a width direction of the flashing board; the draining holes communicate below with downpipes; and the downpipes are fixedly connected on a side wall of the cabinet body. The normally-closed moisture-proof power distribution cabinet is suitable for power distribution cabinets.

Owner:新都区大丰鹏宇机械厂

Precise positioning system of lifting appliance

ActiveCN107934737AImprove continuityHigh precisionNuclear energy generationLoad-engaging elementsLaser rangingDisplay device

The invention discloses a precise positioning system of a lifting appliance. The length and the width of a lifting appliance body are matched with those of a container, the top of the lifting appliance body is fixed to a lifting rope of a crane, four corners of the side wall of the lifting appliance body are vertically and movably connected with positioning auxiliary plates, the positioning auxiliary plates are vertical plates of L-shaped structures, the four corners of the bottom of the lifting appliance body are each provided with a rotary lock and an ultrasonic receiving module, a laser distance measuring module is arranged on the centre of the bottom of the lifting appliance body, a temperature sensor is arranged on the lifting appliance body, an ultrasonic emission module on the top of the container, a controller and a displayer are further included, the controller and the displayer are arranged in a crane cockpit, the laser distance measuring module, the ultrasonic receiving modules, the temperature sensor and the displayer are in signal or electric connection with the controller, and the ultrasonic emission module is connected with the controller through signals. Through theabove structure, automatic rough positioning, fine positioning and precise positioning continuity and rapidness of the lifting appliance can be achieved, and lifting precision and efficiency can be improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Positioning method of lifting appliance accurate positioning system

ActiveCN107954305AImprove continuityHigh precisionLoad-engaging elementsLaser rangingPositioning aids

The invention discloses a positioning method of a lifting appliance accurate positioning system. A controller controls an ultrasonic emitting module on a container needing to be lifted to emit ultrasonic waves, an ultrasonic receiving module of a lifting appliance body receives the ultrasonic waves, and thus the position of the container needing to be lifted is rapidly found out; when the liftingappliance body moves to the position above the container needing to be lifted, through the joint effects of a laser distance measuring module, the ultrasonic emitting module and the ultrasonic receiving module, the position distance between the lifting appliance body and the container needing to be lifted is accurately measured, and positioning is gradually conducted through a positioning auxiliary plate; and finally, through the effect of an electromagnet B, it is ensured that a rotary lock is coaxial with a lock hole and then enters the lock hole. From the process, it can be known that the continuity and rapidness of automatic coarse positioning, fine positioning and accurate positioning of a lifting appliance are achieved, and the lifting accuracy and efficiency are improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

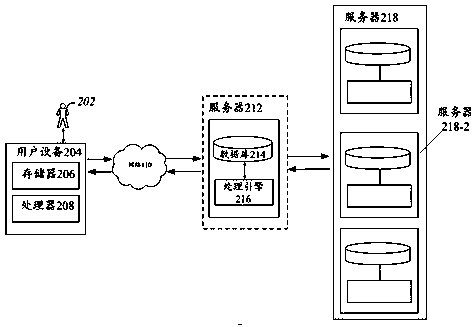

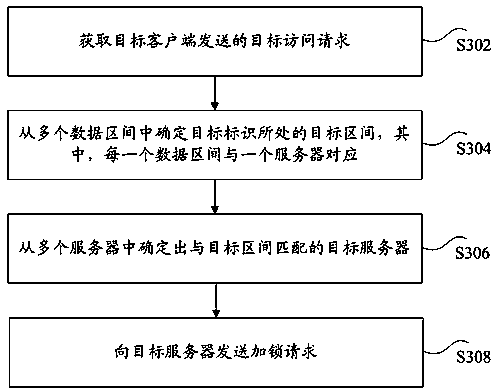

Virtual resource locking method and device, storage medium and electronic device

ActiveCN111399991AReduce computationSolve the technical problem of low locking efficiencySoftware simulation/interpretation/emulationEngineeringDatabase

The invention discloses a virtual resource locking method and device, a storage medium and an electronic device. The method comprises the following steps: obtaining a target access request sent by a target client, wherein the target access request carries a target identifier used for marking a target resource requested to be accessed by the target access request, the target resource is stored in atarget server in a plurality of servers, different resources are stored in each server in the plurality of servers, and the different resources are corresponding to different identifiers; determininga target interval where the target identifier is located from the multiple data intervals, wherein each data interval is corresponding to one server; determining a target server matched with the target interval from a plurality of servers; and sending a locking request to the target server, wherein the locking request is used for requesting to lock the target resource in the target server. The technical problem that the virtual resource locking efficiency is low is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Positioning algorithm of lifting appliance precise positioning system

The invention discloses a positioning algorithm of a lifting appliance precise positioning system. At the moment T, a laser distance measuring sensor measures the vertical distance between a lifting appliance body and the top surface of a container needing lifting at the moment T, namely the length of a line segment EF, and the length of the line segment EF is the distance that the lifting appliance body needs to move downwards and vertically at the moment T; four ultrasonic receiving modules receive ultrasonic wave transmitted by an ultrasonic transmitting module before correspondingly, the respective received time intervals tA, tB, tC and tD of the four ultrasonic receiving modules are calculated, the length of a line segment EA, the length of a line segment EB, the length of a line segment EC and the length of a line segment ED are calculated, the length of a line segment OF is calculated, and the length of the line segment OF is the distance that the lifting appliance body needs tomove horizontally at the moment T. According to the above process, continuity and rapidness of automatically performing crude positioning, fine positioning and precise positioning by the lifting appliance are realized, and the lifting precision and efficiency are improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Shaft lever part locking apparatus

InactiveCN104907846APrecise positioningNovel structural designWelding/cutting auxillary devicesWork holdersSplit ringEngineering

The invention discloses a shaft lever part locking apparatus comprising a split ring arranged on a fixing seat. The outer wall of an opening end of the split ring is provided with an upper extension plate and a lower extension plate parallel to the upper extension plate; the tail ends of the two extension plates are relatively bent to form an upper vertical plate and a lower vertical plate; the upper end surface of the lower extension plate is slideably provided with a top plate; the tial end of the top plate and a transverse locking bolt are fixed; the transverse locking bolt screws and passes through the lower vertical plate; a longitudinal locking bolt is screwed in the upper end surface of the upper extension plate; and the front end of the longitudinal locking bolt is screwed into the lower extension plate. The shaft lever part locking apparatus is structured with novelty; and with the upper locking bolt, the lower locking bolt and the top plate matched with the split ring and the opening end, the shaft lever part can be quickly positioned, so locking efficiency can be improved and great practical use effect can be achieved.

Owner:WUHU CHUANGZHI MACHINERY TECH

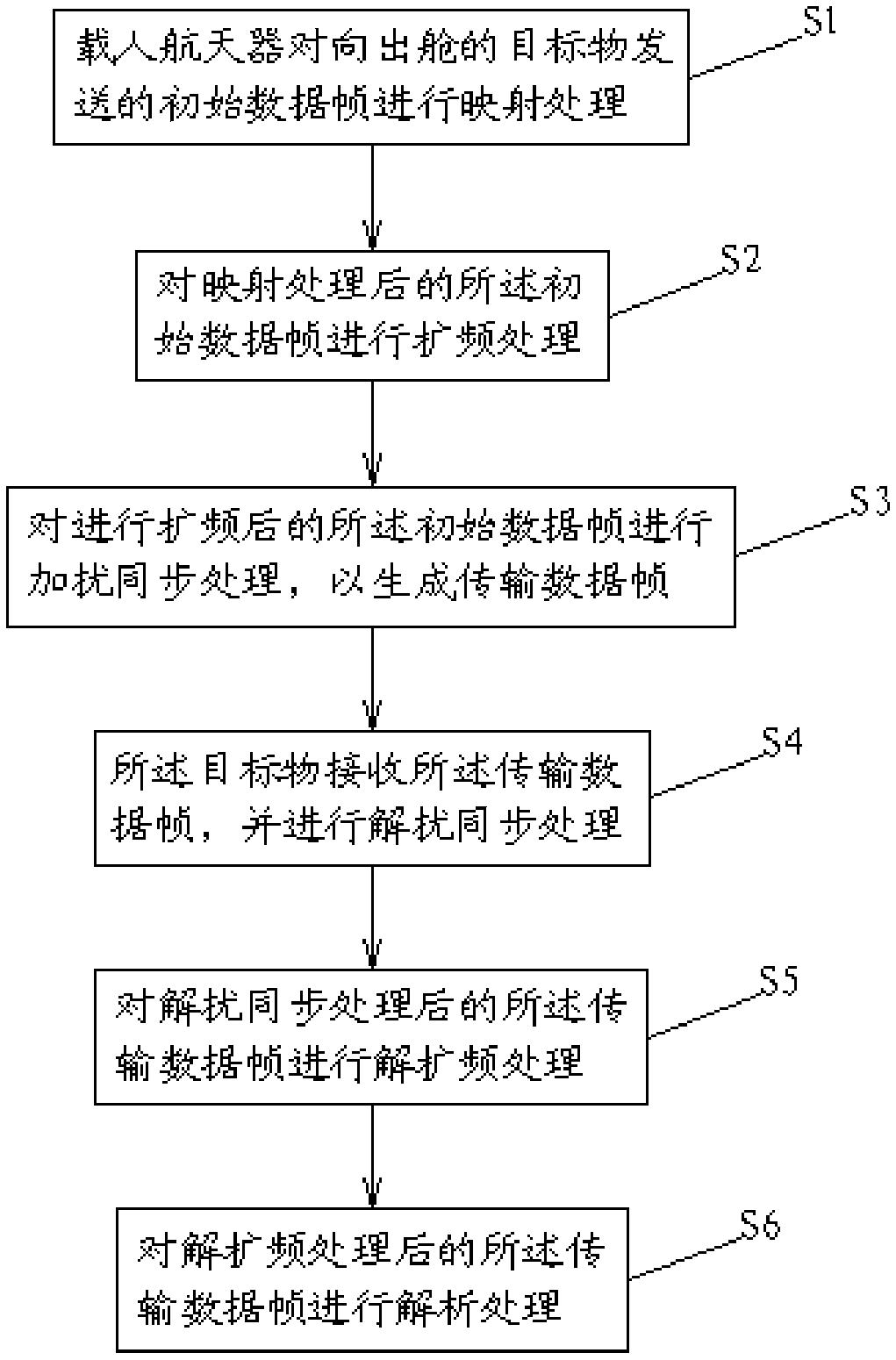

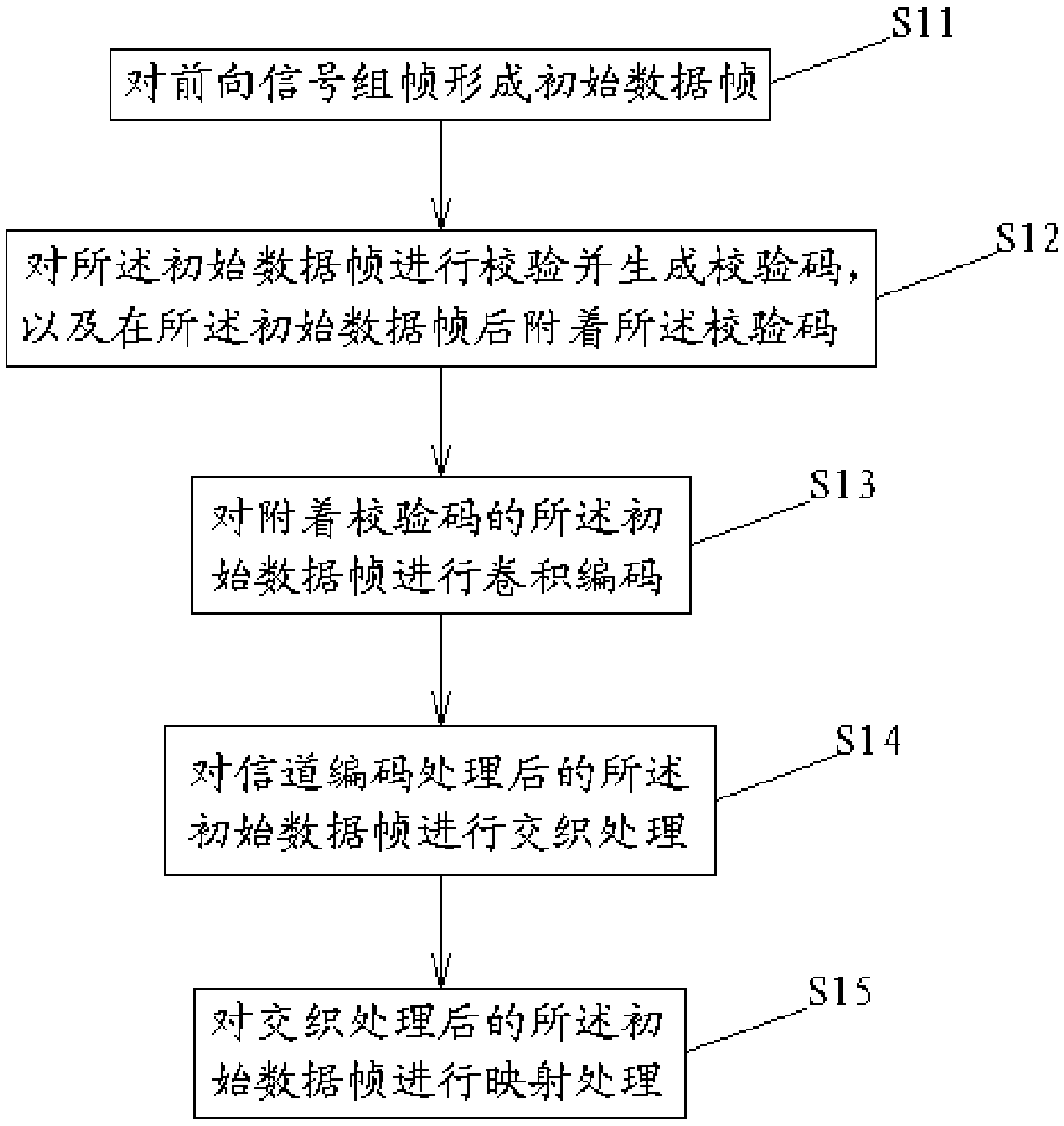

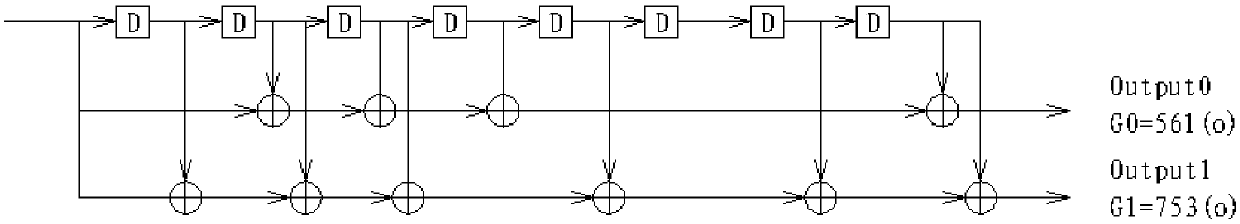

Signal processing method used for manned space communication

ActiveCN107800462AGuaranteed uptimeGuaranteed Simultaneous CommunicationTransmissionMultiplexingComputer science

The invention relates to a signal processing method used for manned space communication. The signal processing method used for manned space communication comprises the steps of S1, by a manned spacecraft, performing mapping processing on initial data frames sent to an extravehicular target object; S2, performing spectrum spreading processing on the initial data frame after being subjected to the mapping processing; and S3, performing scrambling synchronous processing on the initial data frames after the spectrum spreading processing so as to generate transmission data frames. As check codes are attached, checking for the received signals by subsequent target objects is guaranteed, and a key role for guaranteeing normal communication between the manned spacecraft and the target objects is played. Due to the time gap multiplexing processing and spectrum spreading processing, forward signals are guaranteed to be received precisely by the target objects, interference on communication signals between objects is avoided; as the spectrum spreading processing is adopted, multiple forward links can be connected between the manned spacecraft and multiple target objects, simultaneous communication between the manned spacecraft and multiple target objects is guaranteed, and the communication efficiency between the manned spacecraft and the target objects is increased.

Owner:BEIJING SPACE TECH RES & TEST CENT

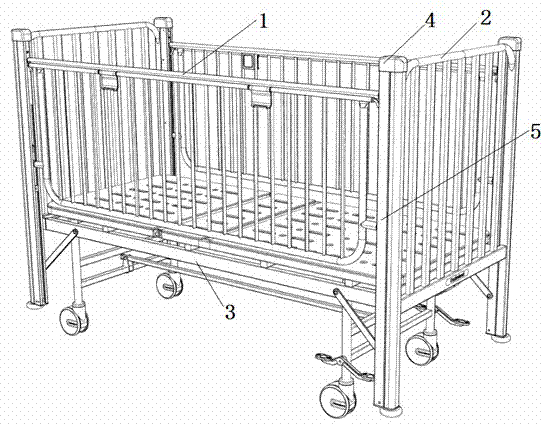

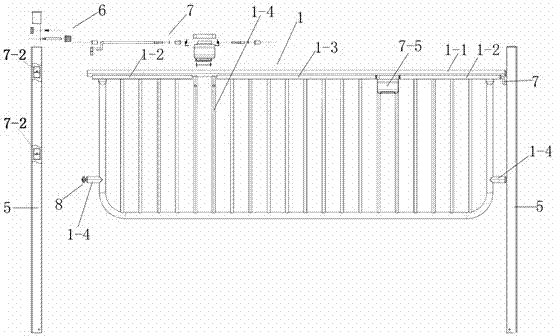

Child sickbed with lifting guardrails

The invention relates to a child sickbed, in particular to a child sickbed with lifting guardrails. The two ends of the front side and the two ends of the back side of a bed frame are each fixedly provided with a bed column sliding rail, the two side guardrails are fixed to the two bed column sliding rails on the left side face and the two bed column sliding rails on the right side face of the bed frame respectively, guide devices, guardrail locks and assistance balance devices on the two sides of the two guardrails are arranged in cavities of the two bed column sliding rails on the front portion and the two bed column sliding rails on the rear portion of the bed frame respectively, each of the two guardrails can move up and down on the two bed column sliding rails through the assistance balance devices and the guide devices on the two sides and can be positioned in the bed column sliding rails through matching of the guardrail locks on the two sides and positioning lock blocks in the cavities of the bed column sliding rails, and decorative caps are buckled on the four bed columns sliding rails and upright columns of the side guardrails. The child sickbed has the advantages that due to the function of constant force of coil springs, the self weight of the guardrails is reduced to about 2 kilograms, so that gravity of the guardrails in the lifting process is overcome, an assistance balance effect is achieved, and lifting operation is easier; the guardrail locks are easy to lock, and locking efficiency is improved.

Owner:星愿兰德(天津)企业有限公司

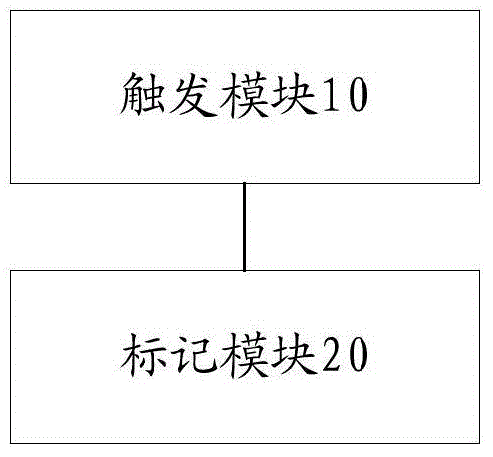

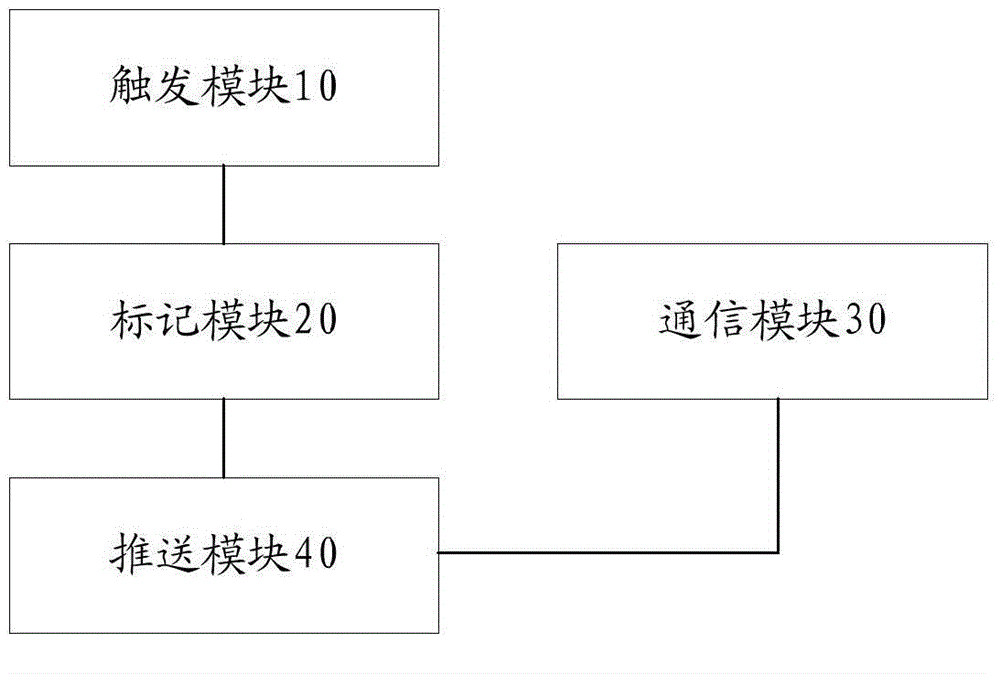

Image recording device and image marking method

ActiveCN106296867ARich image locking methodsImprove locking efficiencyTelevision system detailsRegistering/indicating working of vehiclesImage recordingComputer graphics (images)

The invention discloses an image recording device and an image marking method. The image recording device comprises a triggering module and a marking module, wherein the triggering module comprises a plurality of triggering components, and different triggering components are used for generating marking instructions according to different received triggering instructions; the marking module is connected with the triggering module and used for marking a current recording image of the image recording device according to the marking instructions from the triggering module and obtaining a marked image. By means of the image recording device and image marking method, the technical problem of the relatively single image locking mode of an automobile data recorder in the prior art is solved, and the technical effects of enriching image locking modes and improving locking efficiency are realized.

Owner:HANGZHOU EZVIZ NETWORK CO LTD

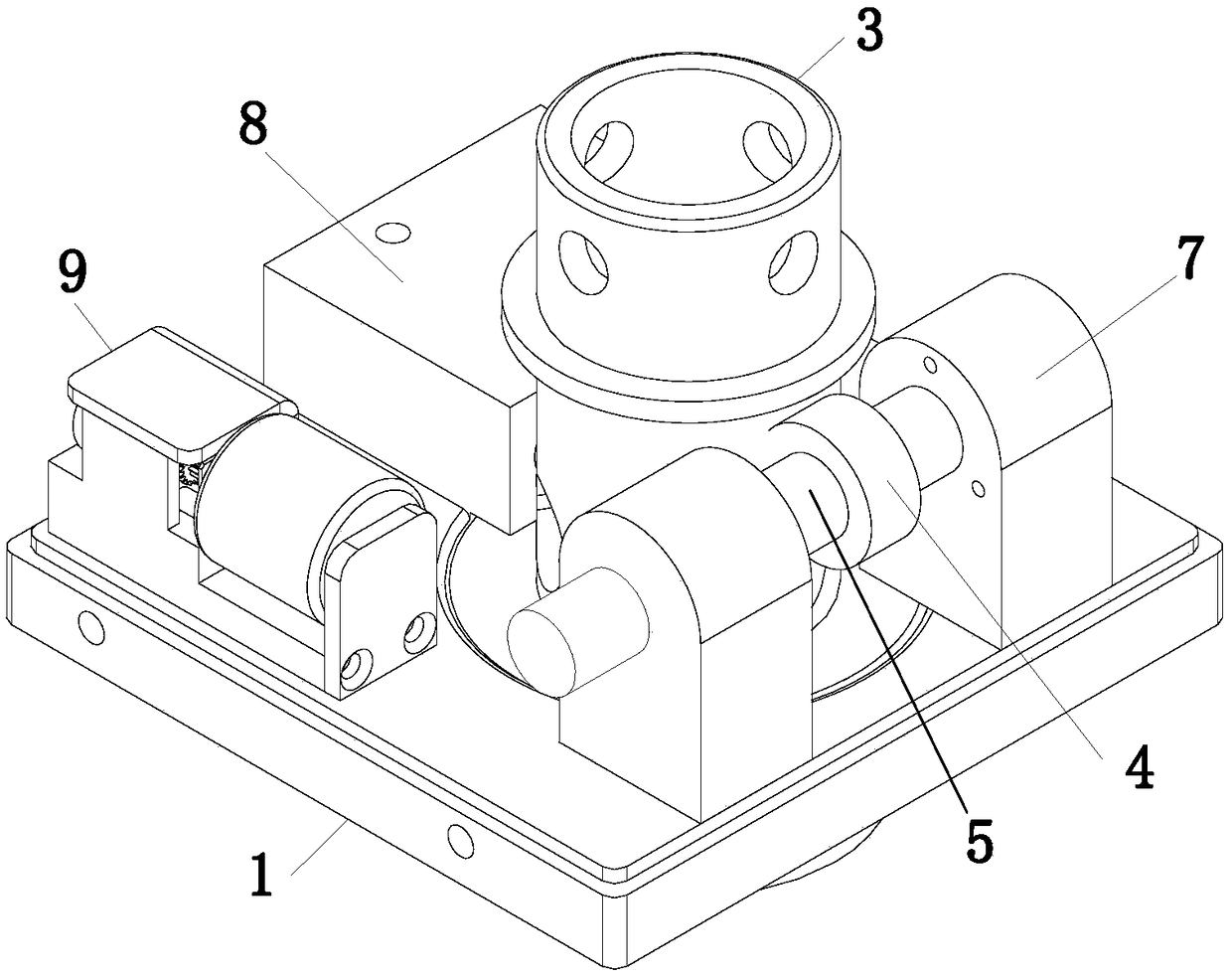

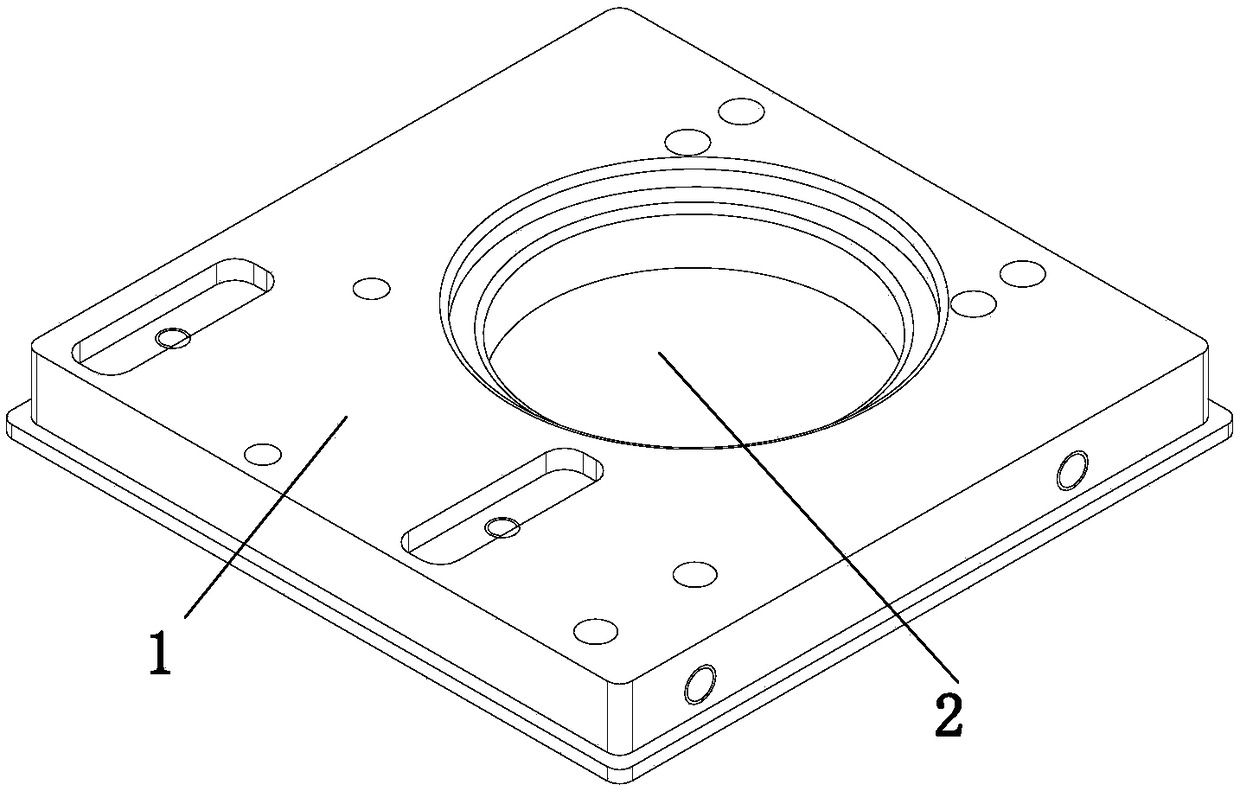

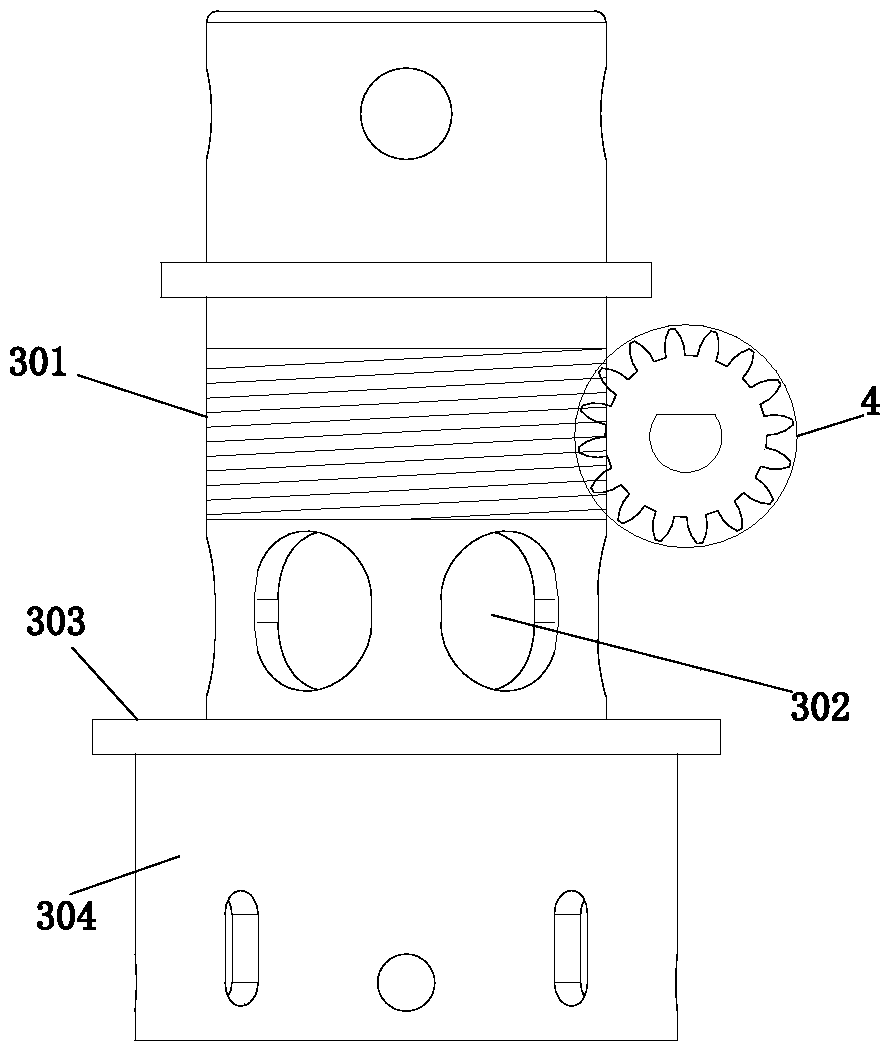

Gate valve locking mechanism

PendingCN109114297AHigh precisionEasy to operatePreventing unauthorised/accidental actuationDrive shaftLocking mechanism

The invention discloses a gate valve locking mechanism. The gate valve locking mechanism comprises a base, a stepped through hole is formed in the middle of the base, a worm is arranged in the steppedthrough hole, a worm gear matched with the worm is arranged on the side face, a transmission shaft is arranged on the worm gear, limiting worms are arranged at the two ends of the transmission rod, and the base is provided with mechanical memories matched with the limiting worms; the base is further provided with a Bluetooth locking device; and the worm comprises a worm body which is of a hollowstructure, the worm body is provided with a locking hole of which the position corresponds to that of the Bluetooth locking device, an installing disc matched with the stepped through hole is arrangedunder the locking hole, and a valve rod connecting rod is arranged on the lower portion of the worm body. The gate valve locking mechanism has the characteristics that locking operation is convenient, and the locking position precision is improved.

Owner:STATE GRID CORP OF CHINA +3

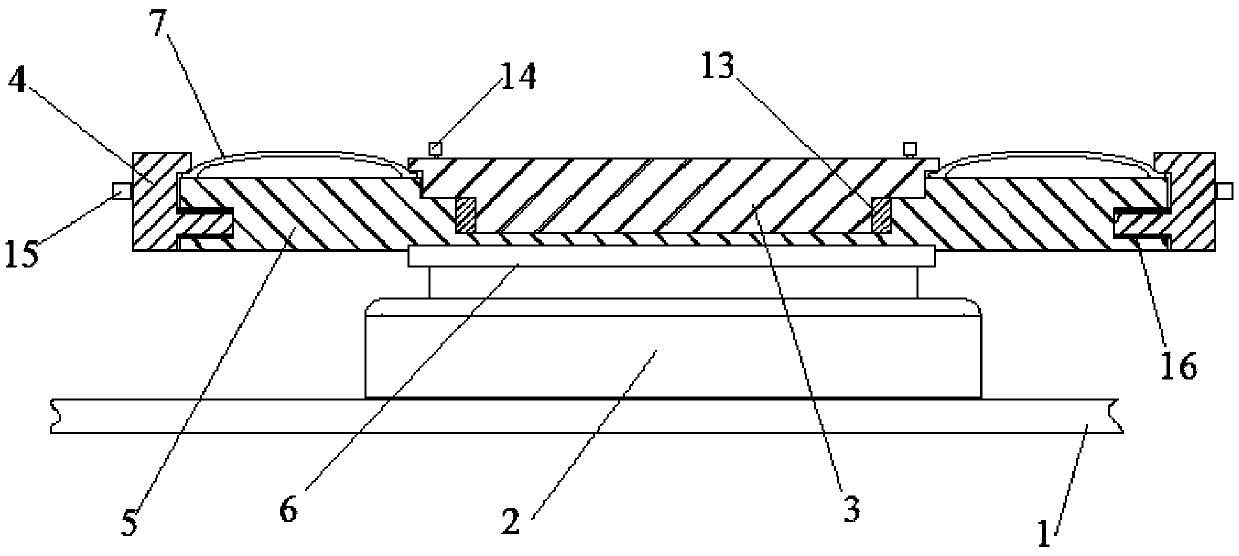

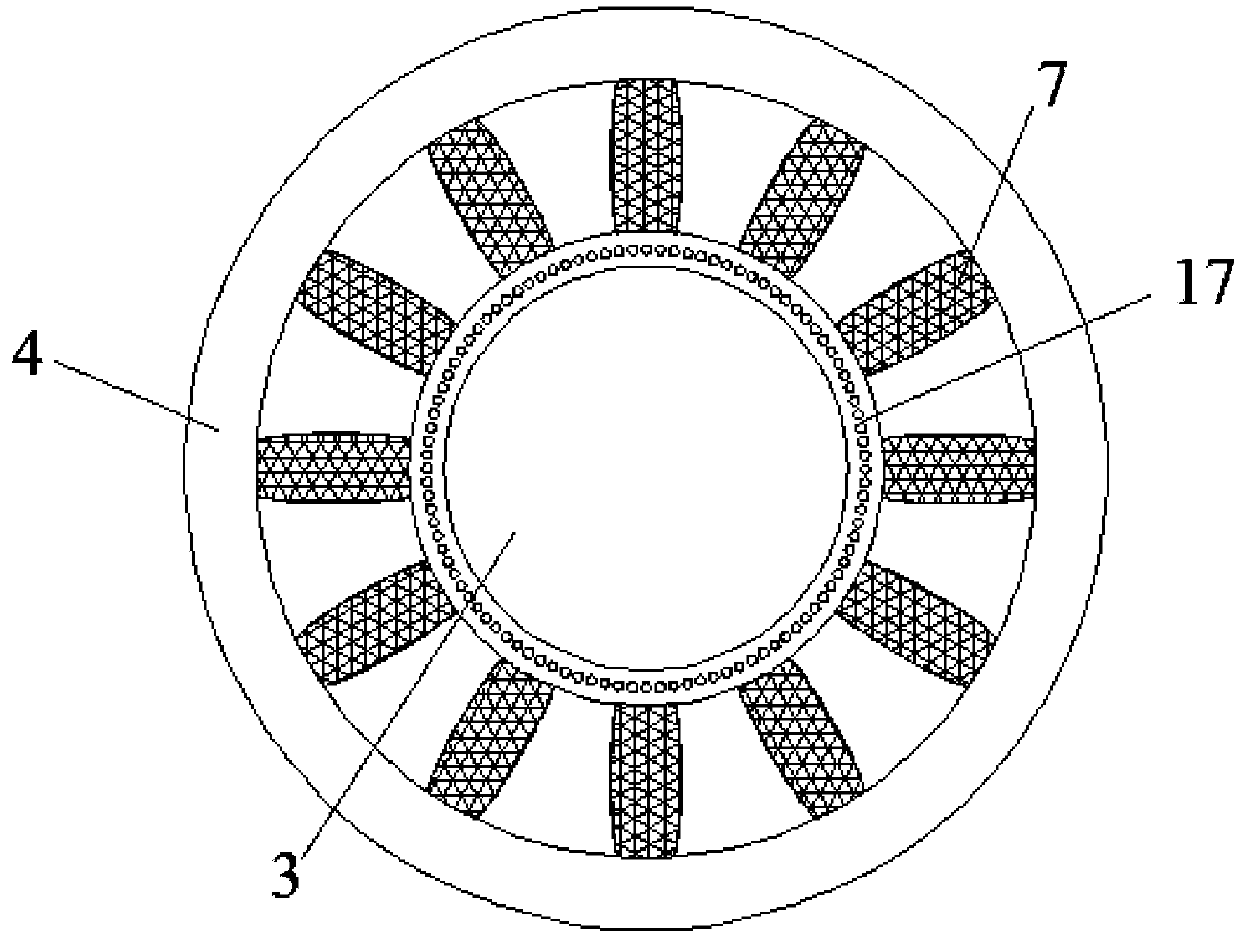

Automobile brake pad processing device

InactiveCN109648337AImprove locking efficiencyGuarantee the efficiency of mass productionOther manufacturing equipments/toolsPositioning apparatusEngineeringBrake pad

The invention discloses an automobile brake pad processing device. The automobile brake pad processing device adopts a locking way of an inner locking disk and an outer locking disk, the locking efficiency can be greatly improved, a plurality of brake pads can be locked only by needing to rotate the inner locking disk and the outer locking disk, and the efficiency of the batch production is ensured. The automobile brake pad processing device adopts a wedge-shaped groove to clamp, the clamping and locking force can guarantee the stability of the processing; each group of processing tools can move and adjust in the radial direction of a processing tool disk so as to process the different parts of each brake pad, in this way, drilling and grooving operation can be conducted on multiple partsof each brake pad, and the automobile brake pad processing device is simple and convenient; each driving assembly moving in the radial direction adopts the uniform driving, and process coherence can be ensured; and the brake pads are processed at different stages by rotating a rotating disk and using different groups of processing tools.

Owner:东莞市中帆新材料科技有限公司

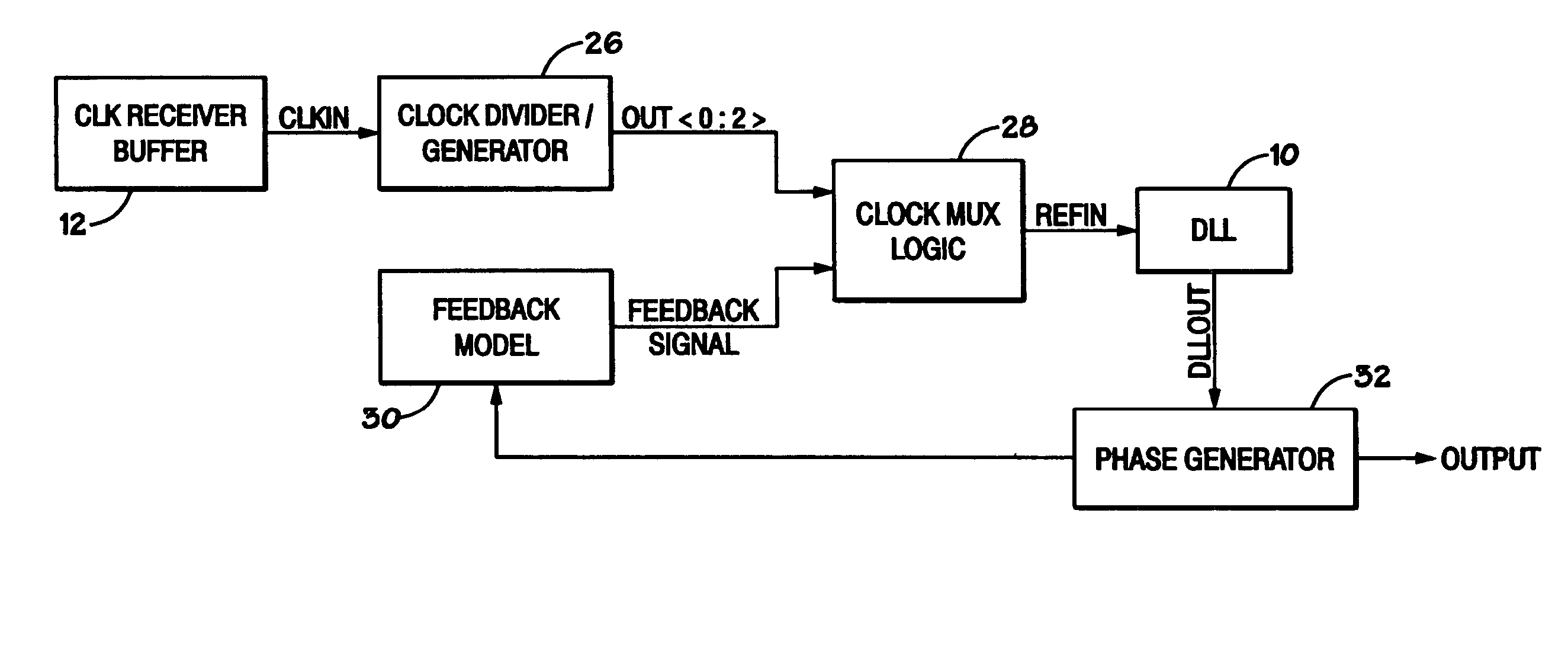

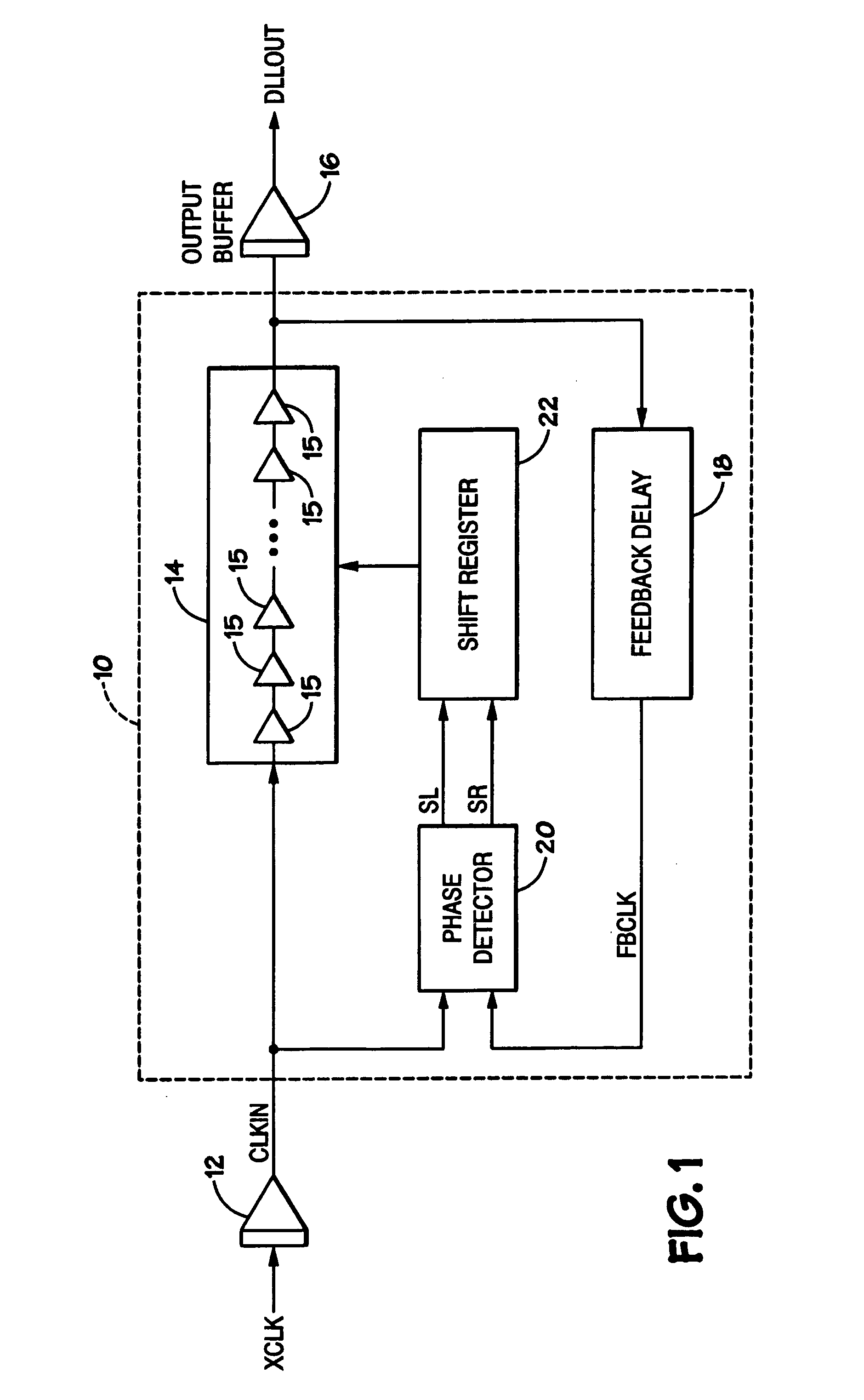

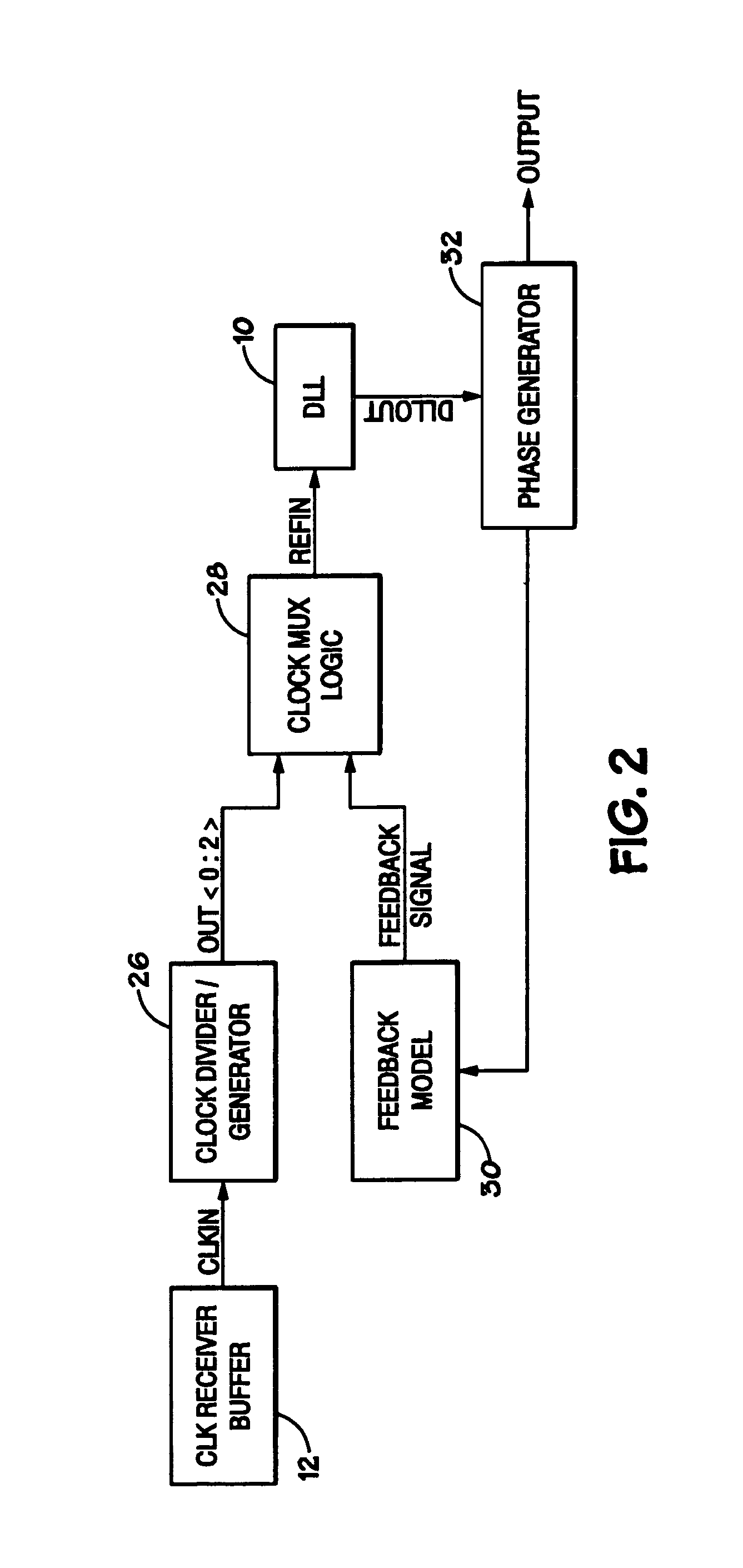

Efficient clocking scheme for ultra high-speed systems

ActiveUS7454646B2Shorten lock timeShorten the lengthPulse automatic controlElectronic circuit testingUltra high speedPhase relationship

There is provided a system for comparing the phase characteristics of three generated clock signals, each having a unique phase relationship with an original clock signal, with the original clock signal and to select a signal based on the proximity of the phase characteristic of the three signals to the original signal. The selection of a clock signal that most closely approximates the original significantly reduces lock time when attempting to synchronize an internal clock with an external clock. Additionally, there is provided a method for comparing three clock signals with an original clock signal and selecting from the three clock signals one that is approximately in phase with the original clock signal.

Owner:MICRON TECH INC

Draught fan system and locking device thereof

The invention provides a draught fan system and a locking device of the draught fan system. The locking device comprises a body, a locking piece and an operating piece, wherein the body is provided with a containing cavity, the side wall of the body is provided with a hole, the locking piece is flexibly arranged in the hole of the body, the operating piece is detachably connected with the body, an axial positioning structure is arranged between the operating piece and the body, one end of the operating piece is inserted into the containing cavity, and the locking piece extrudes from the outside of the body under the function of one end of the operating piece. The locking device has the advantages of being convenient to disassemble and install, is not limited by installation tools, can lock objects easily, and can greatly reduce the difficulty of locking when the objects are locked in a narrow and small space. Moreover, by adoption of the locking device, threads need not processing, so that the process of locking is reduced, the problem that thread holes are difficult to be processed in a narrow space is solved, and the locking efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Oil tube packer capable of conveniently replacing rubber sleeve

PendingCN114856486AGuaranteed firmnessIncreased anti-off performanceDrilling rodsSealing/packingThreaded pipeStructural engineering

The tubing packer comprises a center pipe, a slip bowl and a centralizing block sheath, an upper connector and a lower connector are installed at one end of the outer side of the center pipe through threaded pipes, the centralizing block sheath is installed on the outer side of the center pipe, a centralizing block seat is installed in the centralizing block sheath, and a rubber sleeve is installed in the centralizing block seat. Two sets of centralizing block pieces are movably installed in the centralizing block protective sleeve through installation grooves, and two sets of second springs are installed in the centralizing block pieces through fixing grooves. Outward elastic extrusion force can be applied to the centralizing block piece under the action of the second spring, so that the centralizing block piece elastically moves in the mounting groove under the elastic force of the second spring, the centralizing block piece is tightly attached to the inner wall of an oil pipe and does not move under the action of elastic potential energy of the second spring, and therefore the packer can be conveniently positioned; and the packer can be locked at a specified seat key position, so that the accuracy of the packer on the sealing position of the oil pipe is ensured, and the practicability of the device is improved.

Owner:江苏柯沣石化机械有限公司

Method for preventing drop and hoisting of single hanging ring

The invention discloses a method for preventing drop and hoisting of a single hanging ring. The method comprises the steps that a, a drop preventing mechanism of a system for preventing drop and hoisting of the single hanging ring is opened and made to be in an unlocking state; b, when one of the hanging rings is mounted in the position, on one side of an elevator, of a lug hole of a lifting lug, an induction part of a drop preventing part sends a signal, after receiving the signal, a controller forbids moving of a runner wagon, the runner wagon is in a stop state, and after the hanging ring enters the lug hole, the drop preventing mechanism is in a locking state, and the hanging ring is blocked in the lug hole; and c, and the other hanging ring is mounted in the position, on the other side of the elevator, inside the lug hole of the lifting lug, the induction part of the drop preventing part sends a signal, and after receiving the signal, the controller allows the runner wagon to move. It can be effectively guaranteed that the two hanging rings both enter the lug hole, so that single hanging ring hoisting is avoided. Through the joint effect of the drop preventing mechanism and the drop preventing part, the hanging rings can be blocked firmly in the lug hole, slipping is avoided, the working stability and reliability of the elevator are improved, and the safety accident is eradicated.

Owner:CHENGDU ZHUOXIN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com