Screwdriver

A screwdriver and knife handle technology, applied in the field of manual press screwdrivers, can solve the problems of time-consuming and laborious, low screw locking efficiency, etc., and achieve the effect of preventing gyration and improving locking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

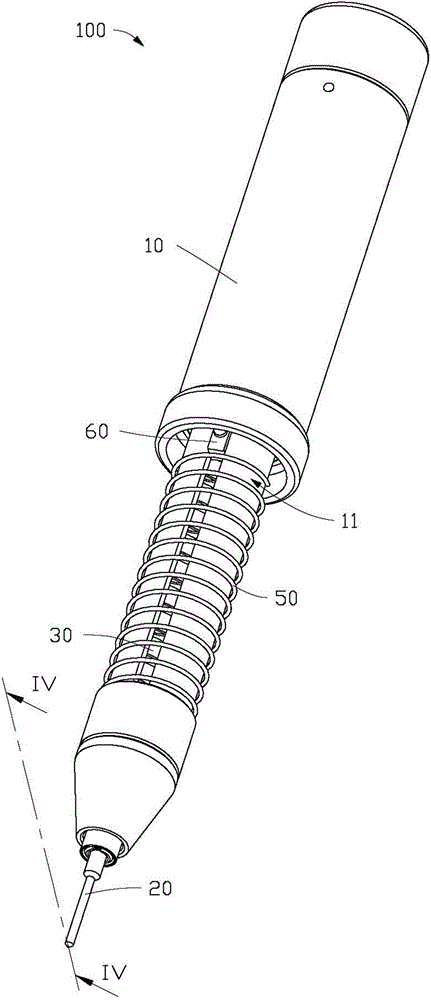

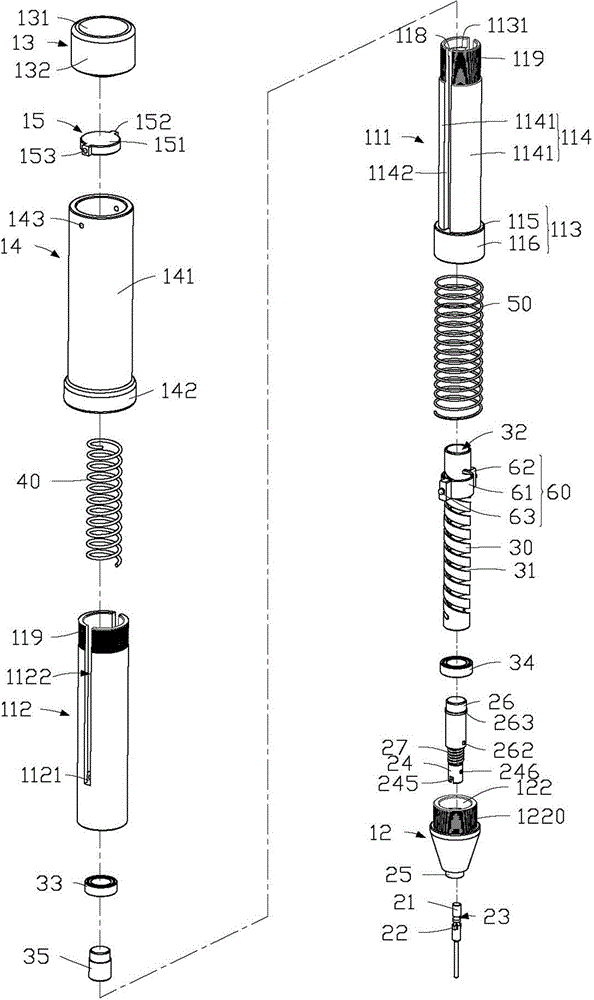

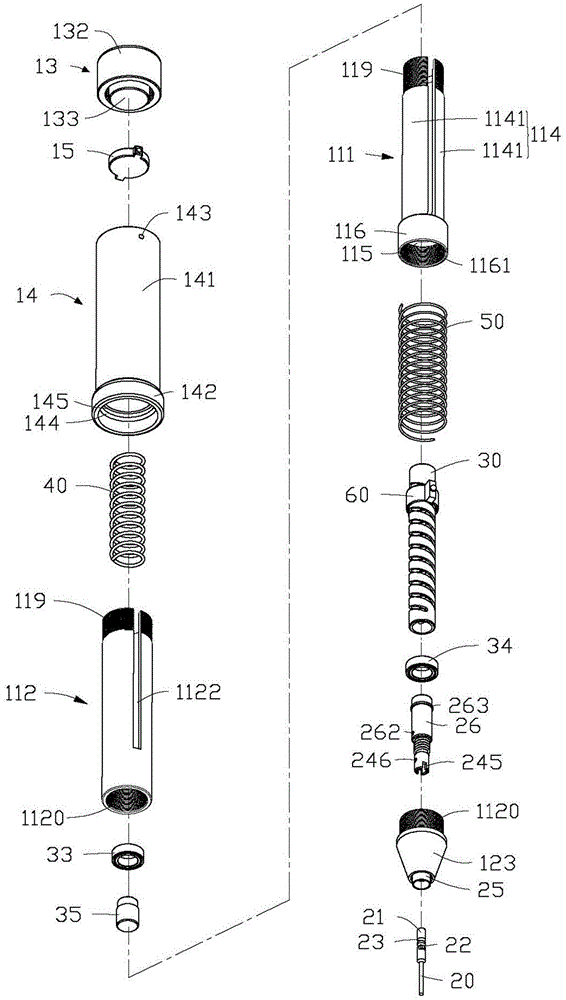

[0014] figure 1 and Figure 4 A preferred embodiment of a screwdriver 100 of the present invention is shown. The screwdriver 100 includes a handle 10, a cutter head 20 located at the front end of the handle 10, a screw rod 30 housed inside the handle 10, a first elastic element 40, and a second elastic element sleeved on the outer surface of the handle 10. 50 and operating part 60.

[0015] Specifically, please also refer to Figure 2-3 , the handle 10 includes a body 11 , connecting caps 12 and rear covers 13 respectively located at opposite ends of the body 11 , and a sleeve 14 sleeved on the body 11 .

[0016] The body 11 is a hollow cylinder. In this embodiment, it includes a first body 111 and a second body 112 connected to each other, and the first body 111 and the second body 112 are both annular. In this embodiment, the outer diameter of the first body 111 is smaller than the outer diameter of the second body 112 , and the first body 111 and the second body 112 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com